Automatic carton sealing machine capable of continuously sealing corners of carton

A box sealing machine and box sealing technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve problems such as cumbersome operations, and achieve the effect of good straightening effect, easy positioning, and easy box sealing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

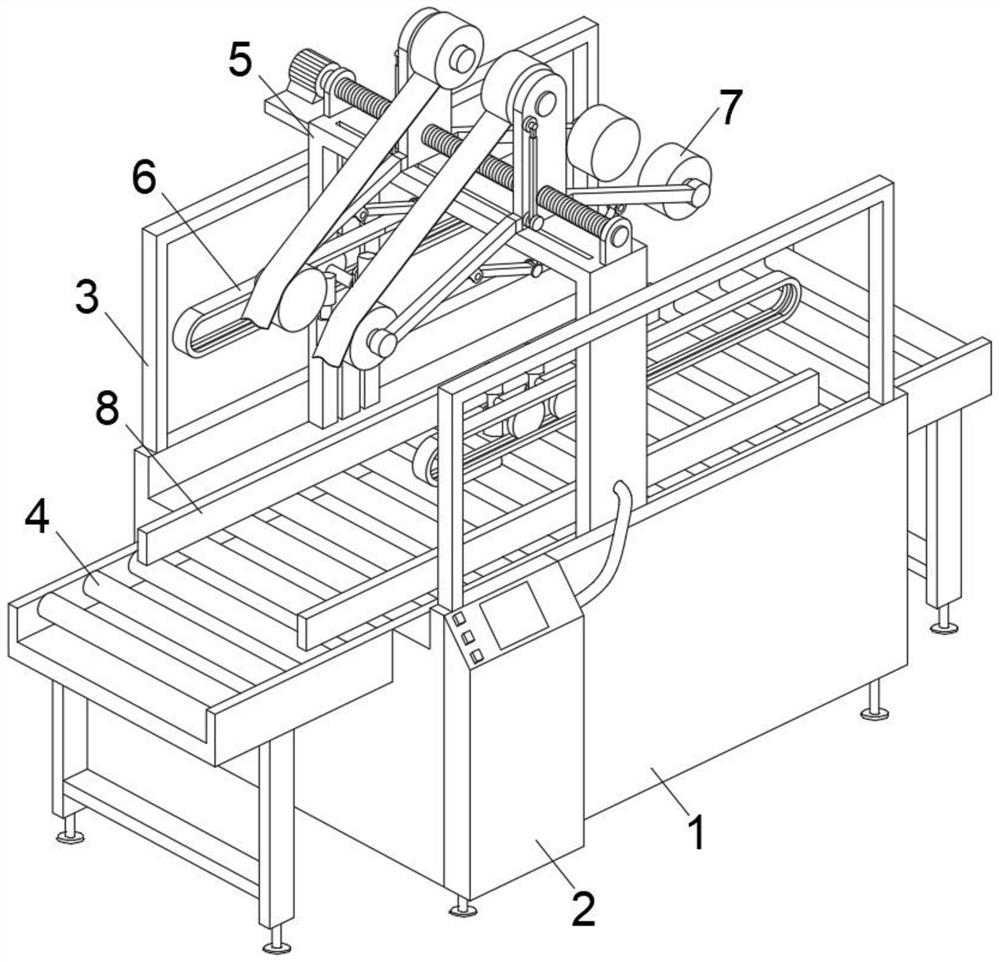

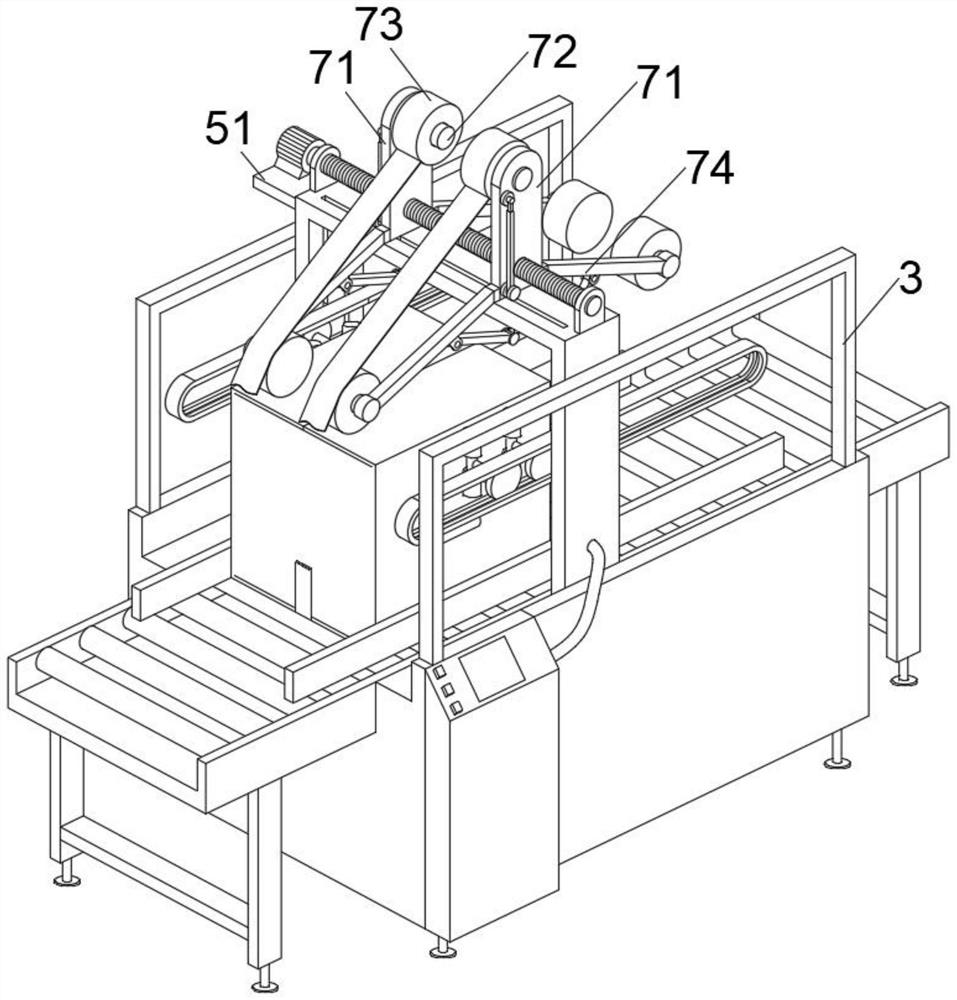

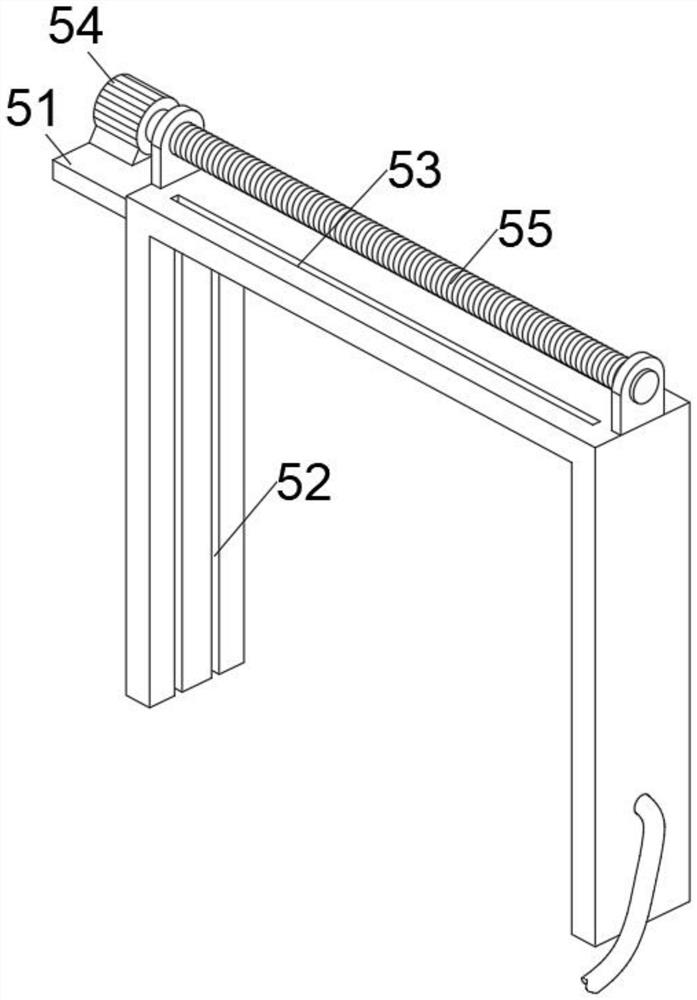

[0028] This embodiment is intended to promote the solution of how to continuously seal corrugated boxes, please refer to figure 1 , figure 2 , image 3 and Figure 5 , an automatic box sealing machine capable of continuous corner sealing, comprising an operation table 1 and a support stand 5 fixedly installed on the upper end of the operation table 1, the support stand 5 is provided with a box sealing mechanism 7, and the box sealing mechanism 7 includes The support vertical plate 71 that is slidably installed on the upper end of the support stand 5 and the rotating shaft 72 that is fixedly installed on the inner wall of the support vertical plate 71, the rotating shaft 72 is interspersed with a sealing tape 73, and the lower end of the support vertical plate 71 is movably installed with a rear rod 74, the rear rod 74 is rotatably installed with a compacting roller shaft 75 away from one end of the support vertical plate 71, and the front rod 76 is movably installed on the ...

Embodiment 2

[0036] This embodiment is intended to help solve the problem of how to ensure that the sealing tape 73 does not shift between the corrugated box. This embodiment is an improvement made on the basis of Embodiment 1. Specifically, please refer to Figure 1-4 , the inner wall of the support stand 5 is provided with a straightening mechanism 6, and the straightening mechanism 6 includes an annular slideway 61 arranged on the inner wall of the support stand 5 and a first electric slider 62 fixedly installed on the annular slideway 61. The slider 62 is compatible with the side groove body 52, the inner wall of the annular slideway 61 is provided with a built-in groove body 63, and the second electric slider 64 is slidably installed in the annular slideway 61, and the outer periphery of the second electric slider 64 is embedded in the built-in groove Inside the body 63.

[0037] A telescopic push rod 65 is fixedly installed on the second electric slider 64 , and an inner shaft body 6...

Embodiment 3

[0042] This embodiment is intended to promote the solution of how to continuously transport corrugated boxes. This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to Figure 1-2 , the control panel 2 is fixedly installed on the console 1, the outer frame 3 is also fixedly installed on the console 1, the support stand 5 is installed on the inner wall of the outer frame 3, and the console 1 is interspersed with a carton transport assembly 4, a carton transport assembly 4 Side baffles 8 are also installed on the top, and the control panel 2 is electrically connected with the support stand 5, the straightening mechanism 6 and the sealing mechanism 7.

[0043] Turn on the carton transport component 4 to work, the carton transport component 4 drives the corrugated carton to move from the guide roller shaft 77 to the compacting roller shaft 75, the side baffles 8 limit the two ends of the corrugated carton, and multiple groups of corrugated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com