Compact and efficient cold cathode arc source of quasi diffusion arc

A cold cathode, high-efficiency technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of rate reduction, magnetic field leakage, and unfavorable plasma transmission, so as to improve ion density and ionization rate, promote particle-to-particle collisions, and enhance bombardment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

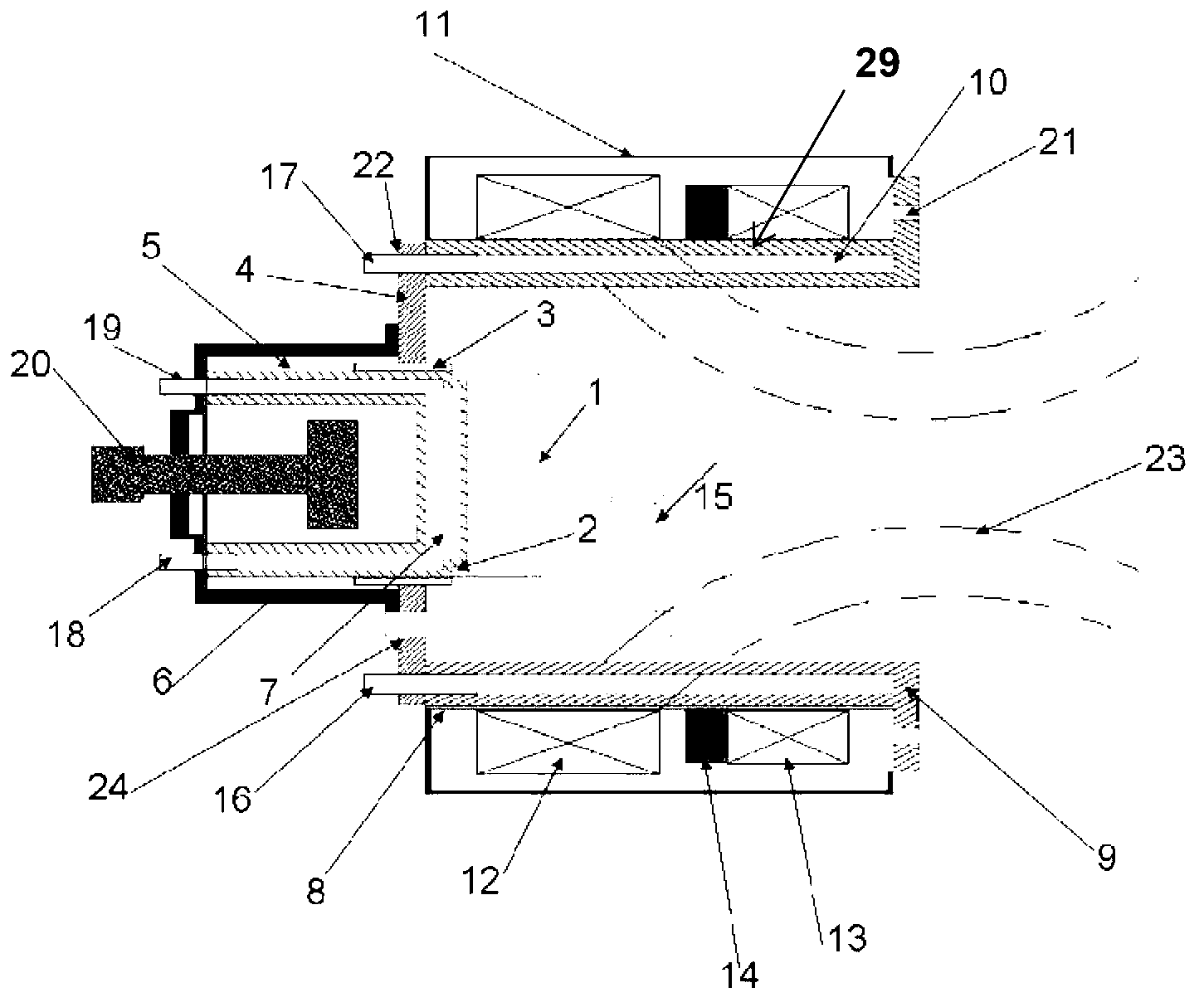

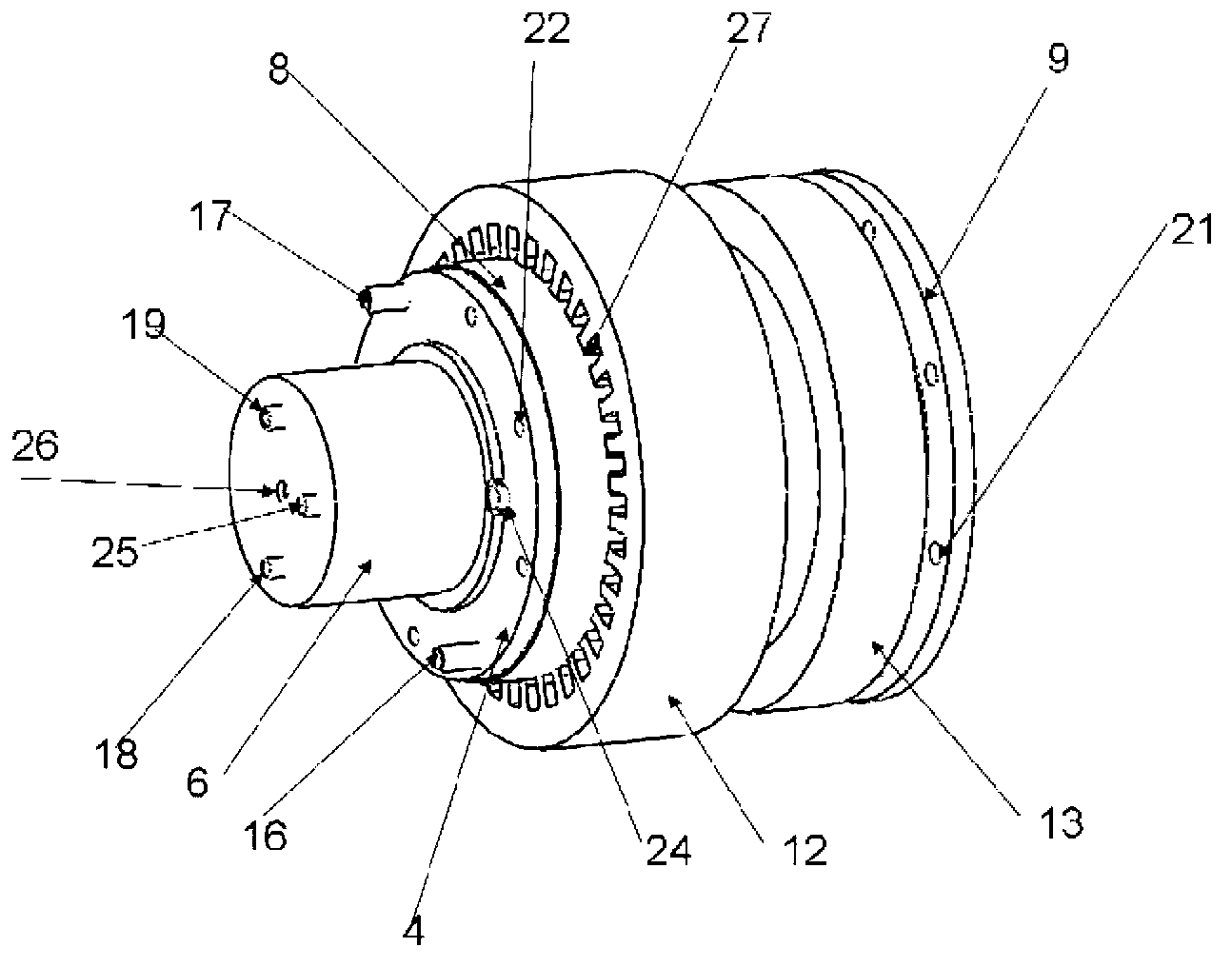

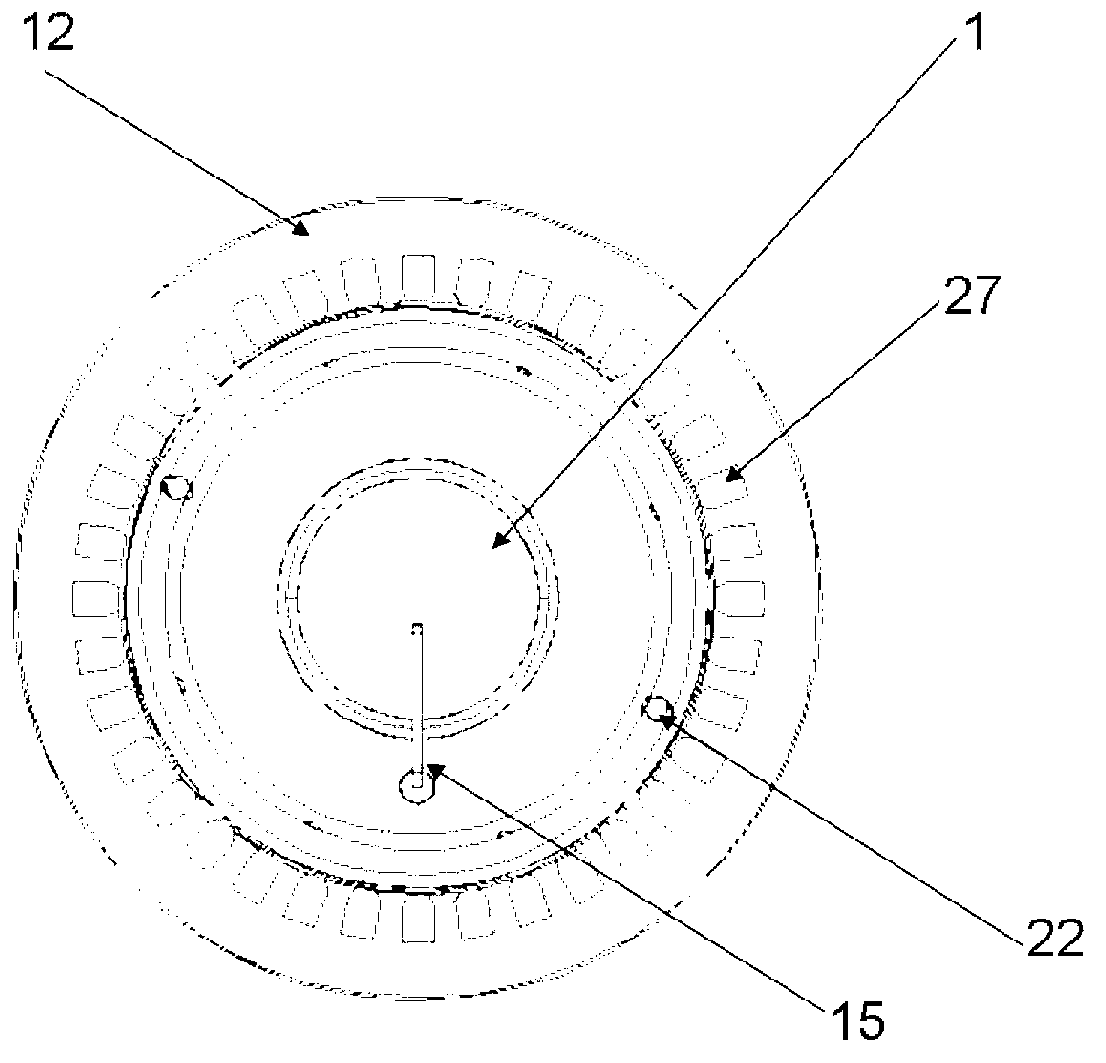

[0045] The invention breaks through the traditional cold cathode arc source magnetic field design idea, improves the traditional arc source structure, and provides a compact and efficient quasi-diffusion arc cold cathode arc source for circular targets with a diameter of 60-150mm. figure 1 It is a two-dimensional schematic diagram of the overall structure of a compact and efficient quasi-diffusion arc cold cathode arc source, figure 2 It is a three-dimensional schematic diagram of the overall internal structure of a compact and efficient quasi-diffusion arc cold cathode arc source without a flange sleeve shield. It can be seen from the figure that the compact and efficient quasi-diffusion arc cold cathode arc source is composed of the arc source and the control magnetic field group. The arc source includes the target 1, the target base 5, the target base shield 6, the target chassis 4, the The arc device 15 and the permanent magnet device 20, the control magnetic field group ...

Embodiment 2

[0057] The present invention provides multiple implementations of magnetic field coupling. Example 2 is an implementation of the coupling between the axial magnetic field generated by the permanent magnet device at the rear end of the traditional target and the dipole radial rotating magnetic field. The axis of the front section of the dipole radial rotating magnetic field The focus-guiding magnetic field does not participate in the coupling. Figure 9 (a)- Figure 9 (c) is a schematic diagram of the transient magnetic field distribution of embodiment 2 where the two-pole rotating radial magnetic field is coupled with the axial magnetic field of the permanent magnet at the rear end of the target, Figure 9 (a) is the transient distribution diagram of the two-pole rotating radial magnetic field on the cross-section of the target without the coupling of the axial magnetic field at the rear end of the target. It can be seen that when other magnetic fields do not work, the two pol...

Embodiment 3

[0060] Although the quasi-diffusion arc state can be realized under the comprehensive coupling effect of a certain rotating dipole radial magnetic field strength and a certain rotating frequency, the radial magnetic field has the effect of confining the plasma. In order to further improve the transmission efficiency of the plasma, embodiment 3 It provides a solution to extract the purified high-density plasma through the axial focusing guiding magnetic field of the front section of the target. Embodiment 3 is an embodiment in which there is no participation of the axial magnetic field generated by the conventional permanent magnet device at the rear end of the target, and the two-pole radial rotating magnetic field is coupled with the front axial focusing guiding magnetic field. There are two situations in this scheme, one is the situation without focus guiding yoke, and the other is the situation with focus guiding yoke. Figure 10 (a) is the transient distribution diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com