Pigment dispersion and ink composition and ink set both containing the same

A technology for pigment dispersion liquid and ink composition, which is applied in the fields of pigment dispersion liquid, ink composition using pigment dispersion liquid and ink set, can solve the problem of insufficient glossiness of color images, insufficient storage stability of ink composition, and inability to achieve high Image quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach A

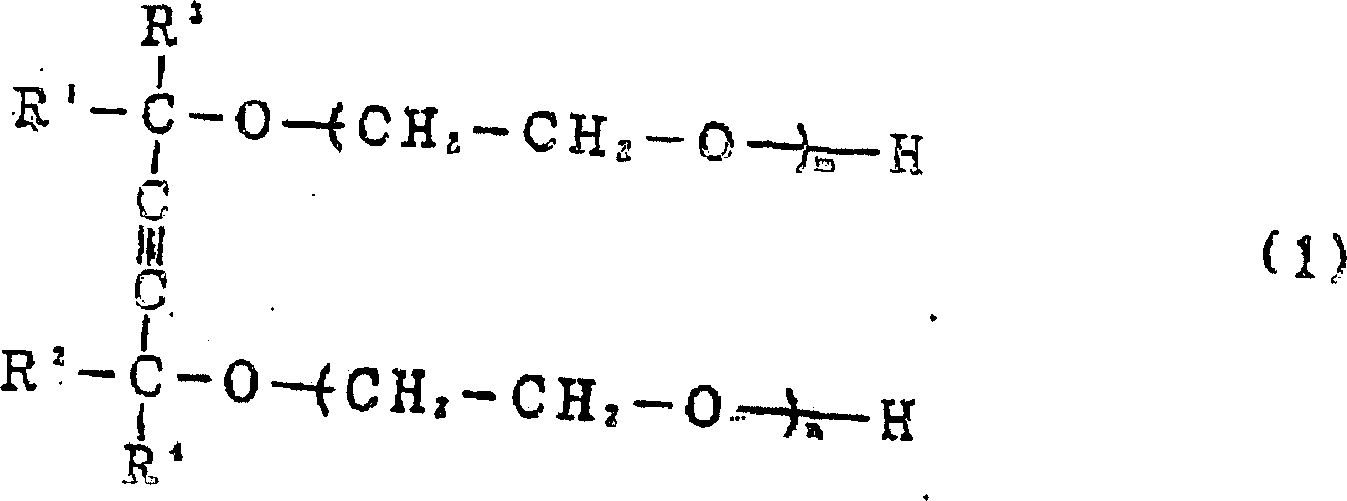

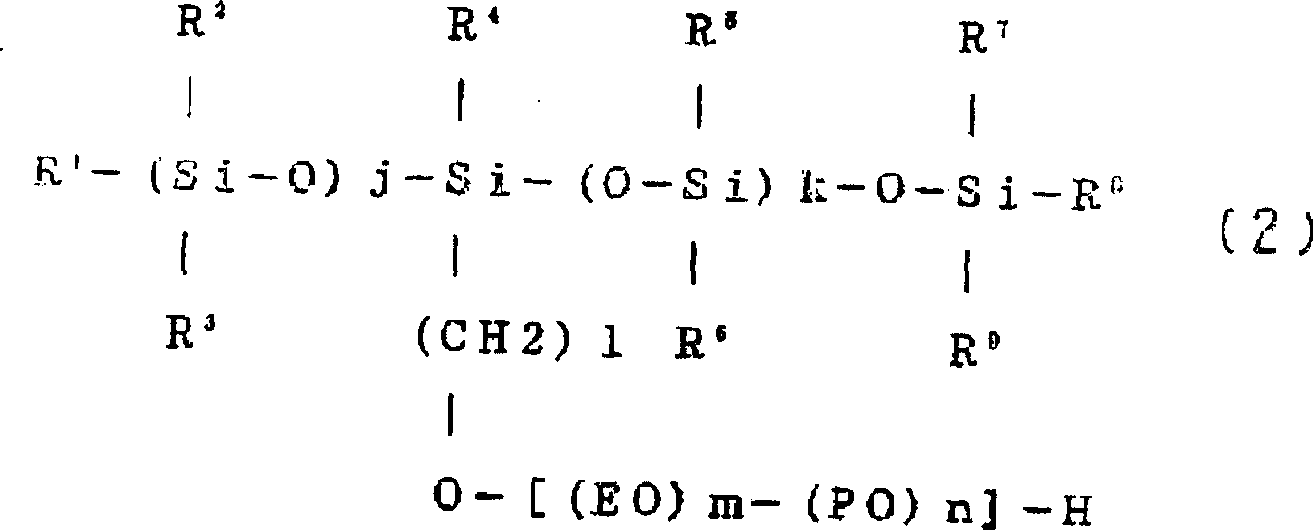

[0019] (pigment dispersion)

[0020] The pigment dispersion of Embodiment A of the present invention includes at least a pigment, an aqueous medium, a copolymer resin of a hydrophobic monomer and a hydrophilic monomer, and a polyurethane resin, wherein the weight ratio of the above-mentioned copolymer resin to the above-mentioned polyurethane resin (the former / The latter) is 1 / 2 to 2 / 1.

[0021] Thus, the pigment dispersion liquid of Embodiment A of the present invention, by making it contain two specific resins in a specific weight ratio, can be prepared to have excellent storage stability and to be used for forming pigments having good gloss and preventing copper flooding. In addition to the glossiness of recorded images and the prevention of copper flooding, it also achieves output stability, anti-clogging properties, color stability, and high image quality comparable to silver salts. The pigment dispersion liquid according to the embodiment A of the present invention can...

Embodiment approach B

[0115] (pigment dispersion)

[0116] The pigment dispersion according to embodiment B of the present invention at least includes a pigment, an aqueous medium, a copolymer resin of a hydrophobic monomer and a hydrophilic monomer, and a polyurethane resin, wherein the content of the above-mentioned copolymer resin is 10 to 50 parts by weight / 100 parts by weight The above-mentioned pigment, the content of the above-mentioned polyurethane resin is 10-40 parts by weight / 100 parts by weight of the above-mentioned pigment.

[0117] In this way, the pigment dispersion liquid of Embodiment B of the present invention contains two specific resins in a specific content, so that an ink composition having excellent storage stability for forming an image having good gloss and preventing copper flooding can be prepared, In addition to recording image gloss and anti-copper floating color, it also realizes output stability, anti-clogging performance, color stability, and high image quality comp...

Embodiment approach C

[0139] (pigment dispersion)

[0140] The pigment dispersion according to Embodiment C of the present invention at least includes: a pigment, an aqueous medium, a copolymer resin of a hydrophobic monomer and a hydrophilic monomer, and a polyurethane resin, wherein the acid value of the copolymer resin is 50-320.

[0141] In this way, the pigment dispersion liquid of Embodiment C of the present invention contains two specific resins one of which has an acid value in a specific range, thereby making it possible to prepare an image having excellent It is an ink composition with storage stability, and in addition to the glossiness of recorded images and copper flooding resistance, it can also achieve output stability, anti-clogging properties, color stability, and high image quality comparable to silver salts. The pigment dispersion liquid according to the embodiment C of the present invention is as described above, and can realize the glossiness of the recorded image, the anti-cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com