Three-degree-of-freedom program control wire machinery

A program-controlled Weiya machinery and degree of freedom technology, which is applied in entertainment, stage installations, and installations for theaters and circuses, etc., can solve problems such as the restriction of shooting elements, and achieve fast response time, rich shooting elements, and high movement speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

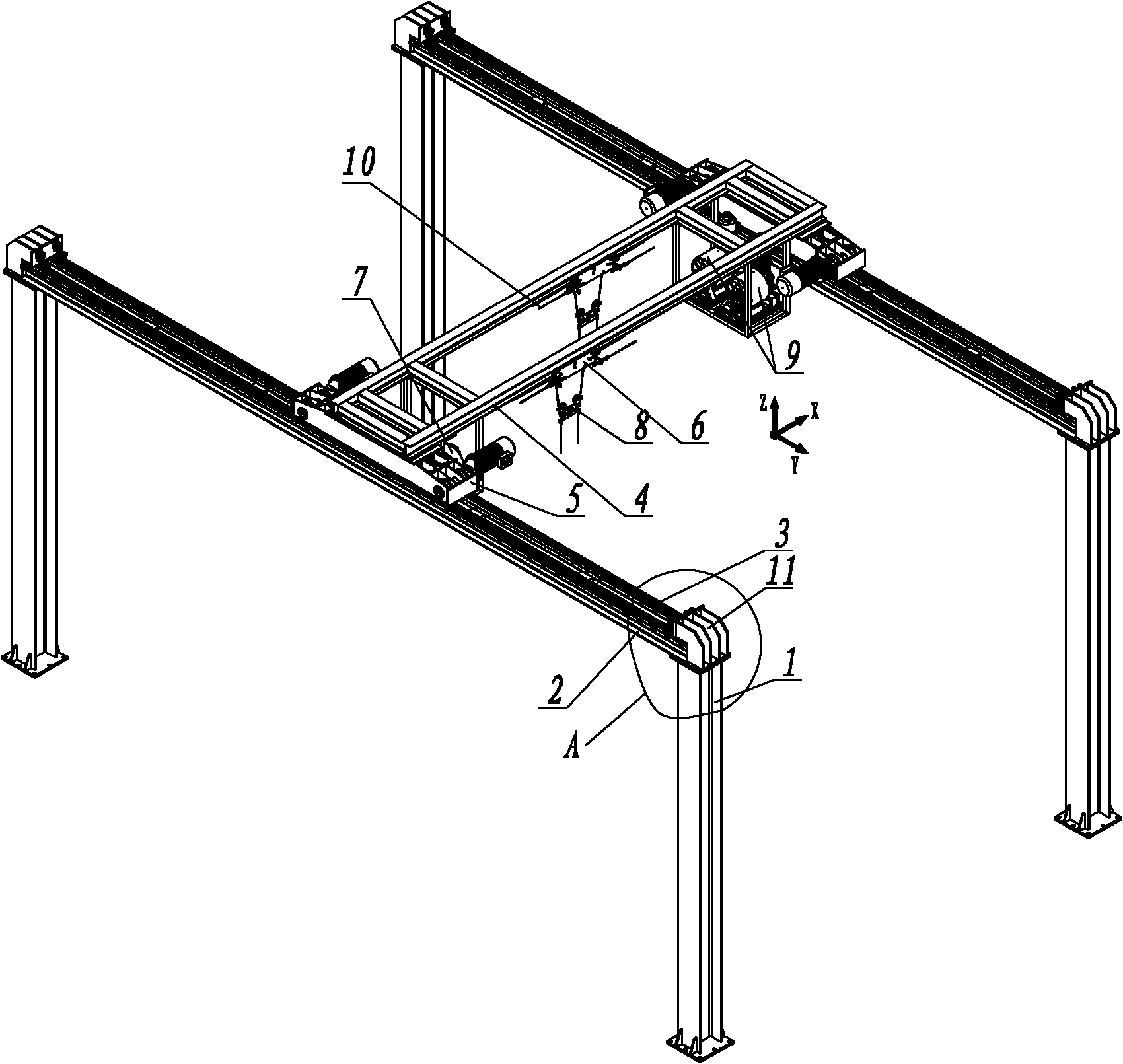

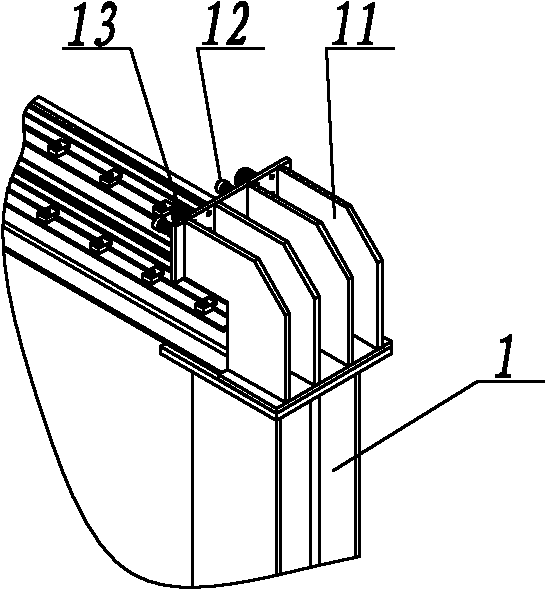

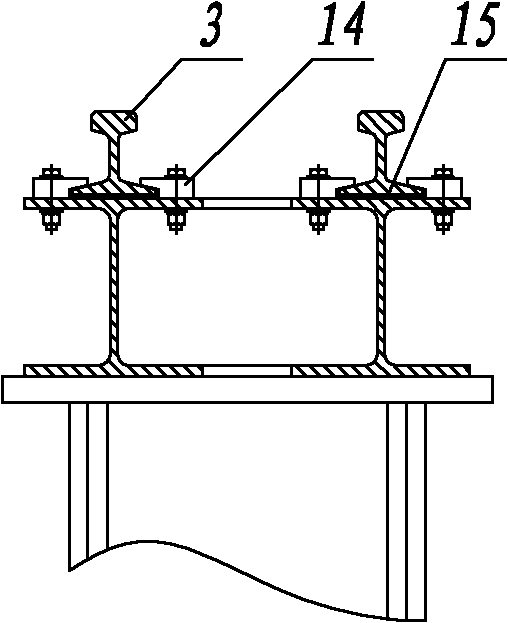

[0026] As an embodiment of the three-degree-of-freedom program-controlled Wia machinery of the present invention, please refer to Figure 1 to Figure 9 , including the foundation column 1, the Y-direction foundation beam 2, the Y-direction rail 3, the X-direction beam 4, the Y-direction moving vehicle 5, the X-direction moving vehicle 6, the X-direction tractor 7, the Z-direction vertical lifting pulley spreader 8 and the Z-direction To the vertical lifting tractor 9, the Y-direction foundation beam 2 is arranged on the foundation column 1, the Y-direction rail 3 is arranged on the Y-direction foundation beam 2, and the Y-direction moving vehicle 5 is arranged on the Y-direction track 3 , the X-direction crossbeam 4 is erected on the Y-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com