Biodegradable box-sealing tape

A biodegradation and sealing technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of environmental pollution of biodegradable sealing tapes, improve processing production efficiency and energy utilization rate, and reduce environmental pollution , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

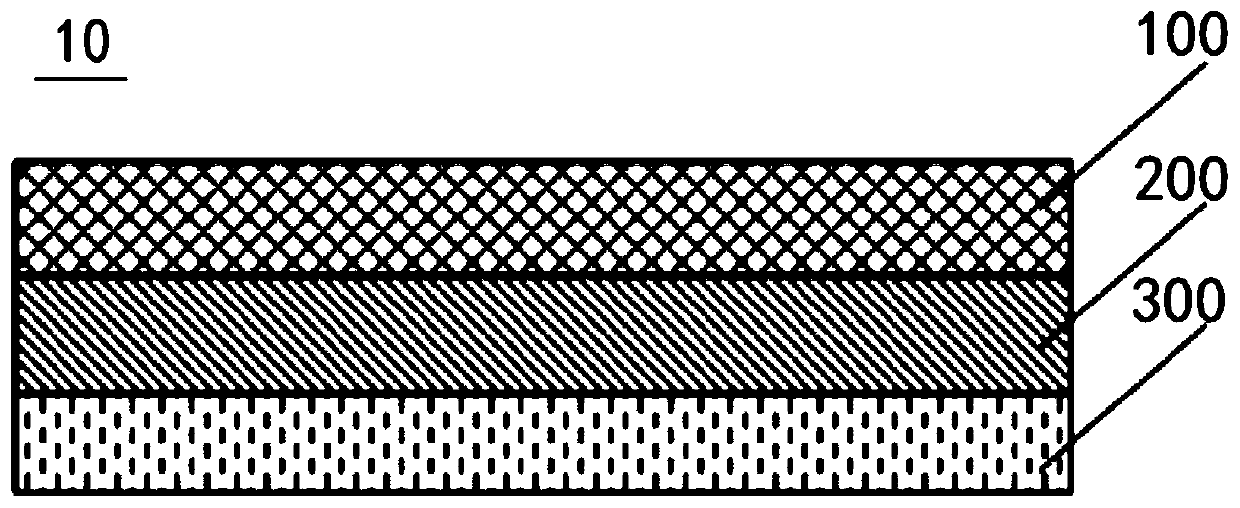

[0037] This embodiment also provides a biodegradable box sealing tape 10 prepared by a method for preparing the biodegradable box sealing tape. The preparation method of the biodegradable sealing tape comprises the following steps:

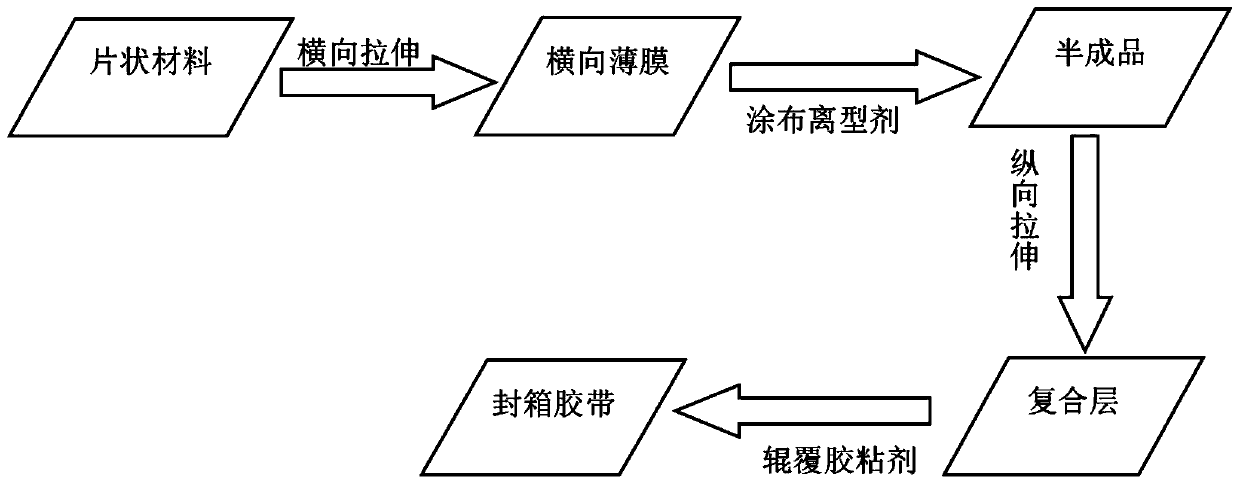

[0038] see figure 2 As shown, S1: Take the substrate layer 200, which is a modified PLA film. The preparation method of the substrate layer 200 in step S1 includes the following steps: melting and masticating PLA particles, PCL particles and a plasticizer to form a PLA / PCL composite film, that is, the substrate layer 200 . The mass ratio of PLA particles to PCL particles is 1:10-10:1. PLA particles, PCL particles and plasticizers are melted and masticated at 70°C-200°C.

[0039] S2: Stretch the substrate layer 200 in step S1 laterally, then apply a release agent on its upper surface, and then perform longitudinal stretching, the release agent is cured at the temperature of the longitudinal stretching to form the release layer 100, The release...

Embodiment 1

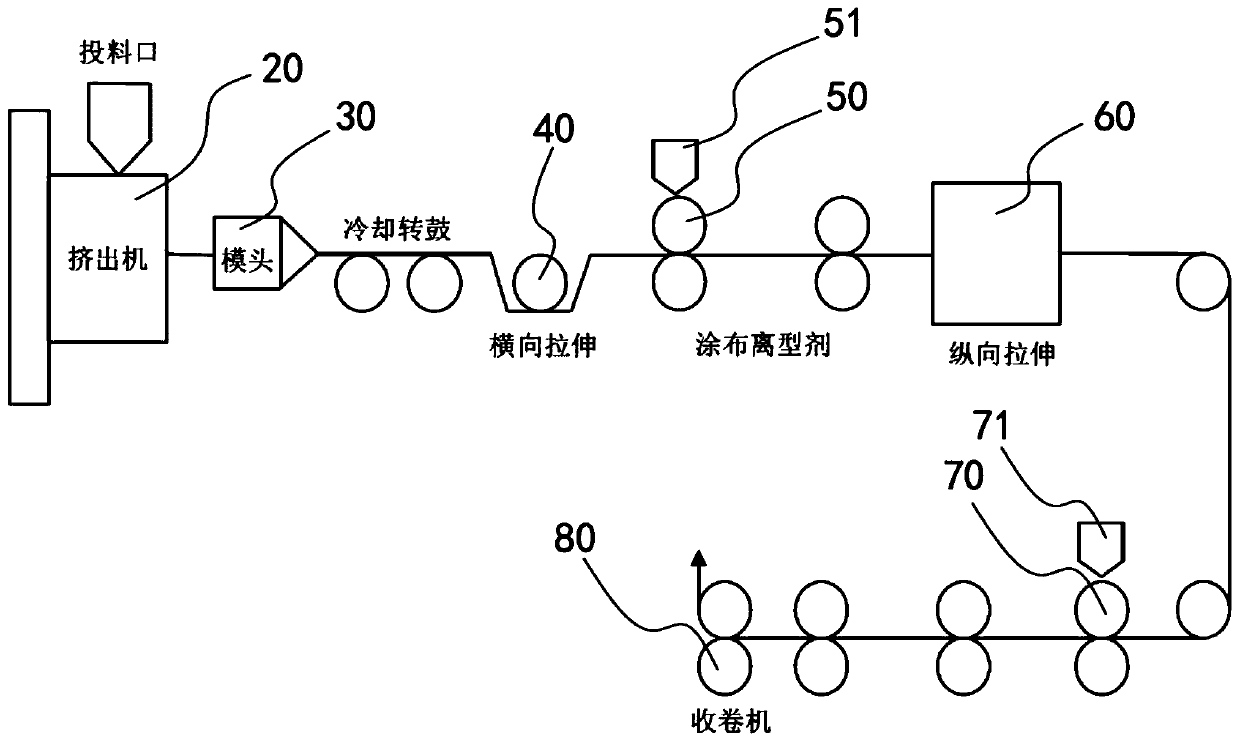

[0044] see image 3 As shown, in this embodiment, the biodegradable box sealing tape 10 is prepared by the biodegradable box sealing tape 10 production equipment. The production equipment of the biodegradable sealing tape 10 includes an extruder 20 , a die head 30 , a horizontal drawing machine 40 , a first gluing machine 50 , a longitudinal drawing machine 60 , a second gluing machine 70 and a winding machine 80 arranged in sequence. Specifically include the following steps:

[0045] (1) Preparation of release agent

[0046] According to the formula in Table 1, take a certain mass of water-based heat-curable polysiloxane and a certain mass of thermal initiator, and mix them uniformly by ultrasonic to prepare a heat-curable polysiloxane resin, that is, a release agent. Potassium persulfate and ammonium persulfate are free radical thermal initiators. Table 2 shows the performance test data of the heat-cured silicone resin corresponding to each formulation.

[0047] Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com