Electrochemical aluminium gold-stamped water decal paper, and its production process and use

A production process, anodized aluminum technology, applied in papermaking, packaging paper, paper coatings, etc., can solve the problems of arc surface product limitation, inability to meet demand, and difficulty in achieving satisfactory results in anodized aluminum bronzing, to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

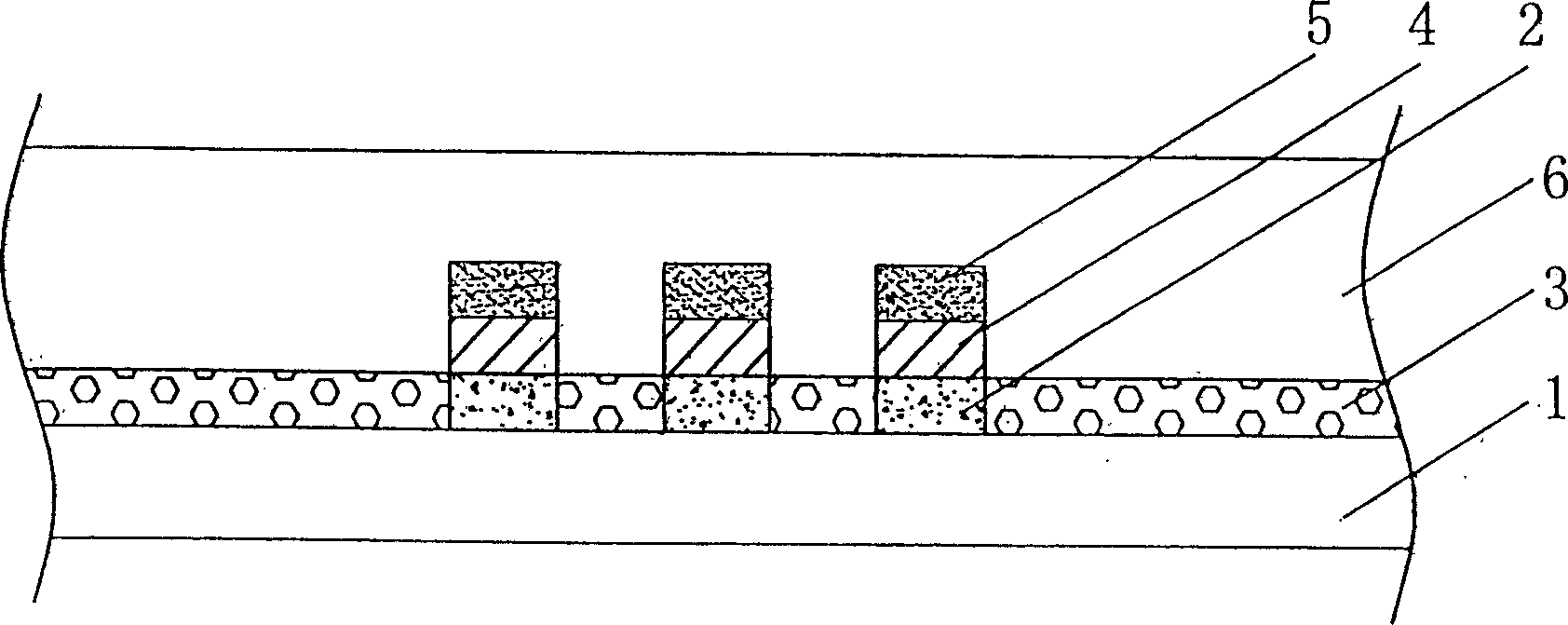

[0019] Such as figure 1 As shown, the processing technology of water-transfer anodized aluminum gold-plated products is as follows:

[0020] (A) Use the water transfer backing paper as the carrier 1, print or coat the adhesive layer 2, the adhesive layer is pressure-sensitive or heat-crosslinked (80-180°C) resin ink, such as acrylic acid, nitro Or epoxy resin ink, etc.

[0021] (B) printing fiber resin ink on the surface of the carrier 1 as the isolation layer 3, flat with the adhesive layer 2;

[0022] (C) Hot-stamping the anodized aluminum graphic 4 on the surface of the adhesive layer, the operating temperature is 100-120°C, the hot-stamping time is 0.1-0.5 seconds, and the operating pressure is 4-9Pa;

[0023] (D) printing or coating such as PU, UV ink on the surface of the graphic as the sealing layer 5;

[0024] (E) printing or coating positioning film on the surface of the semi-finished product obtained in step D, the positioning film can be a non-tearable positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com