Series-parallel robot combined processing system and control method thereof

A technology of combined processing and control methods, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as poor flexibility and adaptability, low production efficiency, and small work space, so as to enhance adaptability and flexibility, The effect of improving the degree of automation and improving the reliability of fault tolerance

Inactive Publication Date: 2010-08-25

BEIHANG UNIV

View PDF0 Cites 50 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main disadvantages of this type of system are: simple structure, which can only realize a single movement form; small working space, limited load capacity; series manipulators have joint cumulative error, which reduces the repeated positioning accuracy of the end effector; flexibility and adaptability Poor performance, usually does not have redundant fault tolerance function; most of the work load is concentrated on the series manipulator, the task distribution of equipment is not balanced, affecting the overall life of the system; only the series manipulator moves to complete the main task, resulting in low production efficiency

Most of the software control methods of the system are simple offline teaching and programming methods, which can only provide limited and single motion instructions for the robot, which limits the working mode and flexibility of the robot; all motion instructions must be set offline, Once the robot starts working, it can no longer change the instructions in real time, resulting in the robot having no ability to respond to changes in the on-site environment and emergencies

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

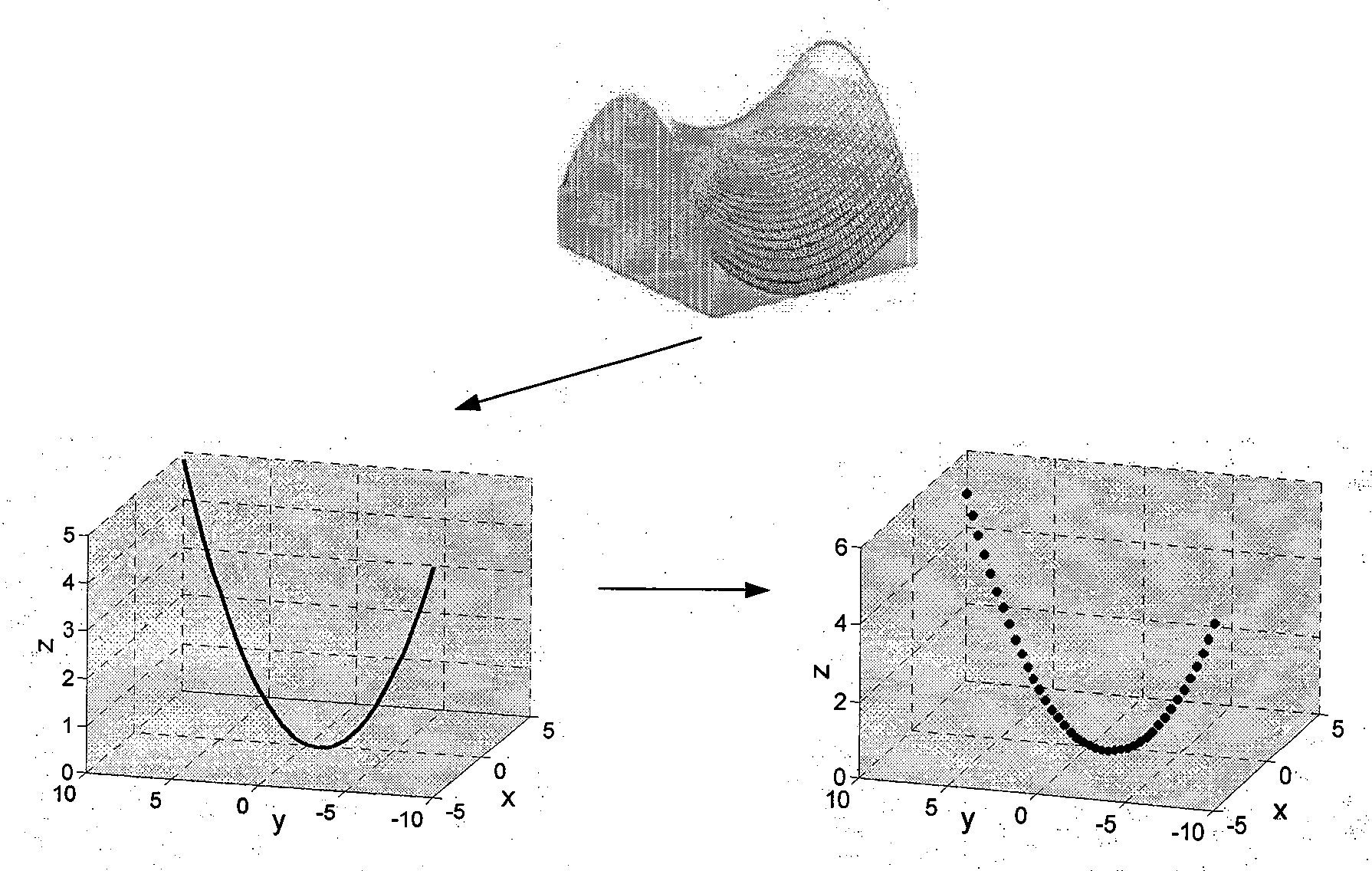

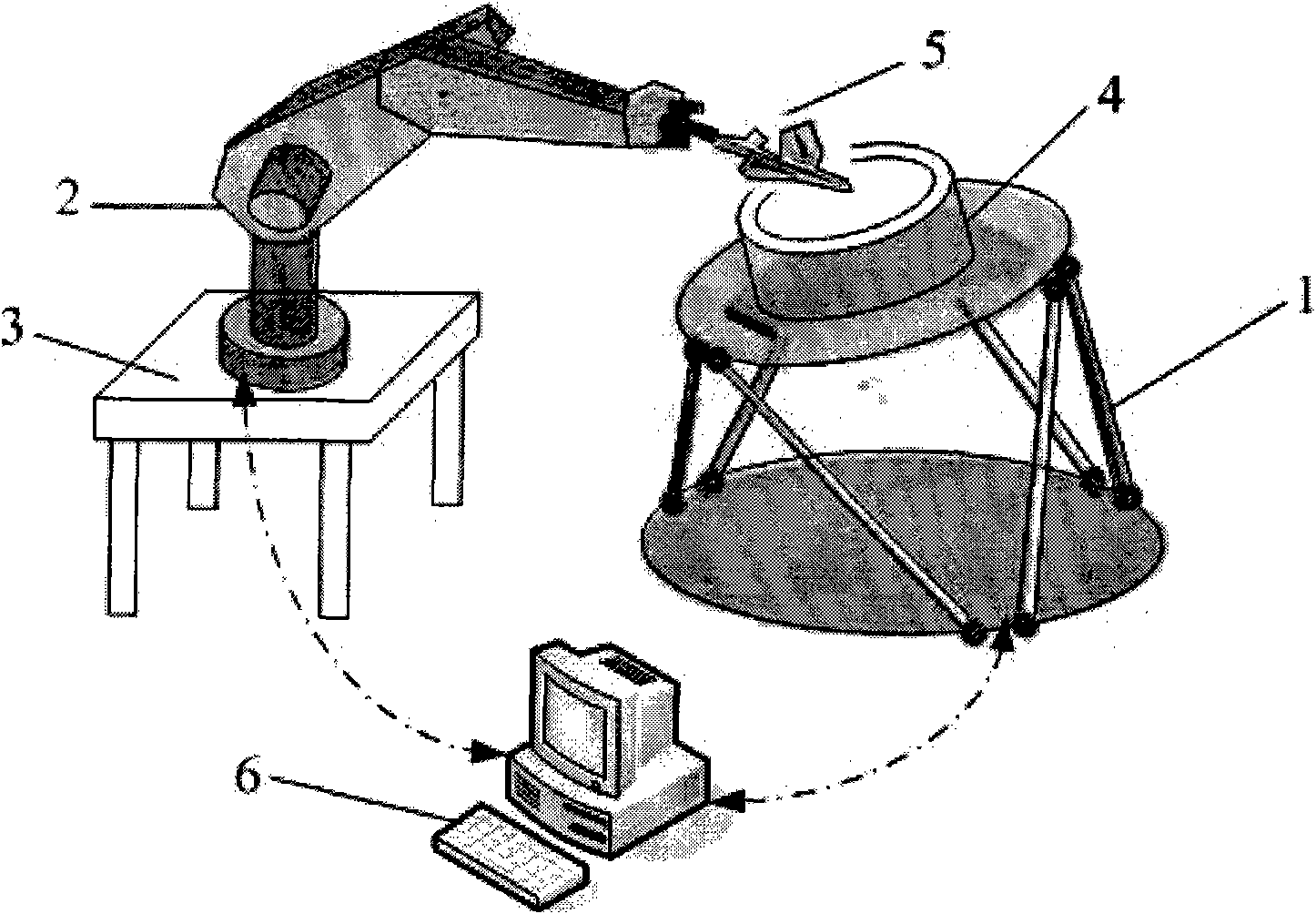

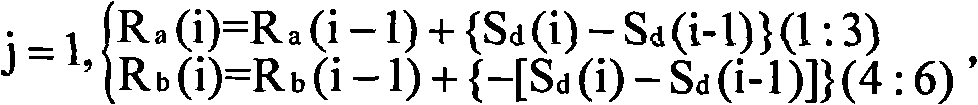

The invention discloses a series-parallel robot combined processing system and a control method thereof. The system comprises a series robot, a parallel robot, a controller, a platform, workpieces to be processed and a terminal executer. The controller controls the series robot and the parallel robot by adopting a layering control system, the upper controller is used for distributing tasks and controlling movement, and the lower series-parallel robot is used for driving hardware and executing the tasks. The invention combines the system hardware with software, thereby enhancing the automation degree, production efficiency, bearing capability and repetitive positioning accuracy of processing, strengthening the flexibility and adaptability of the system, realizing real-time control on line, and having a certain intelligent performance.

Description

technical field The invention relates to a dual-robot cooperative system for industrial processing and a software control method thereof, in particular to a series-parallel robot joint processing system and a software control method thereof. Background technique In recent years, the application of robots to industrial processing production lines has become one of the mainstream trends in domestic and foreign processing industries. The number of such robots is growing rapidly, new types are emerging, and corresponding software control methods are gradually diversifying. Robots for industrial processing are usually composed of three basic parts: main body, drive system and control system, with 3 to 6 degrees of freedom of movement. The drive system includes a power device and a transmission mechanism to make the actuator perform corresponding actions; the control system sends command signals to the drive system and the actuator and controls them according to the input program...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B25J9/08

Inventor 罗婉琴付永领祁晓野王岩彭朝琴

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com