Valve device

A technology of valve device and valve body, which is applied in the direction of valve device, valve details, valve shell structure, etc., can solve the problems of hard seal detection, reduce product production efficiency, etc., improve sealing performance, ensure reliability, and avoid flanging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

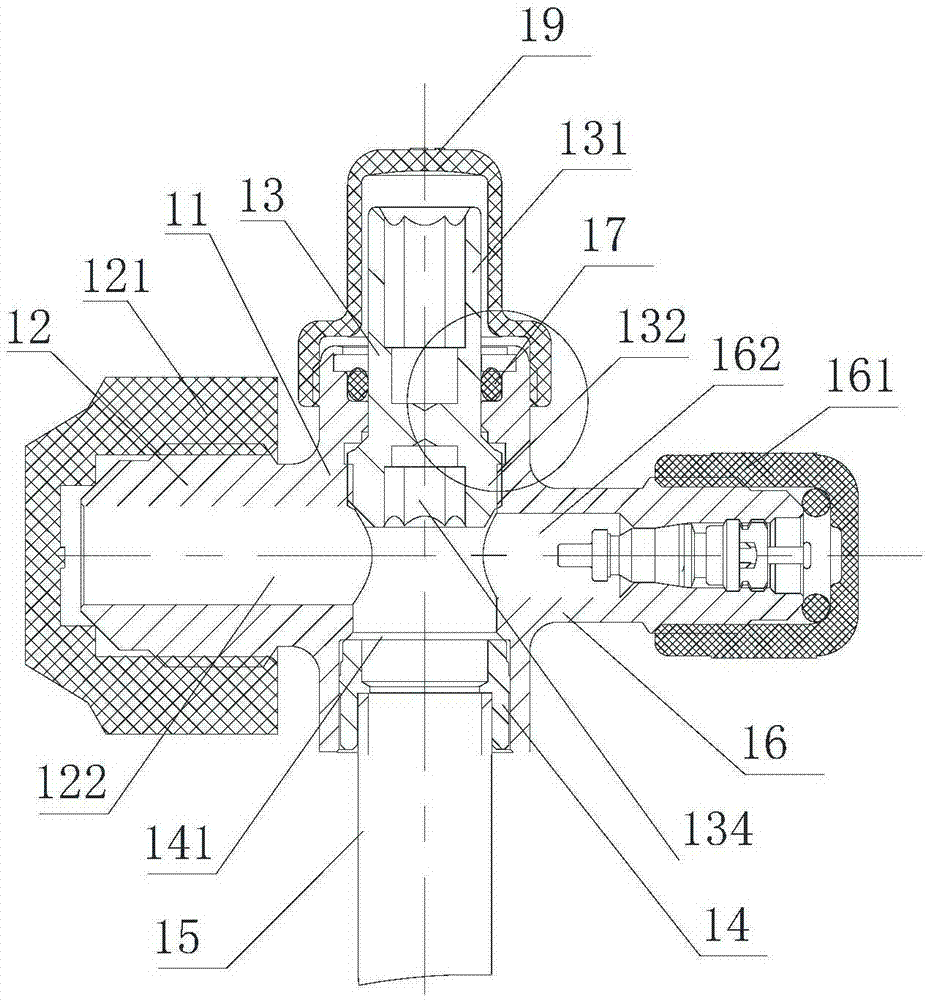

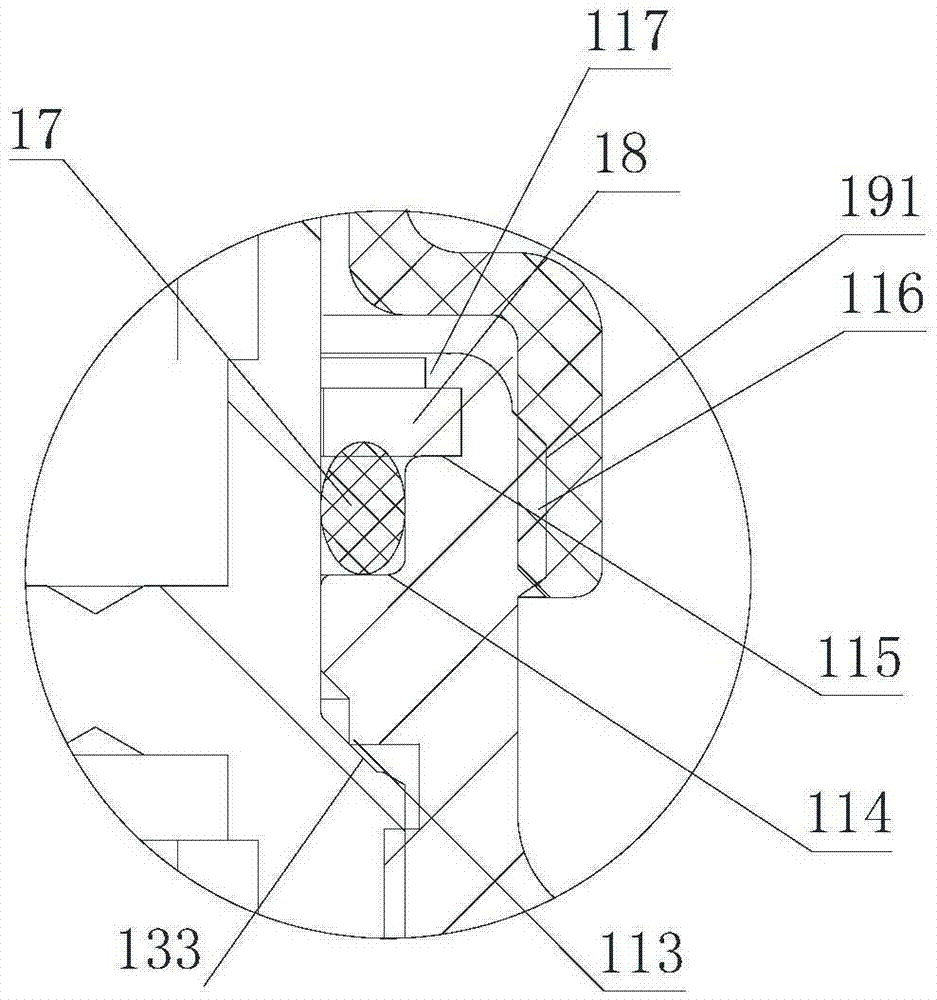

[0032] Please refer to figure 2 , image 3 ,in, figure 2 It is a schematic diagram of the appearance of the valve device of the first embodiment provided by the present invention, image 3 for figure 2 A partial enlargement of the .

[0033] Such as figure 2 As shown, the valve device has a generally cylindrical valve body 11. The valve body 11 can be made by forging or casting, and has a valve cavity 112 inside it, and forms a passage for refrigerant circulation. The lower end of the valve body 11 The opening is used to connect the valve seat 14 and the connecting pipe 15.

[0034] In the valve chamber 112 of the valve body 11, there is provided a generally rod-shaped valve stem 13. The valve stem 13 can be made of materials such as cutting brass or aluminum. The valve stem 13 has a small-diameter section 131 and a large-diameter section 132. The small-diameter section 131 and the large-diameter section 132 are connected by a sealing surface 133 . When the valve st...

no. 2 approach

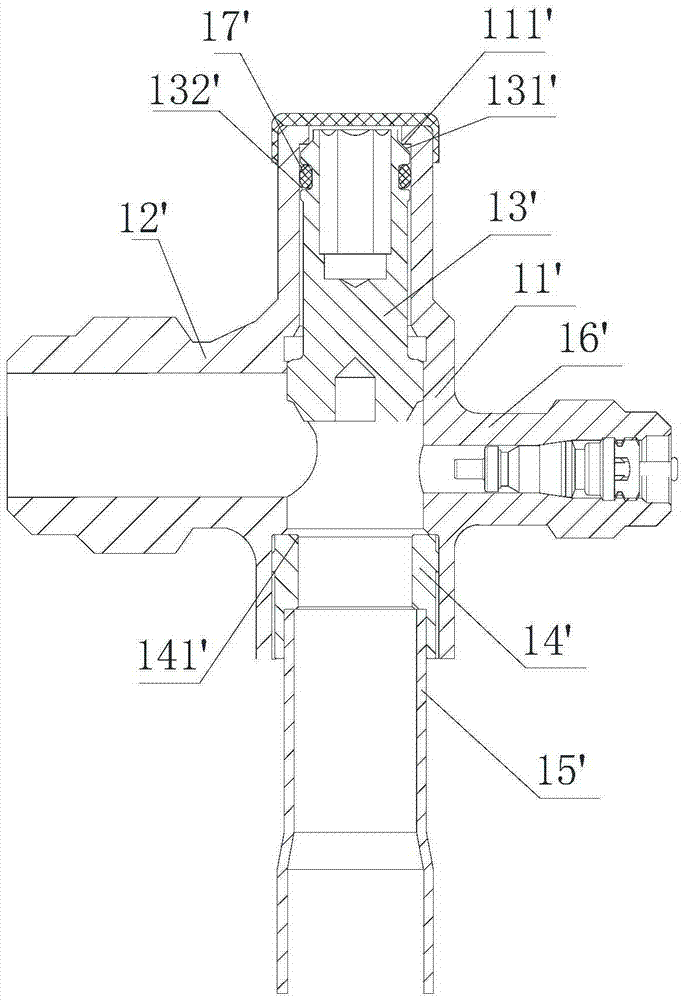

[0049] Please refer to Figure 4 , Figure 4 It is a schematic structural diagram of the valve device according to the second embodiment of the present invention.

[0050] Since there are some similarities between the second embodiment and the first embodiment, in order to avoid cumbersome repeated descriptions, the following description will focus on the differences between the two. In order to facilitate understanding of the technical solution of the second embodiment, the same reference numerals are used for components having the same structure and function as those of the first embodiment.

[0051] In the second embodiment, the installation part is an annular groove 11a provided on the inner wall of the valve body 11, and the sealing member is placed in the annular groove 11a. During installation, since the sealing component has certain elasticity, it can be placed in the annular groove 11a first. After the valve stem 13 is assembled, the sealing component can form a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com