Anti-flanging die cutting technology for aluminum foil

An aluminum foil and side die technology, applied in metal processing and other directions, can solve the problems of edge flanging, the appearance is difficult to meet customer requirements, and achieve the effect of improving quality, improving die-cutting knife structure, and optimizing die-cutting process methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

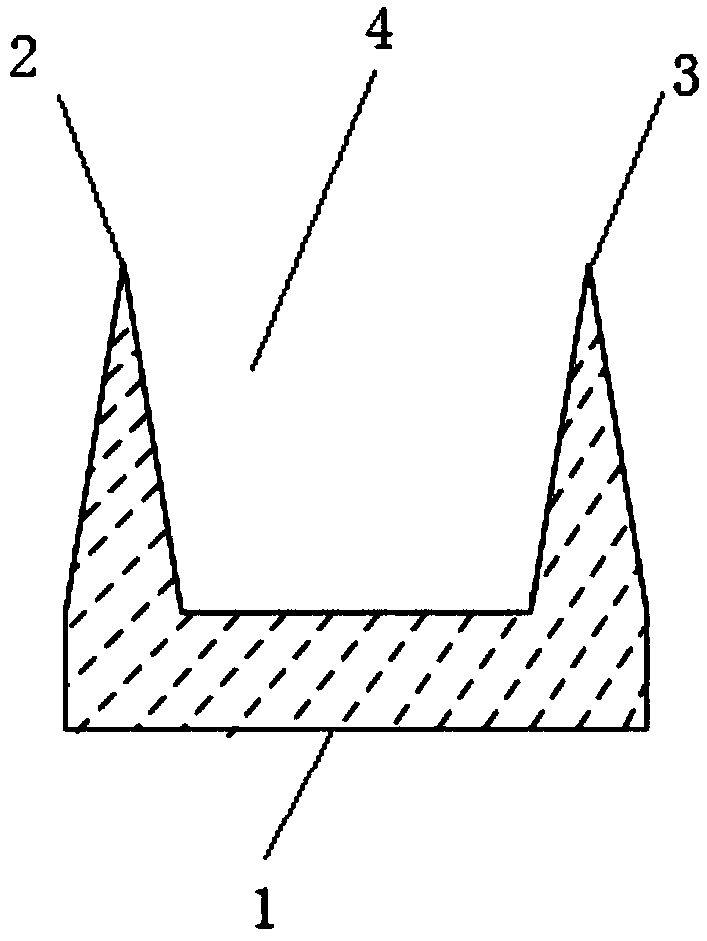

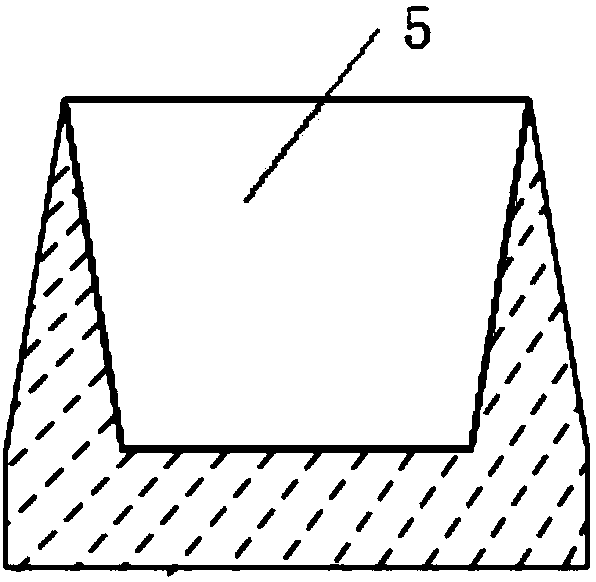

Image

Examples

Embodiment

[0018] A kind of anti-flange die-cutting process for aluminum foil of the present embodiment comprises the following steps:

[0019] S1 die-cutter pretreatment: Soak the die-cutter in 5% sodium hydroxide strong alkali solution, heat to 60°C, keep it warm for 30 minutes, take out the die-cutter and rinse it with clean water, then dry it in a dryer and install it for later use;

[0020] S2 Uncoiling: Put the aluminum foil parent roll on the unwinding device, the aluminum foil unwinds the material roll through the unwinding arm and the unwinding control roller, and keeps the unwinding tension constant;

[0021] S3 cover film: apply a double-sided adhesive layer on the front of the aluminum foil, and stick a release film on the other side of the adhesive layer;

[0022] S4 Slitting: The aluminum foil is guided by the traction roller to the bottom of the special die-cutter, and the upper and lower die-cutters cooperate with each other to cut the aluminum foil. When a cut is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com