3-degree-of-freedom 6-UPS tri-translational parallel robot

A 6-UPS, degree-of-freedom technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of redundant self-motion, small working space, bending moment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

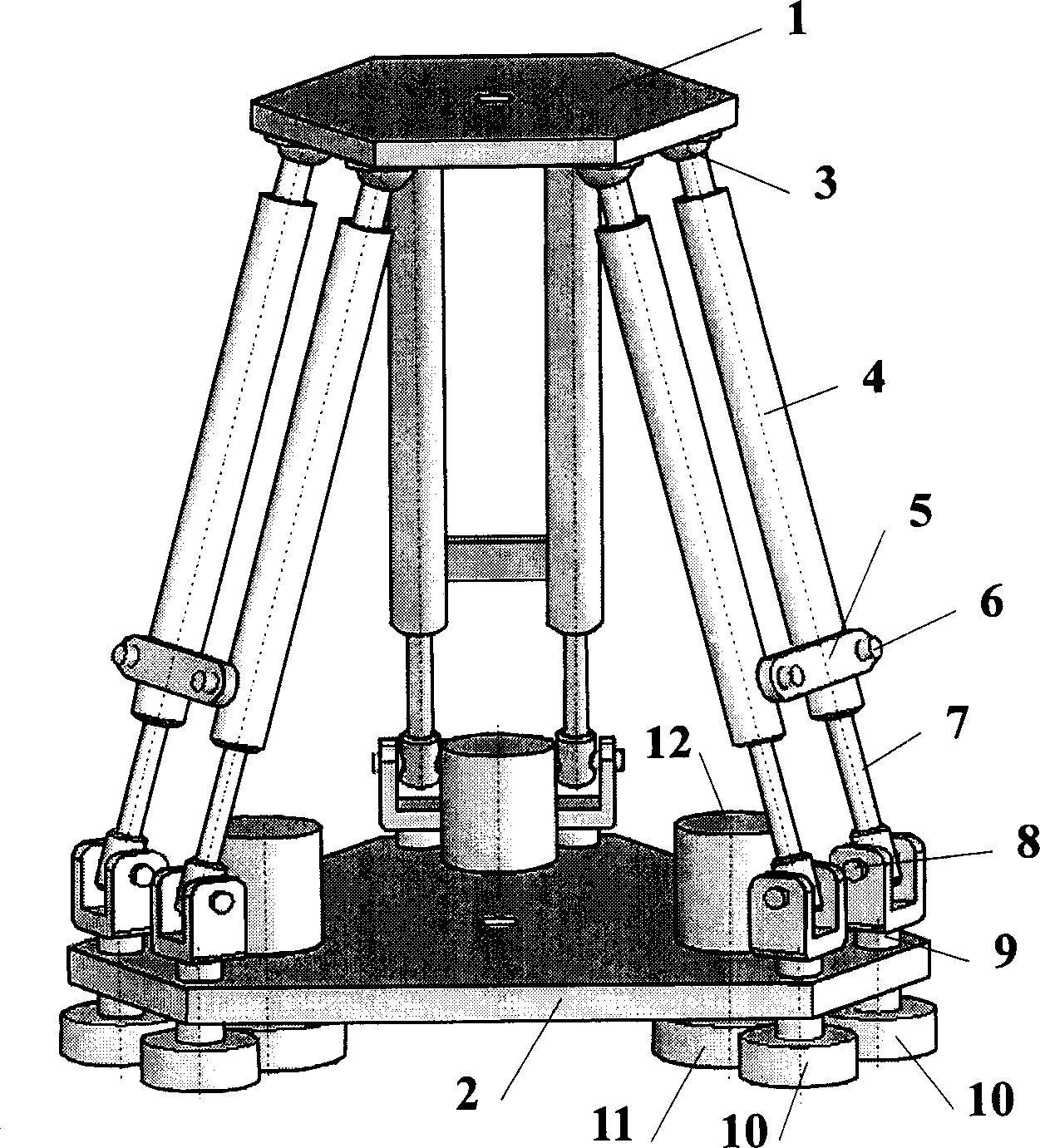

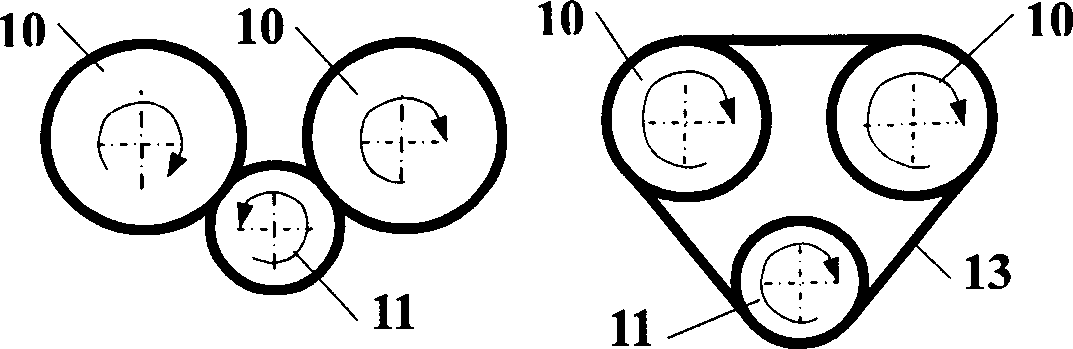

Embodiment 1

[0013] figure 1 It is a mechanical synchronously driven three-degree-of-freedom 6-UPS three-moving parallel robot disclosed in the present invention. Three pairs of linear drive branches are connected to the upper platform 1 and the base 2, and the three pairs of linear drive branches are positively connected between the upper platform 1 and the base 2. Triangular symmetrical distribution; each pair of linear drive branches includes two SPU type synchronous telescopic drive branches with the same structure, each SPU type branch has a ball pair at the upper end, a moving pair in the middle, and a universal pair at the lower end. The distance between the two ball pairs 3 of the branches is equal to the distance between the vertical axes 9 of the two universal joints. The upper end of each nut sleeve 4 is connected with the upper platform 1 by a ball pair 3, and the side surfaces of the lower ends of the two nut sleeves 4 are connected with the connecting rod 5 by two pin shafts ...

Embodiment 2

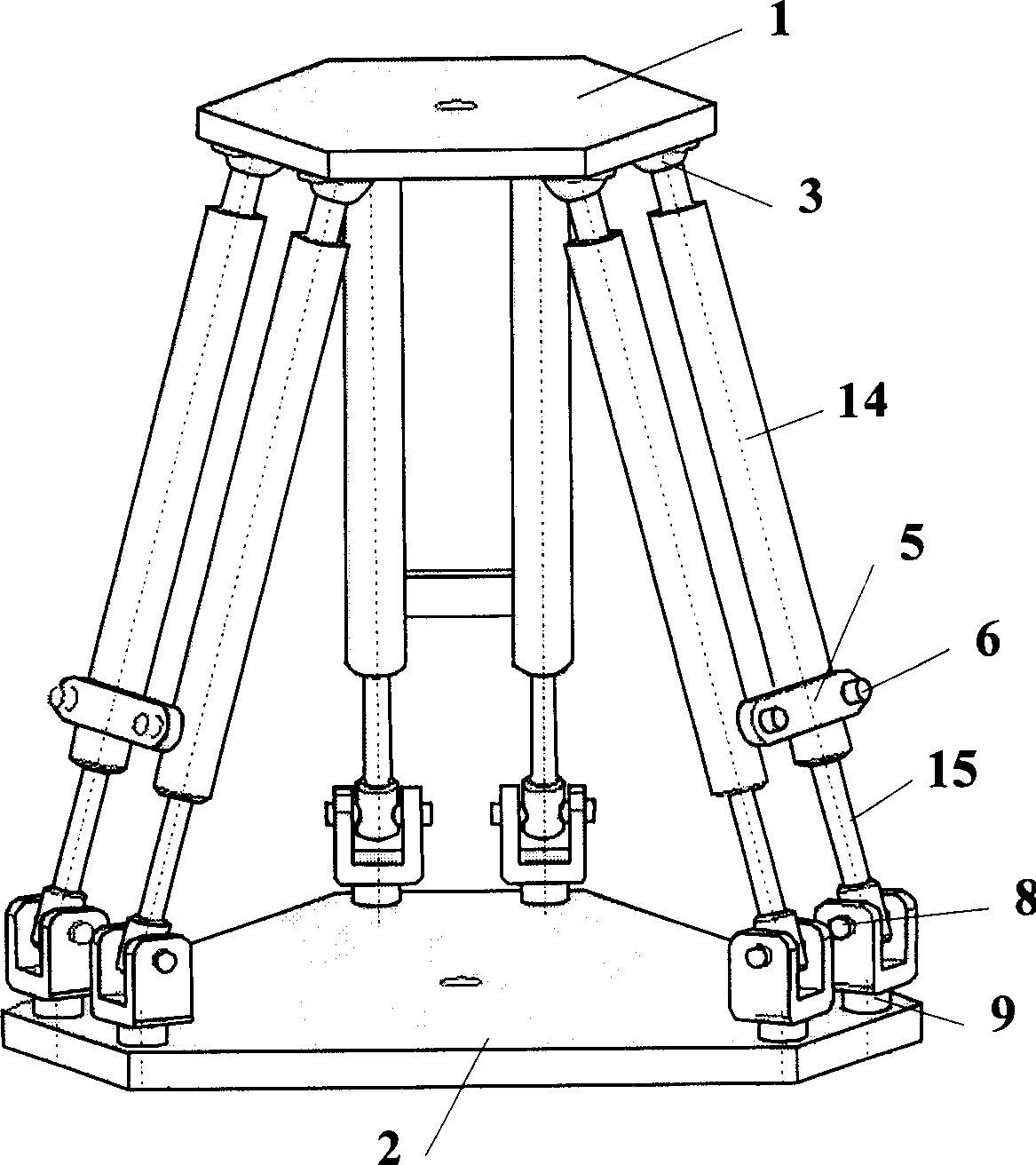

[0015] image 3 It is a hydraulic synchronously driven three-degree-of-freedom 6-UPS three-moving parallel robot disclosed in the present invention. Three pairs of linear drive branches are symmetrically distributed in an equilateral triangle between the upper platform 1 and the machine base 2; each pair of linear drive branches includes two structural forms The same size as the SPU type hydraulic synchronous telescopic drive branch, each SPU type branch has a ball pair at the upper end, a moving pair in the middle, and a universal pair at the lower end to connect with the machine base 2, and the moving pair is composed of a hydraulic cylinder 14 and a piston. 15 constitutes a hydraulic synchronous telescopic drive mechanism, the hydraulic cylinder 14 is connected with the upper platform 1 with the ball pair 3, the two hydraulic cylinders 14 are connected with the connecting rod 5 with two pins 6, the piston rod 15 is connected with the horizontal shaft 8 in rotation, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com