Transfer printing paper for disposable printing thermal sublimation pattern and brilliant color pattern and preparation method and use

A technology of transfer printing paper and sublimation, which is applied in the production of special varieties of prints, post-processing of printing, printing, etc. It can solve the problems of increasing the number of handling turnover, time-consuming and labor-intensive, and inability to align, and achieve the product pattern. Clear, avoid a lot of waste, save the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of transfer printing paper for one-time printing of sublimation patterns and bright patterns

[0042] 1) Print a release agent on the transfer printing base paper by a gravure printing machine, and form a release agent layer after being dried by electric heating and blowing;

[0043] 2) Print ink patterns on the release agent layer by a gravure printing machine, and form an ink layer after being dried by electric heating and blowing;

[0044] 3) printing bright-color substrate layer raw materials on the ink layer by a gravure printing machine, forming a bright-color substrate layer after being dried by electric heating and blowing, and obtaining transfer printing paper that can print sublimation patterns and bright-color patterns at one time;

[0045] The mass percent composition of bright color substrate layer raw material is:

[0046] Hot melt glue 93%;

[0047] Gold Dust 7%.

Embodiment 2~9

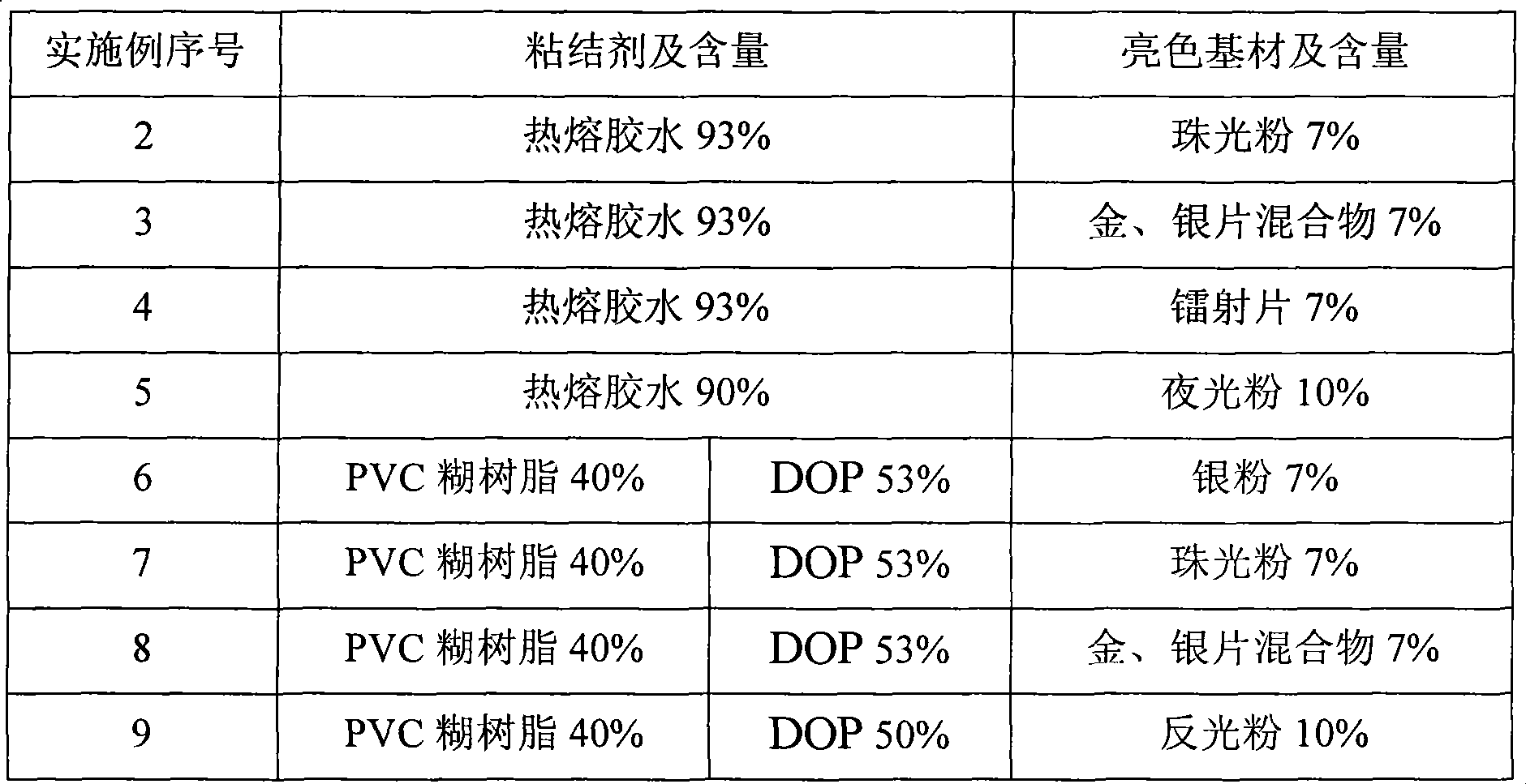

[0049] Transfer printing paper is prepared according to the flow process of Example 1, the difference is that the mass percentage of the bright color substrate layer raw materials used is composed of each composition in Table 1:

[0050] Table 1

[0051]

[0052] Note: All bright color substrates in the table are commercially available general materials, and the weight ratio of gold and silver flakes in the mixture of gold and silver flakes is 1:1.

[0053] Using the transfer printing paper prepared in Example 1, the pattern of the ink layer and the bright pattern of the bright base layer are transferred and printed on the fabric by a transfer printing machine to obtain a fabric with the pattern of pattern and the pattern of bright color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com