Large span foundation pit automatic cover system

An automatic coverage and large-span technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of overlay network damage, increased construction costs, secondary pollution of the surrounding environment, etc., to reduce costs, reduce losses, and facilitate construction flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

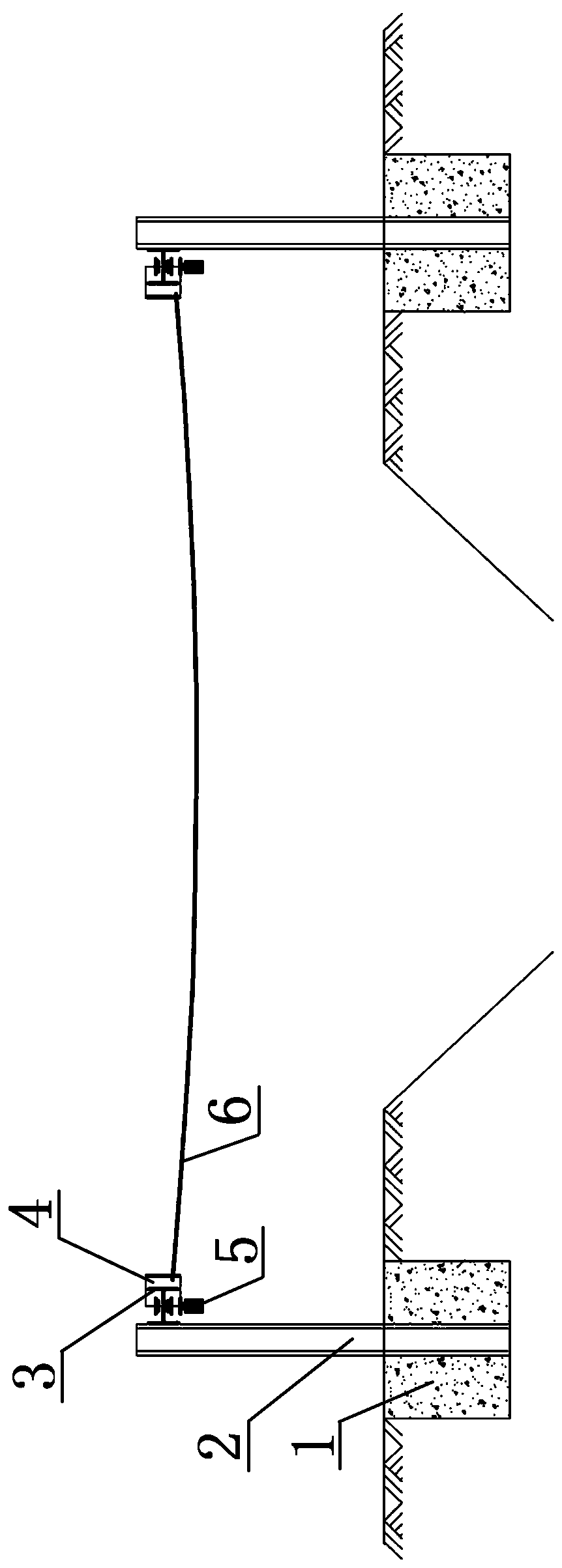

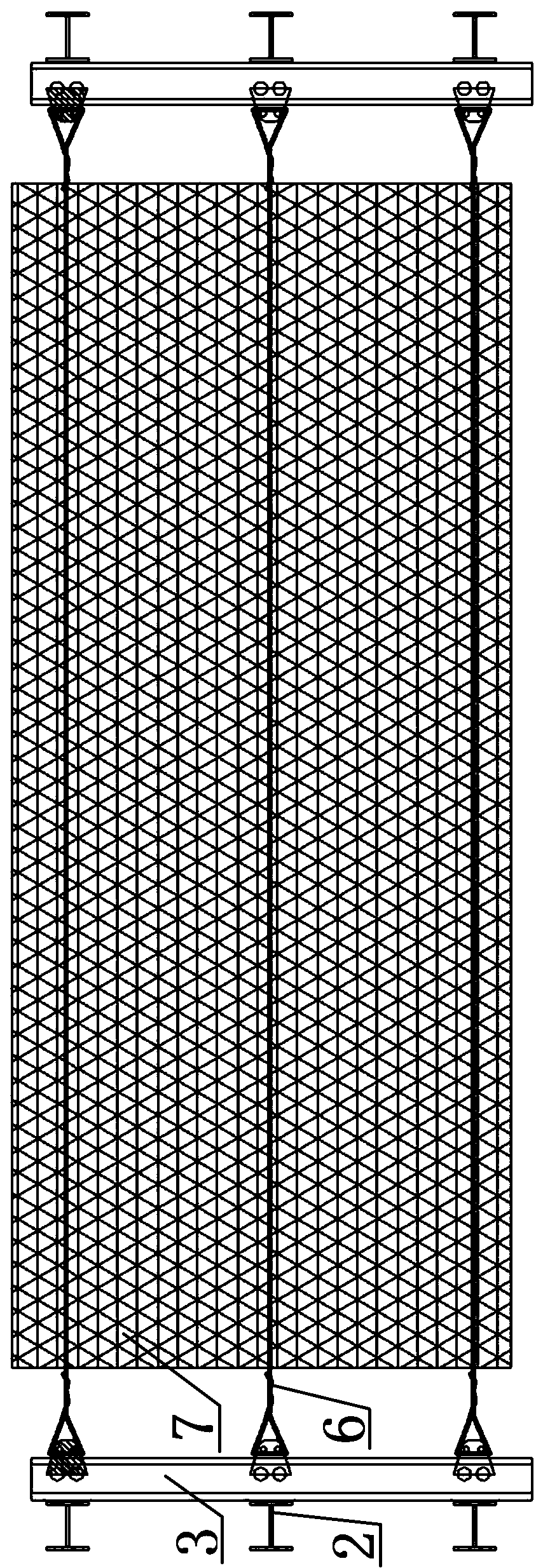

[0041] The construction method of the large-span automatic covering system for the foundation pit includes the following steps:

[0042] Step 1: Excavate the earthwork of the column foundation, and the excavation is positioned outside the range of 2m from the side of the foundation pit or adjusted according to the design instructions of the foundation pit slope; the foundation size is 1m*1m*0.8m (height), and the spacing is 4m

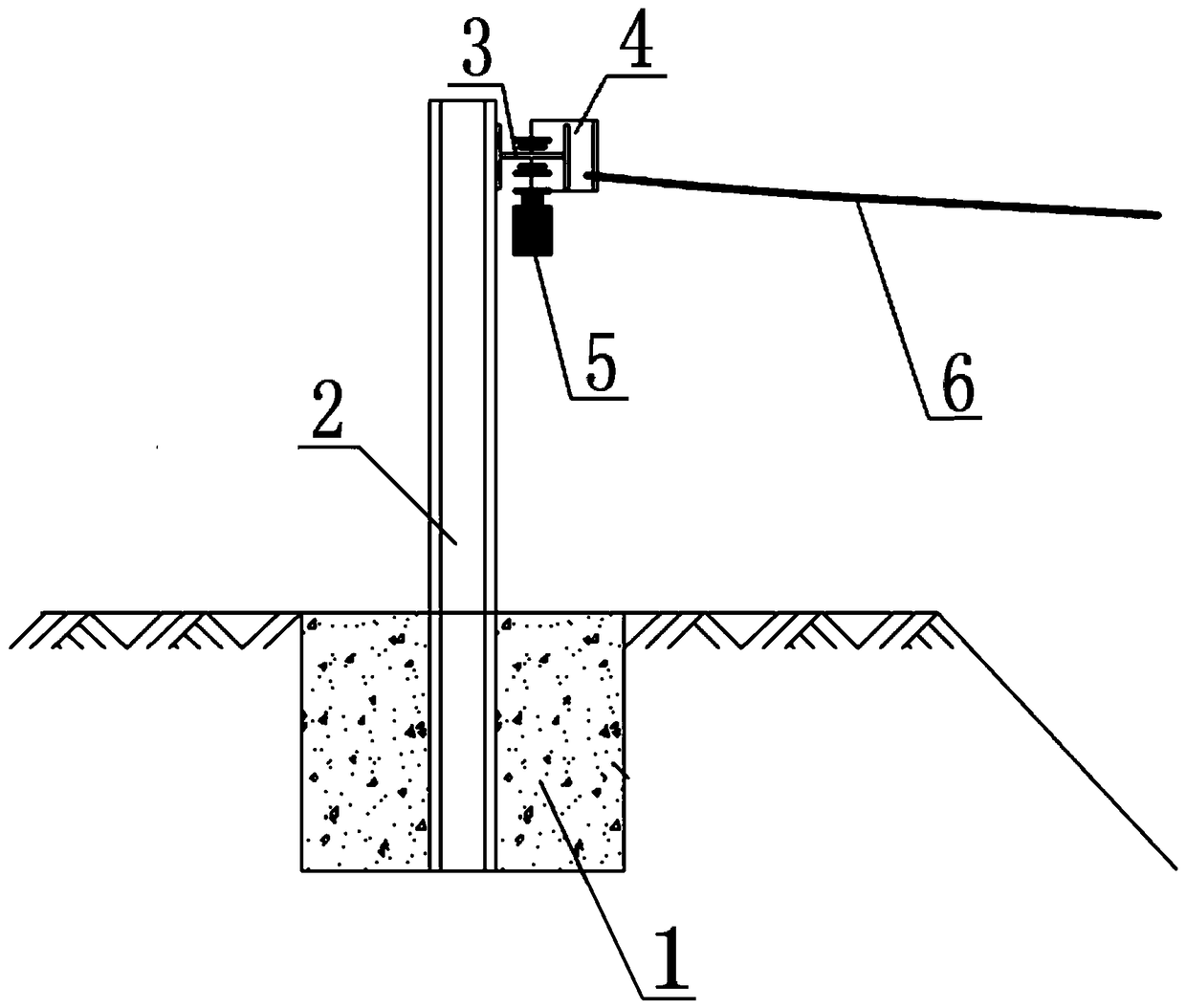

[0043] Step 2: Install the columns and pour the foundation

[0044] Place the I20a column, adjust the verticality, elevation, and align the columns on both sides of the foundation pit, temporarily fix the steel wire rope, pour C30 concrete and carry out watering and maintenance;

[0045] Step 3: Install the track

[0046] Covering system I20a track is welded on the top of the column, the weld seam is 8mm, the track should be perpendicular to the column and straightened;

[0047] Step 4: Install pulleys and wire ropes

[0048] Unscrew the pulley bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com