Box-sealing adhesive tape

A tape and box sealing technology, applied in adhesives, packaging sealing/fastening, external support, etc., can solve the problem that the sealing tape does not have anti-counterfeiting performance, achieve good anti-counterfeiting effect, prevent falling off, and increase manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

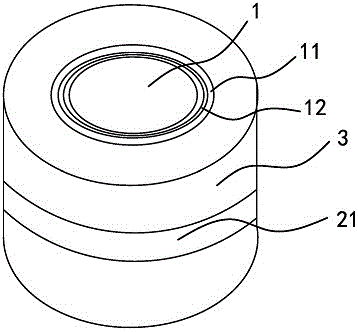

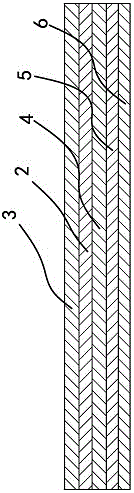

[0018] Such as figure 1 and figure 2 As shown, the sealing tape includes a reel 1 and a tape film 2 wound on a paper core, and an outwardly protruding arc angle 11 is provided between the inner wall and the cross-section at both ends of the reel 1. Angle 11 is also provided with anti-slip lines 12, the adhesive tape film 2 is a PET film, and a silicone oil layer 3 is provided on the upper surface of the adhesive tape film 2, and there is a thin and long transparent area 21 in the center of the silicone oil layer 3 and the adhesive tape film 2. The lower surface of 2 is provided with an epoxy resin release layer 4, a printing ink layer 5 and an adhesive layer 6 sequentially from top to bottom, and the epoxy resin release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com