Large diameter pipeline winter construction equipment and method thereof

A technology for large-diameter pipelines and construction equipment, which is applied to the field of large-diameter pipeline construction equipment in winter, can solve the problems of workers suffering, the quality of the project cannot be effectively guaranteed, and the cost of the project is increased, and the effect of simple construction equipment is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

[0020] existing construction methods (see Figure 7 ) is to use an excavator or a loader to lift the installed pipe off the ground through a wire rope, and the construction personnel use a large crowbar to connect it to the fixed pipe. Construction workers not only have to endure the biting cold wind, but also often slip and fall and cause accidents.

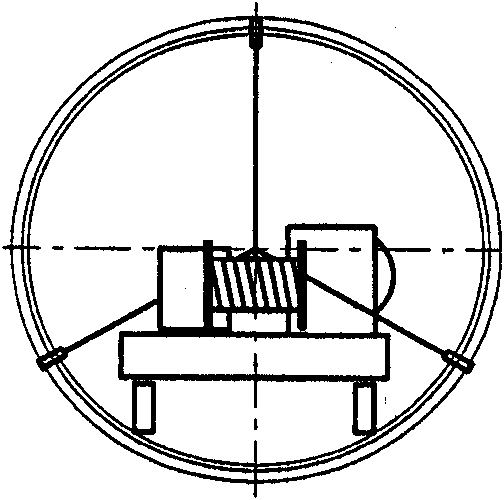

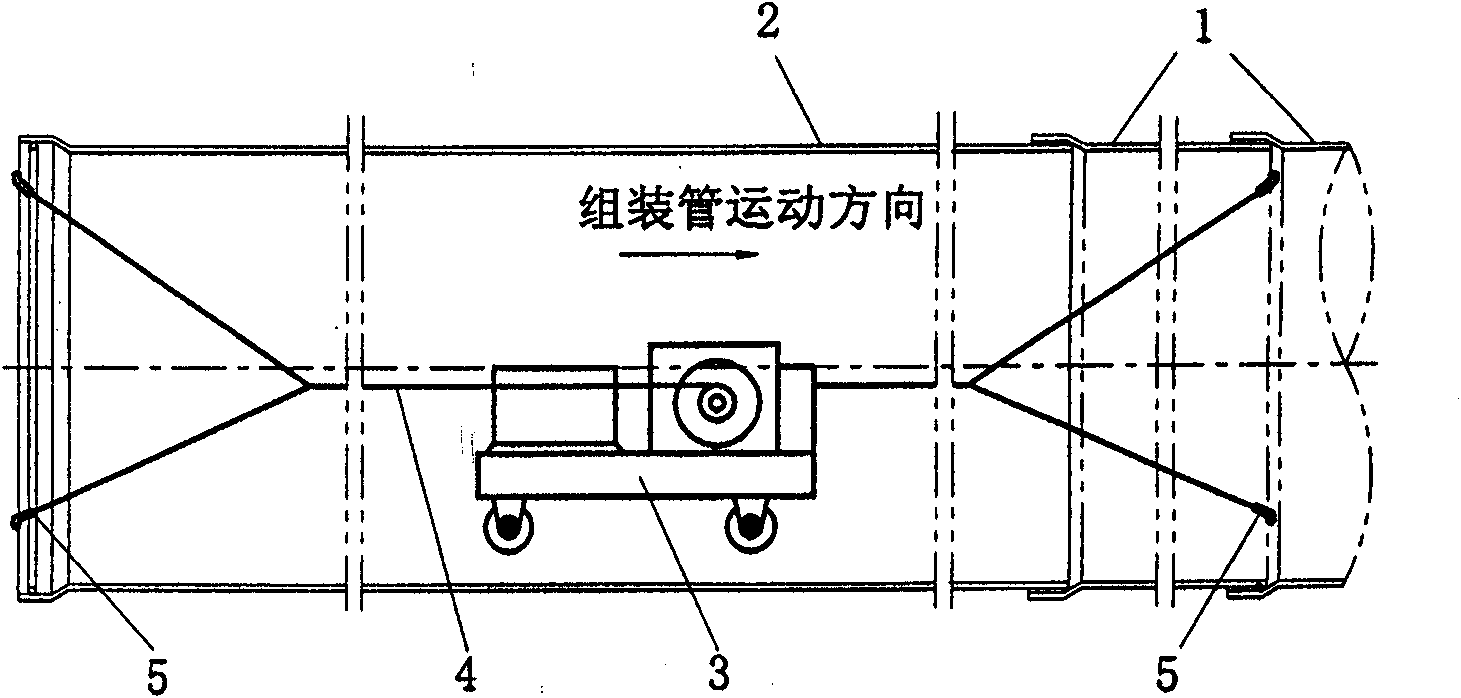

[0021] The present invention uses a set of easy-to-operate installation methods to carry out pipe internal construction (see Figure 6 ), only three people (replacing the original dozen or even dozens of people) can realize the installation of the pipeline, the construction equipment is simple, and only a simple tractor can replace the original excavator or loader. The clearance on the side of the tractor allows construction workers to pass through.

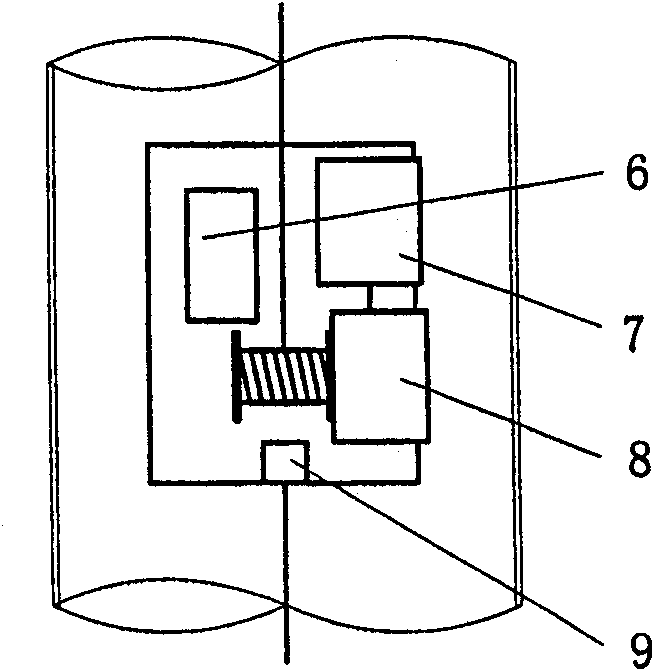

[0022] The construction device of the present invention includes: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com