Transportation cabin for packaging pressure testing and emptying equipment

A transport cabin and pressure test technology, which is applied in the direction of transportation and packaging, packaging, containers, etc., can solve the problems of limiting travel speed, etc., and achieve the effect of improving stability, increasing movement speed, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

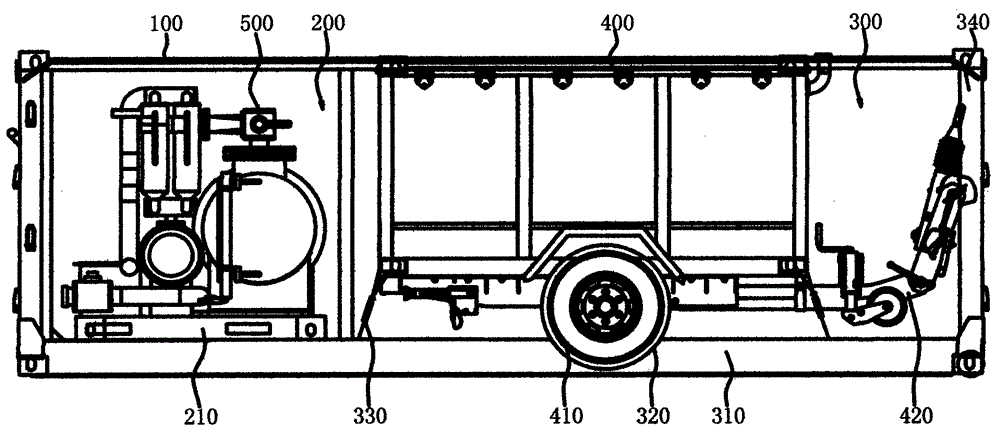

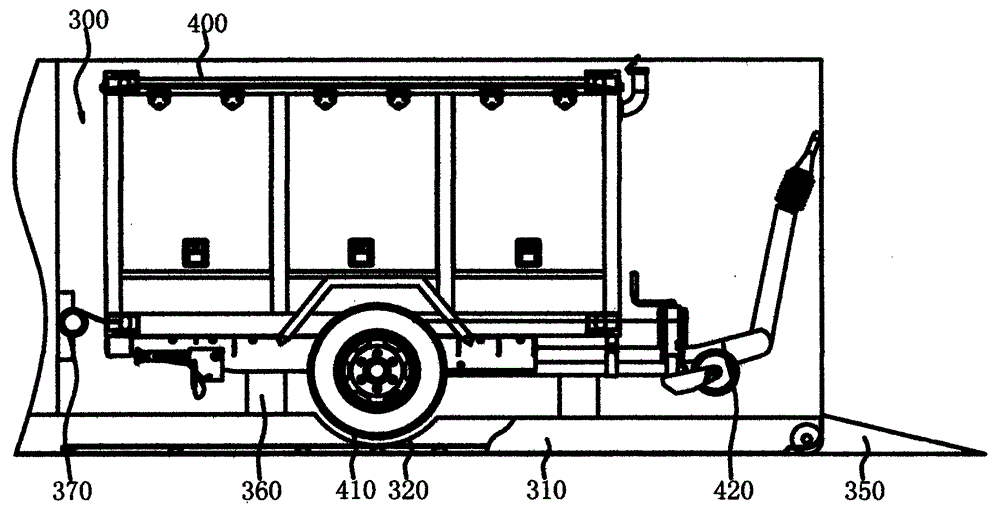

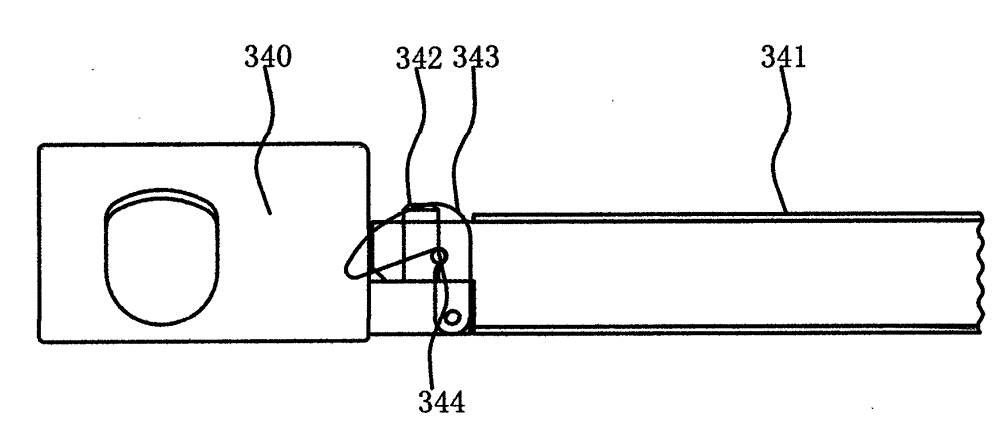

[0027] figure 1 It is a structural schematic diagram of the transport cabin in an embodiment of the present invention. Generally, the transport cabin 100 includes a rectangular box, and the inside of the box can be axially separated into an air compression cabin 300 for placing the air compressor 400 and an air-liquid cabin 200 for placing the gas-liquid separator 500 . Grooves 320 for accommodating the wheels 410 of the air compressor 400 are respectively provided on both axial sides of the bottom plate 310 of the air compressor chamber 300 . The groove 320 is formed by indenting from the upper surface of the bottom plate 310 of the air pressure chamber 300 to the lower surface of the bottom plate 310 . Such as figure 1 As shown, the air compression chamber 300 of the present invention is a frame structure, and other side walls and top plates may not be installed except for the bottom plate and the partition plate with the gas-liquid tank. The gas-liquid separator 500 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com