Rapid self-repairing shape memory polymer and preparation method thereof

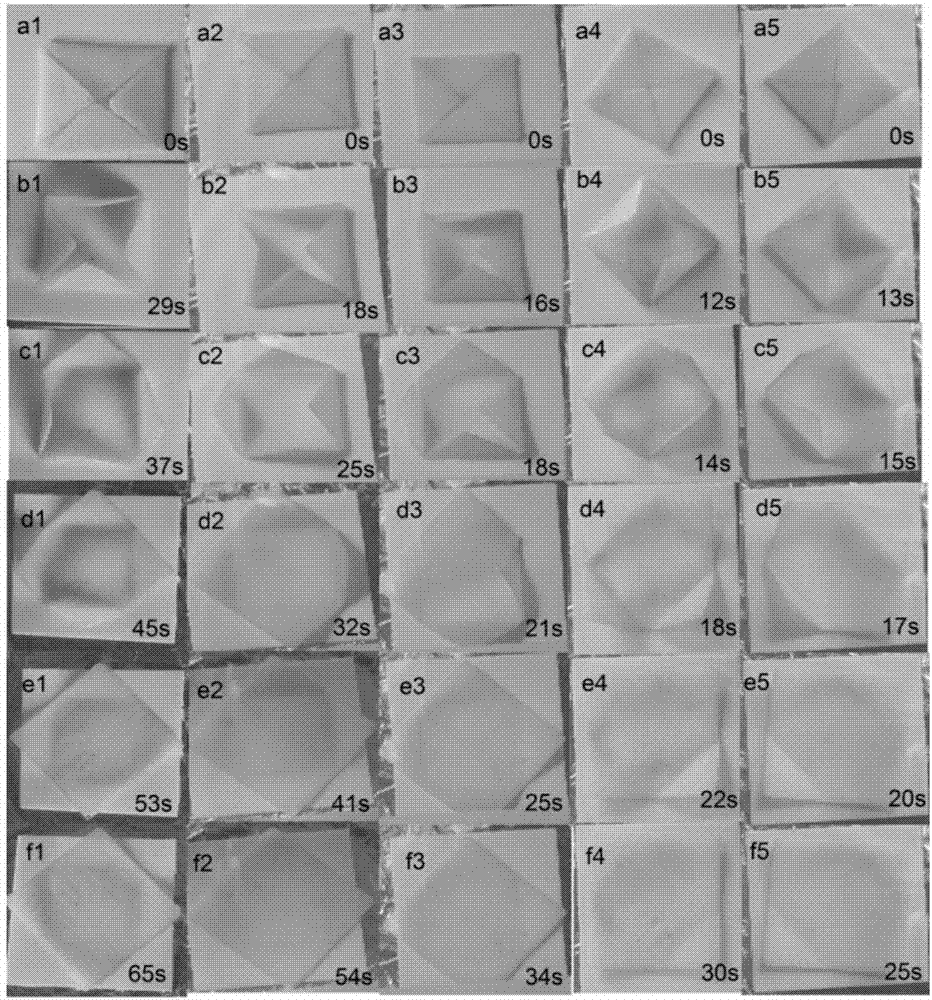

A memory polymer and self-healing technology, applied in the field of shape memory polymers, can solve the problems of high brittleness and affecting the circulation of shape memory polymers, etc., and achieve the effect of fast movement and short shape recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

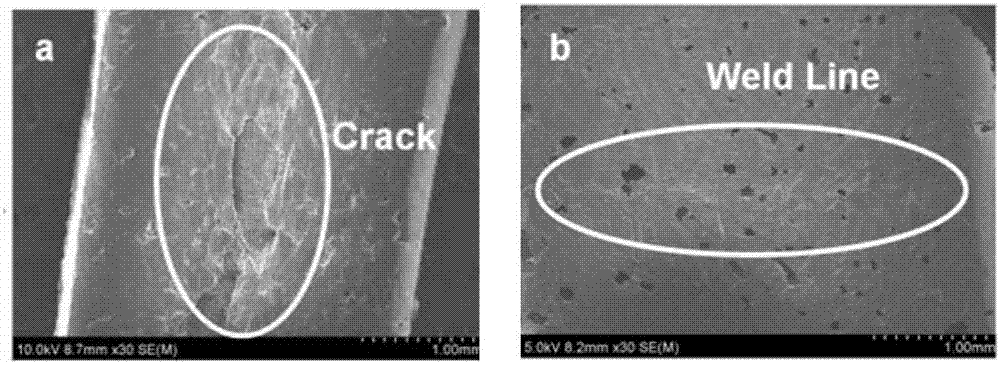

Problems solved by technology

Method used

Image

Examples

Embodiment 1

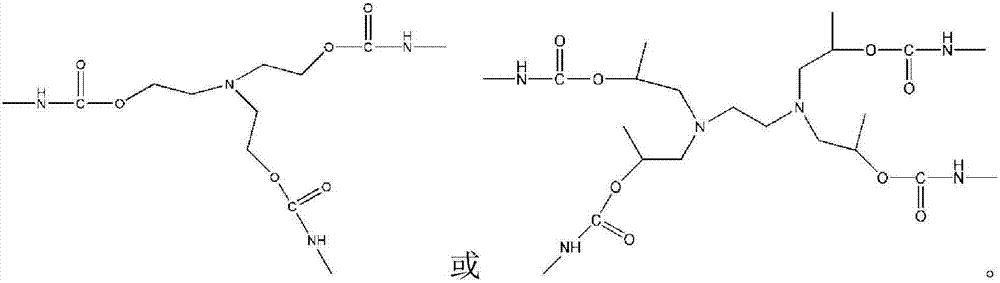

[0030] Stir and dissolve PCL-diol with a number average molecular weight of 2000 in dichloromethane to obtain a uniform solution; add HDI, HPED, TEA in turn to the dichloromethane solution of PCL-diol, protect with nitrogen, and stir at room temperature for 8-10min , and then the temperature was raised to 40-50° C., kept for half an hour, and the dichloromethane solvent was removed.

[0031] Place the above mixed solution in a vacuum oven and vacuumize for 5-10 minutes to remove excess air bubbles in the mixed solution; then pour the mixed solution into a polytetrafluoroethylene mold, place it in an oven, protect it with nitrogen, and slowly heat up. Keep at 30°C for 1h, 50°C for 1h, 70°C for 1h, 90°C for 1h, and finally 110°C for 1h. Then the above product is cooled, demoulded, and set aside.

[0032] The mol ratio of HDI, PCL-diol, HPED, TEA is in this embodiment:

[0033] 2·n DIM : 2·n PCL-diol : 4 n HPED : 3 n TEA =12:8:3:1

Embodiment 2

[0035] Stir and dissolve PCL-diol with a number average molecular weight of 5000 in dichloromethane to obtain a uniform solution; add HDI, HPED, TEA in sequence to the dichloromethane solution of PCL-diol, protect with nitrogen, and stir at room temperature for 8-10min , and then the temperature was raised to 40-50° C., kept for half an hour, and the dichloromethane solvent was removed.

[0036] Place the above mixed solution in a vacuum oven and vacuumize for 5-10 minutes to remove excess air bubbles in the mixed solution; then pour the mixed solution into a polytetrafluoroethylene mold, place it in an oven, protect it with nitrogen, and slowly heat up. Keep at 30°C for 1h, 50°C for 1h, 70°C for 1h, 90°C for 1h, and finally 110°C for 1h. Then the above product is cooled, demoulded, and set aside.

[0037] The mol ratio of HDI, PCL-diol, HPED, TEA is in this embodiment:

[0038] 2·n DIM : 2·n PCL-diol : 4 n HPED : 3 n TEA =2:1.5:0.4:1

Embodiment 3

[0040]Stir and dissolve PCL-diol with a number-average molecular weight of 20,000 in dichloromethane to obtain a uniform solution; add HDI, HPED, and TEA in sequence to the dichloromethane solution of PCL-diol, under nitrogen protection, and stir for 8-10 minutes at room temperature , and then the temperature was raised to 40-50° C., kept for half an hour, and the dichloromethane solvent was removed.

[0041] Place the above mixed solution in a vacuum oven and vacuumize for 5-10 minutes to remove excess air bubbles in the mixed solution; then pour the mixed solution into a polytetrafluoroethylene mold, place it in an oven, protect it with nitrogen, and slowly heat up. Keep at 30°C for 1h, 50°C for 1h, 70°C for 1h, 90°C for 1h, and finally 110°C for 1h. Then the above product is cooled, demoulded, and set aside.

[0042] The mol ratio of HDI, PCL-diol, HPED, TEA is in this embodiment:

[0043] 2·n DIM : 2·n PCL-diol : 4 n HPED : 3 n TEA =5:4:0.8:0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com