Rapid mechanical gob-side entry retaining support system and use method

A support system and mechanical technology, applied in mine roof support, earth square drilling, filling, etc., can solve the problems of low mechanization, high labor intensity and low work efficiency, and achieve high mechanization, low labor intensity and easy construction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

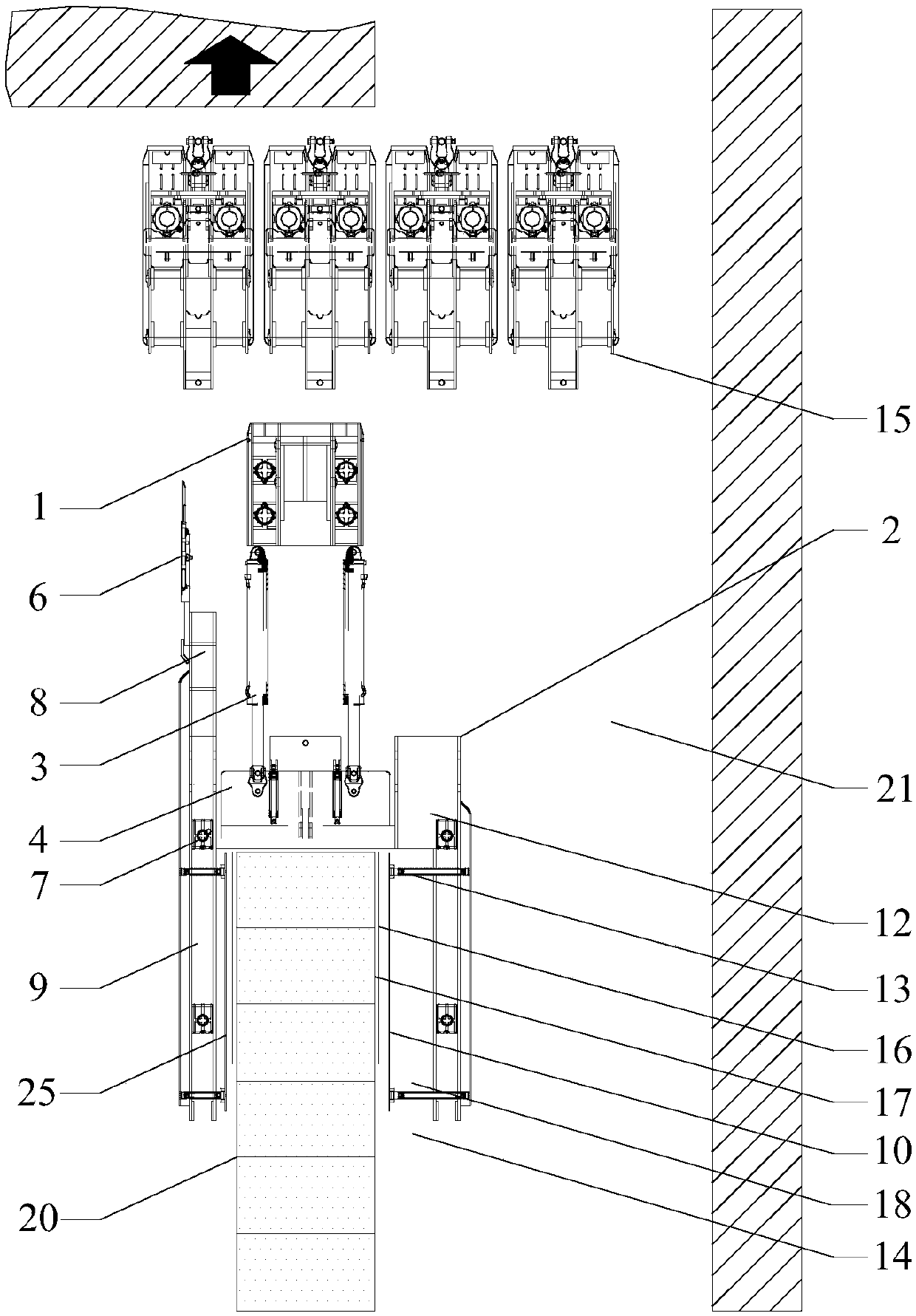

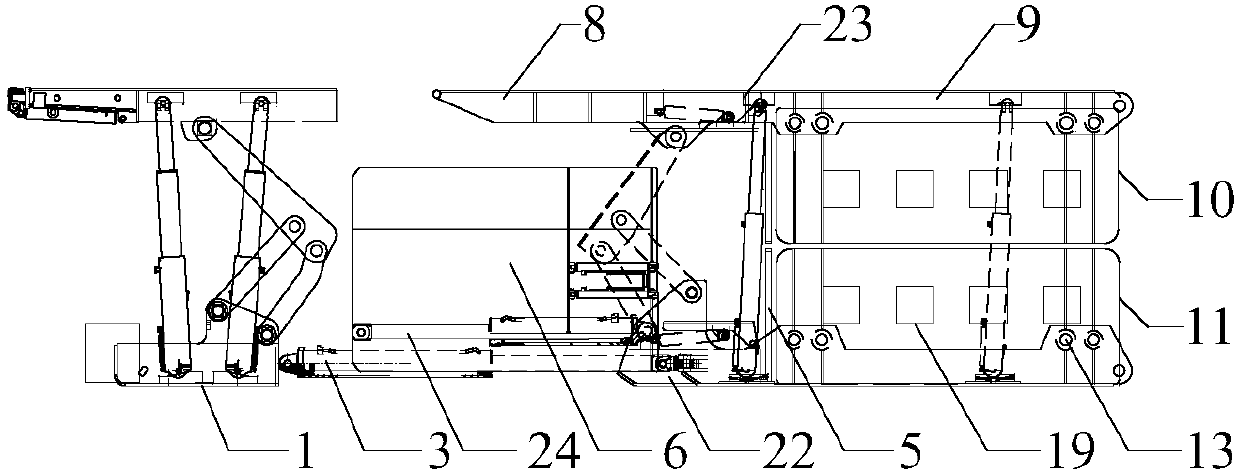

[0029] Such as figure 1 and figure 2 As shown, the fast mechanical gob-side entry retaining support system of the present invention is mainly composed of an auxiliary support 1, a filling support 2, and a rack oil cylinder 3 arranged in the gob-side entry entry roadway 21 behind the end support 15. The auxiliary support 1 and the filling support 2 are mutual fulcrums, move with each other, and are relatively independent from the advancement of the hydraulic support on the working face. The auxiliary support 1 and the filling support 2 are hingedly connected by a tension cylinder 3 . Auxiliary support 1 is a four-column support type support, the width is consistent with the hydraulic support of the working face, and the length is slightly shorter. The hydraulic support is a multi-stage oil cylinder support, and the reciprocating stroke is relatively large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com