Mechanical polishing process of inner wall of stainless steel storage tank

A mechanical polishing and stainless steel technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of shortening the construction period and achieve the effects of reducing production costs, improving production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

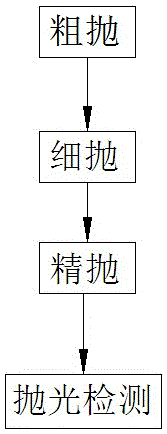

[0018] Such as figure 1 As shown, a mechanical polishing process for the inner wall of a stainless steel storage tank includes the following steps:

[0019] 1) Coarse throwing: Use 60#~100# emery wheels to grind, polish or grind the surface of the workpiece to remove surface burrs, scratches, rust marks, scale, weld reinforcement, welding tumors, Welding slag, etc., just remove the surface oxide layer and expose the metallic luster;

[0020] 2) Fine polishing: Use 80# emery wheel and thousand impellers to further process the surface after rough polishing, remove the scratches left by rough polishing, and produce a smooth to medium bright surface;

[0021] 3) Fine polishing: Use 240#~320# fiber wheel and cloth wheel coated with polishing paste to polish the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com