Patents

Literature

41 results about "Backscatter X-ray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

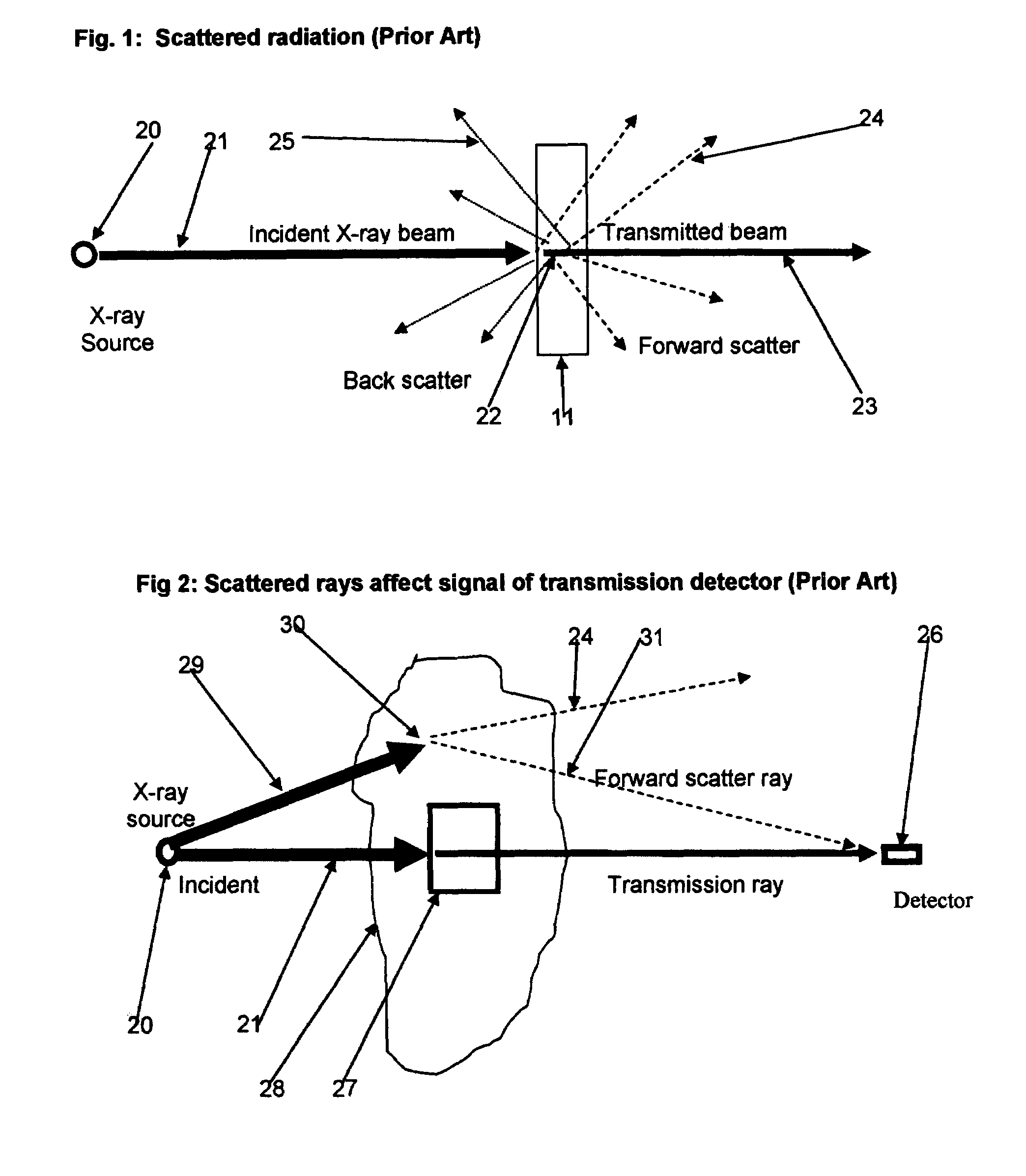

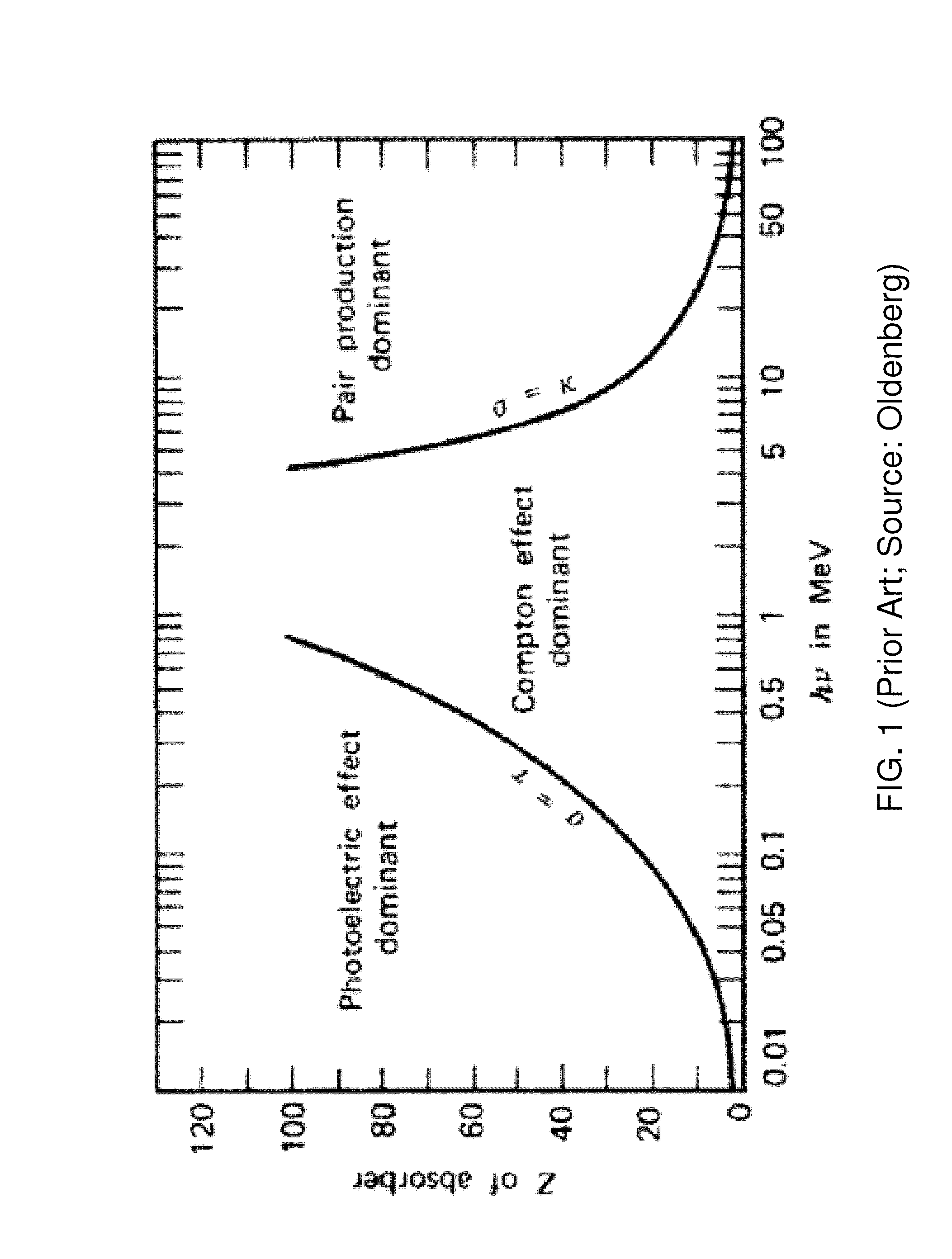

Backscatter X-ray is an advanced X-ray imaging technology. Traditional X-ray machines detect hard and soft materials by the variation in x-ray intensity transmitted through the target. In contrast, backscatter X-ray detects the radiation that reflects from the target. It has potential applications where less-destructive examination is required, and can operate even if only one side of the target is available for examination.

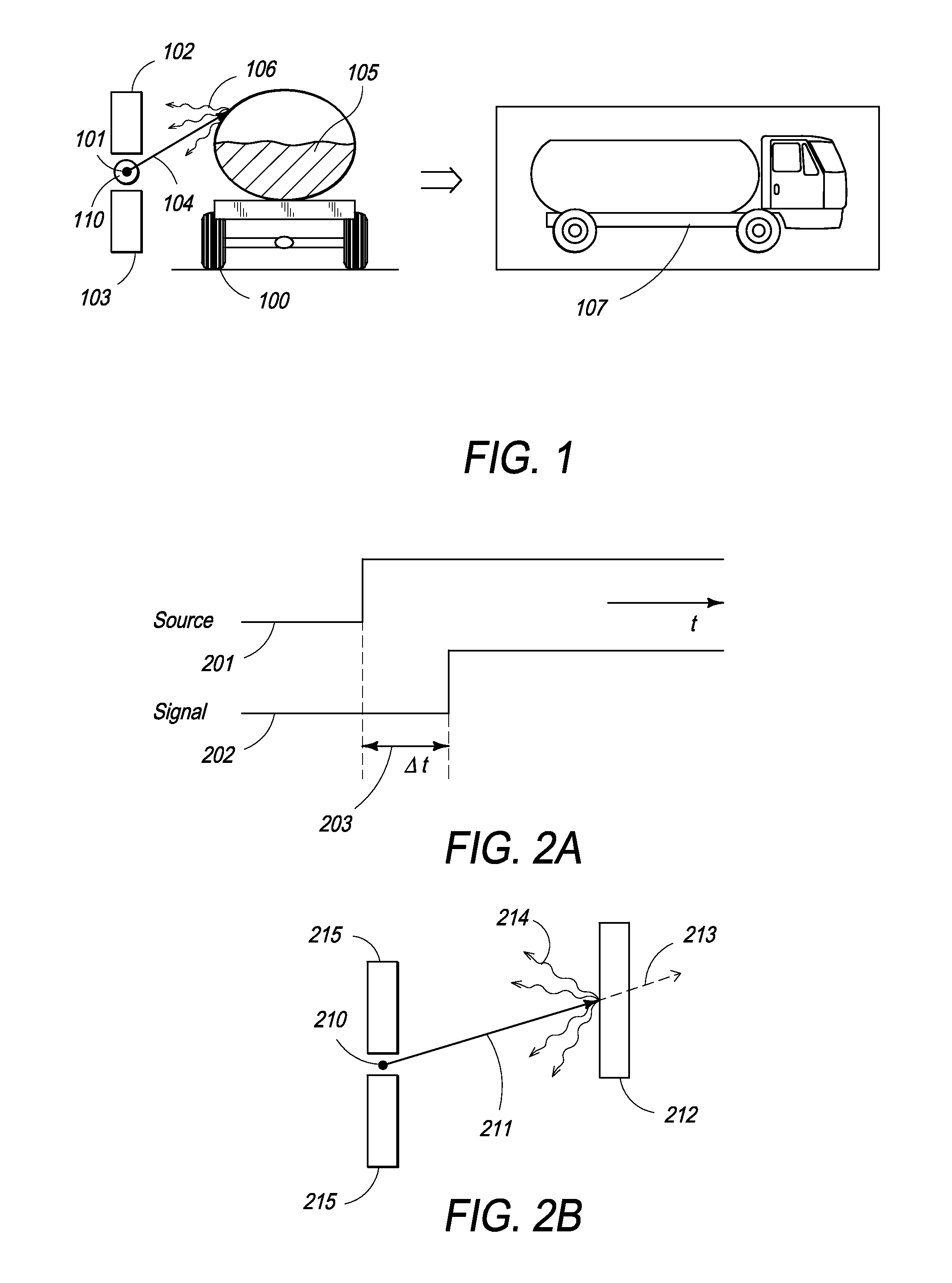

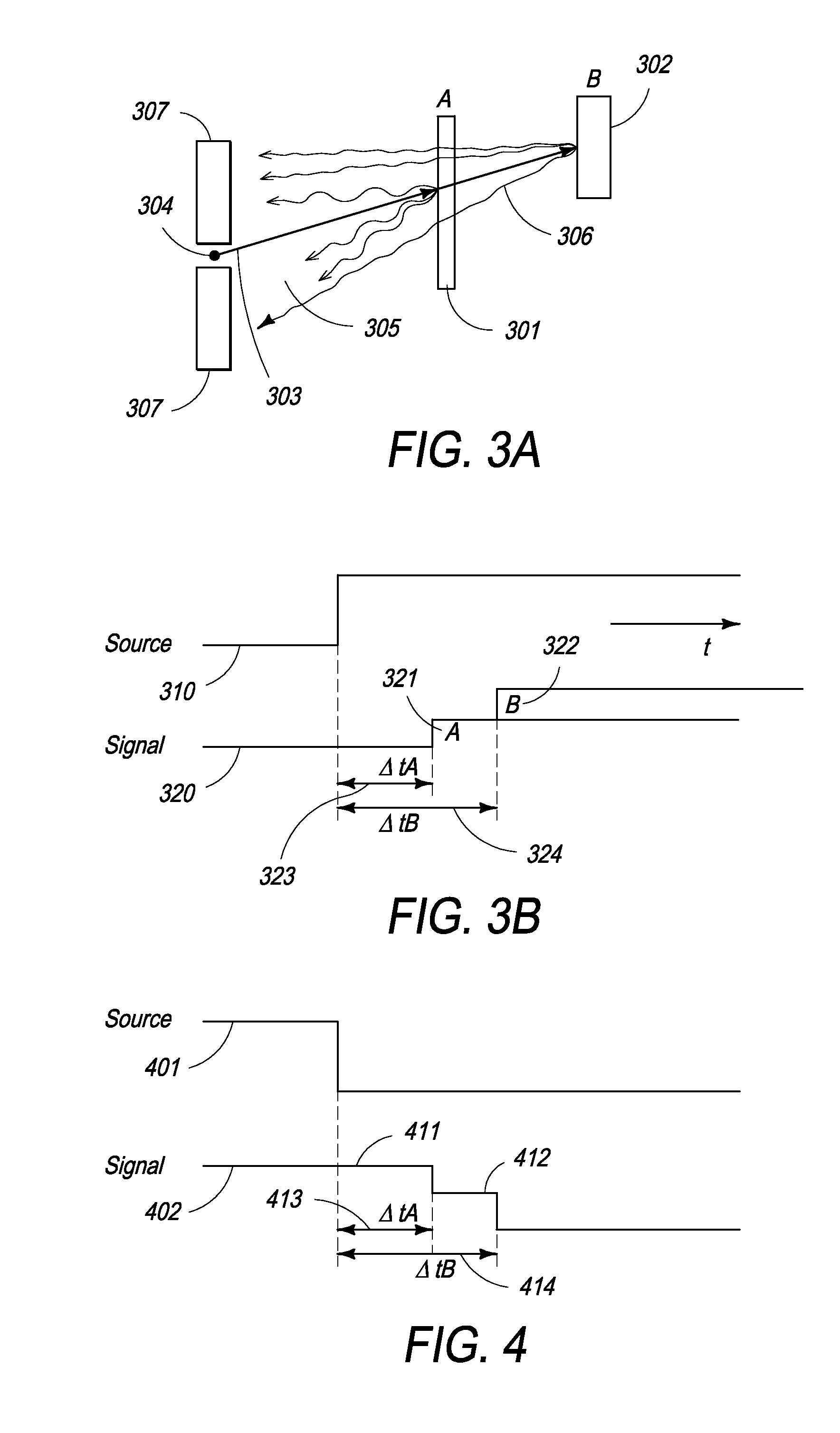

Time of flight backscatter imaging system

ActiveUS8582720B2Radiation/particle handlingMaterial analysis by transmitting radiationBackscatter X-rayX-ray

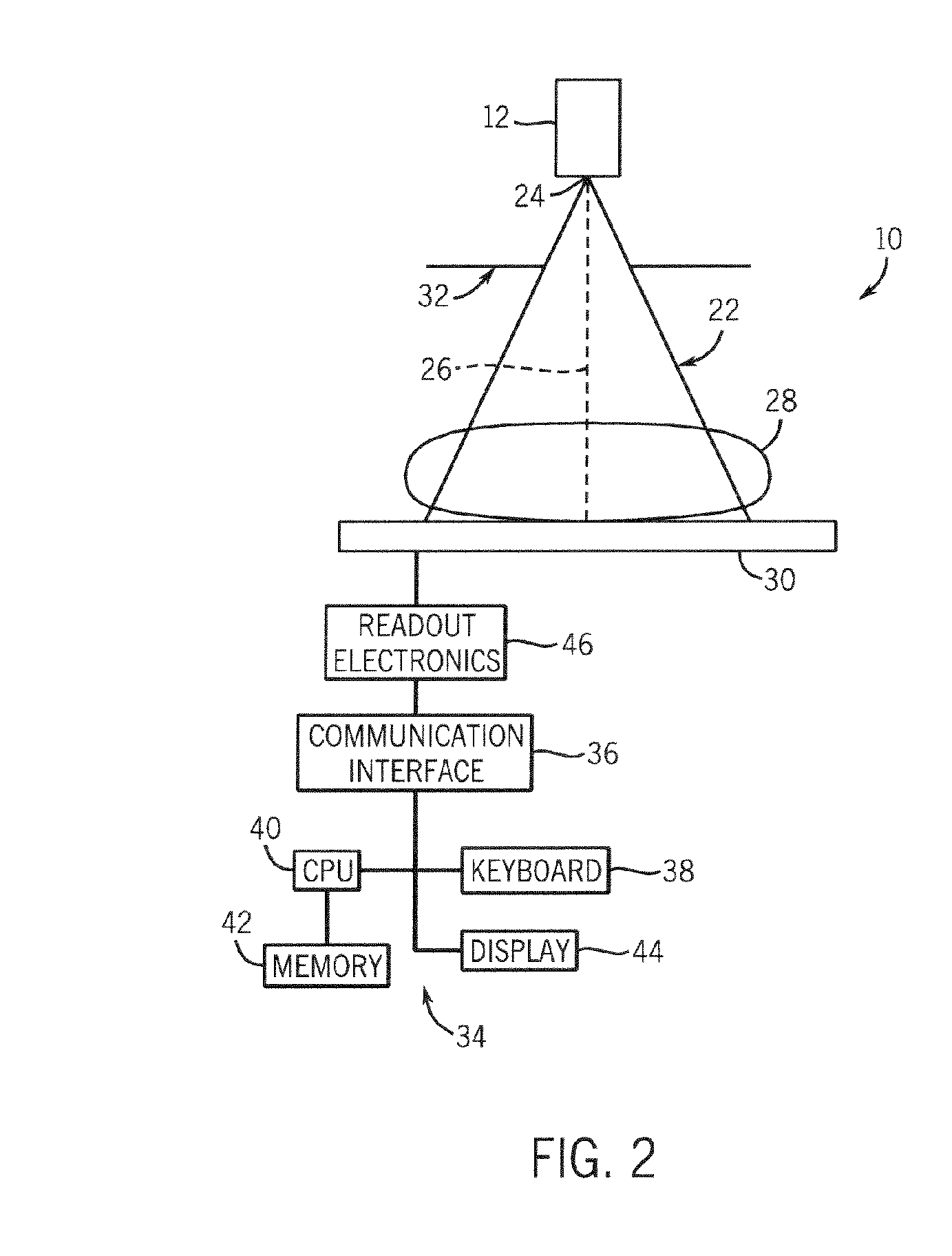

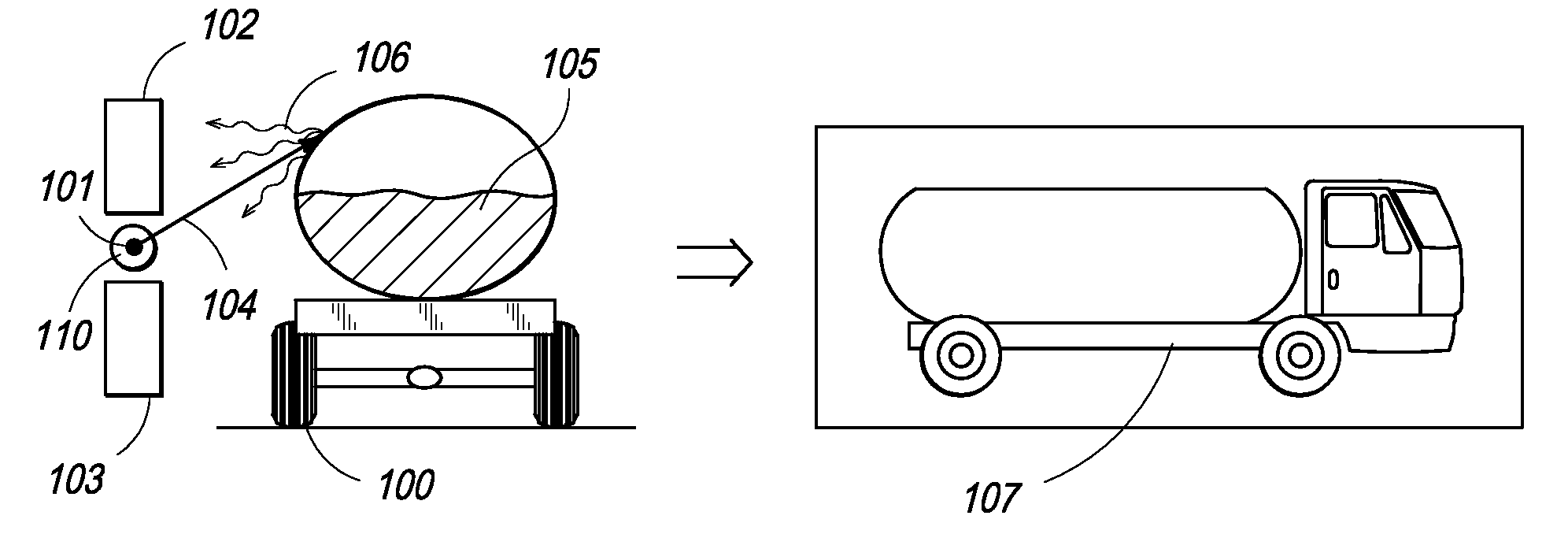

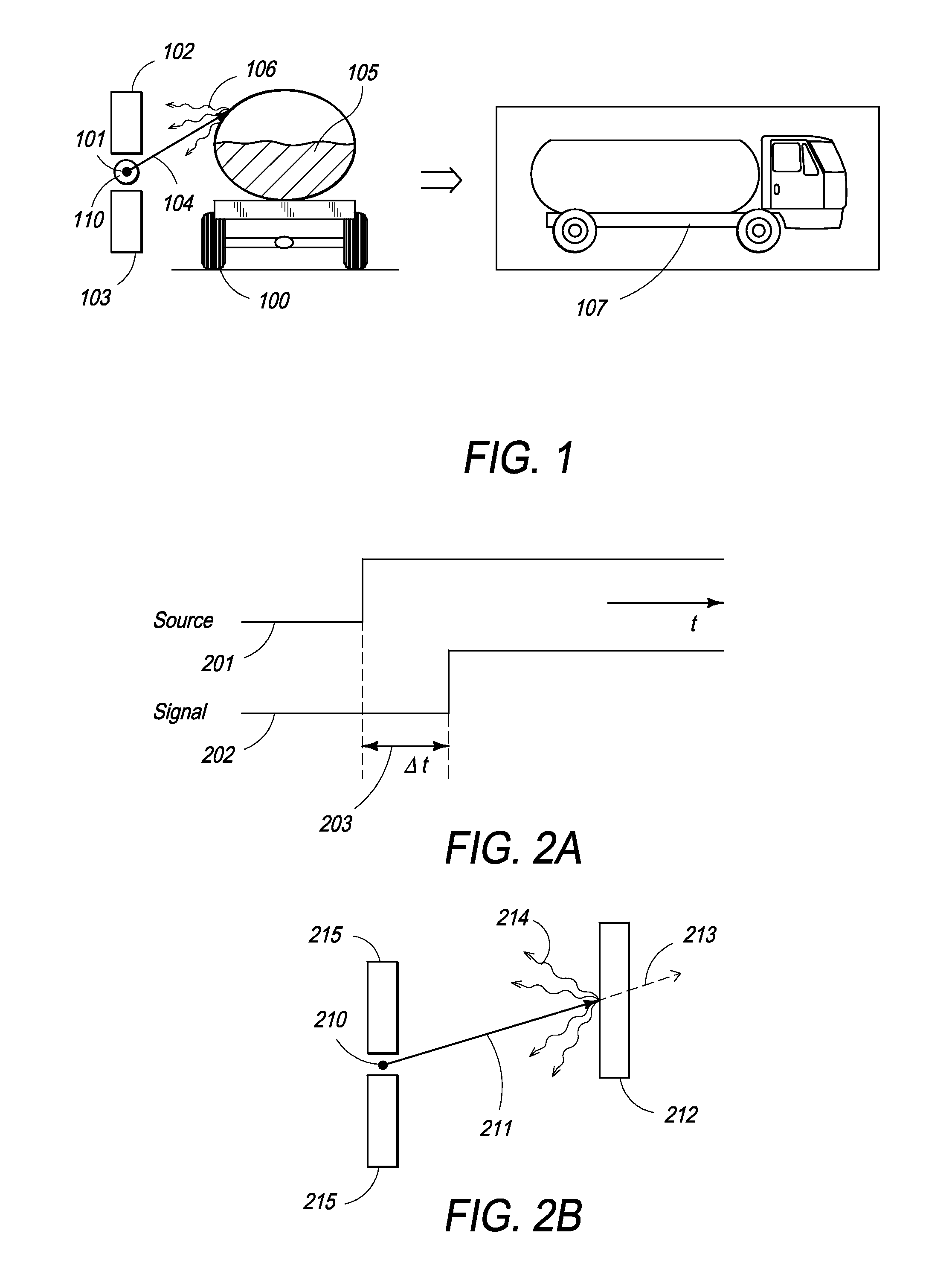

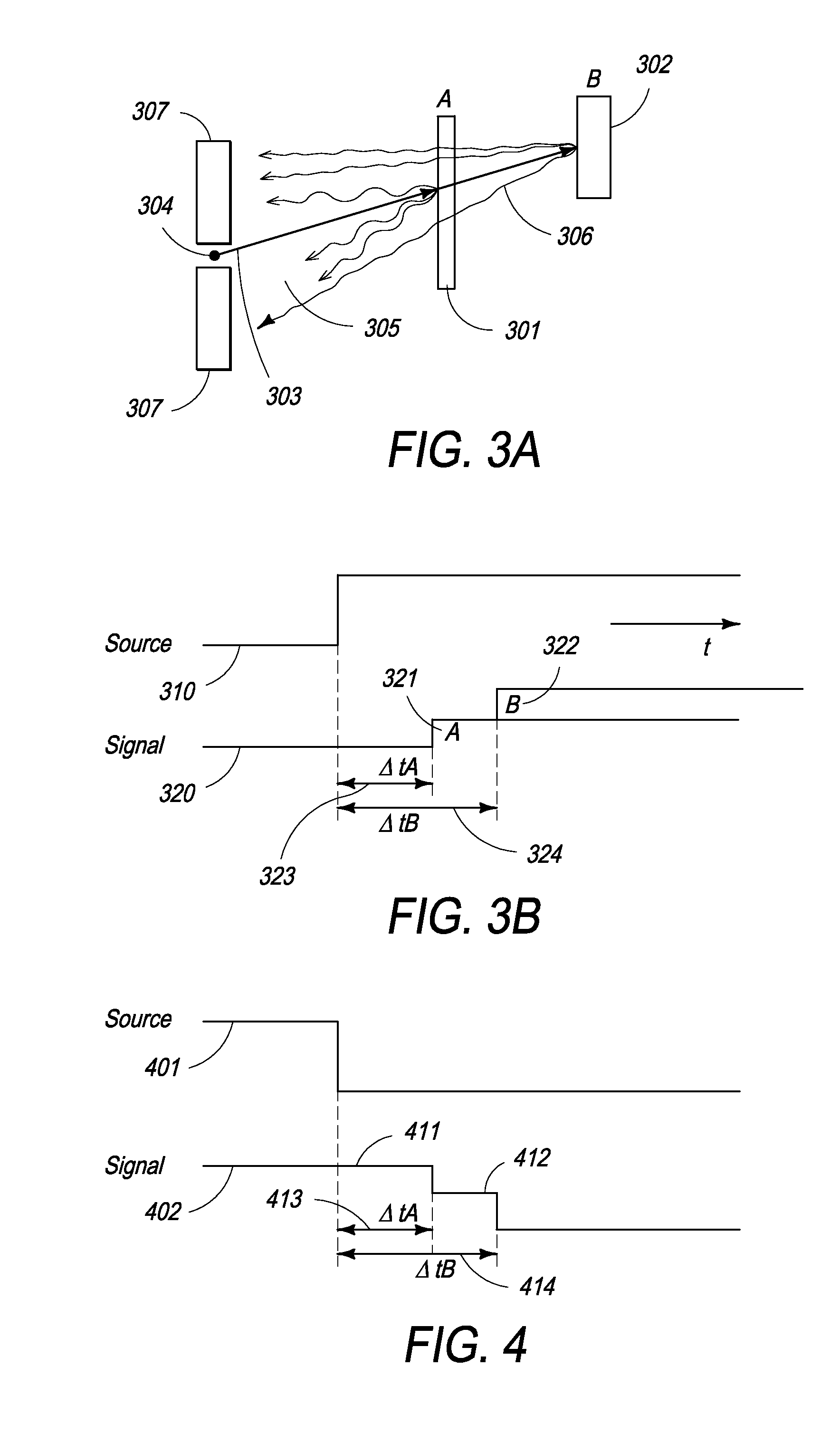

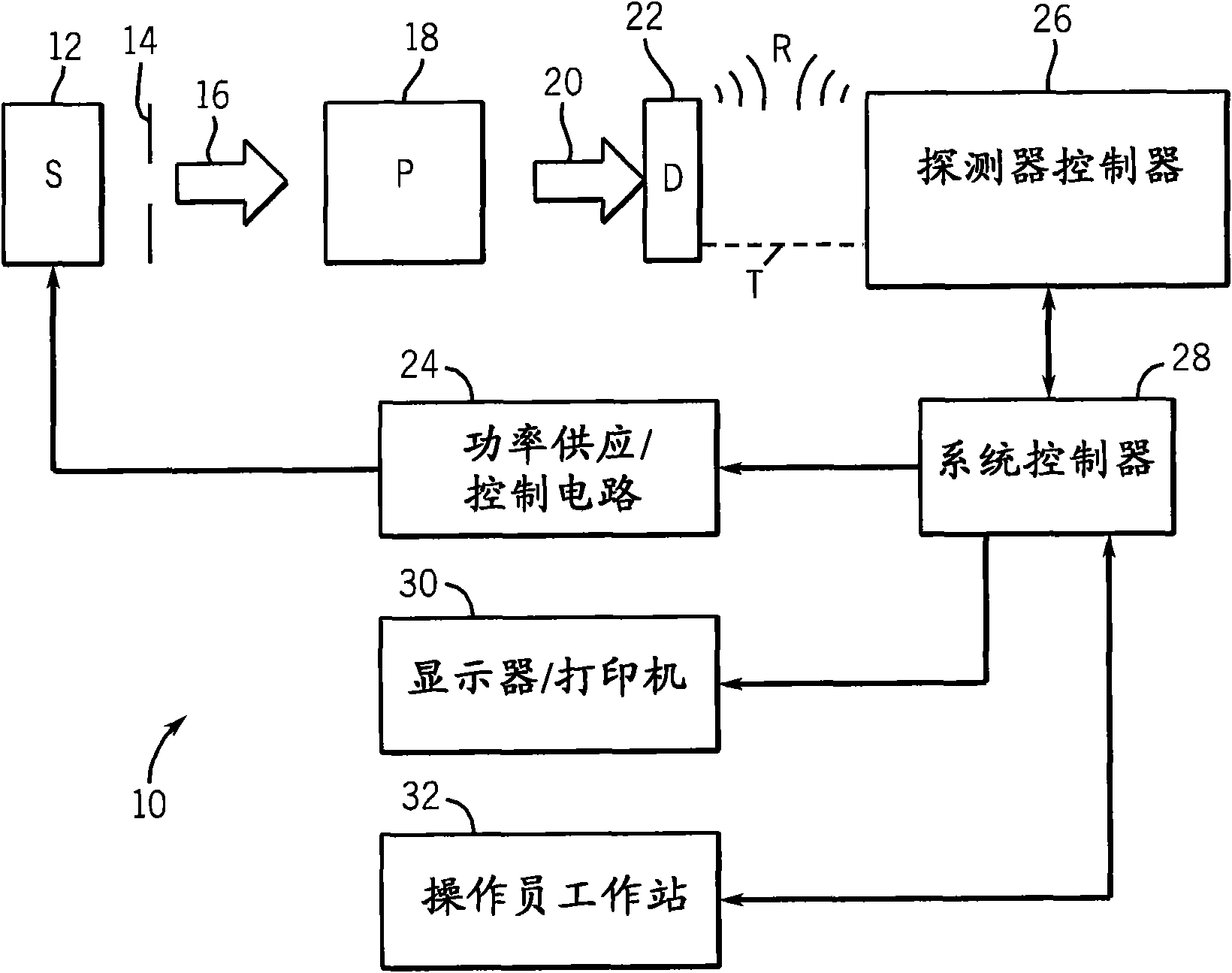

The present application discloses an X-ray imaging apparatus for determining a surface profile of an object under inspection that is positioned at a distance from the apparatus. The X-ray imaging system has an X-ray source for producing a scanning beam of X-rays directed toward the object, a detector assembly for providing a signal representative of an intensity of X-rays backscattered from the object, and processing circuitry to determine a time difference between when the X-ray source is switched on and when the backscattered X-rays arrive at the detector assembly. The processing circuitry is adapted to output data representative of the surface profile of the object under inspection.

Owner:RAPISCAN SYST INC (US)

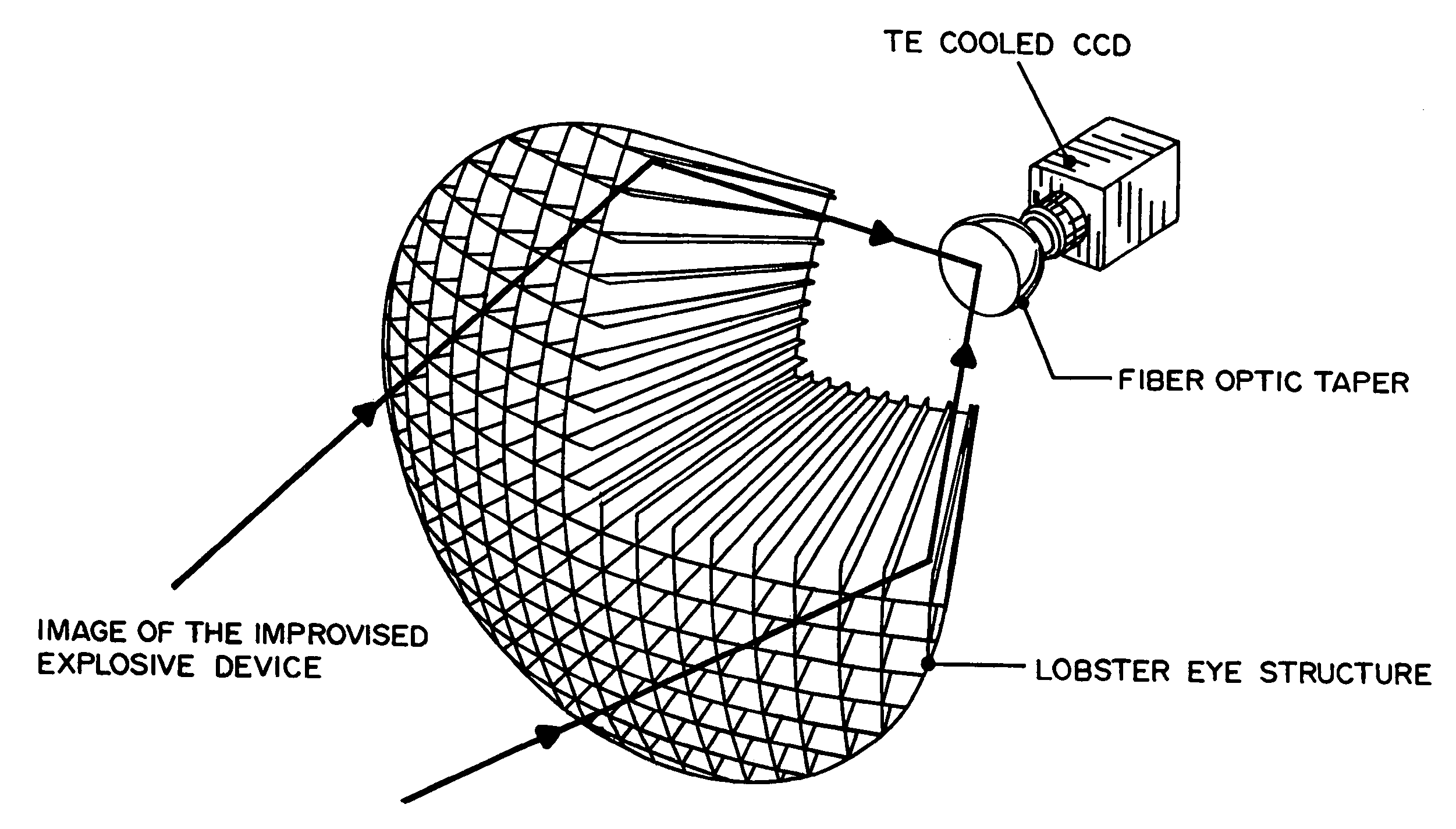

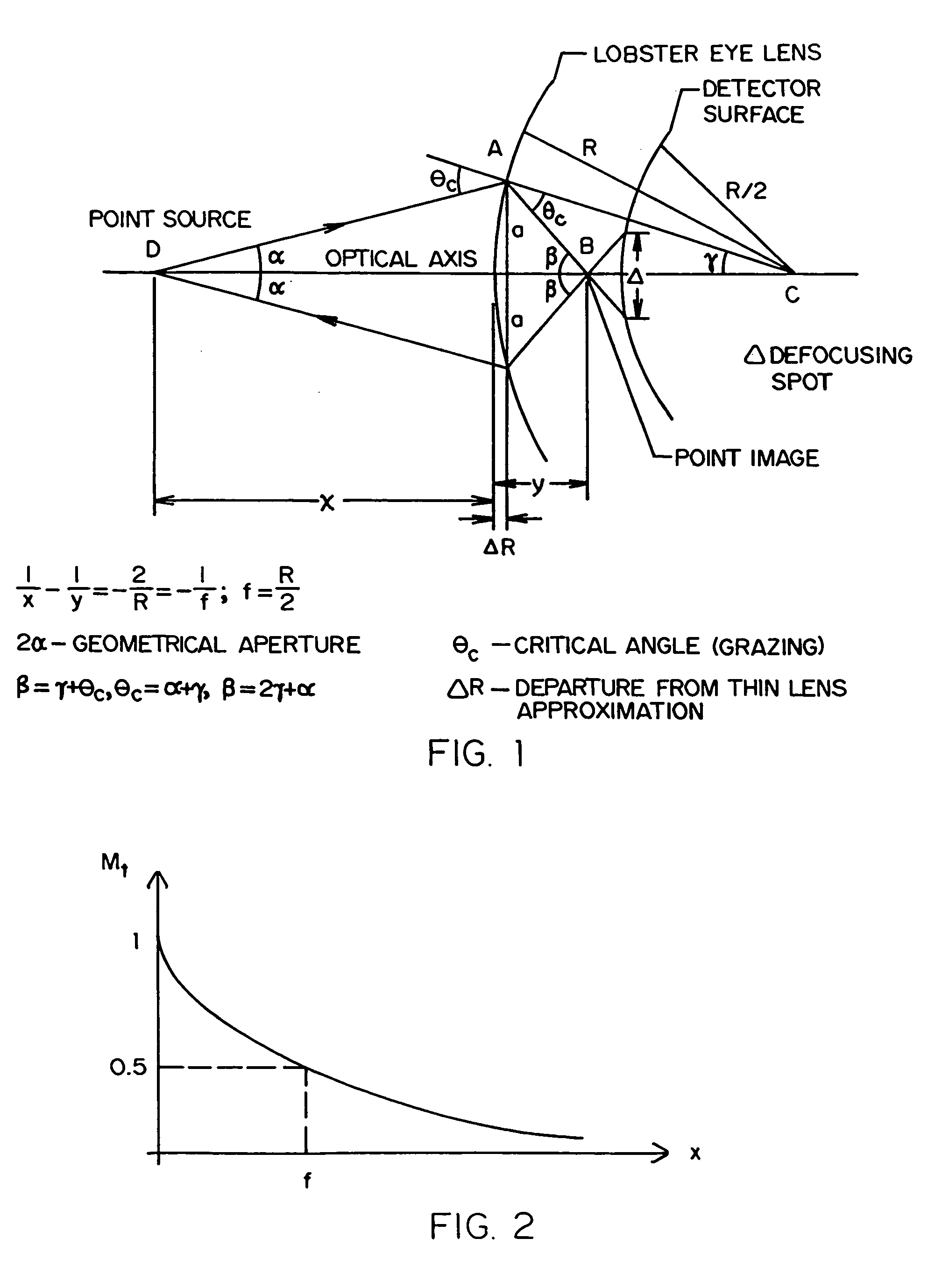

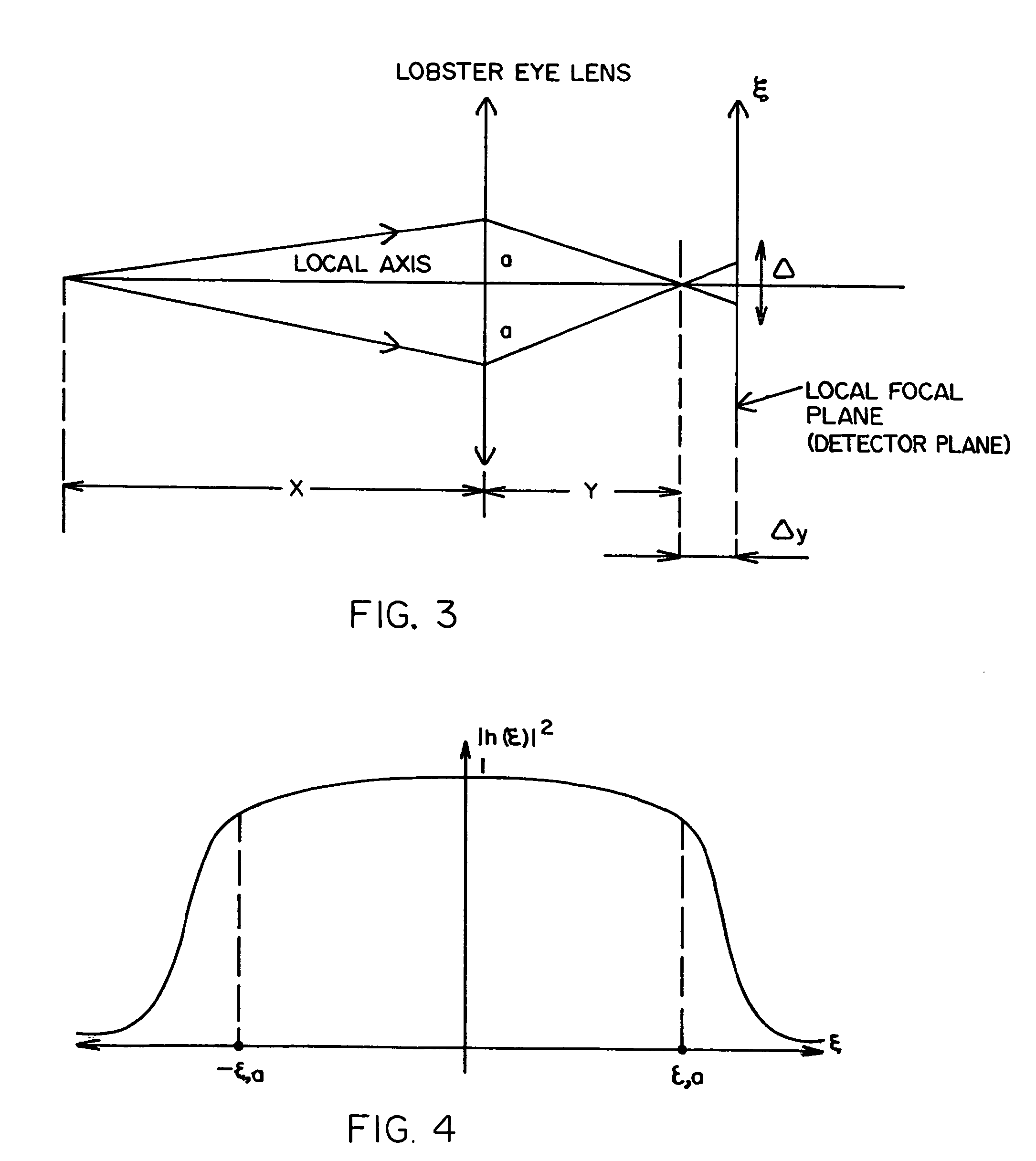

Lobster eye X-ray imaging system and method of fabrication thereof

ActiveUS7231017B2Raise the ratioHigh sensitivityMaterial analysis using wave/particle radiationElectrode and associated part arrangementsHard X-raysBackscatter X-ray

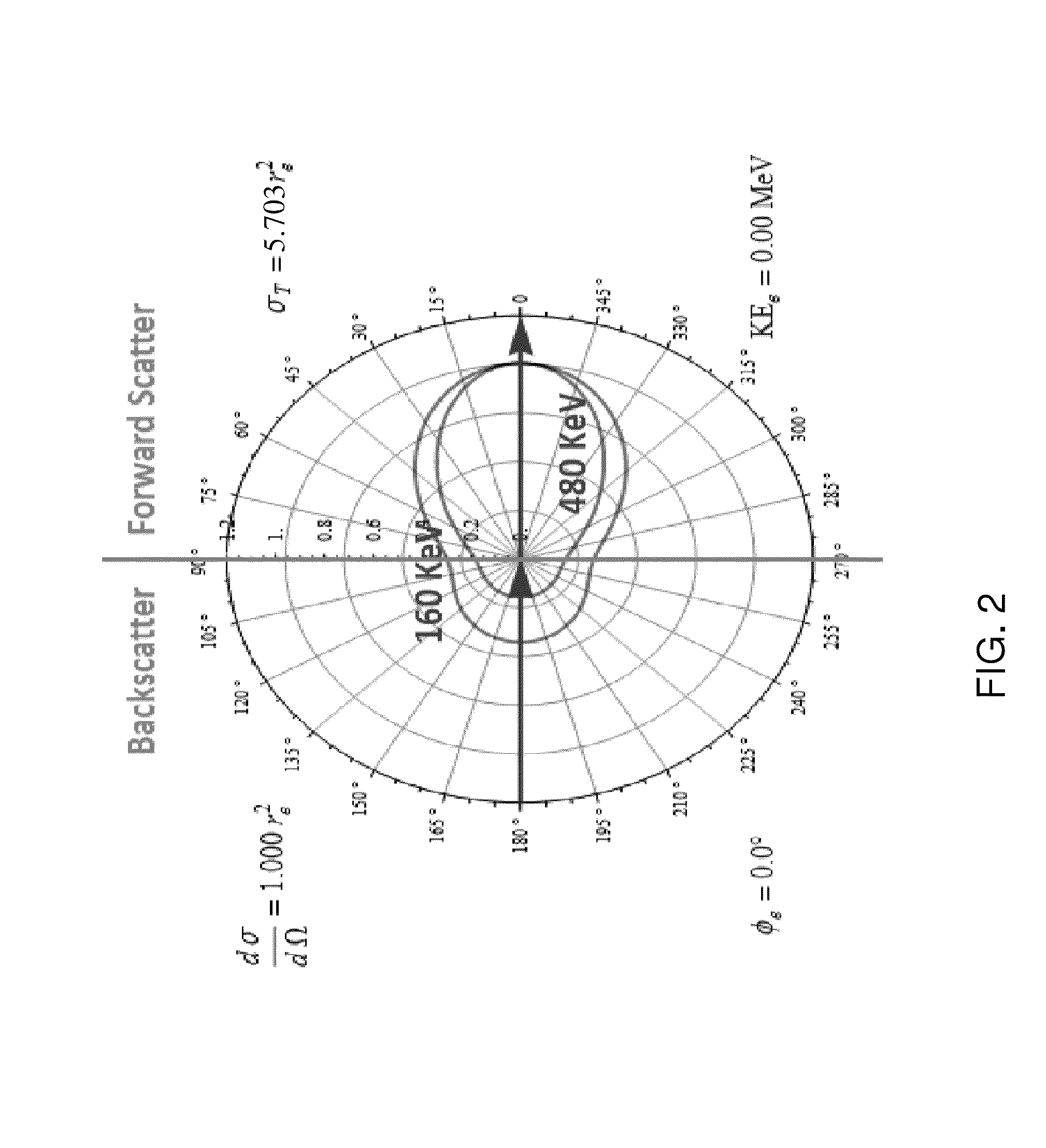

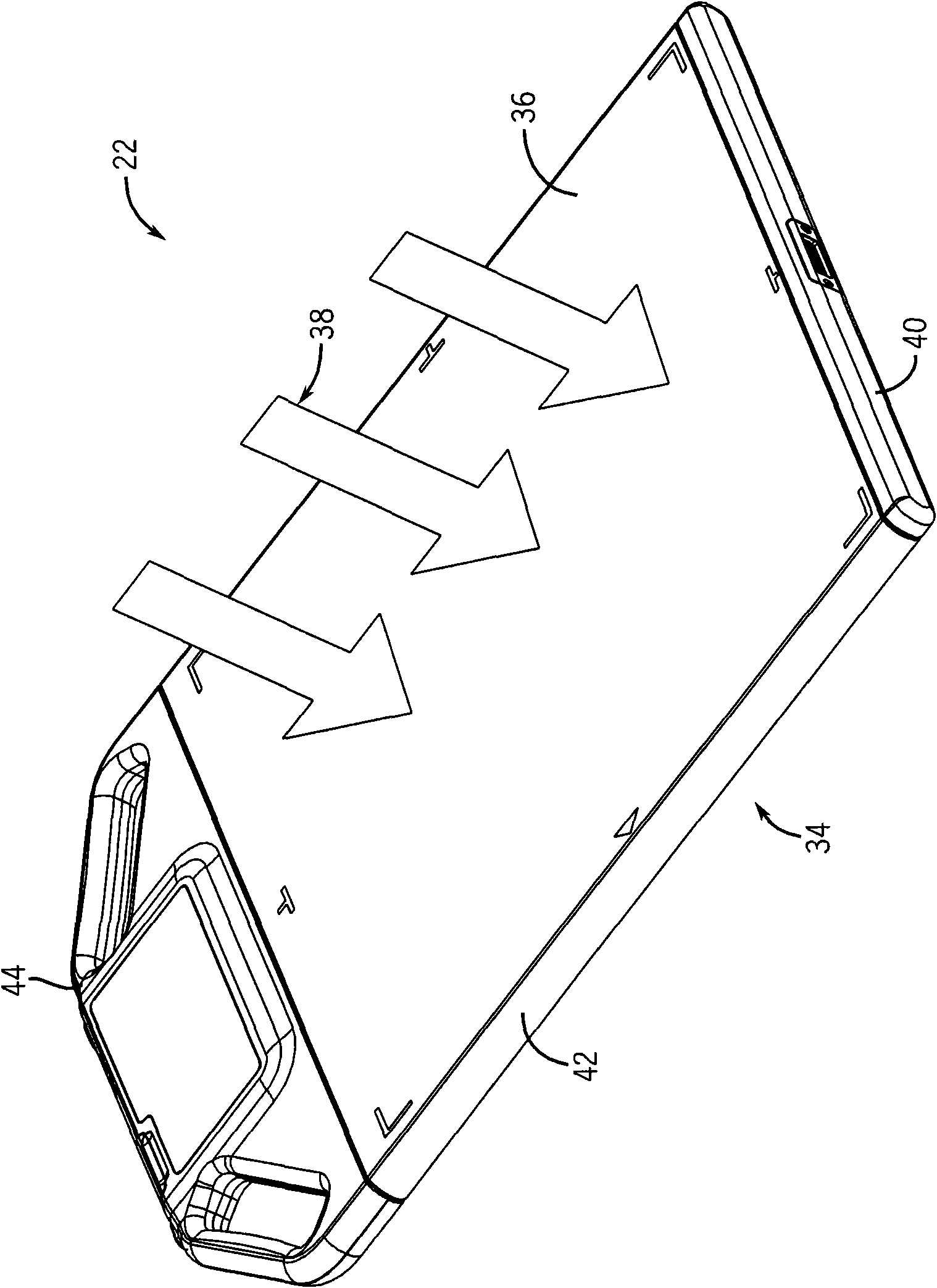

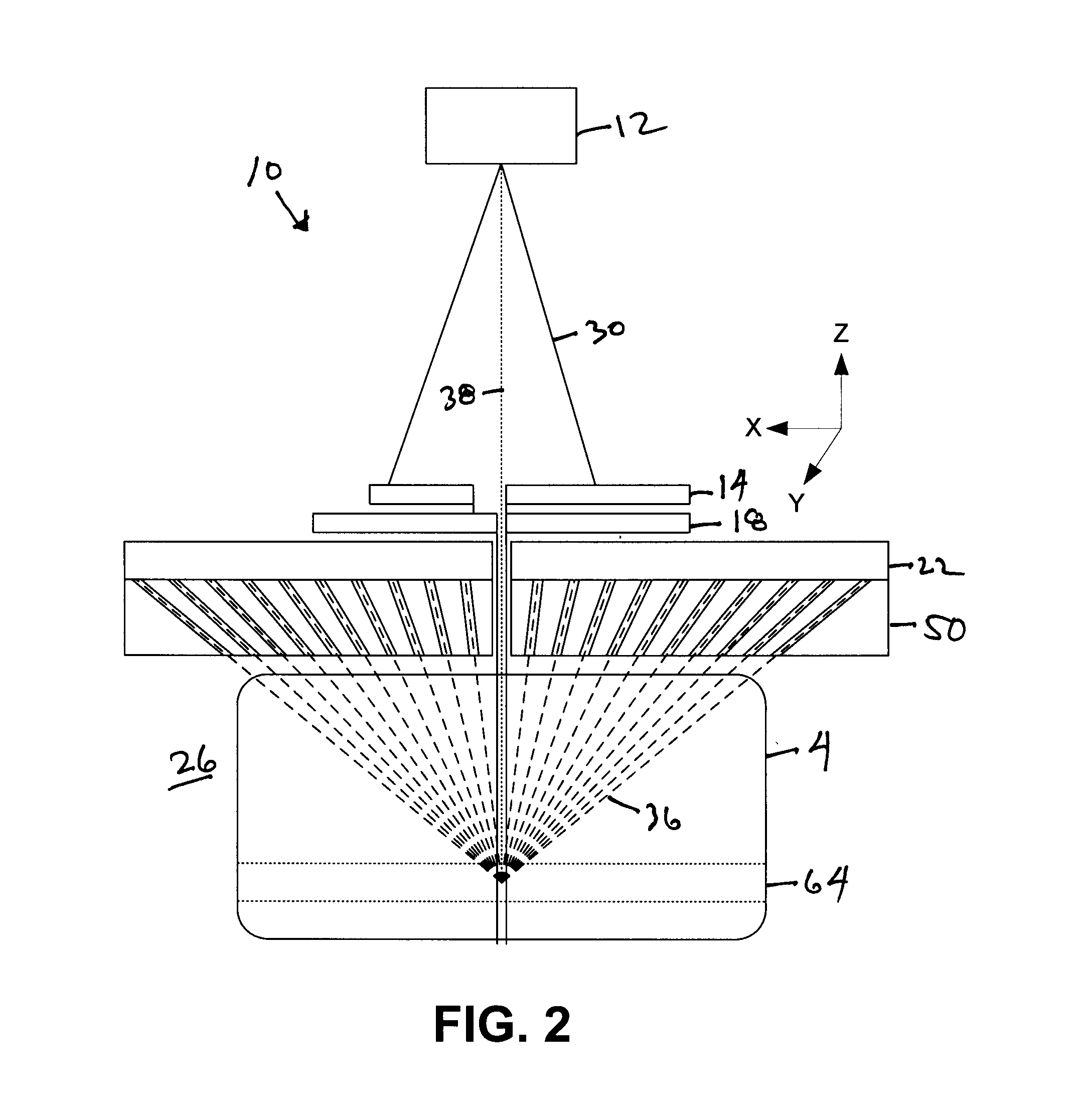

A Lobster Eye X-ray Imaging System based on a unique Lobster Eye (LE) structure, X-ray generator, scintillator-based detector and cooled CCD (or Intensified CCD) for real-time, safe, staring Compton backscatter X-ray detection of objects hidden under ground, in containers, behind walls, bulkheads etc. In contrast to existing scanning pencil beam systems, Lobster Eye X-Ray Imaging System's true focusing X-ray optics simultaneously acquire ballistic Compton backscattering photons (CBPs) from an entire scene irradiated by a wide-open cone beam from one or more X-ray generators. The Lobster Eye X-ray Imaging System collects (focuses) thousands of times more backscattered hard X-rays in the range from 40 to 120 keV (or wavelength λ=0.31 to 0.1 Å) than current backscatter imaging sensors (BISs), giving high sensitivity and signal-to-noise ratio (SNR) and penetration through ground, metal walls etc. The collection efficiency of Lobster Eye X-ray Imaging System is optimized to reduce emitted X-ray power and miniaturize the device. This device is especially advantageous for and satisfies requirements of X-ray-based inspection systems, namely, penetration of the X-rays through ground, metal and other material concealments; safety; and man-portability. The advanced technology disclosed herein is also applicable to medical diagnostics and military applications such as mine detection, security screening and a like.

Owner:MERCURY MISSION SYST LLC

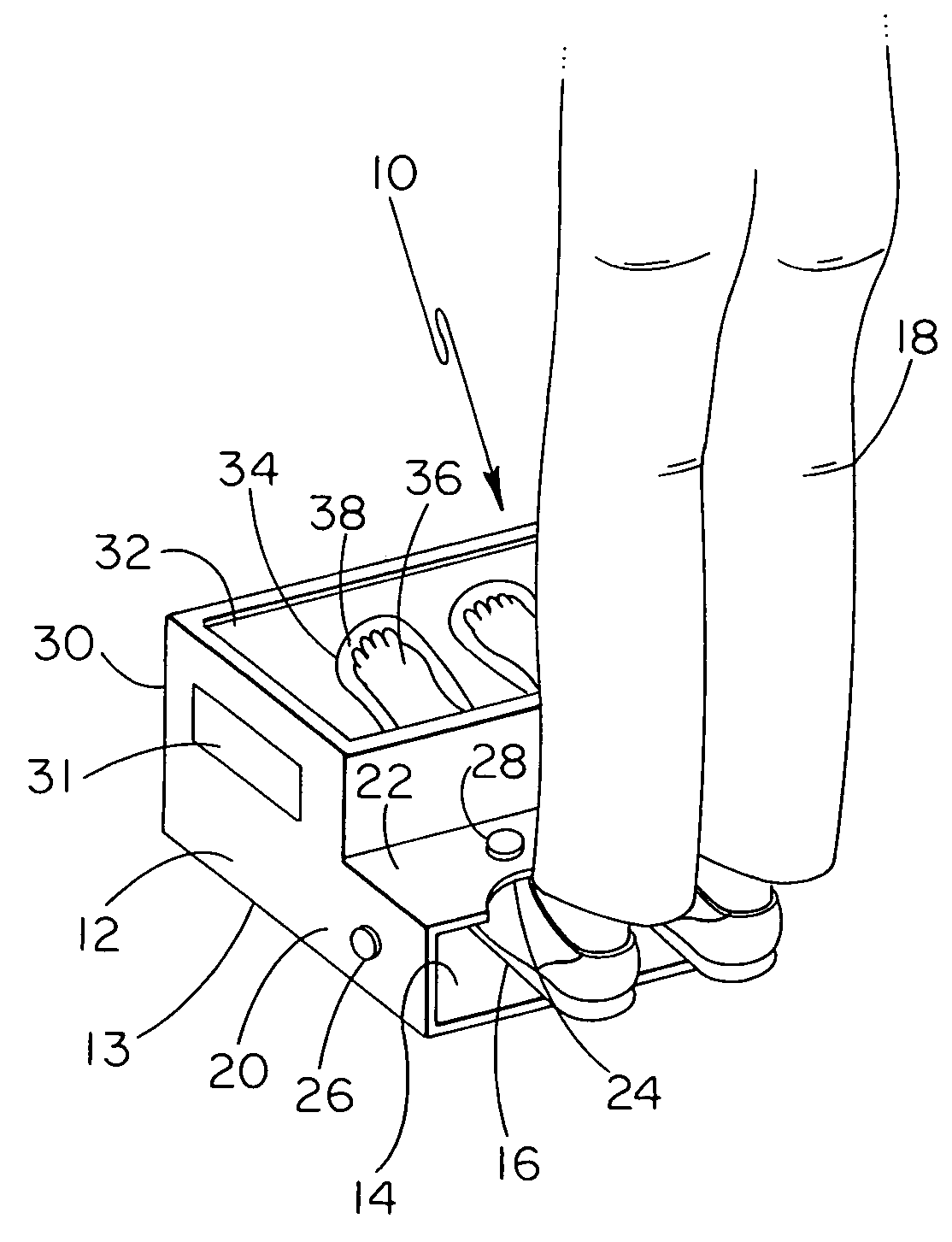

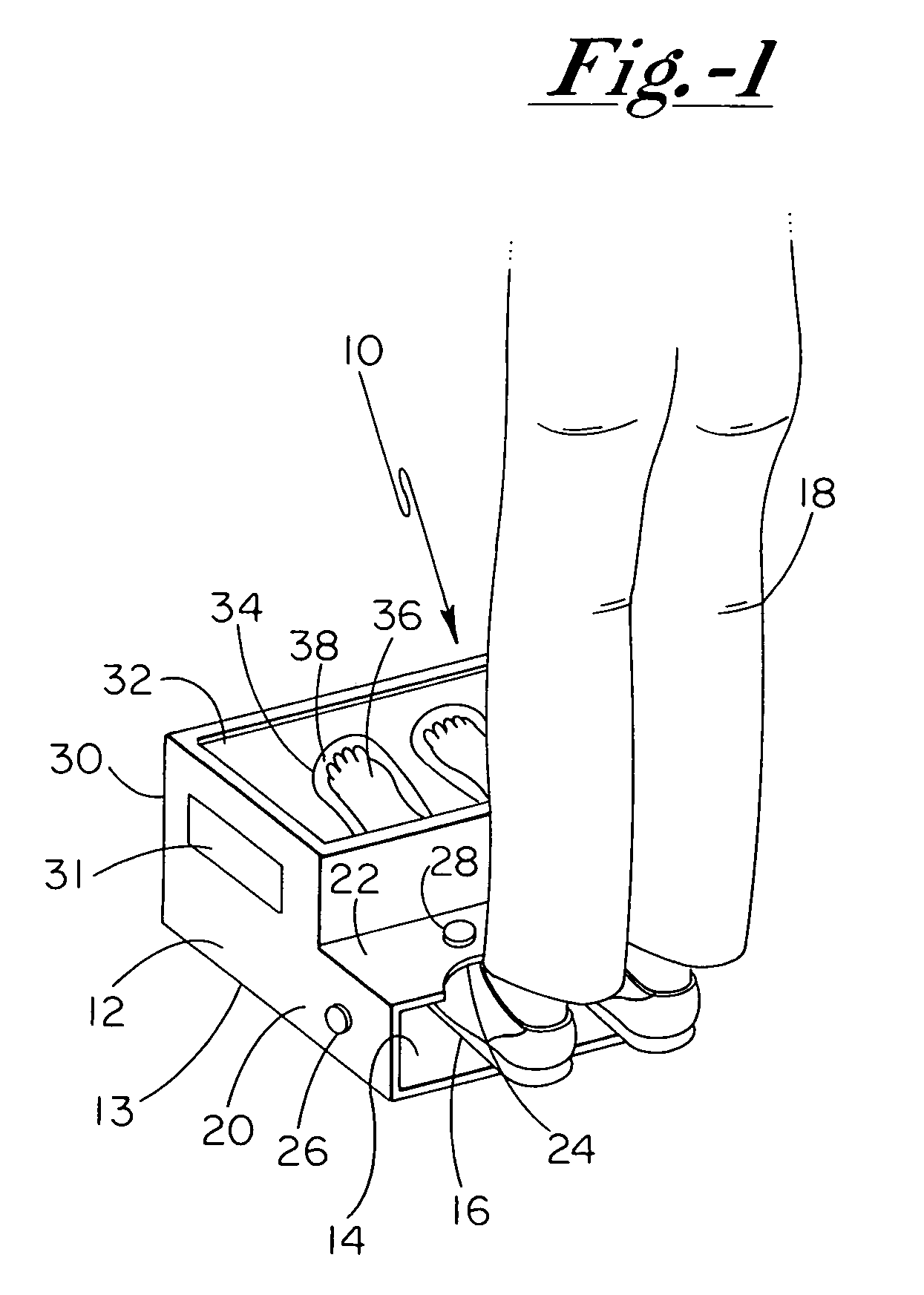

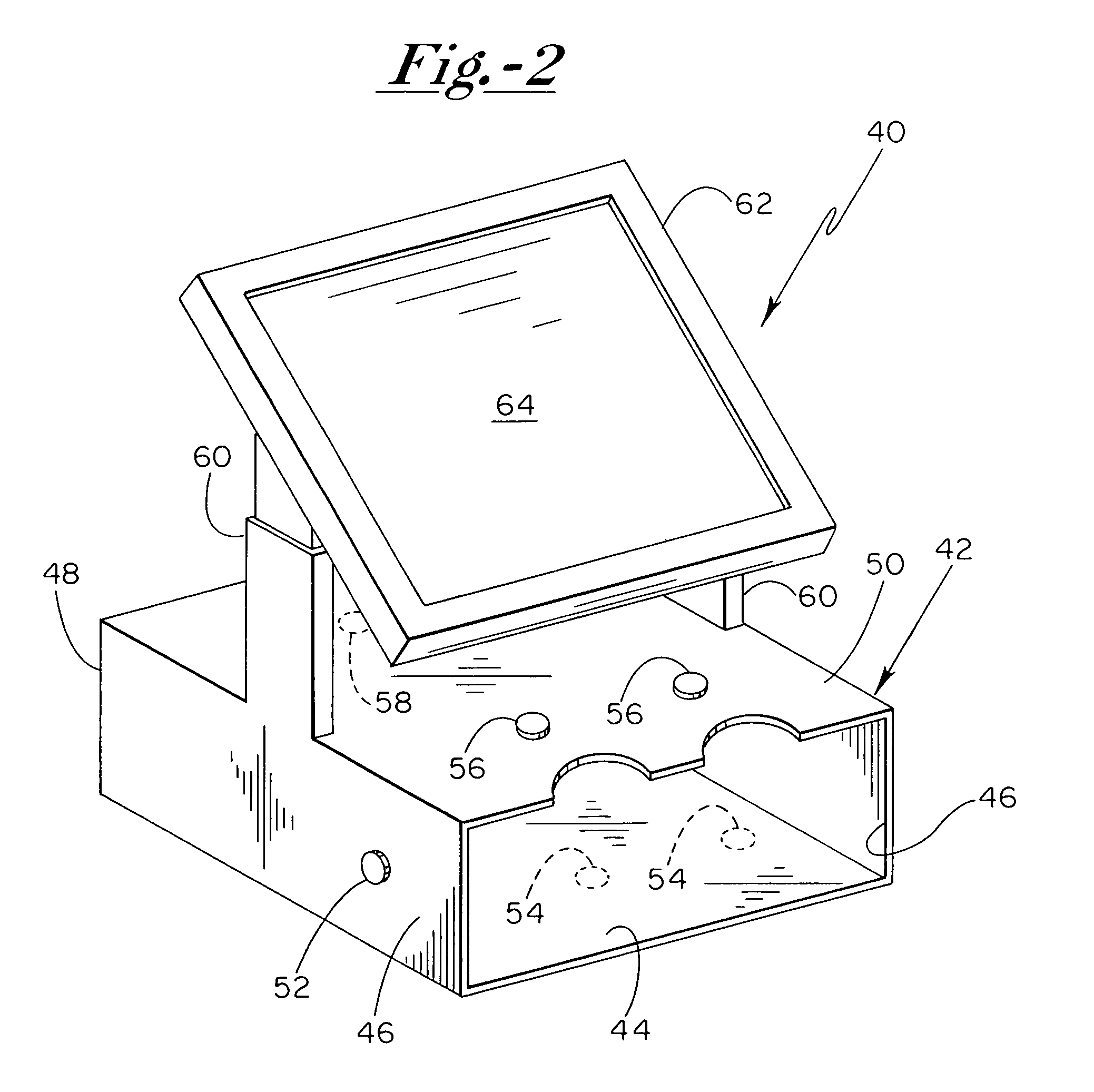

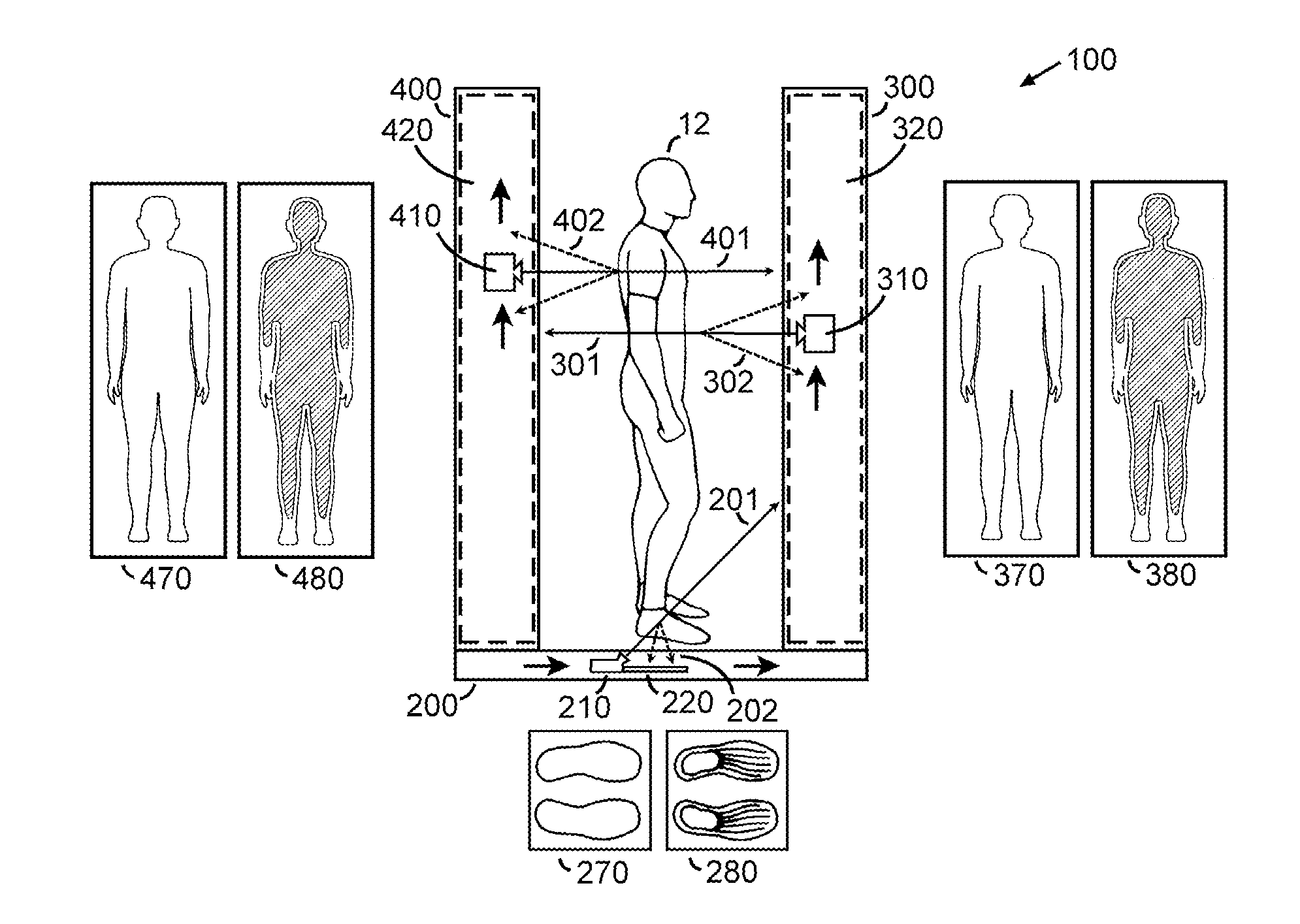

Apparatus and method for "seeing" foot inside of shoe to determine the proper fit of the shoe

InactiveUS6975232B1Minimizes returnFoot measurement devicesDigital computer detailsBackscatter X-rayDisplay device

A thermographic infrared apparatus and method for seeing, and thus measuring, a foot inside of a shoe. The apparatus includes one or more thermographic instruments aimed at a base for capturing one or more thermographic images or fields of view of a shoe on the base and thus the heat transferred to the shoe from the foot. The apparatus further includes a display mounted above the base and aimed at the eye level of a person standing on the base such that the person can determine from the thermographic image how well the shoe or shoes fit. The method includes one or more of the steps of taking a thermal infrared image of a shoe on a foot, taking a thermal infrared image of a foot having no shoe thereon, taking a thermal infrared image of a shoe having no foot therein, taking a thermal infrared image from a first direction, taking a thermal infrared image from a second direction to capture surfaces hidden from the first direction, and then comparing one or more of the thermal infrared images. Other imaging methods for determining proper fit of a shoe include low dose x-ray, backscattering x-ray, microwave, acoustic, radio, and ultrasound imaging methods.

Owner:MCKENNA LOU

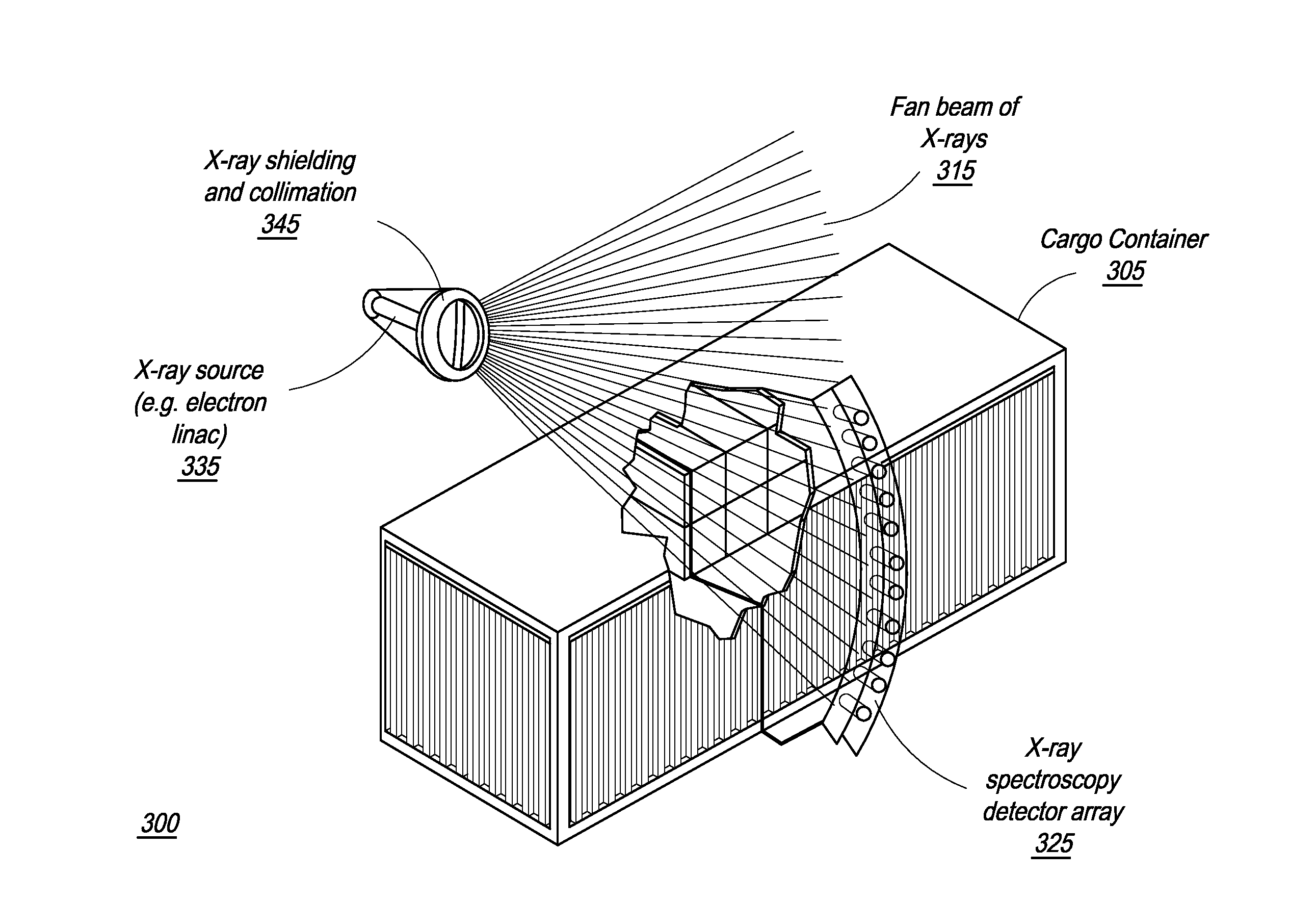

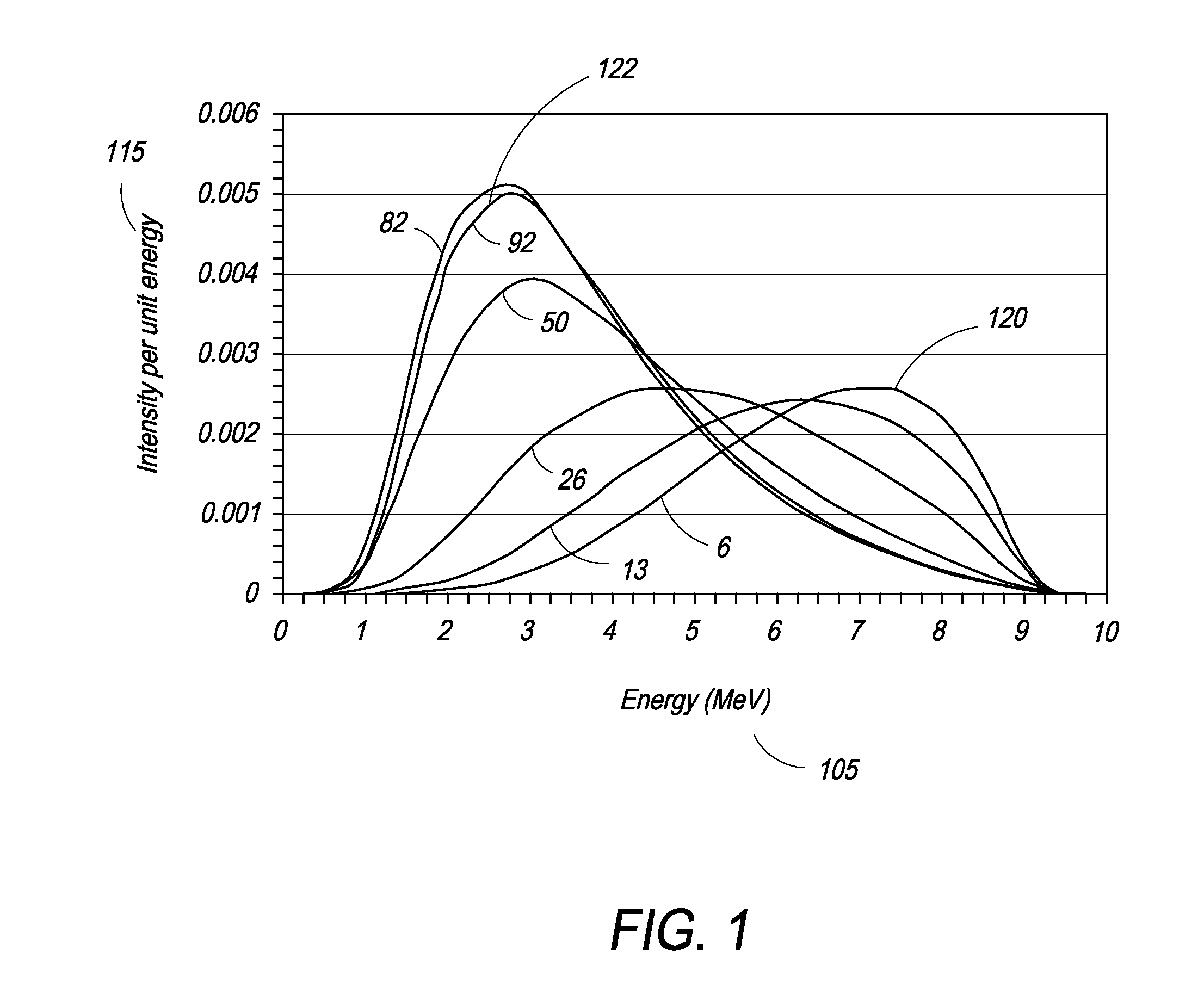

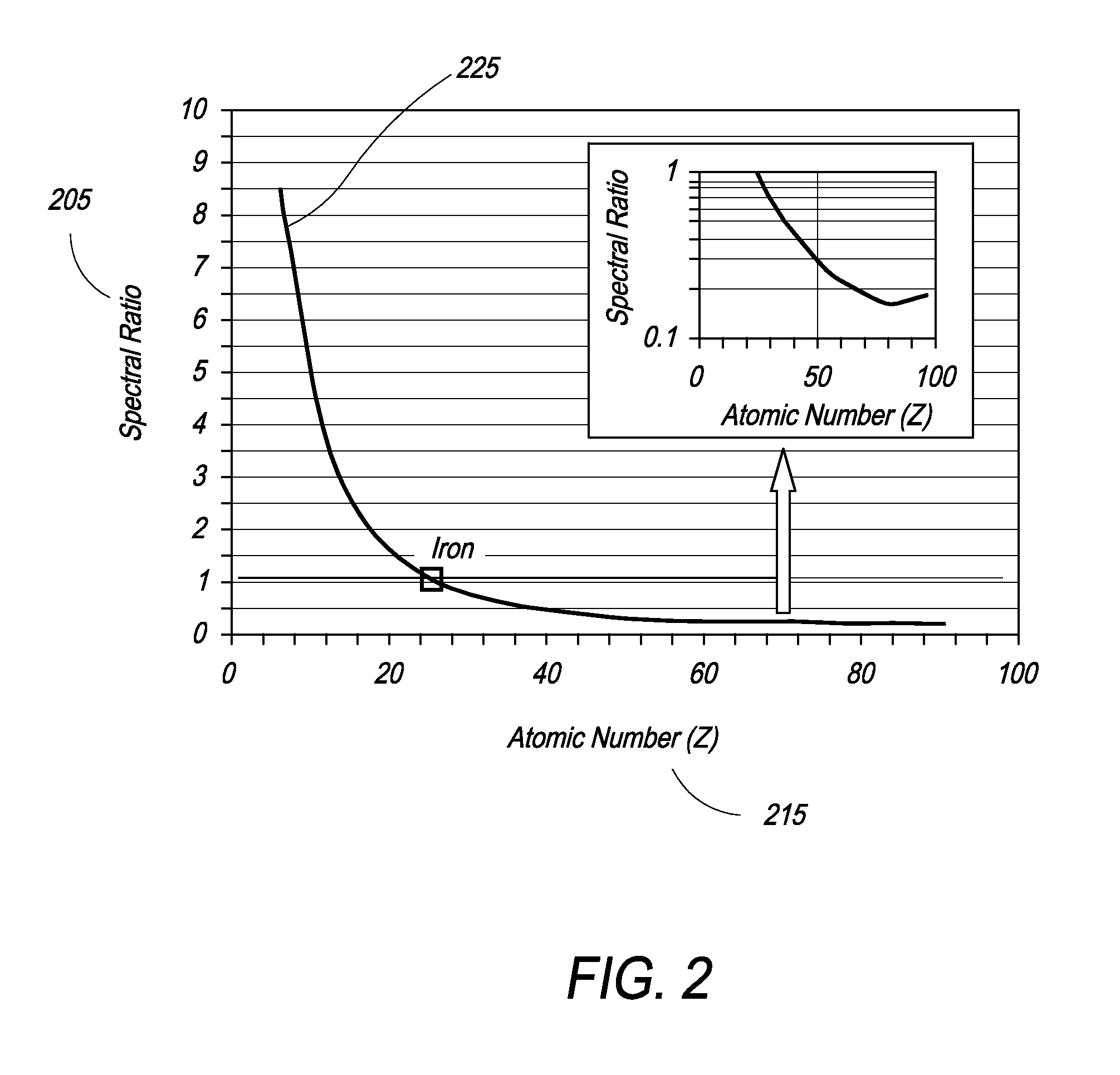

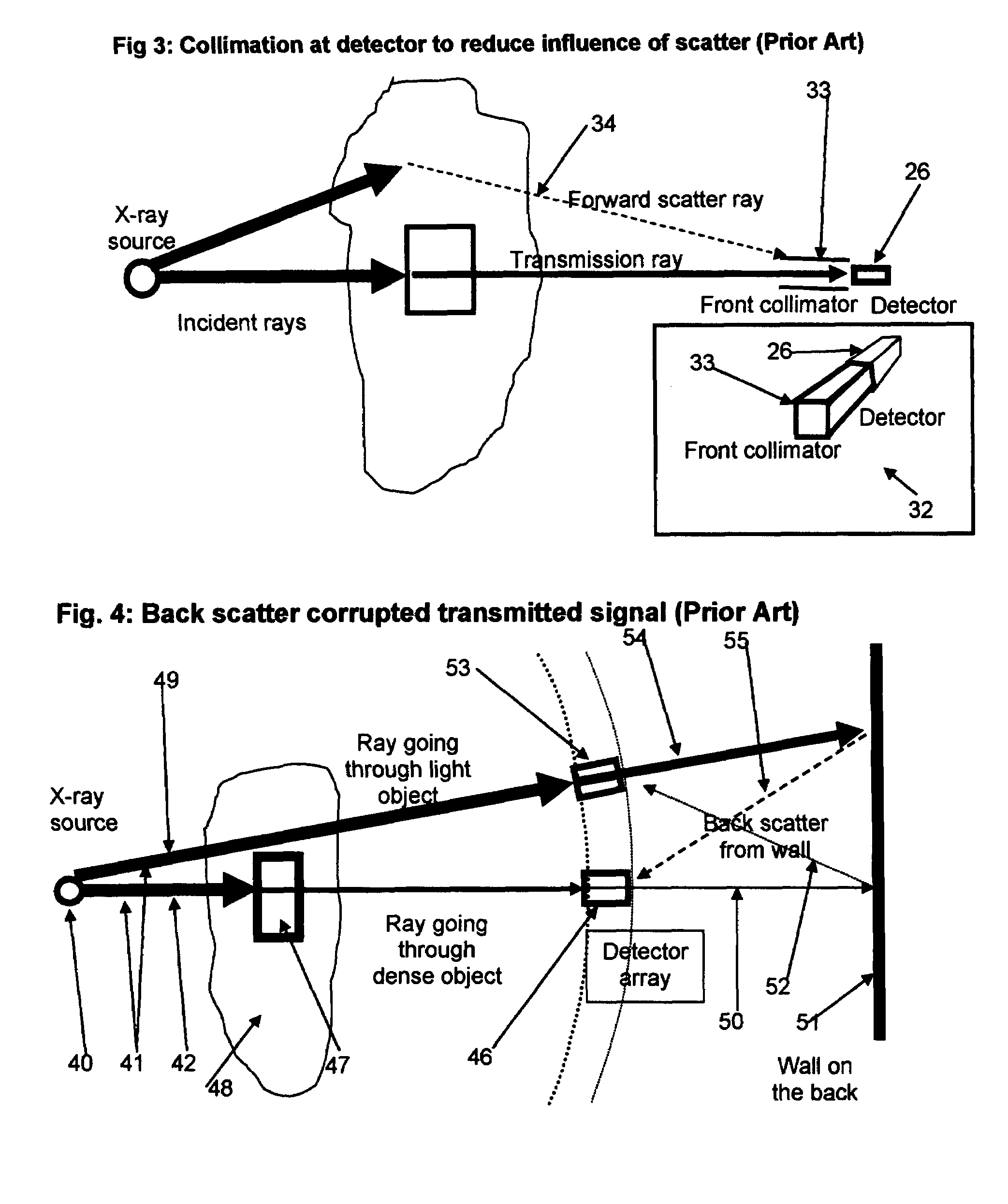

High-Energy X-Ray-Spectroscopy-Based Inspection System and Methods to Determine the Atomic Number of Materials

InactiveUS20110235777A1Material analysis by transmitting radiationNuclear radiation detectionBackscatter X-rayHigh energy

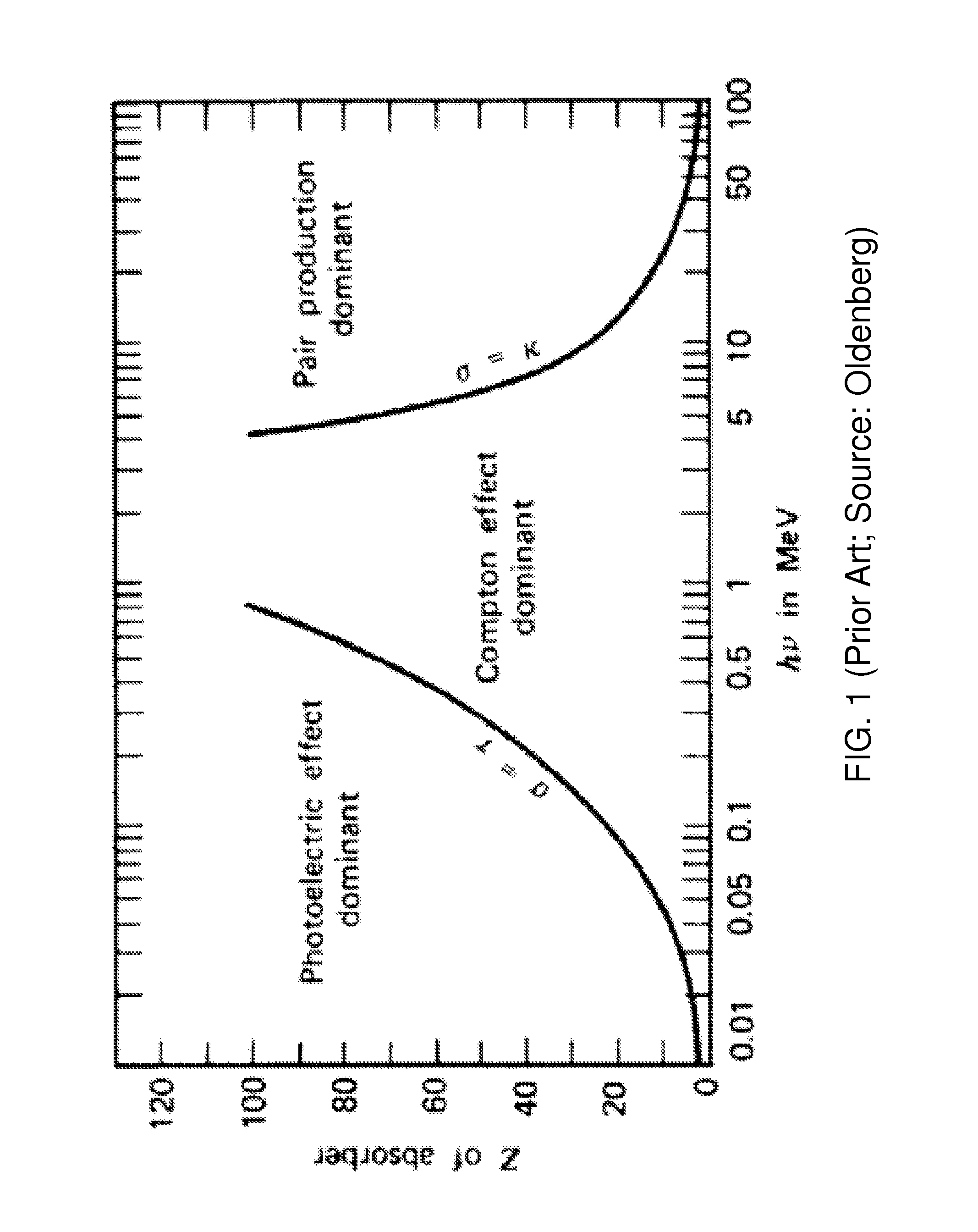

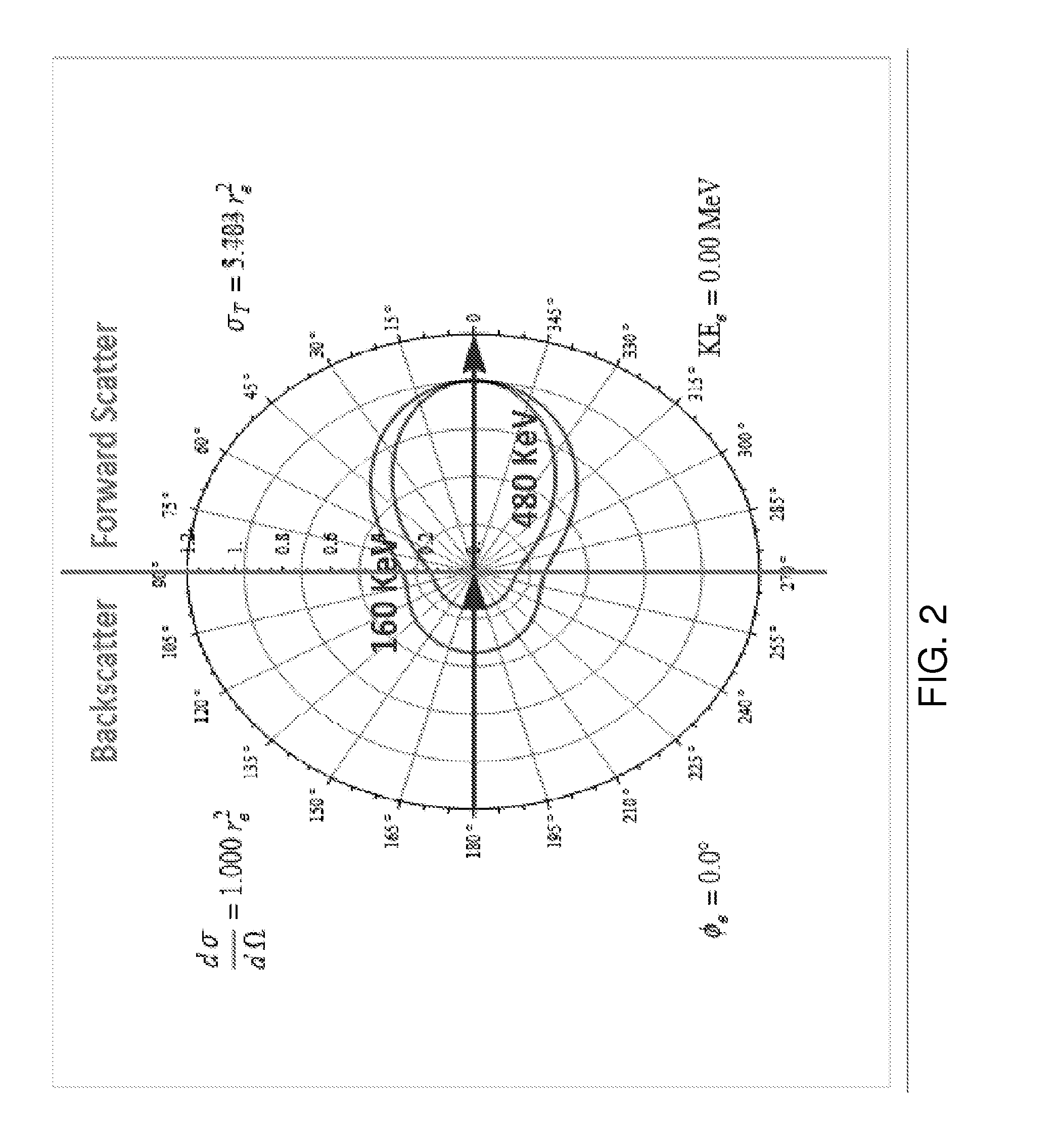

The application discloses systems and methods for X-ray scanning for identifying material composition of an object being scanned. The system includes at least one X-ray source for projecting an X-ray beam on the object, where at least a portion of the projected X-ray beam is transmitted through the object, and an array of detectors for measuring energy spectra of the transmitted X-rays. The measured energy spectra are used to determine atomic number of the object for identifying the material composition of the object. The X-ray scanning system may also have an array of collimated high energy backscattered X-ray detectors for measuring the energy spectrum of X-rays scattered by the object at an angle greater than 90 degrees, where the measured energy spectrum is used in conjunction with the transmission energy spectrum to determine atomic numbers of the object for identifying the material composition of the object.

Owner:RAPISCAN SYST INC (US)

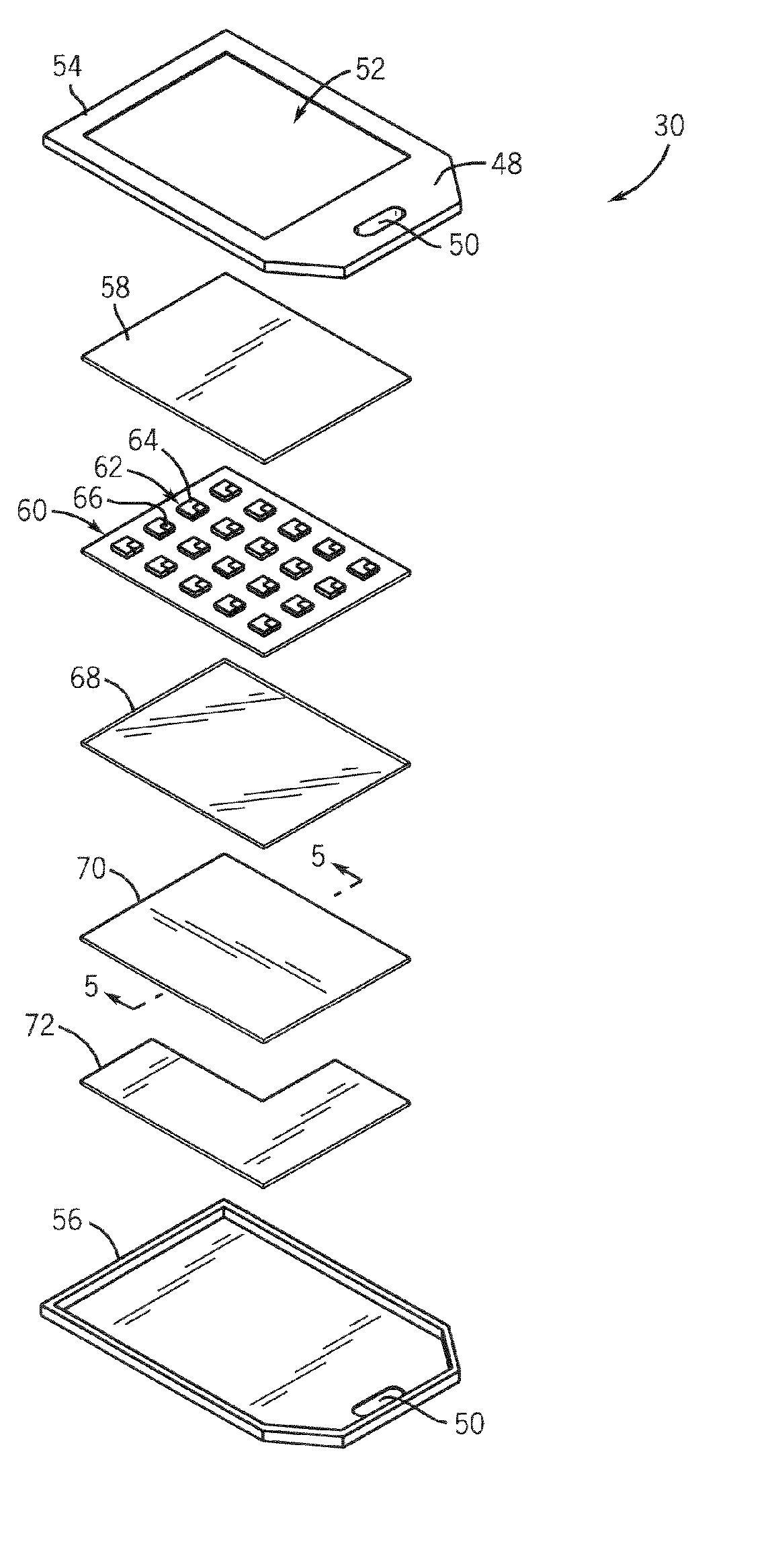

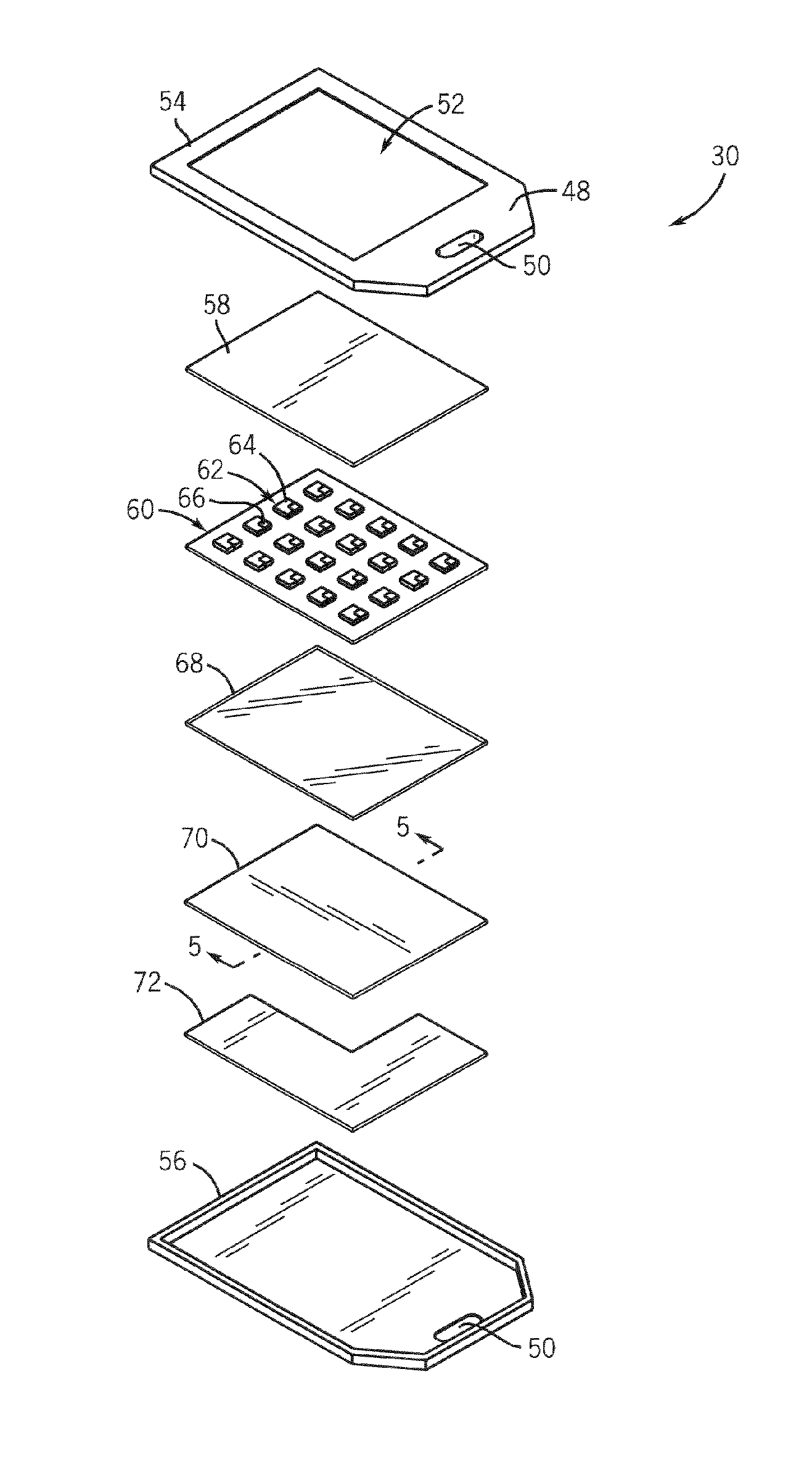

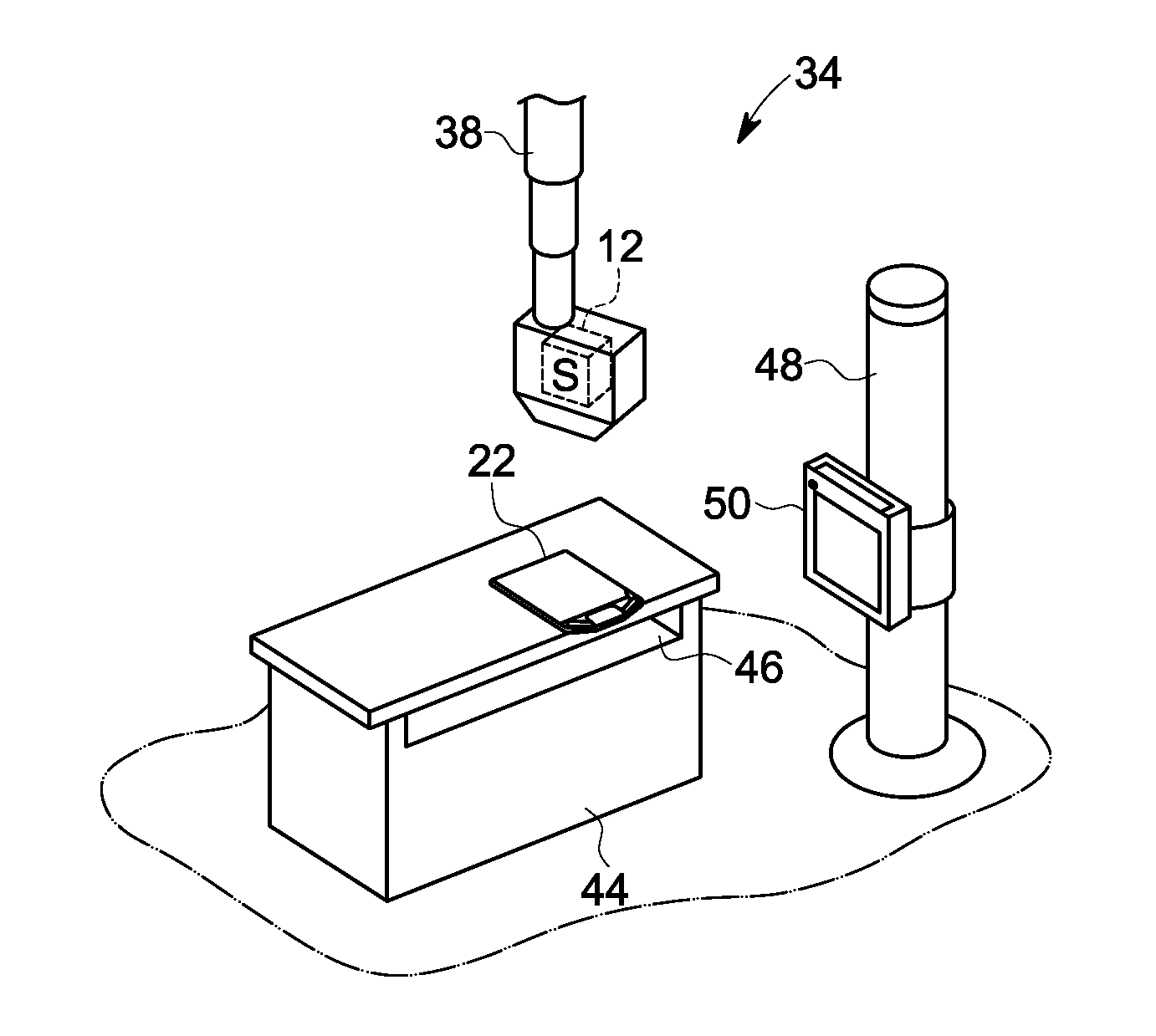

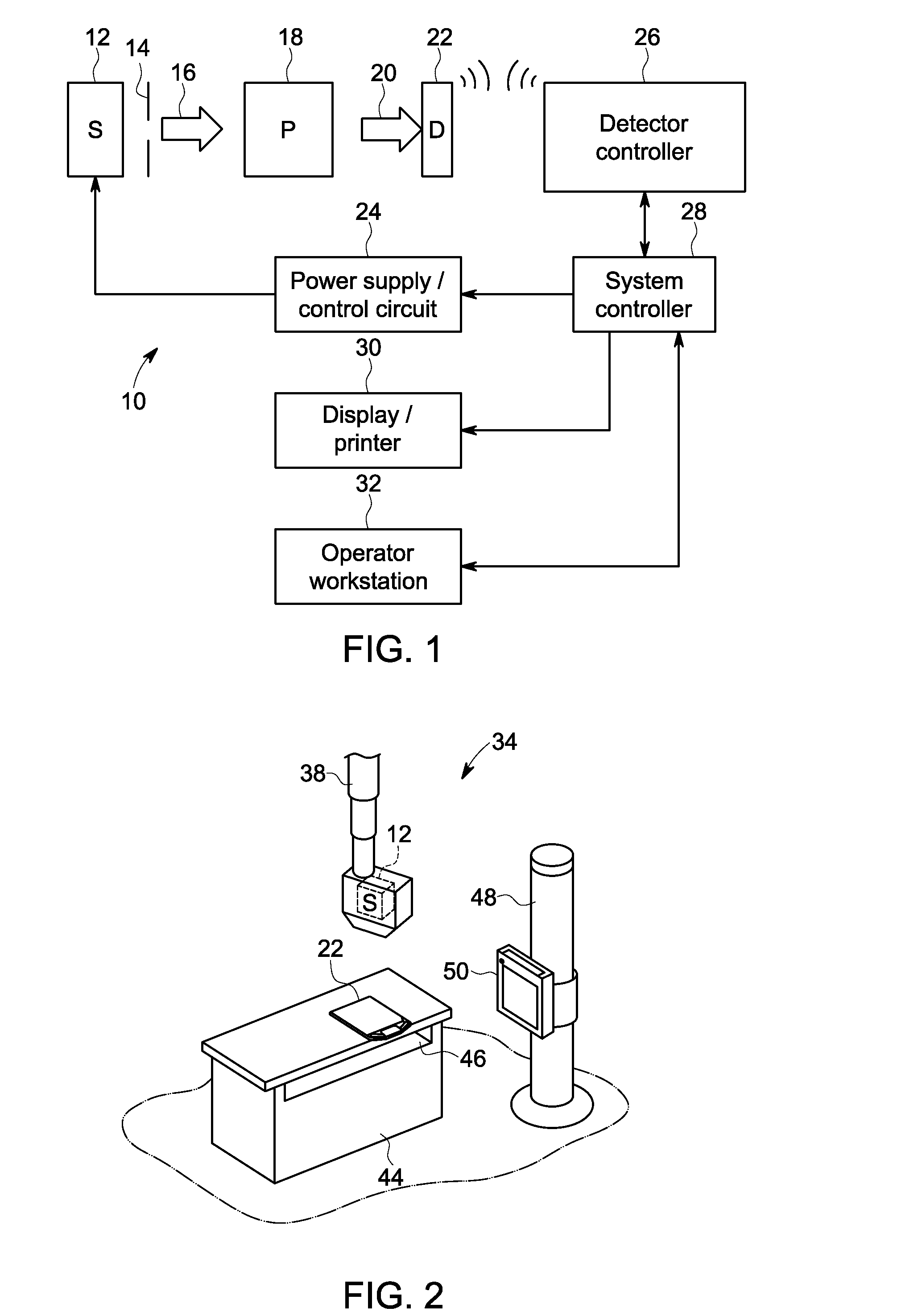

Radiation absorbing x-ray detector panel support

ActiveUS20060065846A1Increasing sizeIncreasing weightMaterial analysis by optical meansShieldingBackscatter X-rayRadar-absorbent material

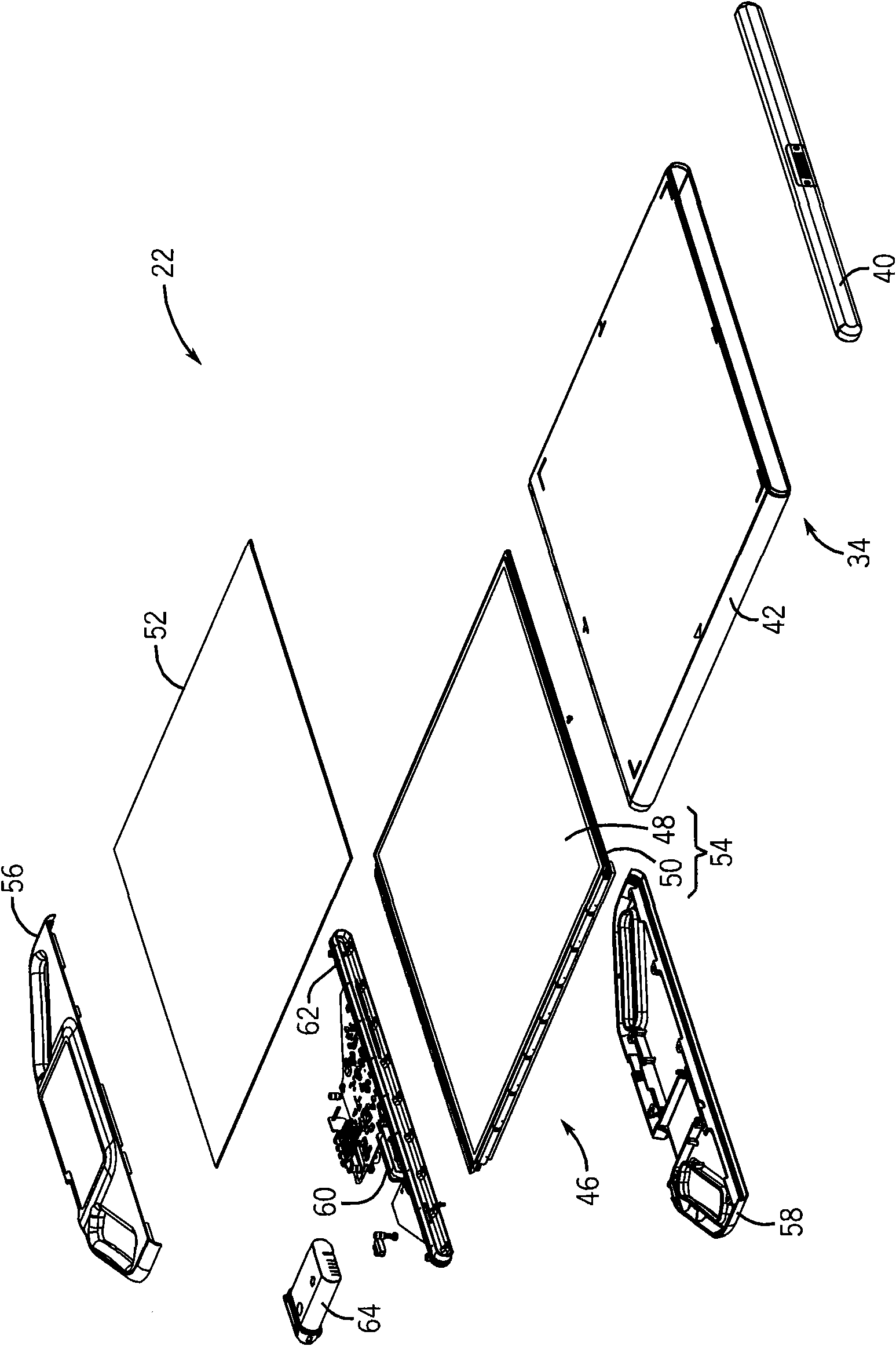

An x-ray detector panel support is disclosed that is formed with radiation absorbing material to reduce the reflection of x-rays off anything behind the scintillator, which may include the geometry of the panel support, the electronics, and the back cover of the x-ray detector. The absorbing material may take the form of a discrete layer secured to or otherwise disposed within the panel support. The radiation absorbing material may also be mixed with the base materials used to fabricate the panel support. As such, when the panel support is formed, it includes radiation absorbing components. The radiation absorbing material may include lead, barium sulfate, tungsten, as well as other materials. The panel support is constructed to inhibit the detection of backscattered x-rays without significantly increasing the size or weigh of the x-ray detector. The panel support is applicable with stationary or fixed as well as portable x-ray detectors.

Owner:GENERAL ELECTRIC CO

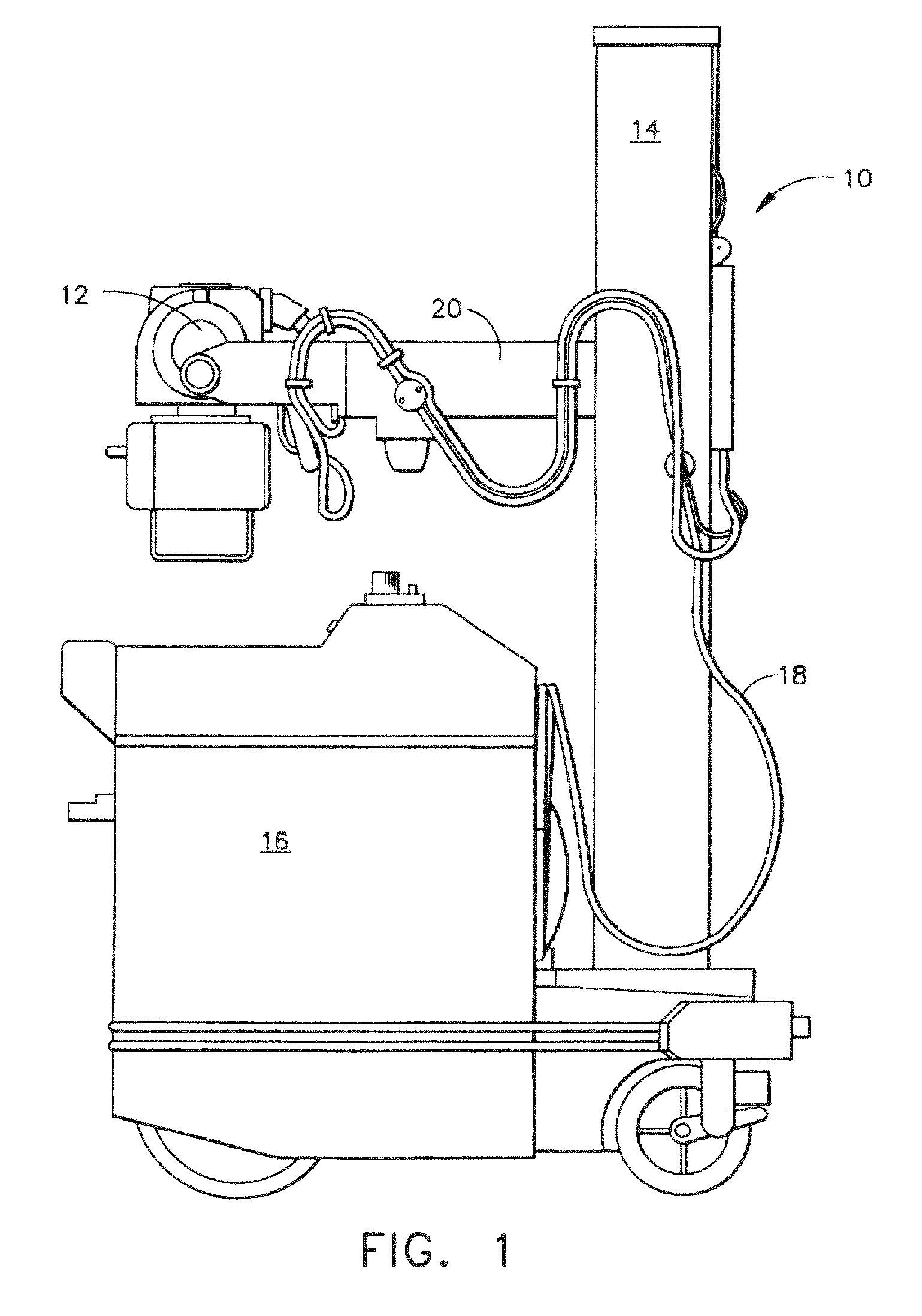

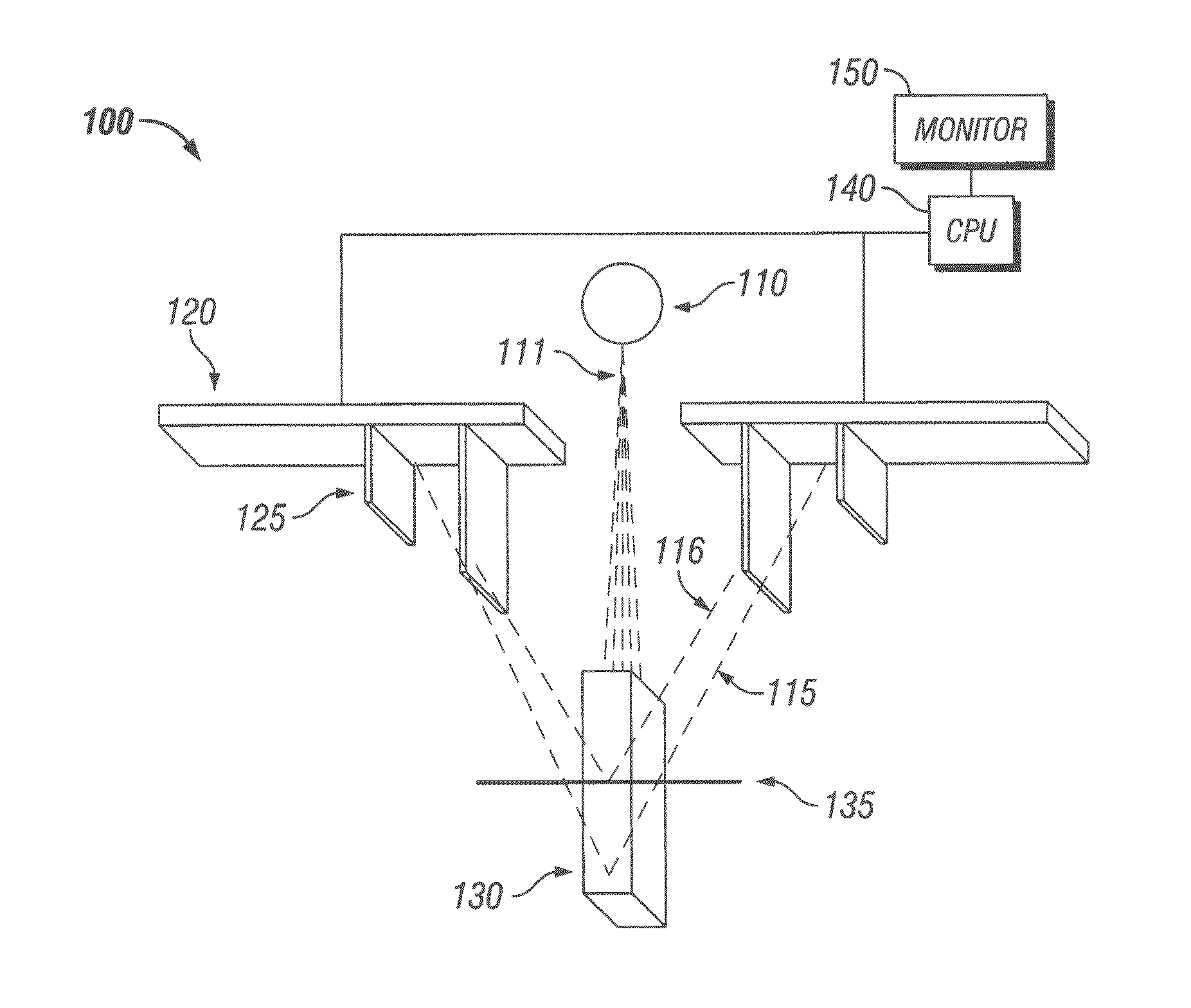

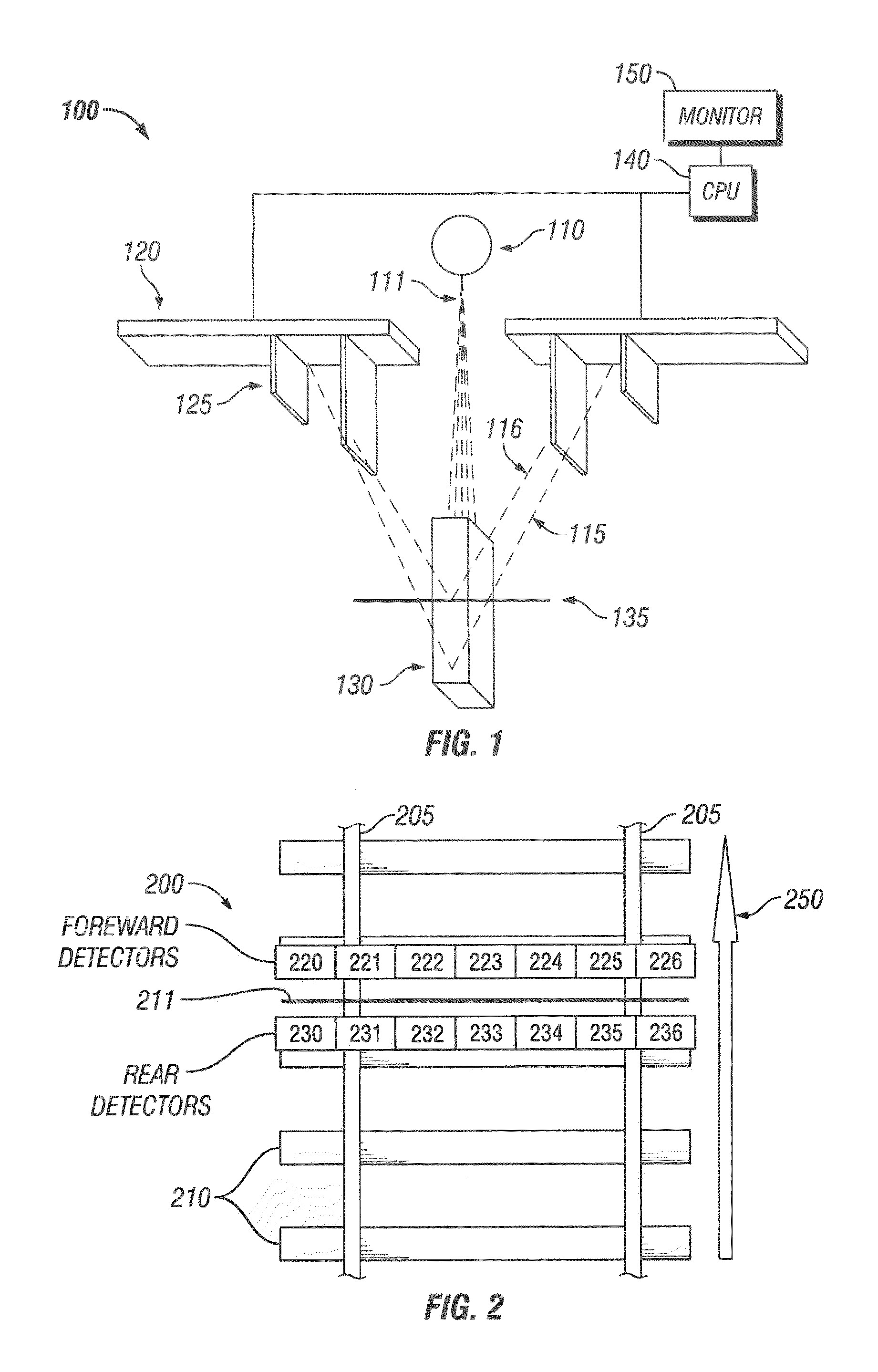

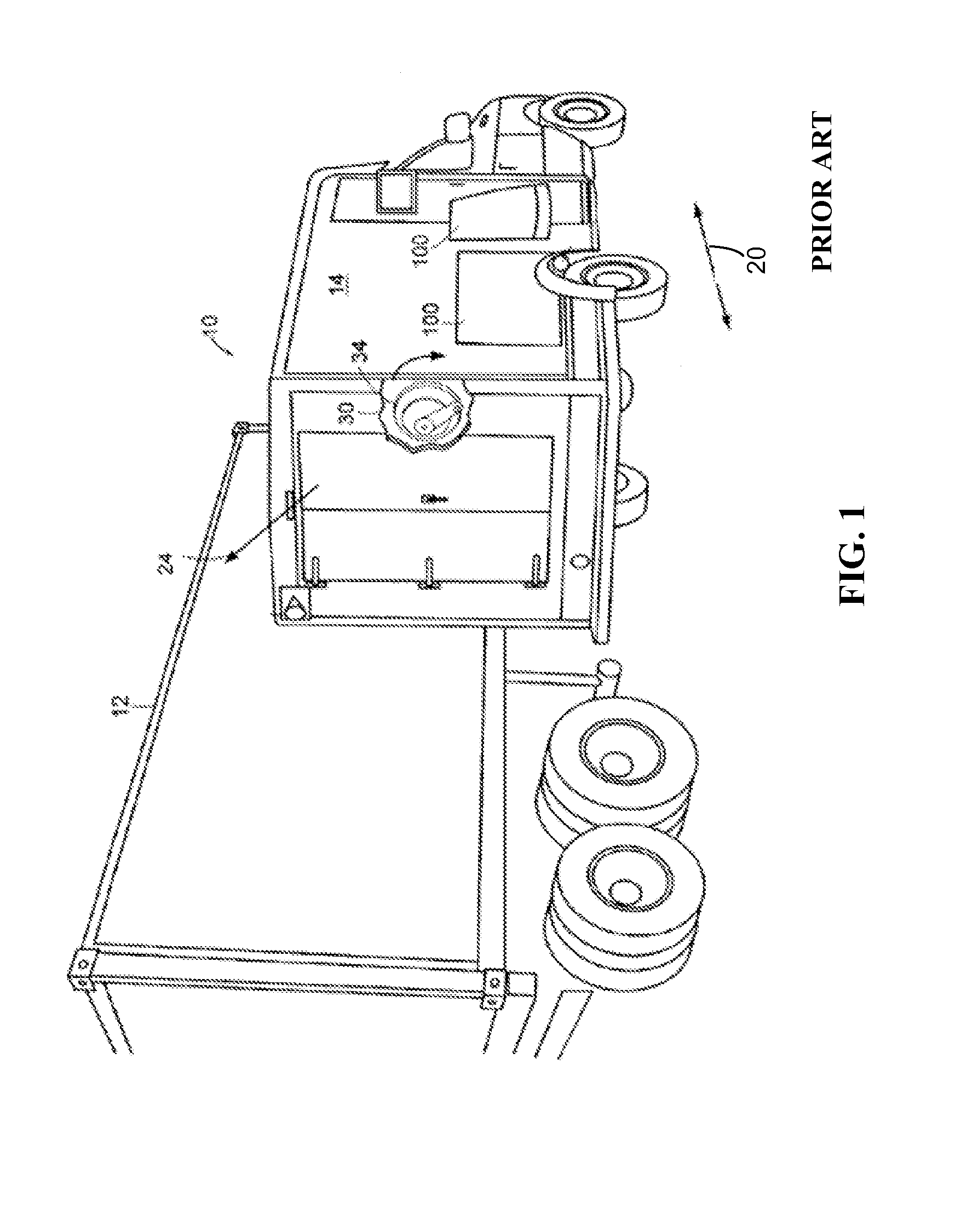

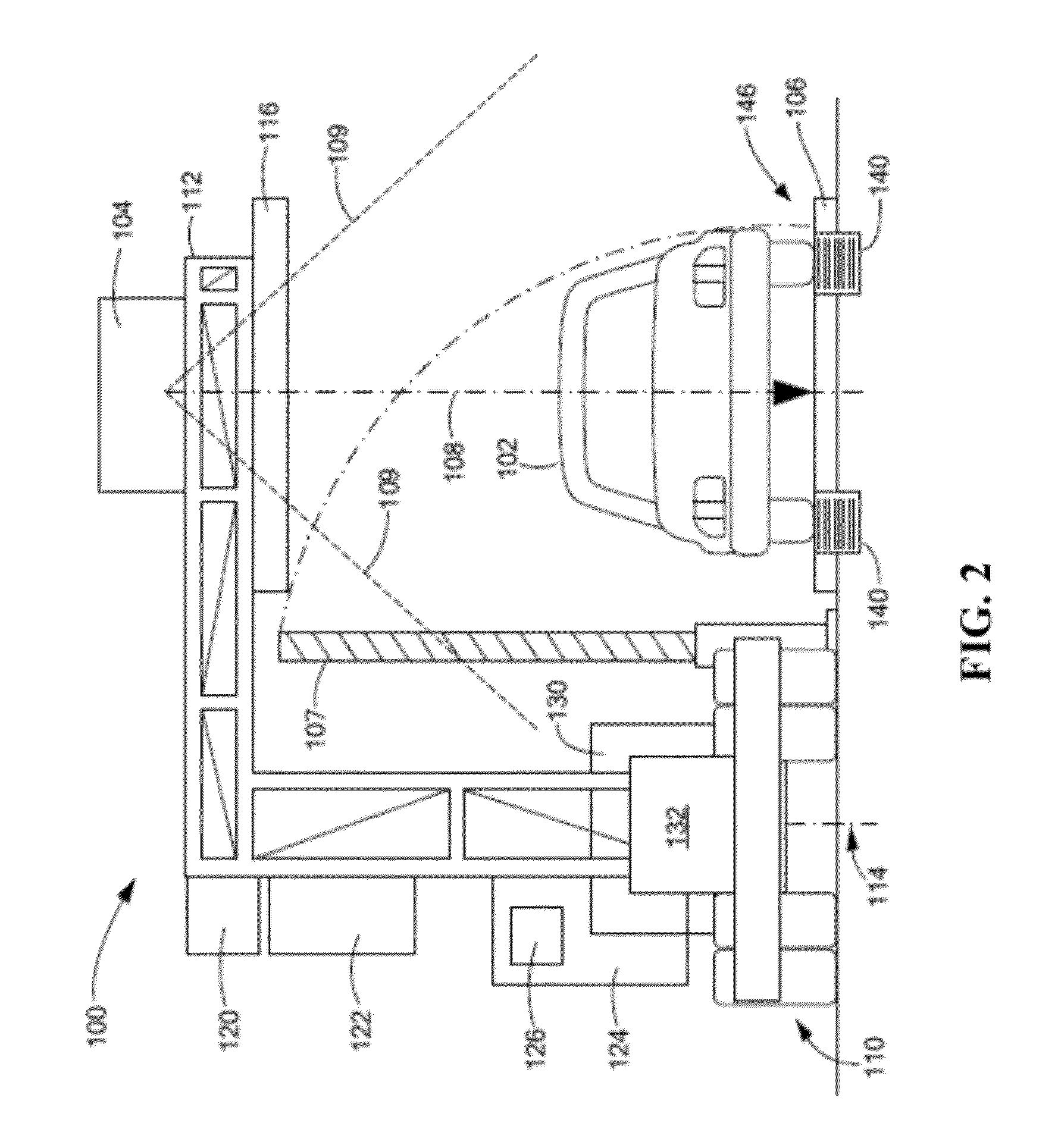

Internal imaging system

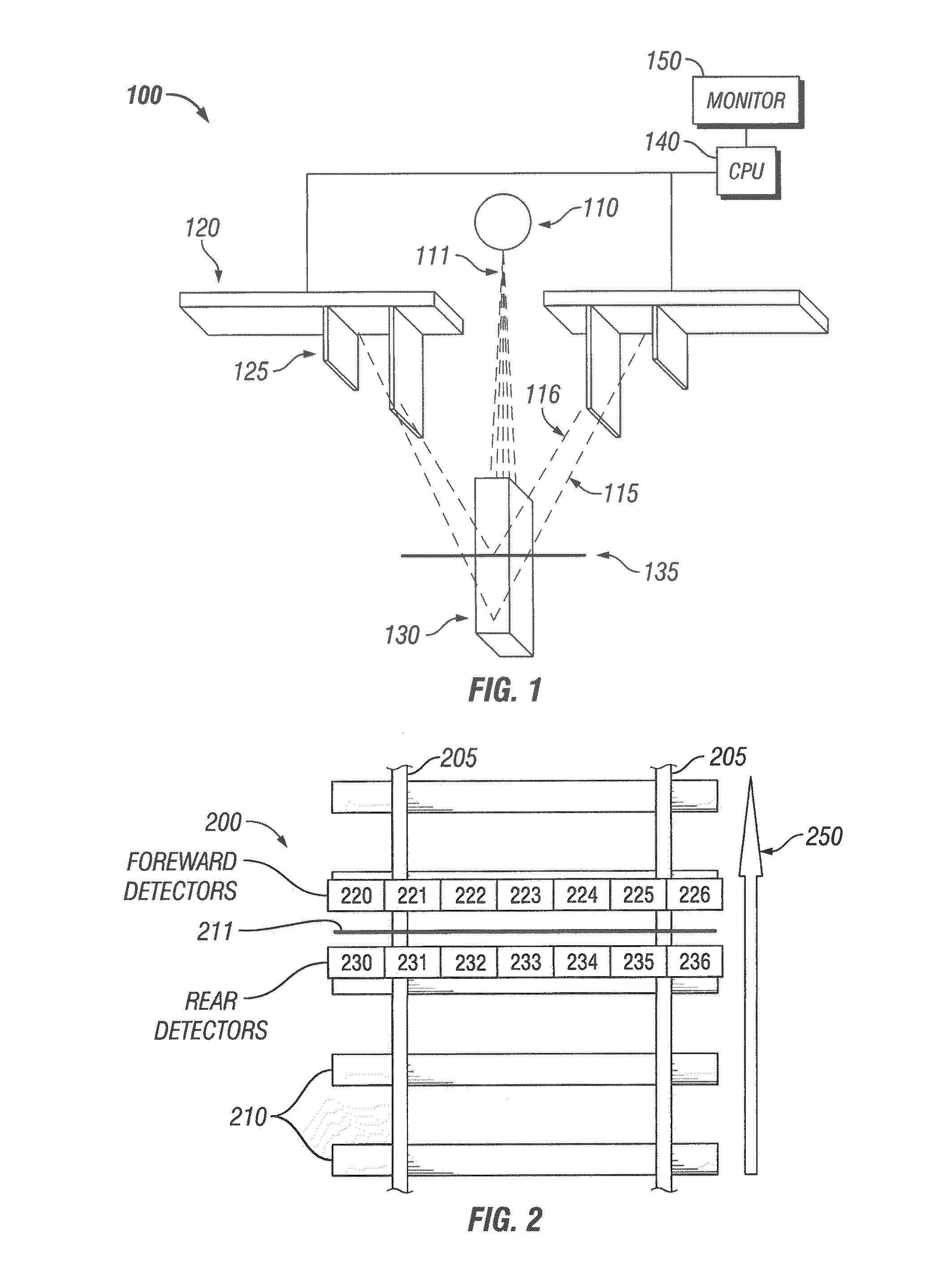

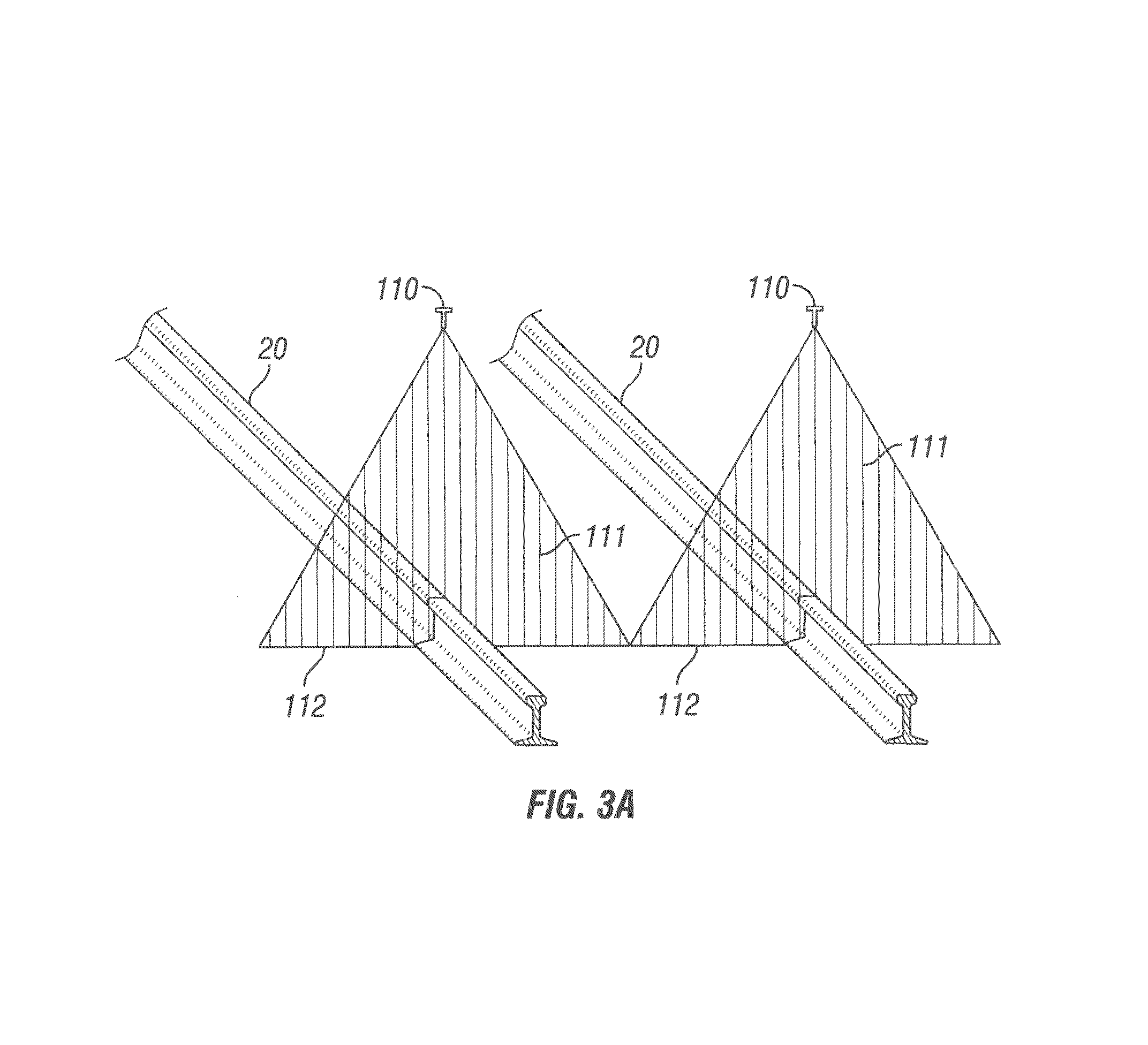

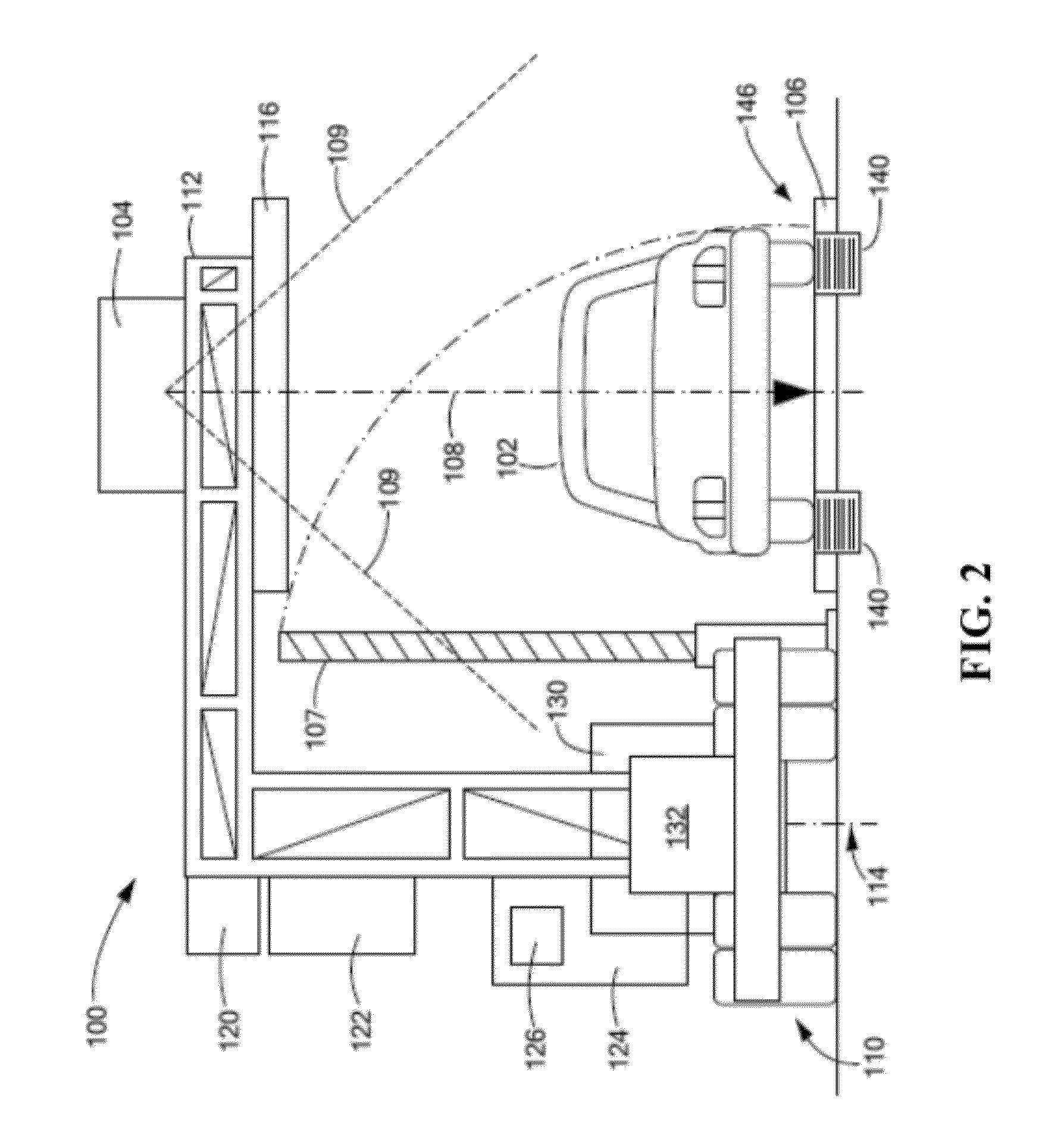

ActiveUS9031188B2Using wave/particle radiation meansRailway auxillary equipmentBackscatter X-rayX-ray

A system for the inspection of the internal structure of a target includes at least one x-ray source that emits collimated x-rays to irradiate the target. At least one detector is positioned to detect backscatter x-rays from the target. The detector may include a collimation slot that limits the field of view of the detector. The target may be a railway component and the system may inspect the internal structure of the component as it is moved along the railway by a vehicle. The system may detect a change in the density of a target based on a comparison of the detected backscatter x-rays. The use of a plurality of segmented backscatter x-ray detectors having a collimation slot may pixelate the internal image in the direction of the collimation slot.

Owner:LORAM TECH INC

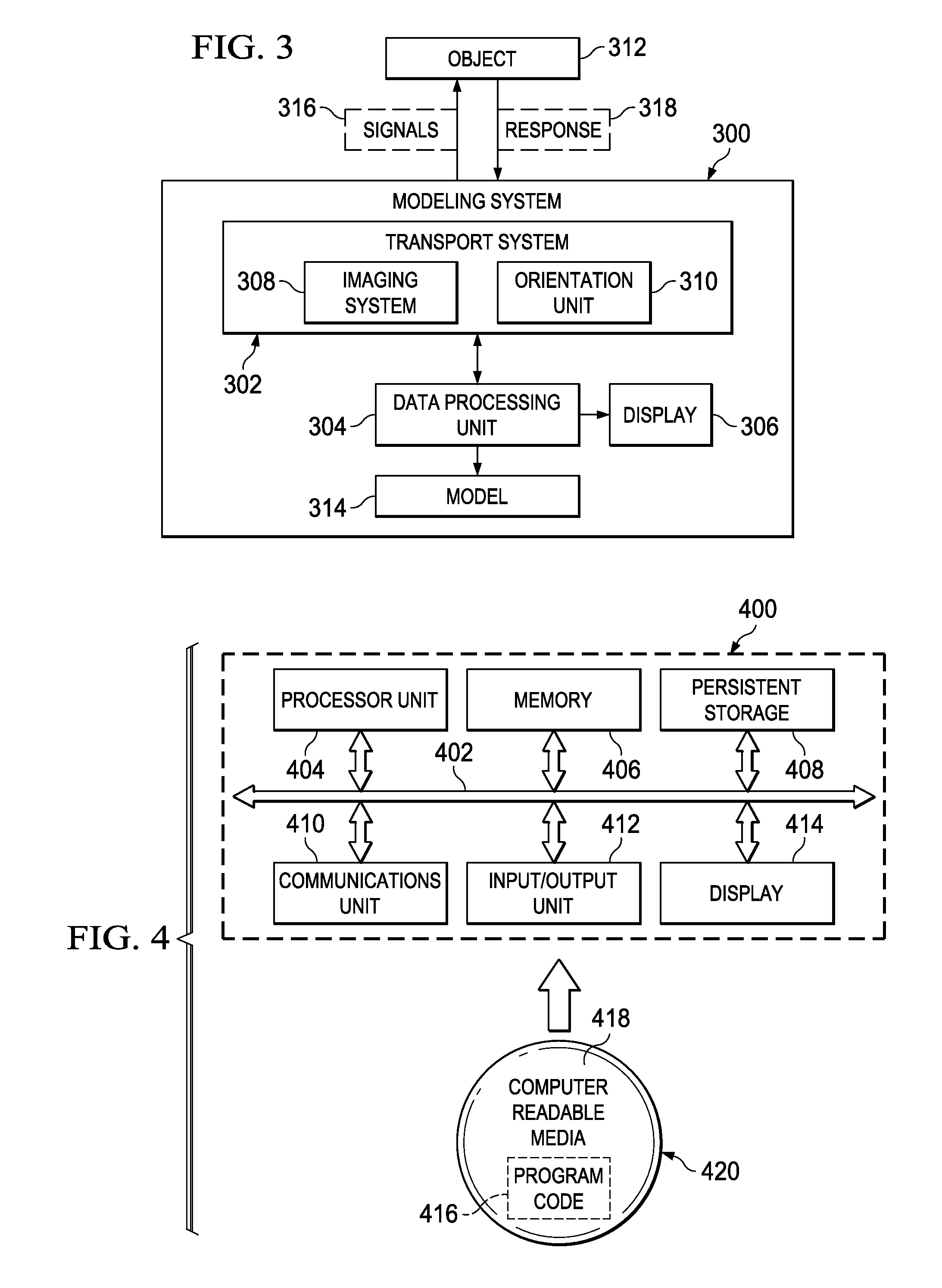

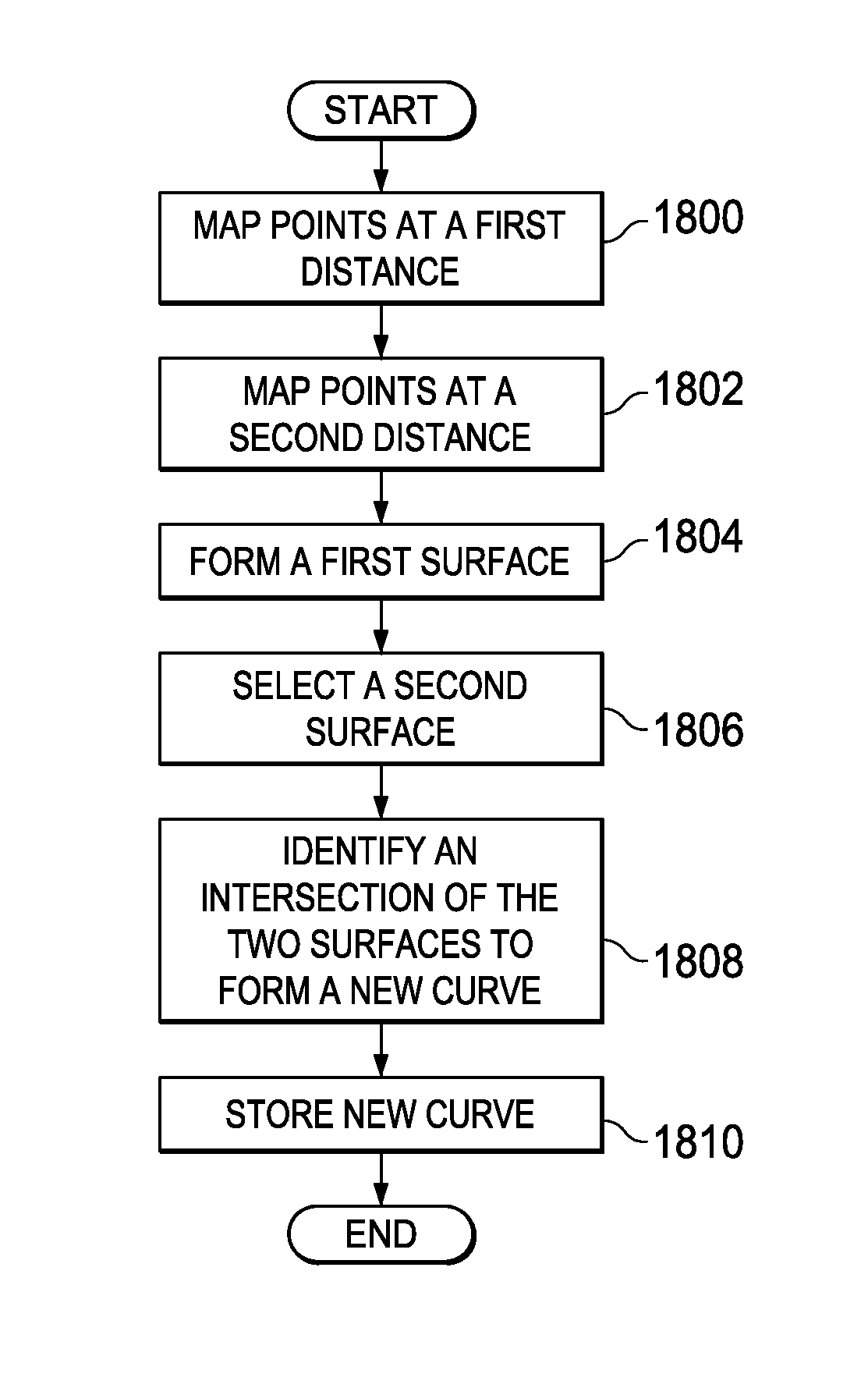

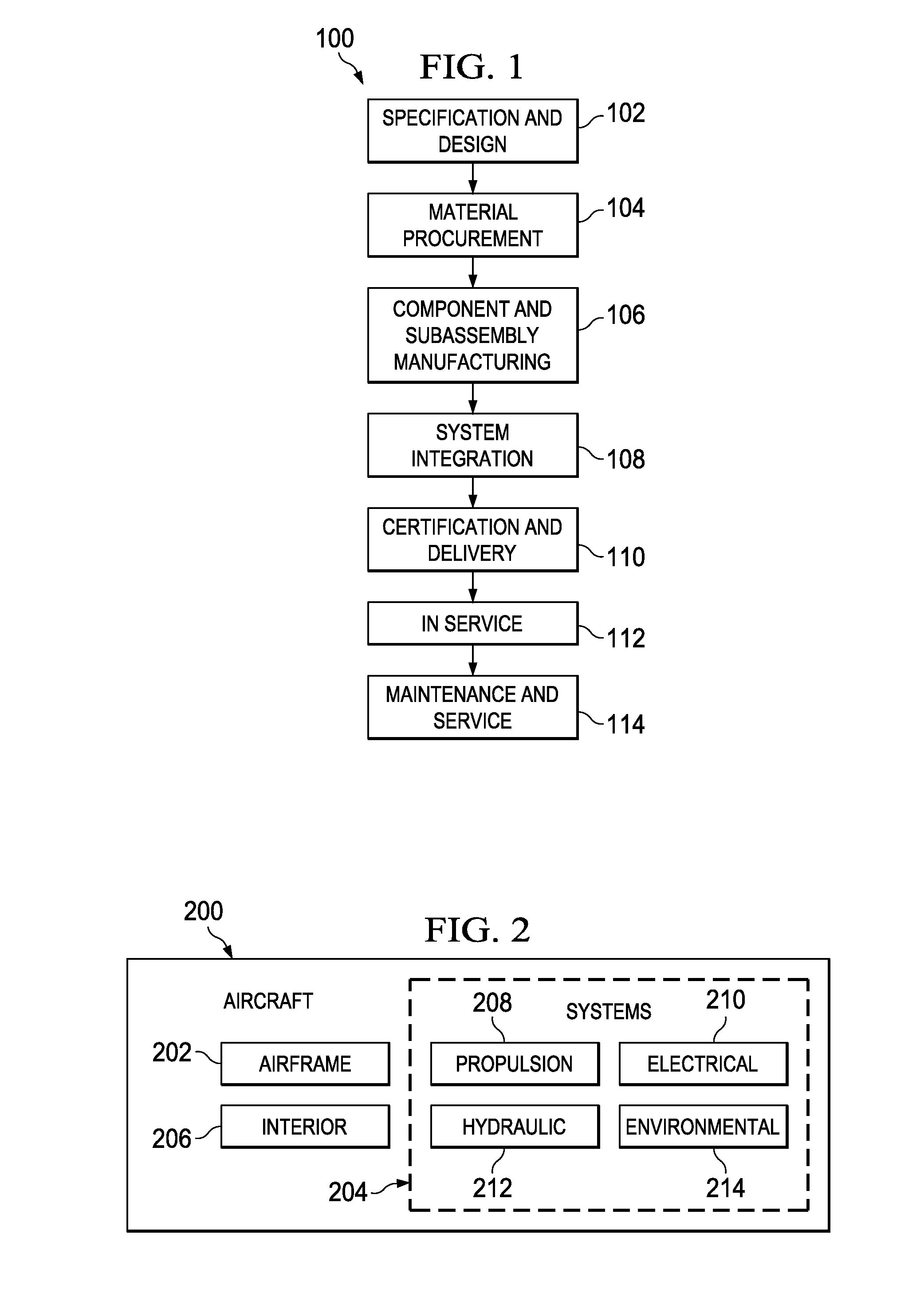

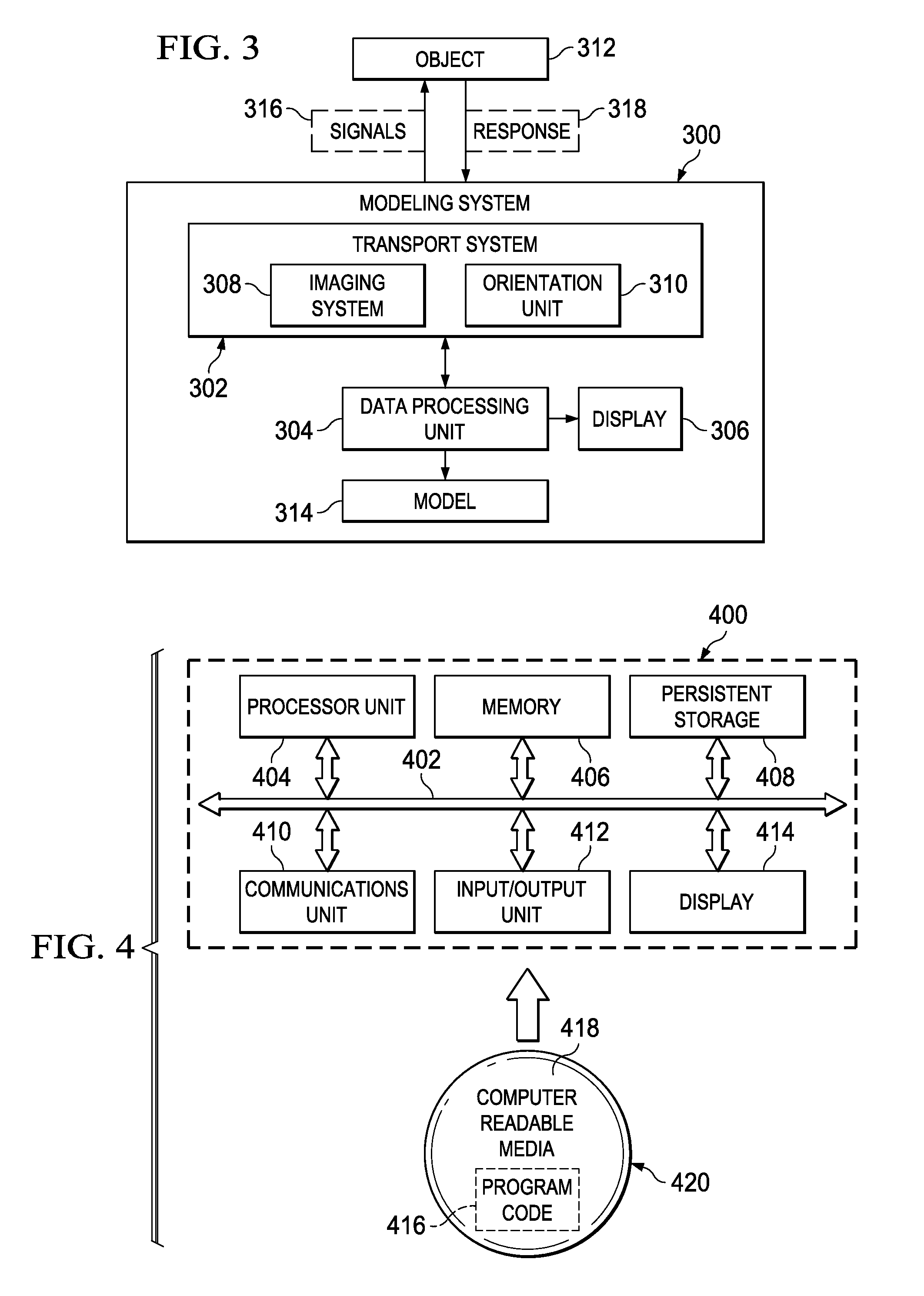

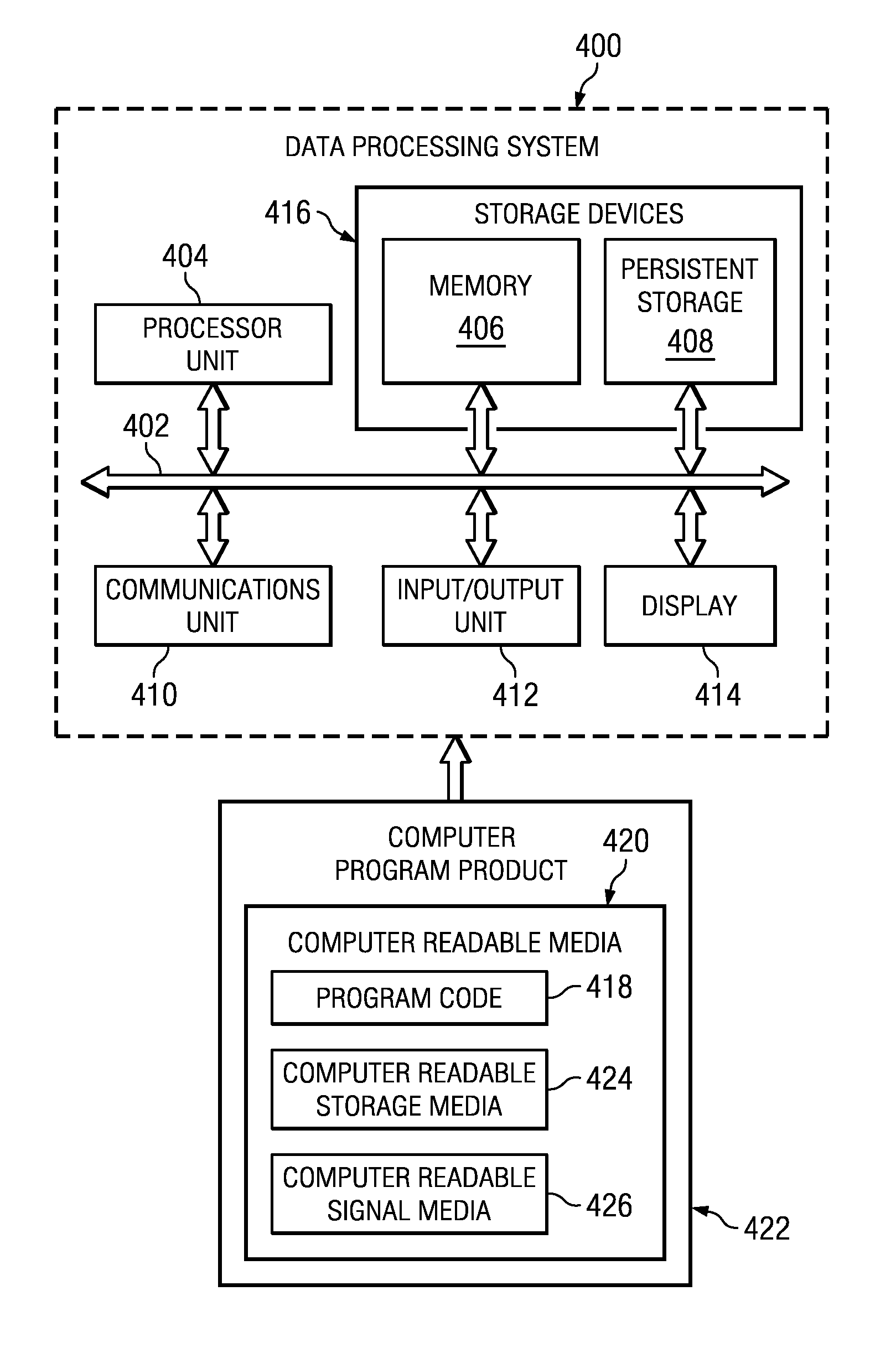

Method and apparatus for generating data for three-dimensional models from x-rays

InactiveUS20090128557A1Details involving processing stepsPosition fixationBackscatter X-rayComputer graphics (images)

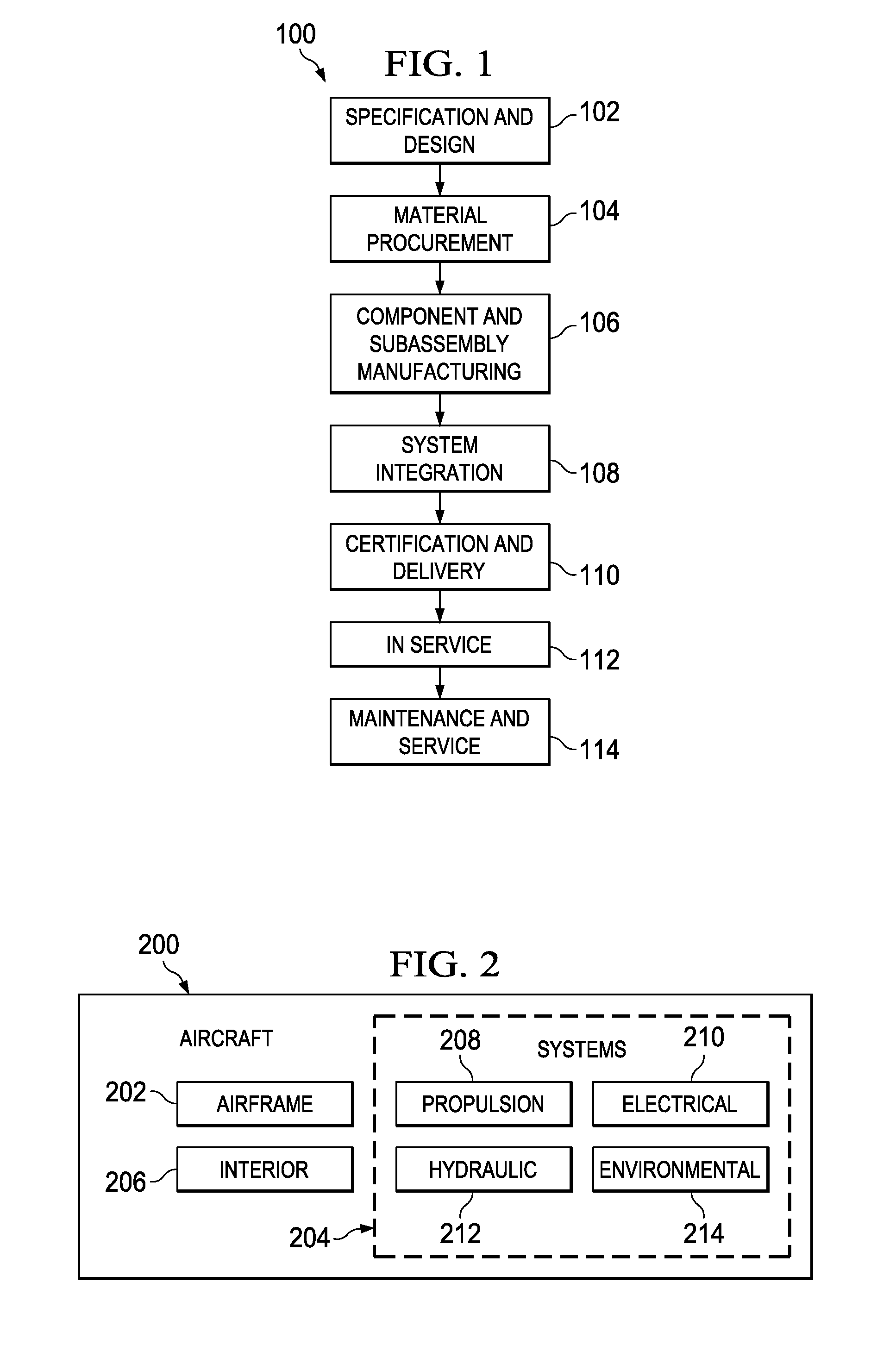

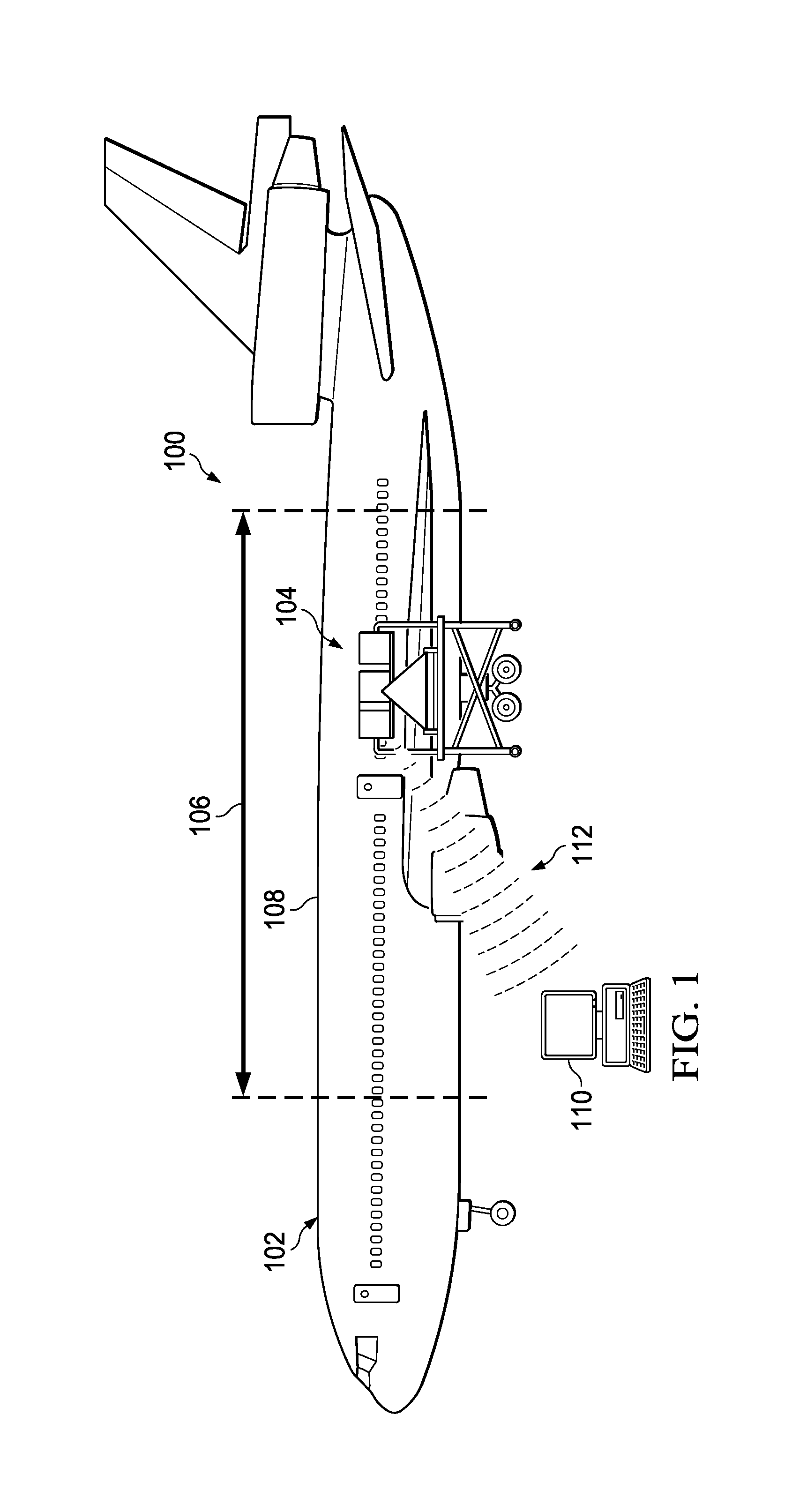

A computer implemented method, apparatus, and computer usable program code for generating a three-dimensional model of an object of interest in an aircraft. In response to transmitting a plurality of x-rays from a set of transmission points into the aircraft, backscatter x-ray data is received. The object identified from a two-dimensional diagram of the backscatter data. Points for the object are created from the identification of the object in the received data. The points are placed at a first distance from the transmission points to form a first curve. The points are placed at a second distance from the transmission points to form a second curve. A first surface is formed from the first and second curves. A second surface is formed that intersects the first surface to form an intersection. Three-dimensional data is generated for the three-dimensional model of the object from the intersection.

Owner:THE BOEING CO

Internal imaging system

ActiveUS20130202090A1Material analysis using wave/particle radiationUsing wave/particle radiation meansBackscatter X-rayX-ray

A system for the inspection of the internal structure of a target includes at least one x-ray source that emits collimated x-rays to irradiate the target. At least one detector is positioned to detect backscatter x-rays from the target. The detector may include a collimation slot that limits the field of view of the detector. The target may be a railway component and the system may inspect the internal structure of the component as it is moved along the railway by a vehicle. The system may detect a change in the density of a target based on a comparison of the detected backscatter x-rays. The use of a plurality of segmented backscatter x-ray detectors having a collimation slot may pixelate the internal image in the direction of the collimation slot.

Owner:LORAM TECH INC

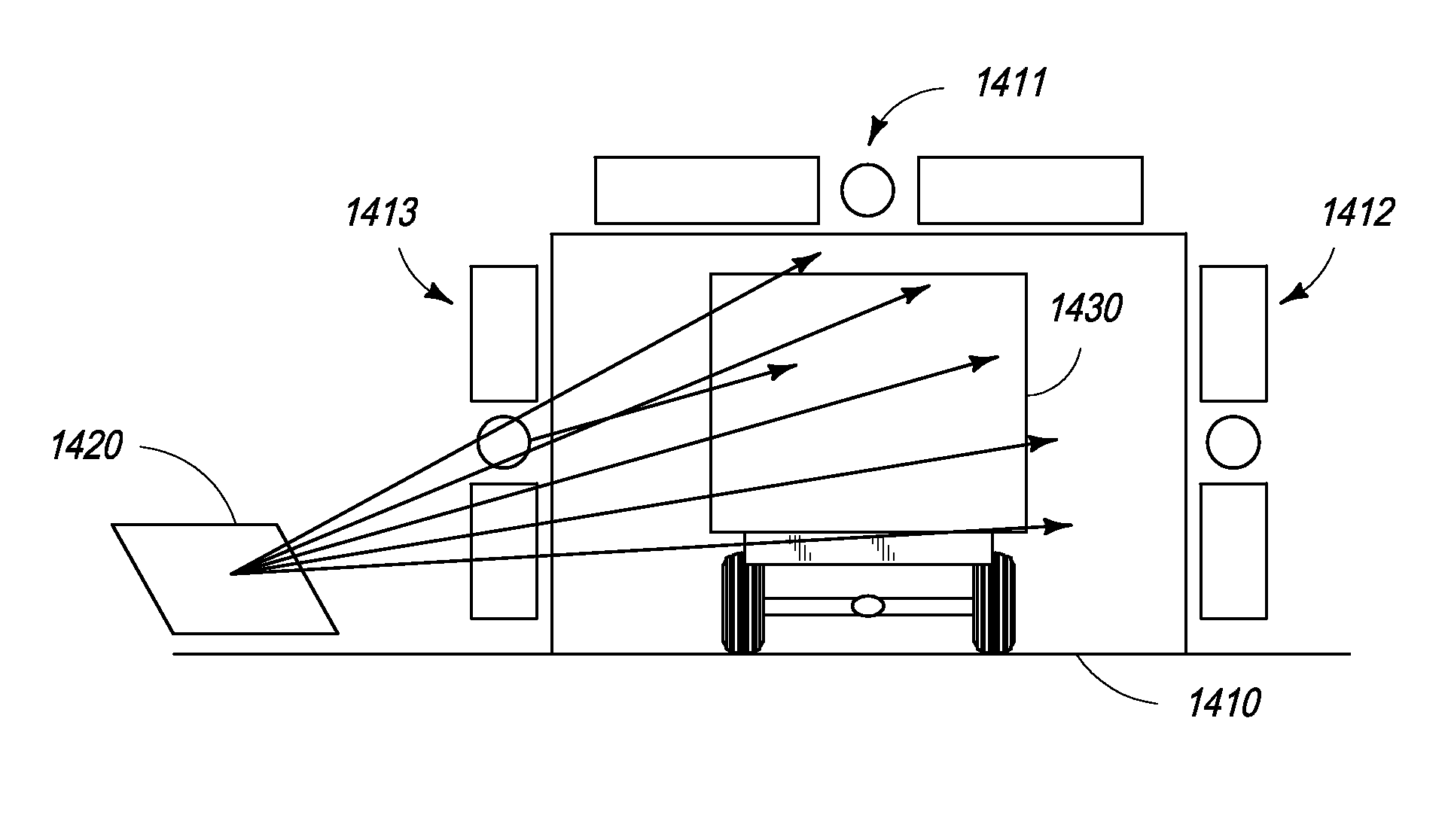

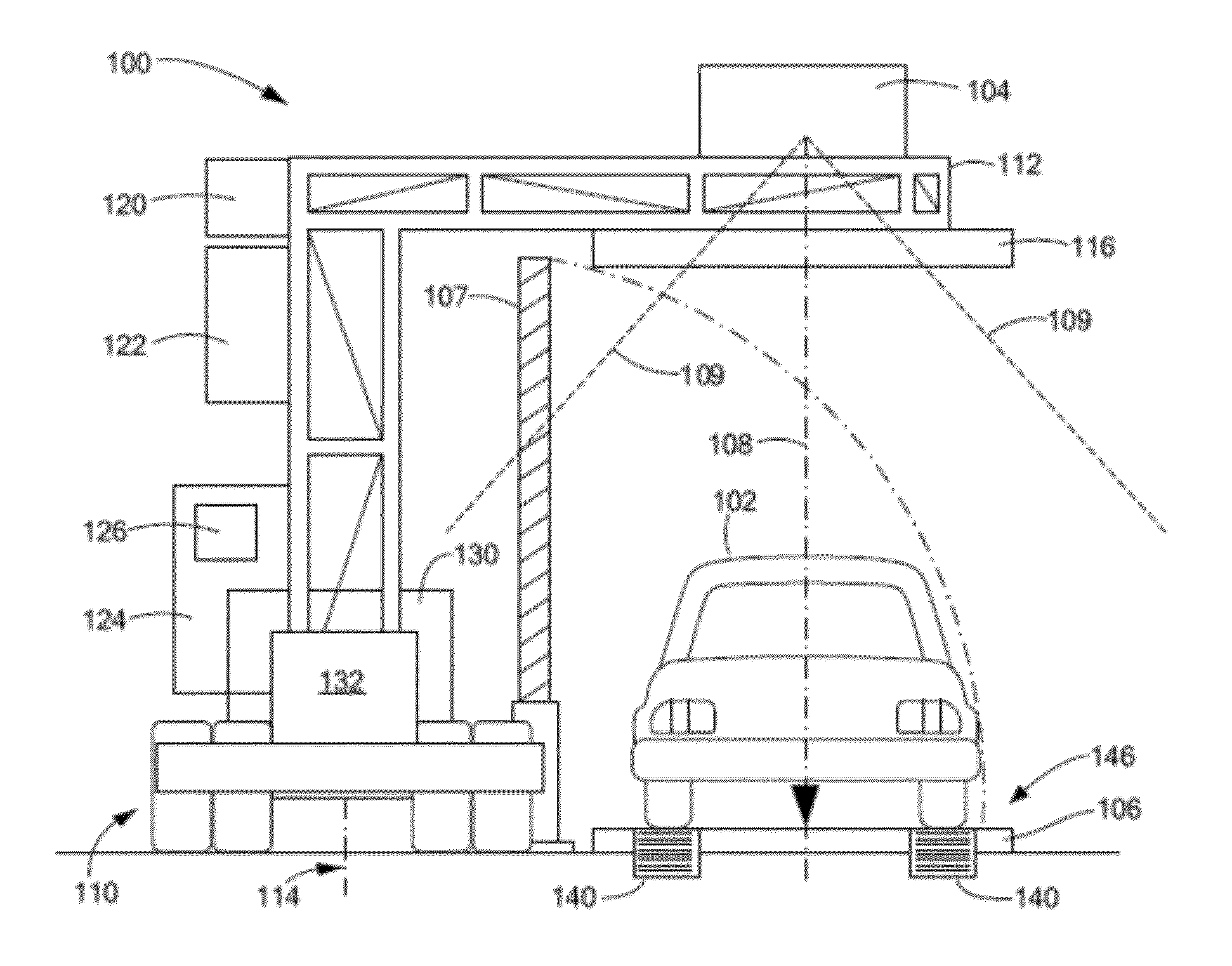

Backscatter X-ray inspection van with top-down imaging

InactiveUS8824632B2Using wave/particle radiation meansMaterial analysis by transmitting radiationBackscatter X-rayOperating point

Owner:AMERICAN SCI & ENG INC

Radiation absorbing x-ray detector panel support

ActiveUS7317190B2Increasing sizeIncreasing weightMaterial analysis by optical meansShieldingBackscatter X-rayRadar-absorbent material

An x-ray detector panel support is disclosed that is formed with radiation absorbing material to reduce the reflection of x-rays off anything behind the scintillator, which may include the geometry of the panel support, the electronics, and the back cover of the x-ray detector. The absorbing material may take the form of a discrete layer secured to or otherwise disposed within the panel support. The radiation absorbing material may also be mixed with the base materials used to fabricate the panel support. As such, when the panel support is formed, it includes radiation absorbing components. The radiation absorbing material may include lead, barium sulfate, tungsten, as well as other materials. The panel support is constructed to inhibit the detection of backscattered x-rays without significantly increasing the size or weigh of the x-ray detector. The panel support is applicable with stationary or fixed as well as portable x-ray detectors.

Owner:GENERAL ELECTRIC CO

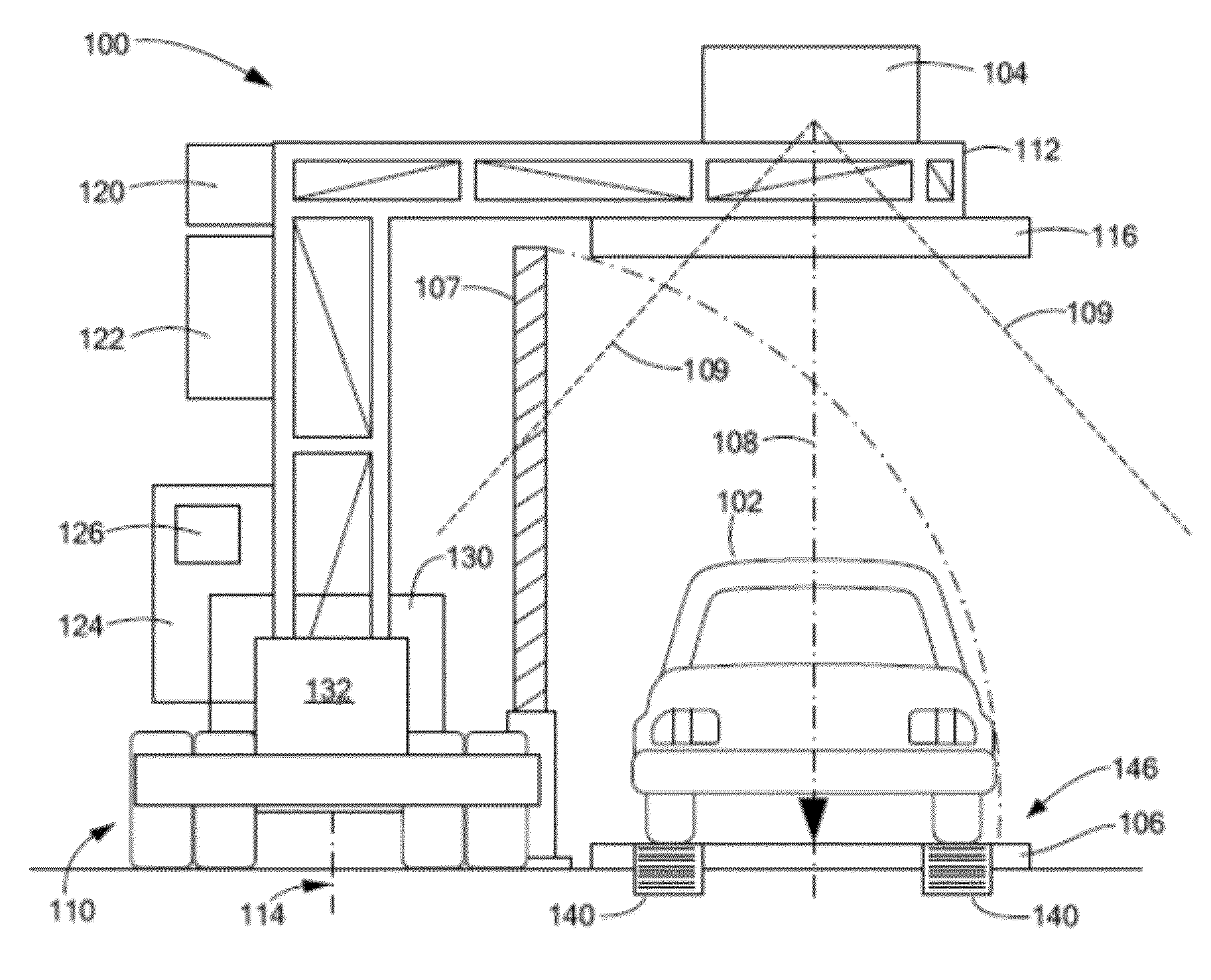

Backscatter X-Ray Inspection Van with Top-Down Imaging

InactiveUS20120033791A1Material analysis using wave/particle radiationNuclear radiation detectionBackscatter X-rayOperating point

A system and method for inspecting a vehicle or other object by means of two sources and one or more detectors of penetrating radiation. The sources and detector(s) are carried on a mobile conveyance and deployed at a point of operation. One source irradiates an inspected object from within an enclosure, while a second source swings away from the conveyance on a deployable member, such as a boom, such that the second source can irradiate the vehicle from above. A backscatter image of the inspected object is based at least in part on radiation from the second source scattered by the inspected object.

Owner:AMERICAN SCI & ENG INC

Method and apparatus for generating data for three-dimensional models from x-rays

InactiveUS9001121B2Details involving processing stepsPosition fixationBackscatter X-rayComputer graphics (images)

Owner:THE BOEING CO

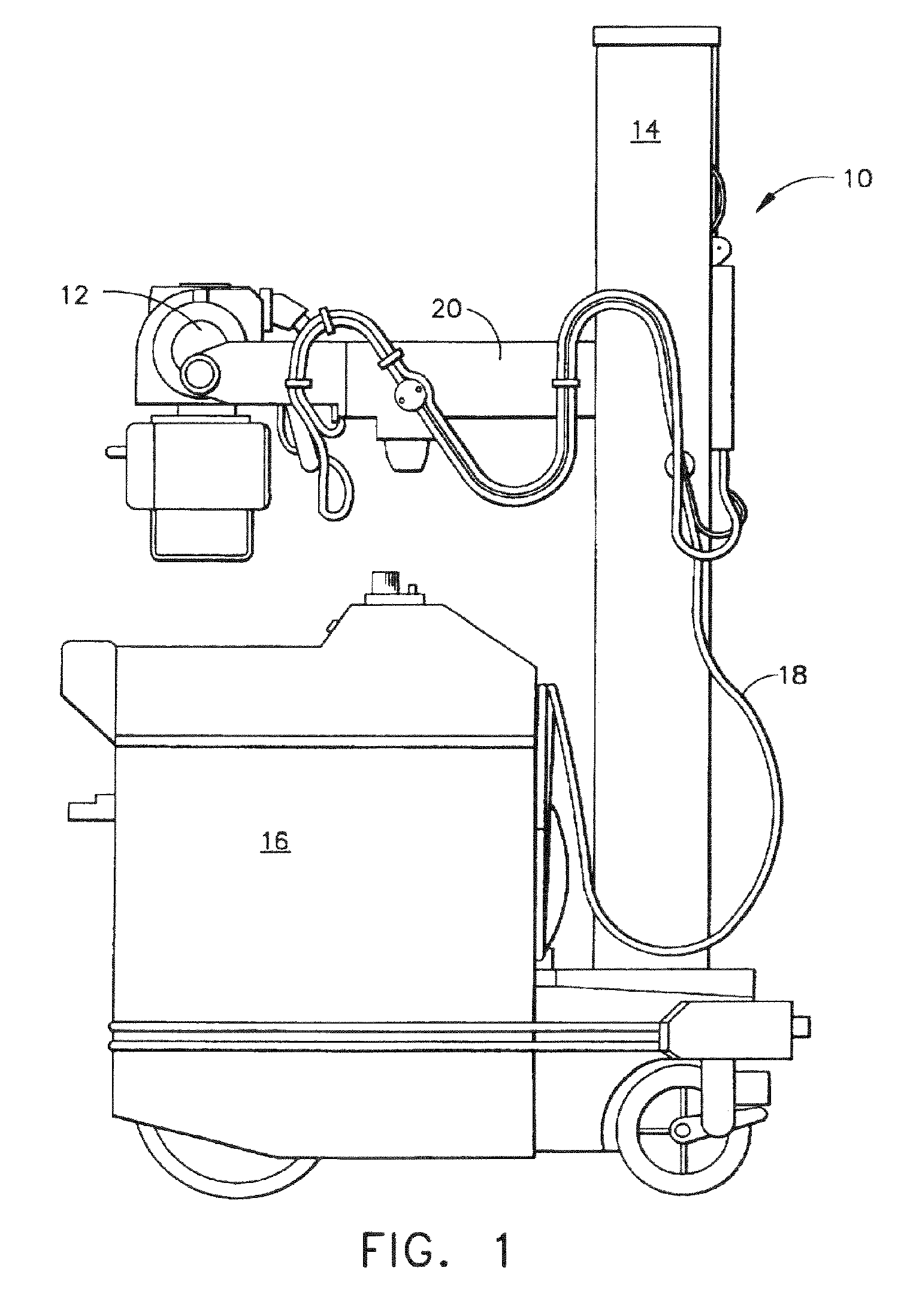

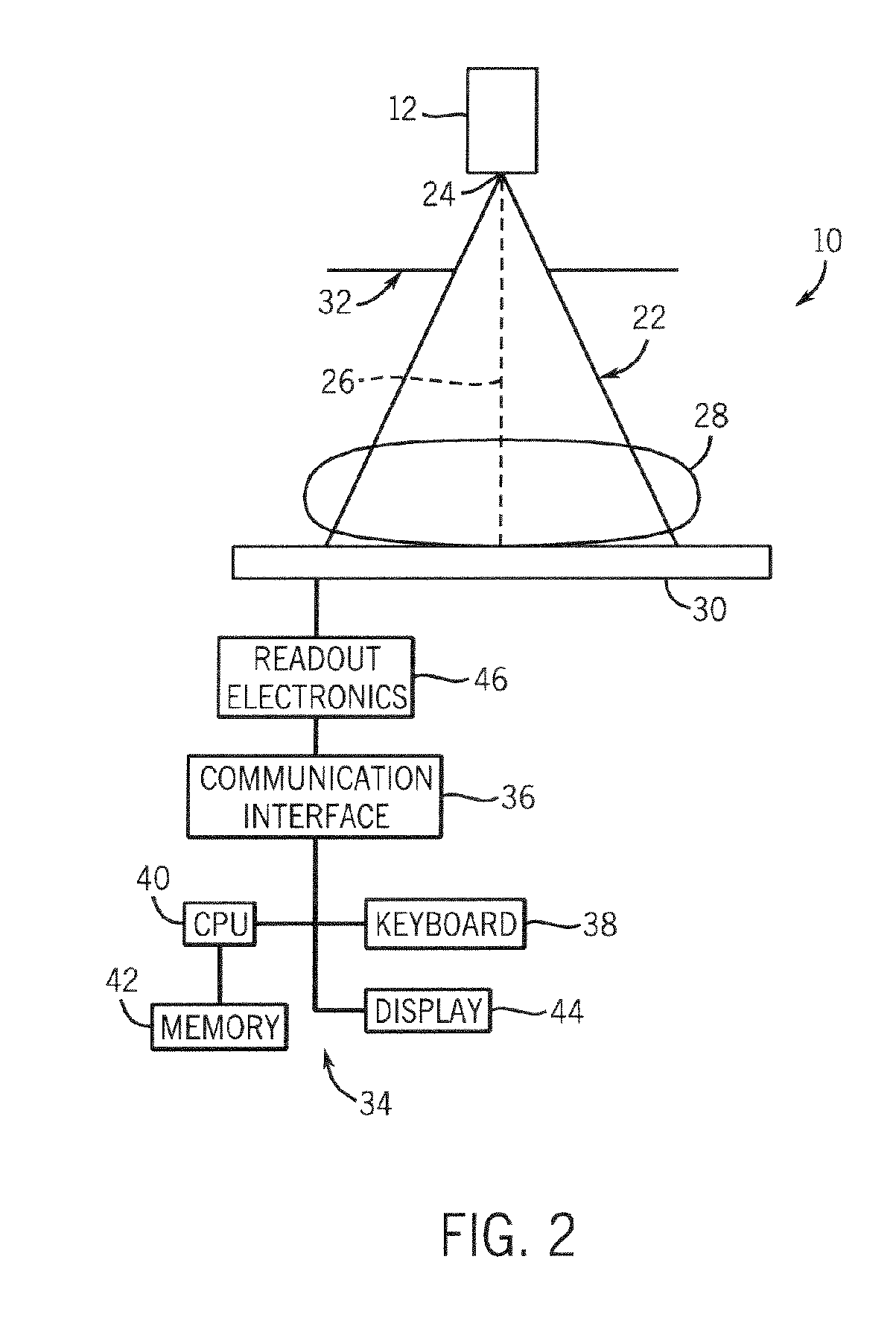

Time of Flight Backscatter Imaging System

ActiveUS20120134473A1Radiation/particle handlingMaterial analysis by transmitting radiationSoft x rayBackscatter X-ray

The present application discloses an X-ray imaging apparatus for determining a surface profile of an object under inspection that is positioned at a distance from the apparatus. The X-ray imaging system has an X-ray source for producing a scanning beam of X-rays directed toward the object, a detector assembly for providing a signal representative of an intensity of X-rays backscattered from the object, and processing circuitry to determine a time difference between when the X-ray source is switched on and when the backscattered X-rays arrive at the detector assembly. The processing circuitry is adapted to output data representative of the surface profile of the object under inspection.

Owner:RAPISCAN SYST INC (US)

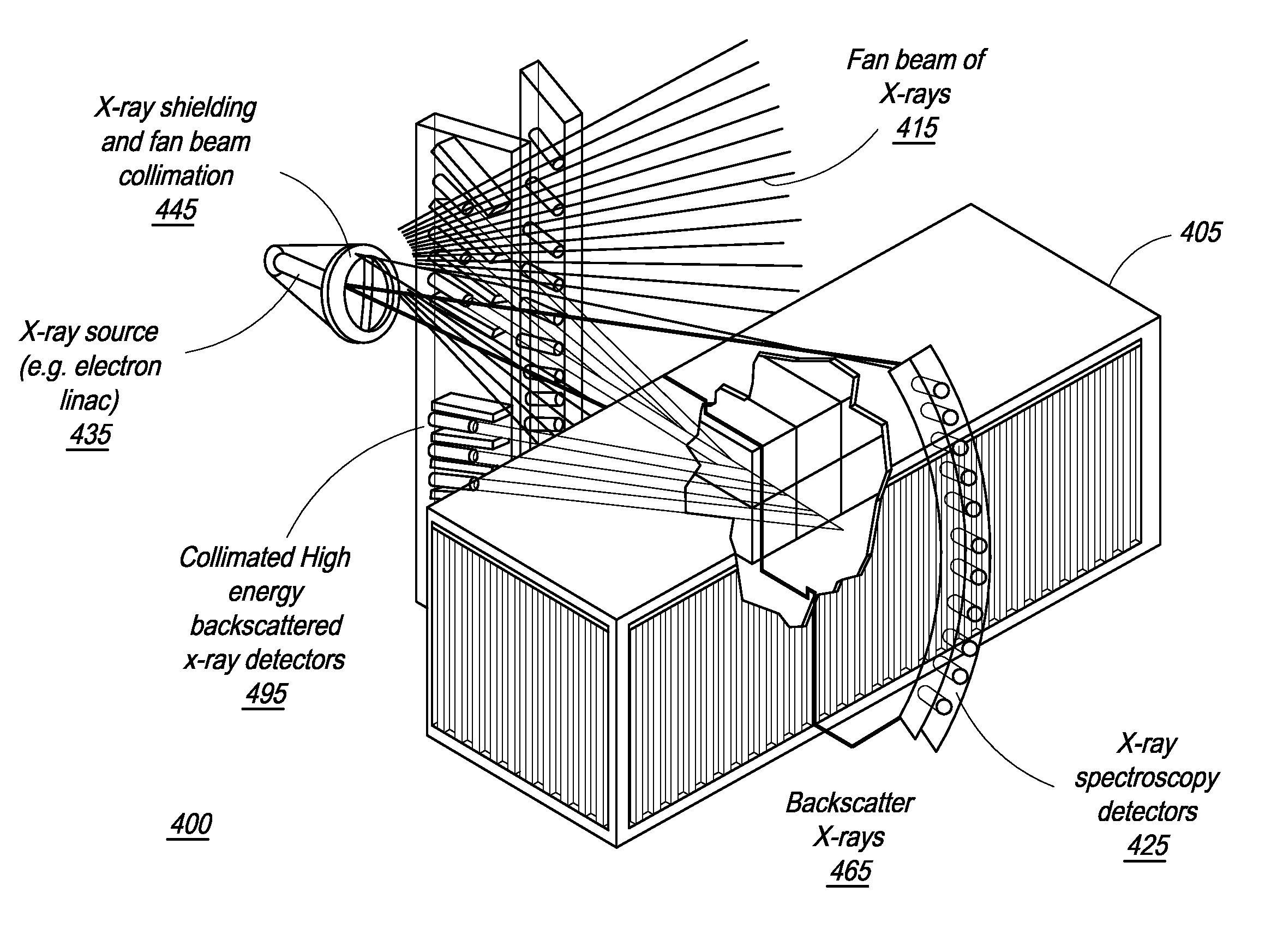

Back-scattered X-ray radiation attenuation method and apparatus

InactiveUS7336767B1Reduce intensityMaterial analysis by optical meansHandling using diaphragms/collimetersSoft x rayBackscatter X-ray

A method for improving resolution of X-ray radiography systems of the type used to obtain images of internal features of human bodies or to view contents of luggage articles, cargo containers and the like comprises positioning a plurality of baffle plates between the rear surface of an X-ray radiation detector array and a back stop used to limit transmitted X-ray radiation to a safe level. The baffle plates are made of a high atomic-number metal such as iron or lead which reduces by absorption, scattering or other attenuating processes the intensity of X-ray radiation back scattered from the back-stop onto the detector array, thus reducing noise contributions to signals output from detector elements of the array and thereby improving the quality of radiographic images formed from detector output signals. A back-scattered X-ray radiation attenuation apparatus according to the present invention utilizes pairs of horizontal upper and lower baffle plates disposed longitudinally rearward from upper and lower sides of individual X-ray radiation detector elements, or groups of elements, of a detector array, and optionally includes pairs of baffle plates disposed transversely to the horizontally disposed plates to thereby form an array of tubular collimatator elements which intercept and attenuate X-ray radiation scattered from locations on a back-stop on lateral sides of as well as above and below the detector elements.

Owner:LE KHAI MINH

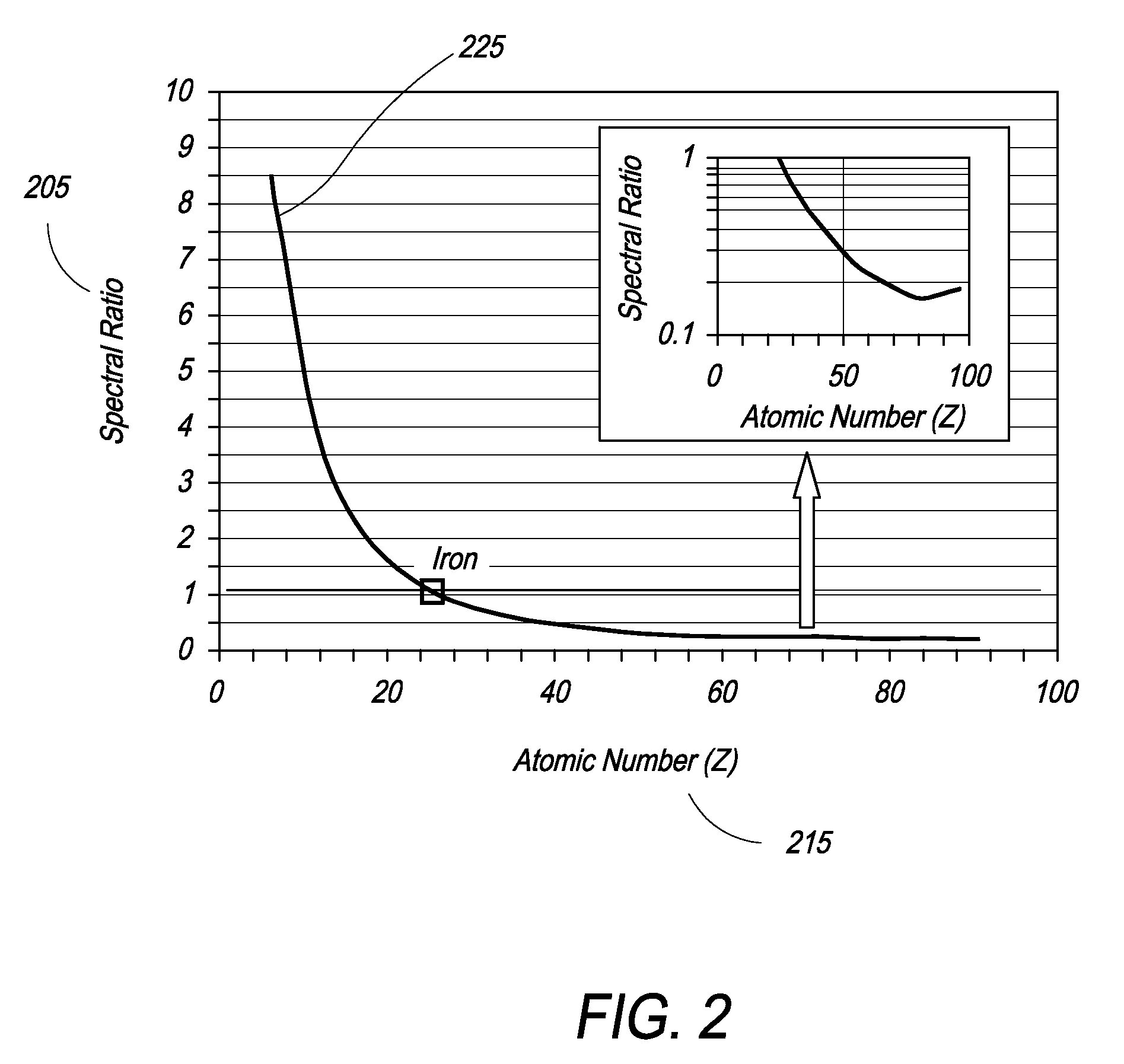

High-energy X-ray-spectroscopy-based inspection system and methods to determine the atomic number of materials

InactiveUS8750454B2Easy to detectUsing wave/particle radiation meansMaterial analysis by transmitting radiationBackscatter X-rayHigh energy

The application discloses systems and methods for X-ray scanning for identifying material composition of an object being scanned. The system includes at least one X-ray source for projecting an X-ray beam on the object, where at least a portion of the projected X-ray beam is transmitted through the object, and an array of detectors for measuring energy spectra of the transmitted X-rays. The measured energy spectra are used to determine atomic number of the object for identifying the material composition of the object. The X-ray scanning system may also have an array of collimated high energy backscattered X-ray detectors for measuring the energy spectrum of X-rays scattered by the object at an angle greater than 90 degrees, where the measured energy spectrum is used in conjunction with the transmission energy spectrum to determine atomic numbers of the object for identifying the material composition of the object.

Owner:RAPISCAN SYST INC (US)

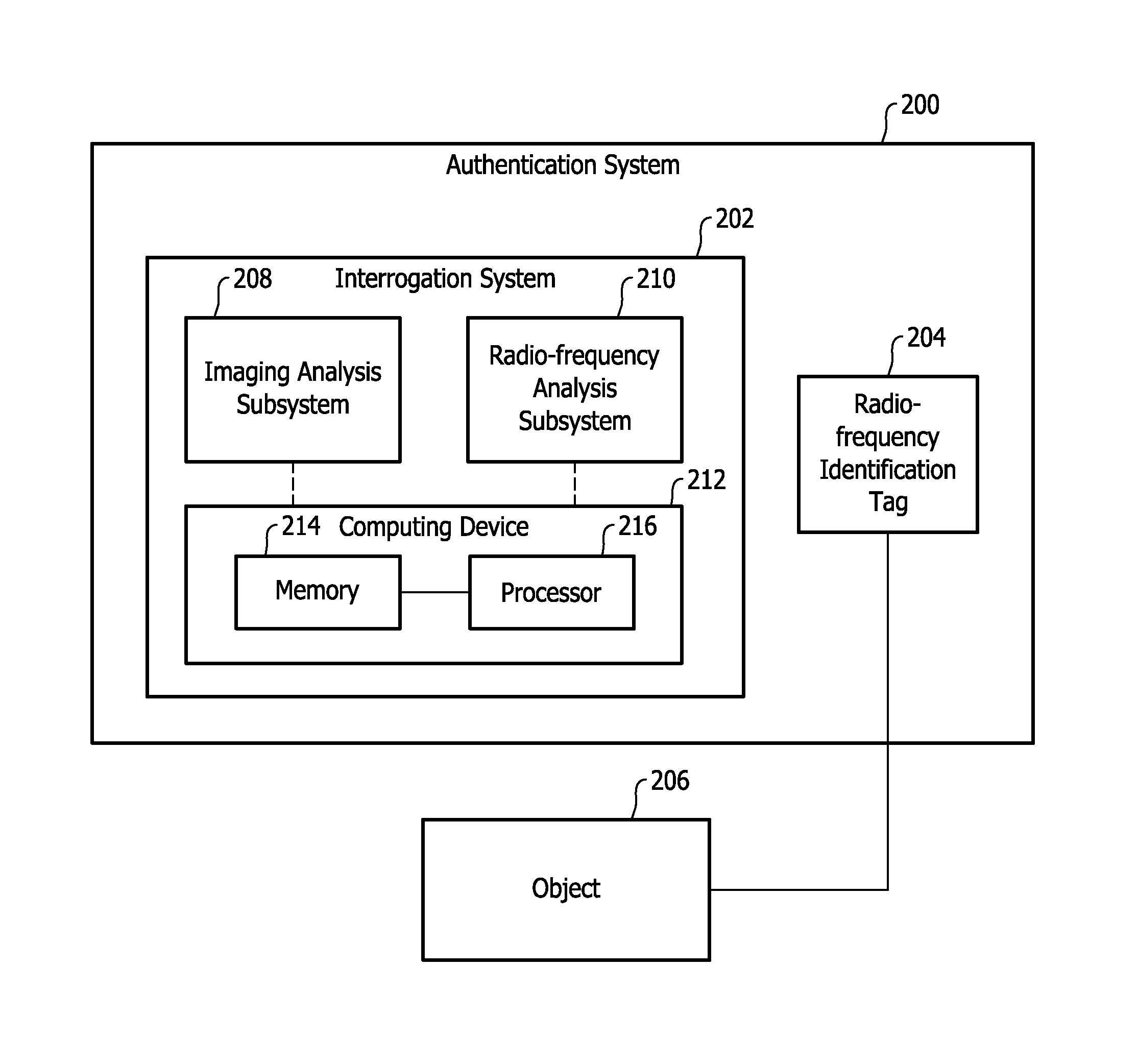

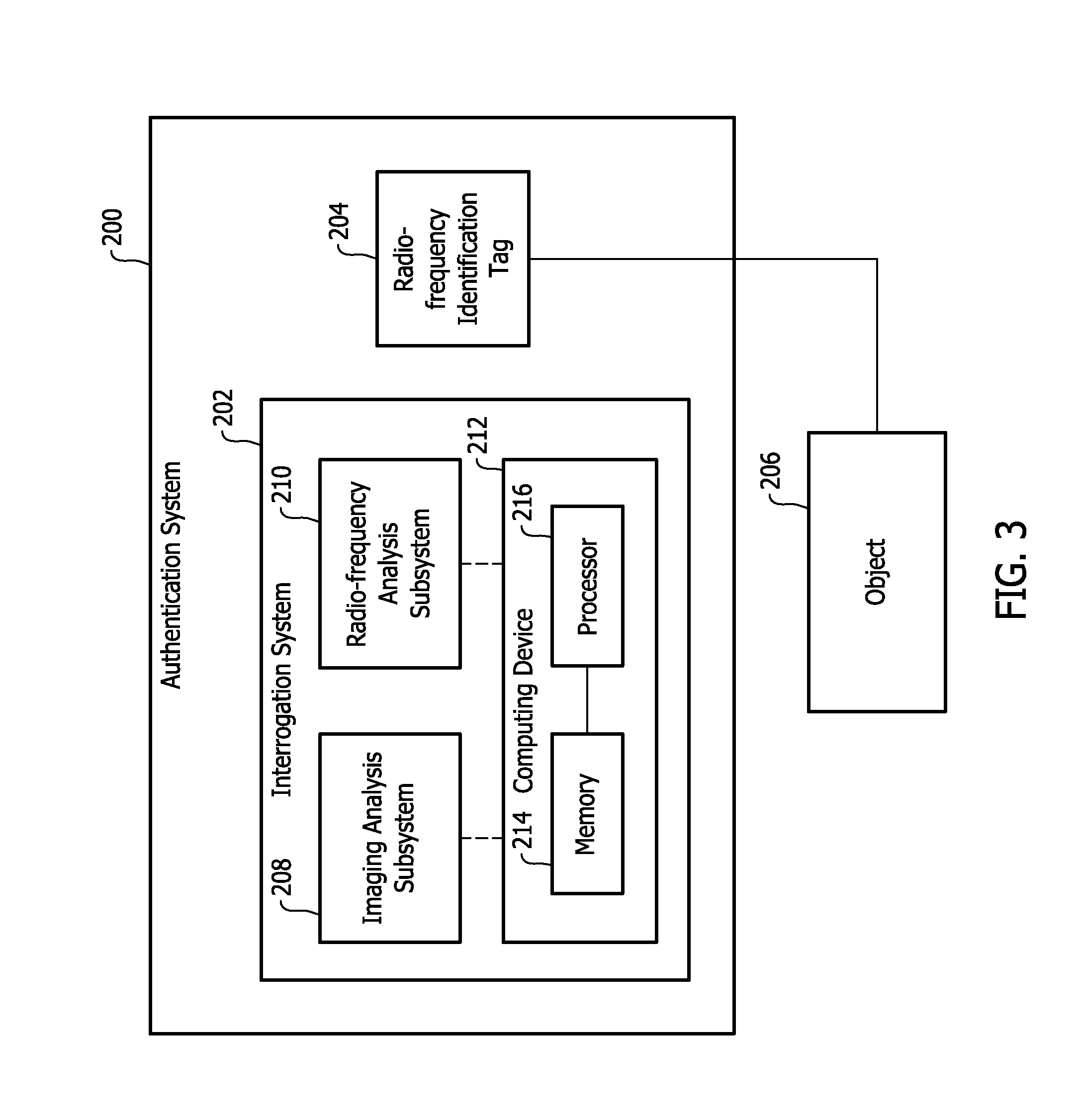

Systems and methods for use in authenticating an object

ActiveUS20150317501A1Programme controlElectric signal transmission systemsBackscatter X-rayEngineering

A system for use in authenticating an object is provided. The system includes a radio-frequency identification tag coupled to the object and an interrogation system. The interrogation system includes a backscatter x-ray source configured to discharge backscatter x-ray beams towards the object. The backscatter x-ray source is calibrated such that the backscatter x-ray beams cause the radio-frequency identification tag to emit a signal. The system also includes a radio-frequency detector configured to receive the signal from the radio-frequency identification tag and a computing device in communication with the radio-frequency detector. The computing device is configured to obtain first identifying information of the object from the signal and authenticate the object from the first identifying information.

Owner:THE BOEING CO

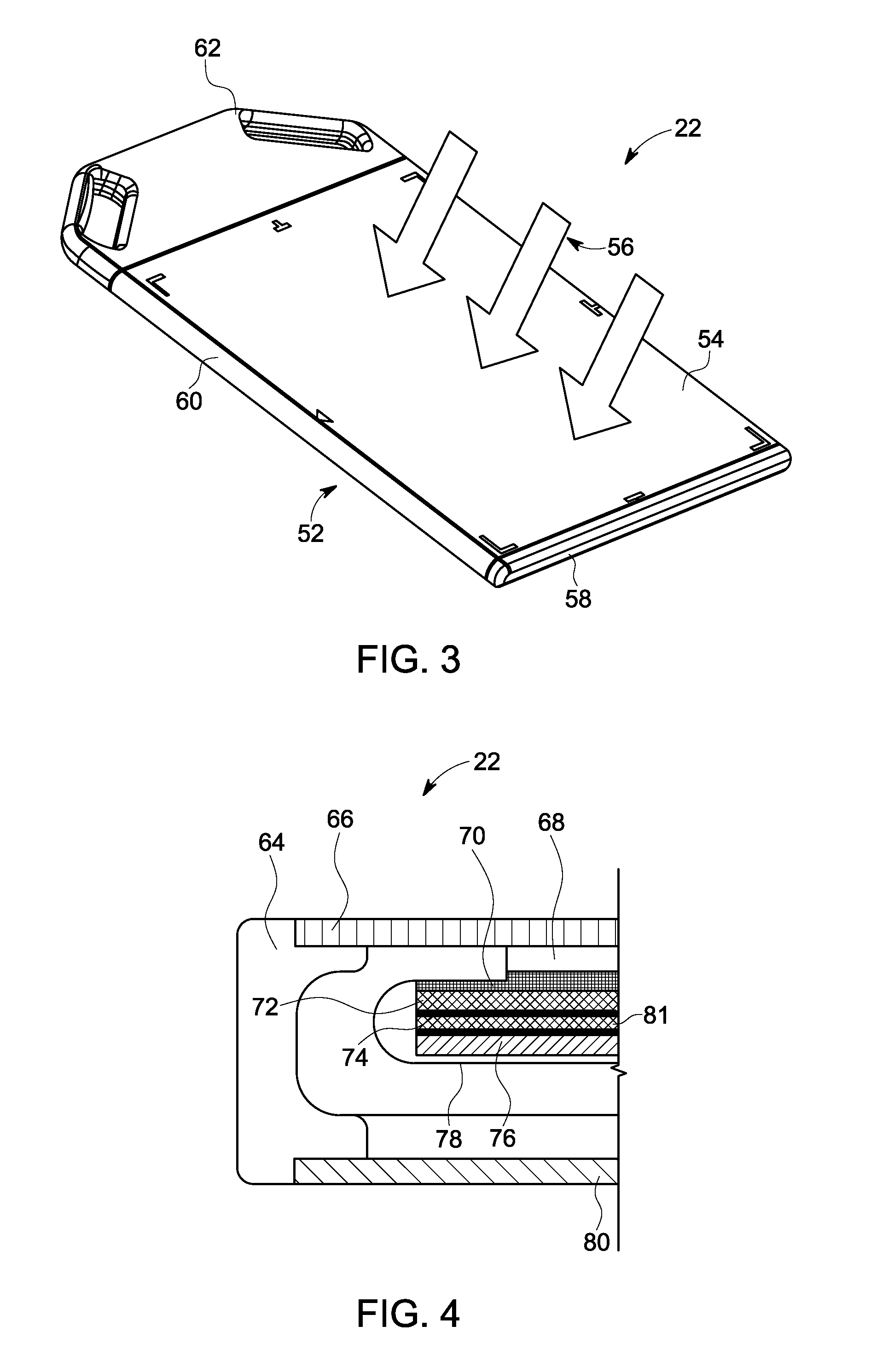

Digital x-ray detector assembly with elastomeric backscatter shield

ActiveUS20140042331A1Material analysis by optical meansSemiconductor/solid-state device manufacturingBackscatter X-rayX-ray

Portable digital X-ray detectors are provided. One X-ray detector includes an outer assembly and a detector assembly disposed within the outer assembly. The detector assembly includes an imager having a scintillator that converts radiographic energy to light and a detector array having one or more detector elements that detect the light from the scintillator. The detector assembly also includes electronic circuitry mounted on at least one printed circuit board and adapted to control operation of the imager during data acquisition and readout. Further, an elastomeric assembly is disposed between the imager and the electronic circuitry, and the elastomeric assembly is configured to absorb backscattered X-rays that pass through the imager or deflect off of a portion of the outer assembly during an X-ray exposure.

Owner:GENERAL ELECTRIC CO

Body Scanner With Improved X-ray Transmission Imaging

ActiveUS20120307968A1Reduce physical sizeEnhanced digital imageMaterial analysis by optical meansMachines/enginesSoft x rayBackscatter X-ray

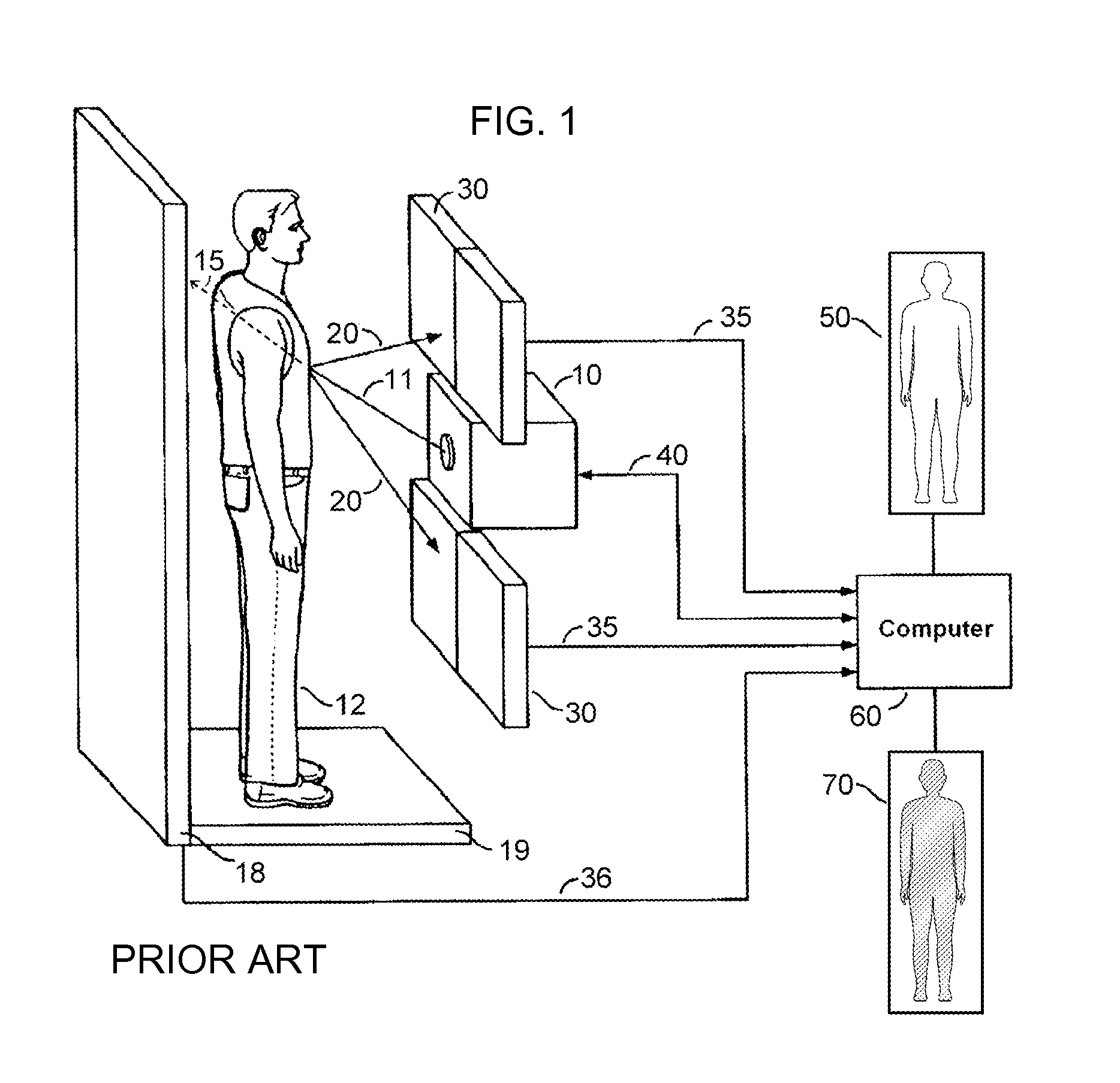

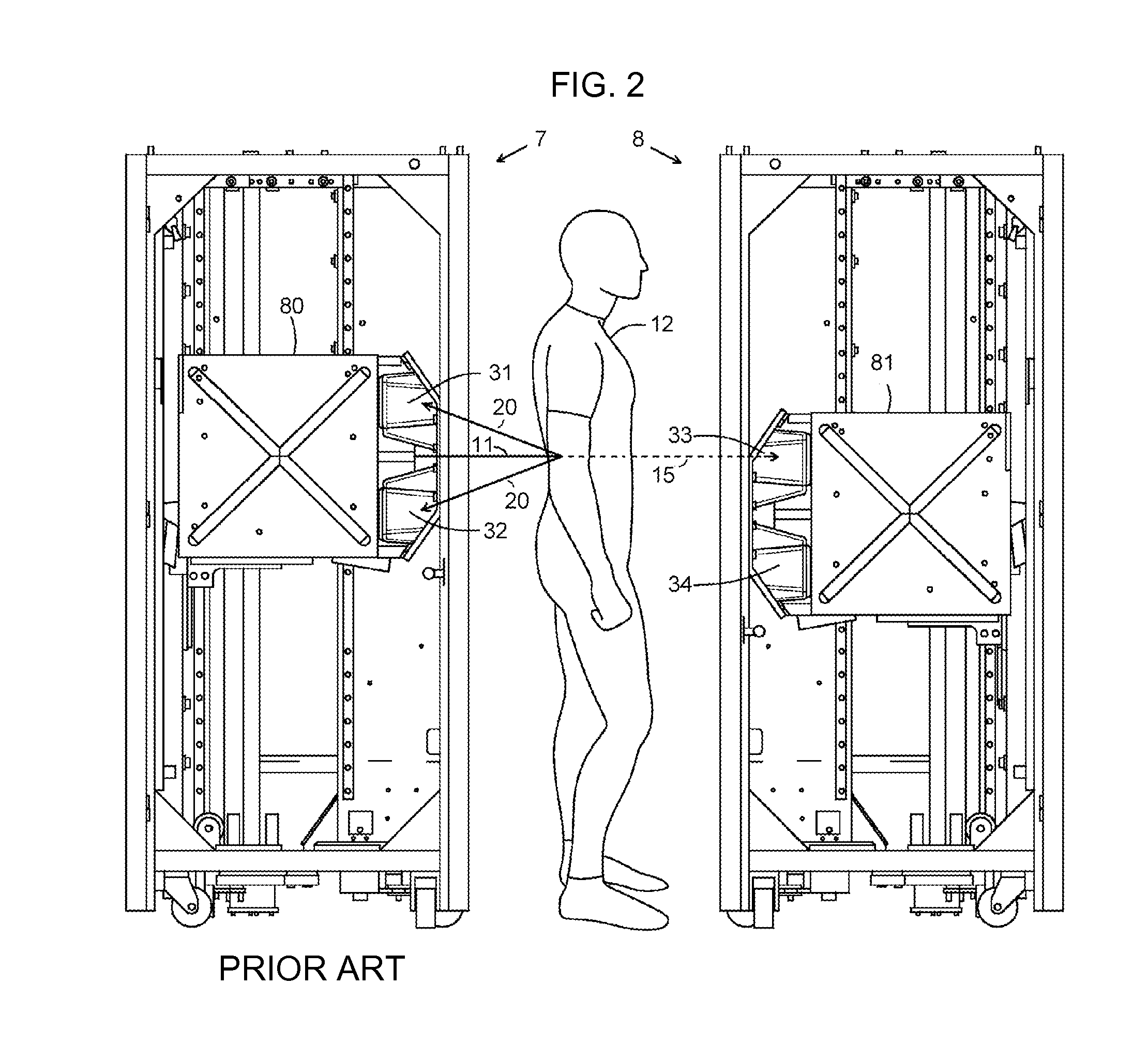

The inventive body scanner is used to screen persons entering a security controlled area for the presence of security threats hidden under the clothing, such as guns, knifes, explosives and contraband. The Invention is an improvement on prior art body scanners that operate primarily by acquiring backscatter x-ray images, but only acquire transmission images over a limited part of the person's body. These prior art systems provide x-ray sources on the anterior and posterior sides of the person being screened, and x-ray sensitive detectors on the sides of these x-ray sources. While sufficient for backscatter imaging, the gaps between these detectors results in blind areas in the transmission images, resulting in lower ability to detect security threats hidden under the clothing. The present Invention overcomes these limitations of the prior art by providing x-ray sensitive detector on the outside of the x-ray sources. That is, the pair of x-ray sources are located within the pair of x-ray detectors, and the person being screened is located within the pair of x-ray sources. In conjunction with this imaging geometry, spatial offsets in the location of the x-ray sources provide effectively full transmission coverage for transmission imaging.

Owner:TEK84 INC

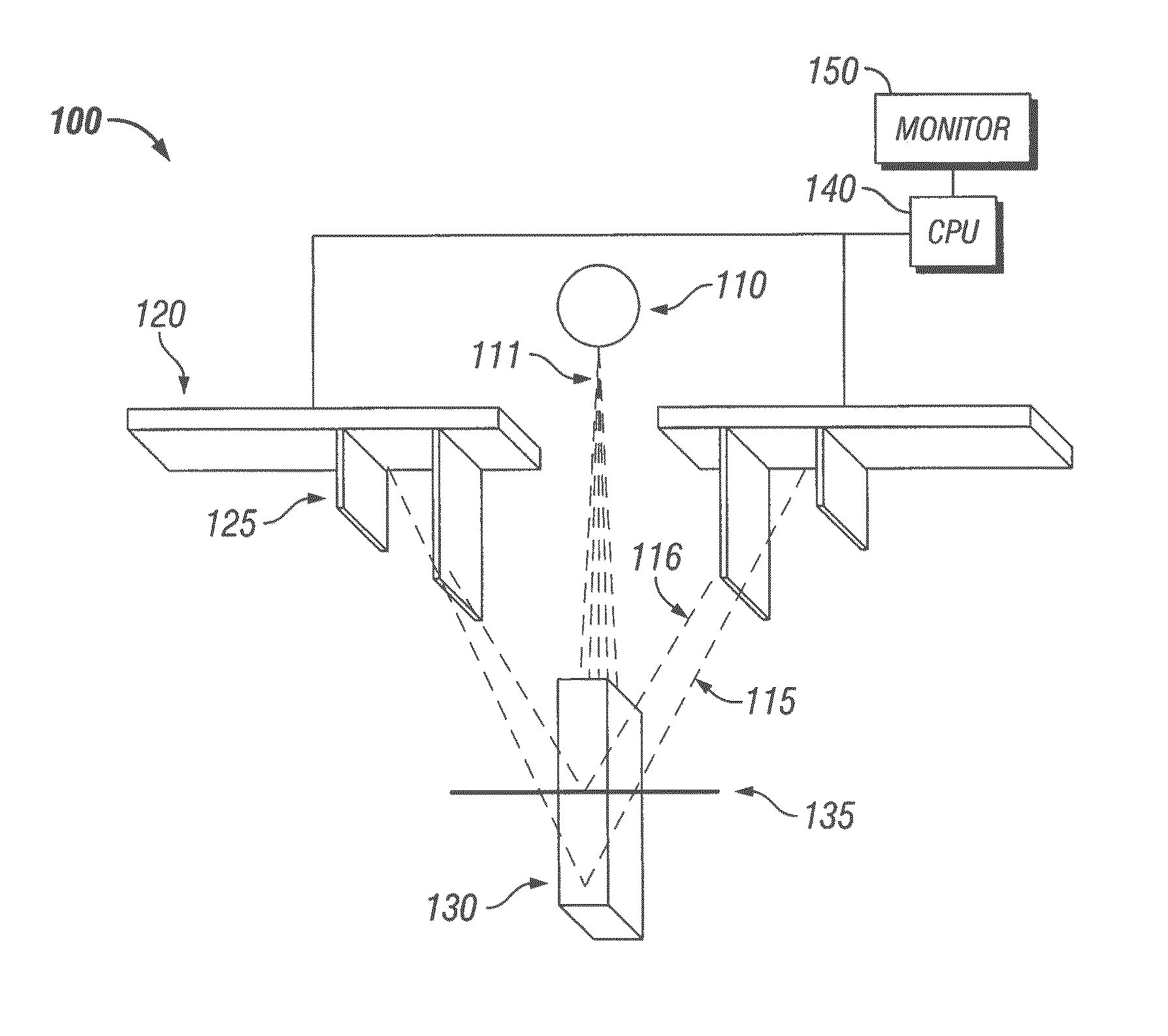

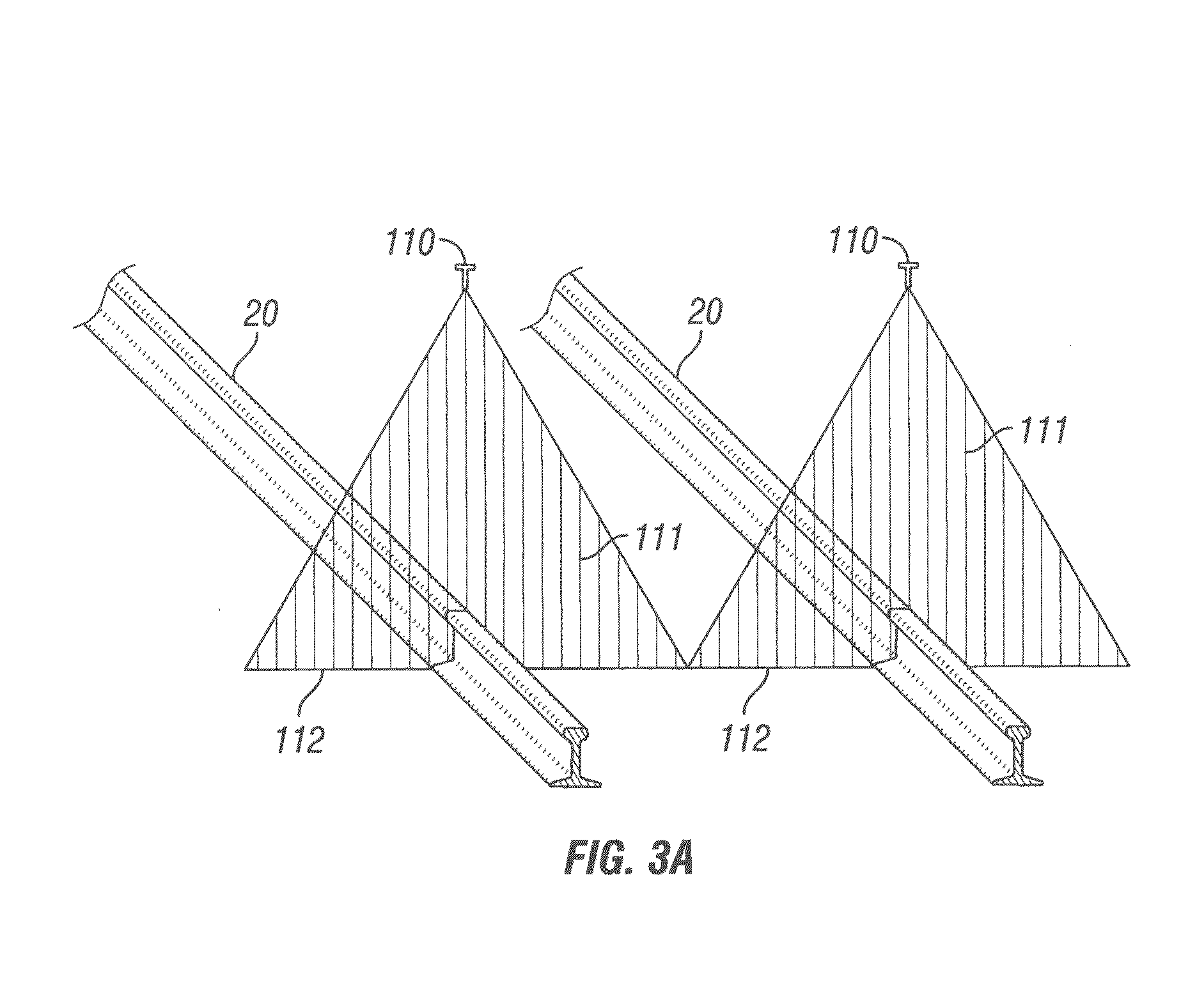

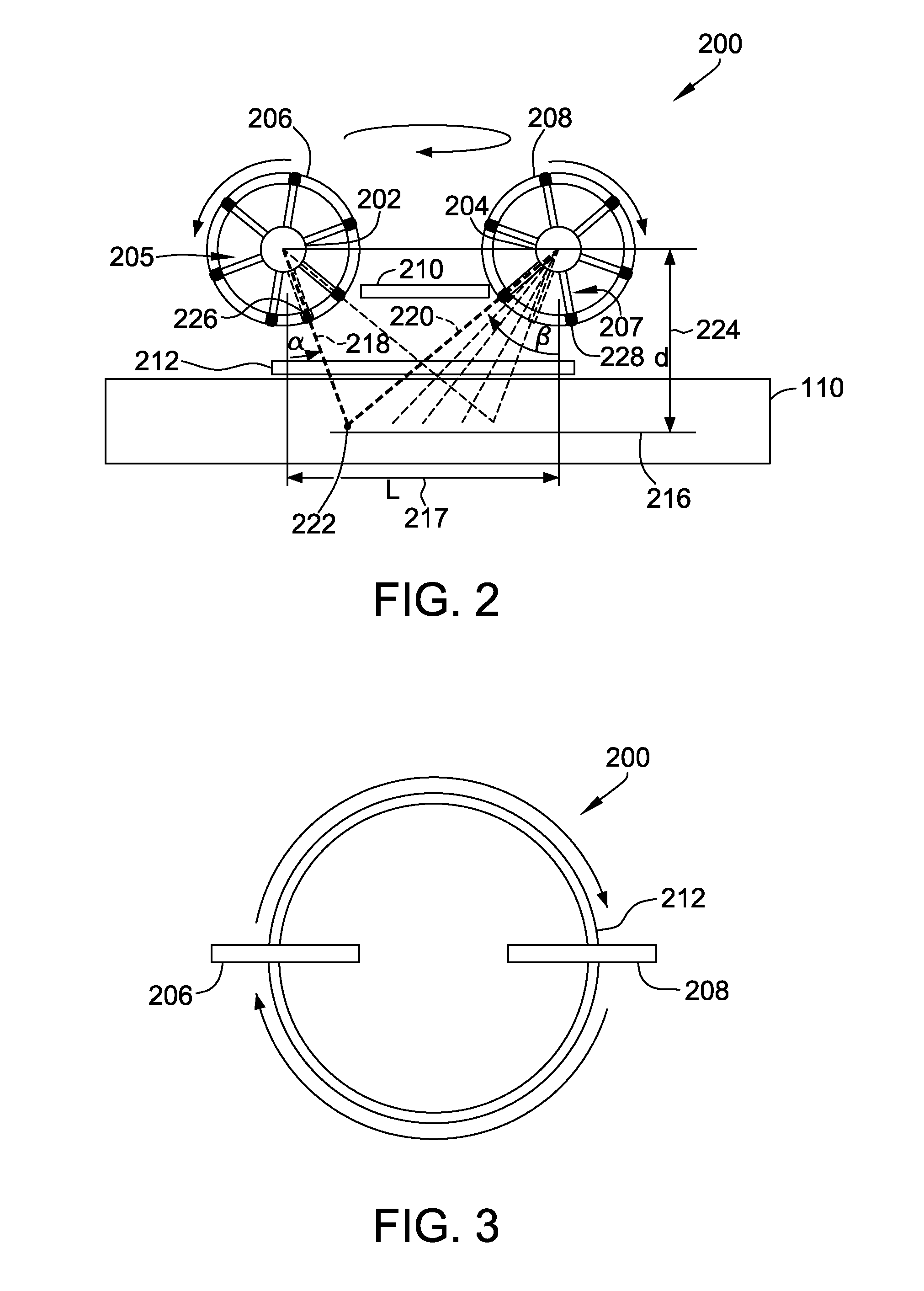

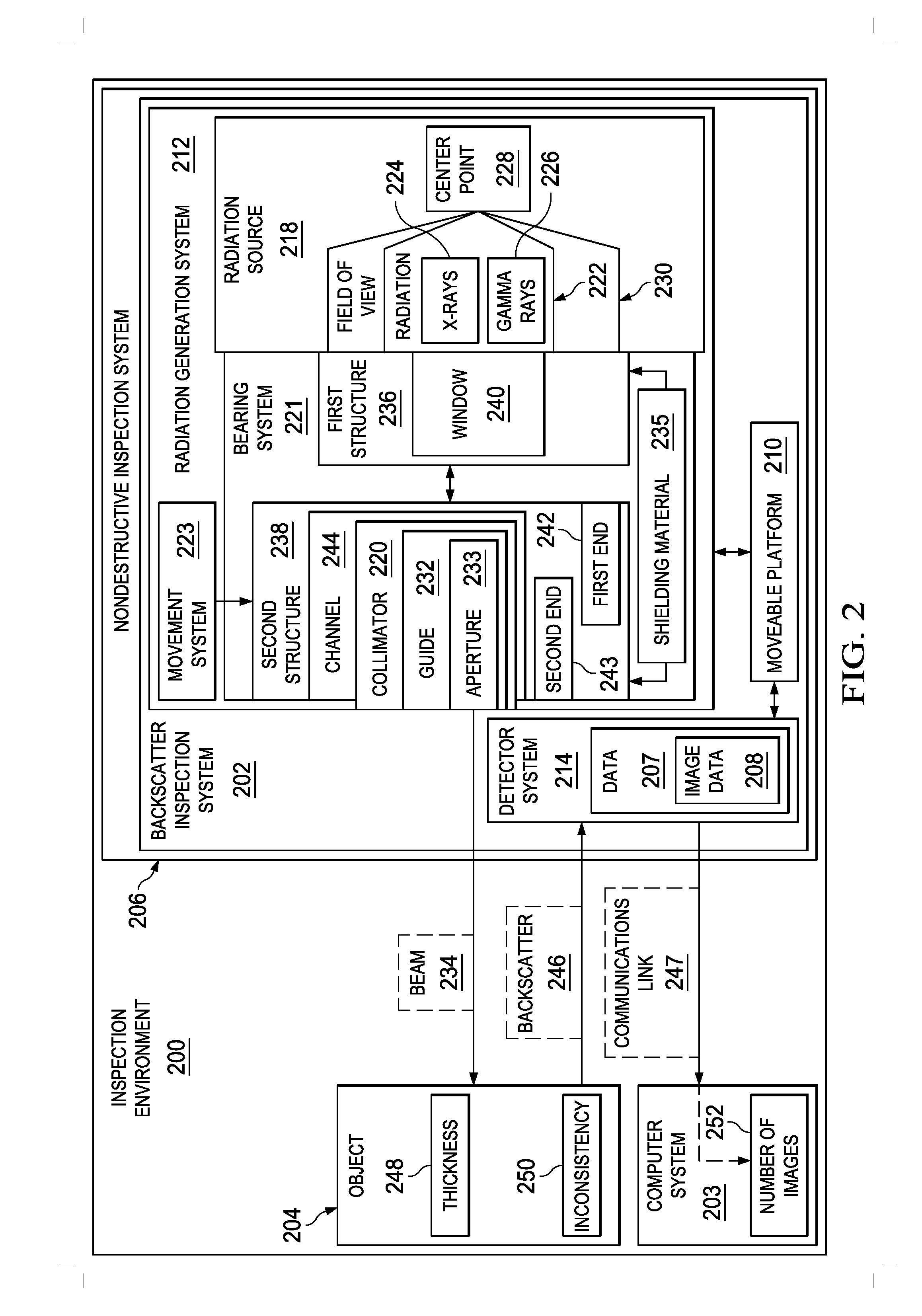

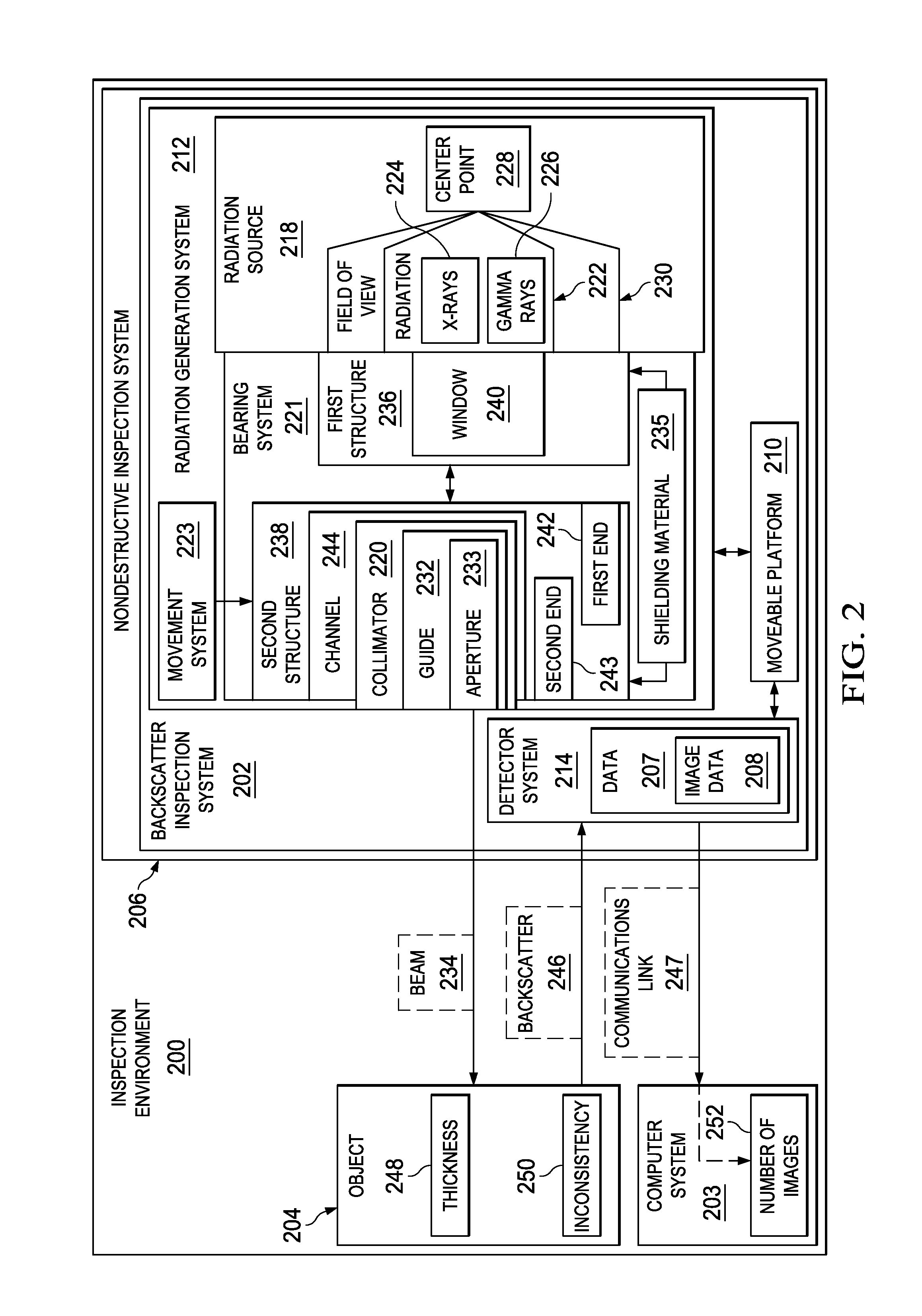

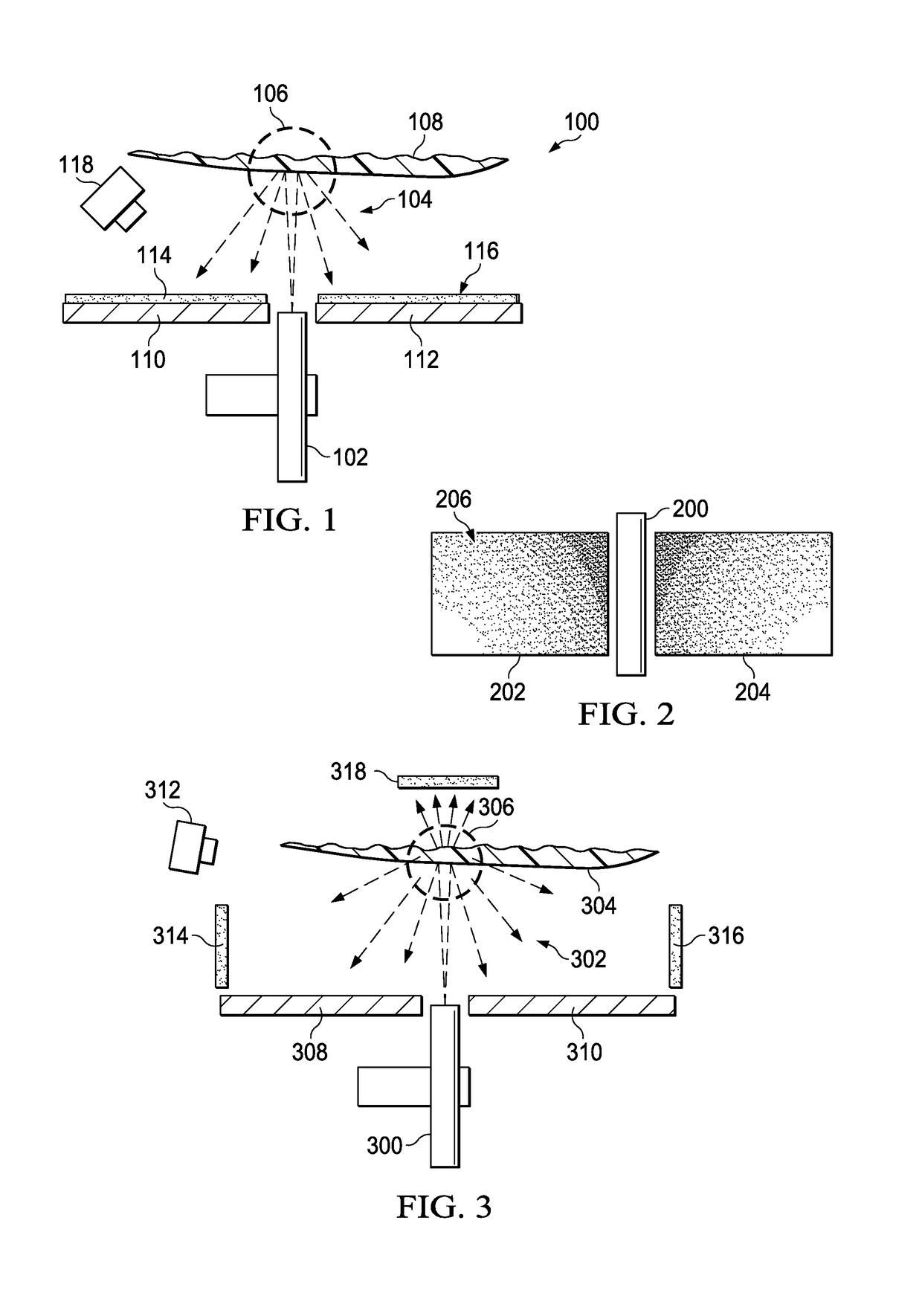

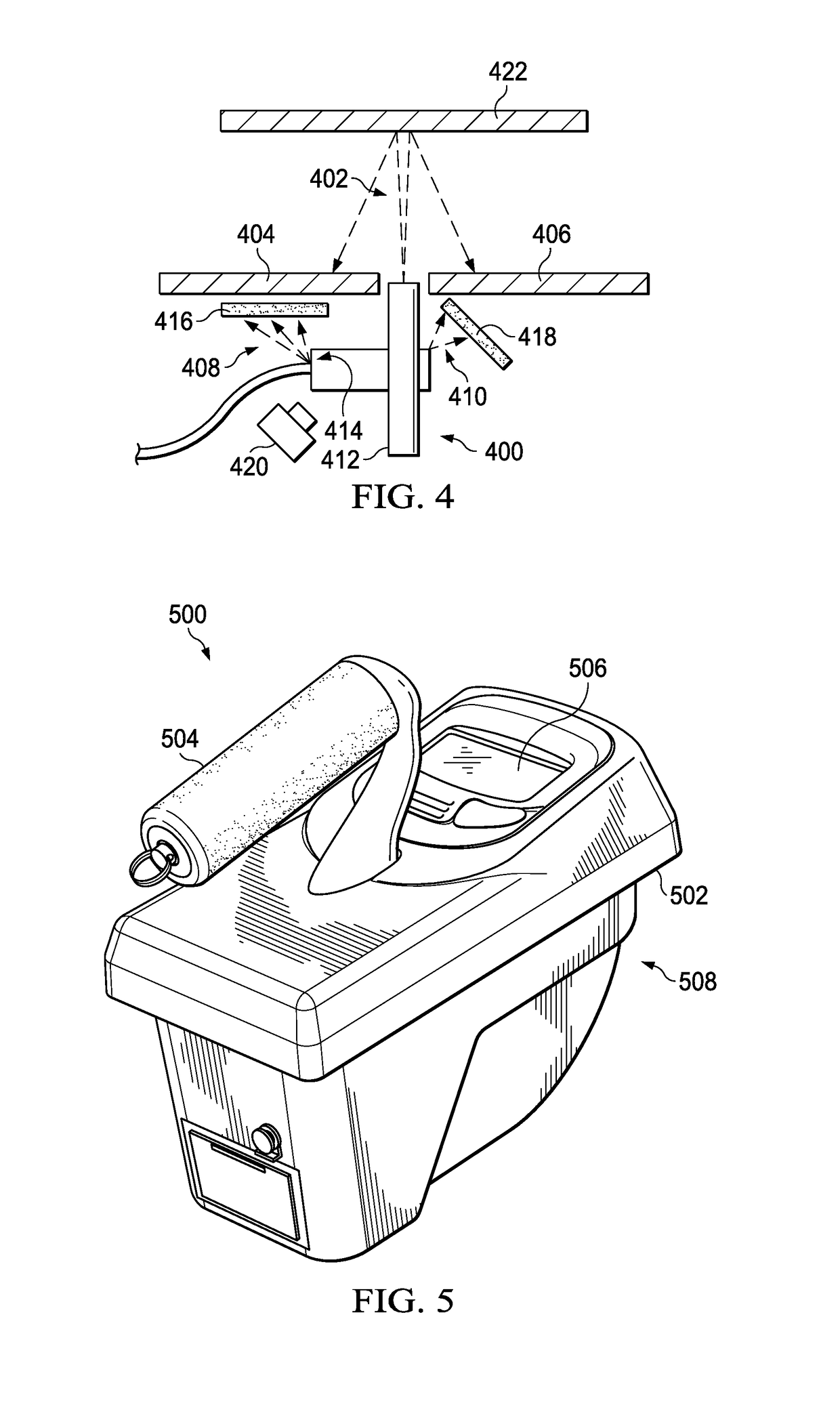

Systems and methods for performing backscatter three dimensional imaging from one side of a structure

ActiveUS20170052125A1Handling using diaphragms/collimetersSterographic imagingBackscatter X-rayX-ray

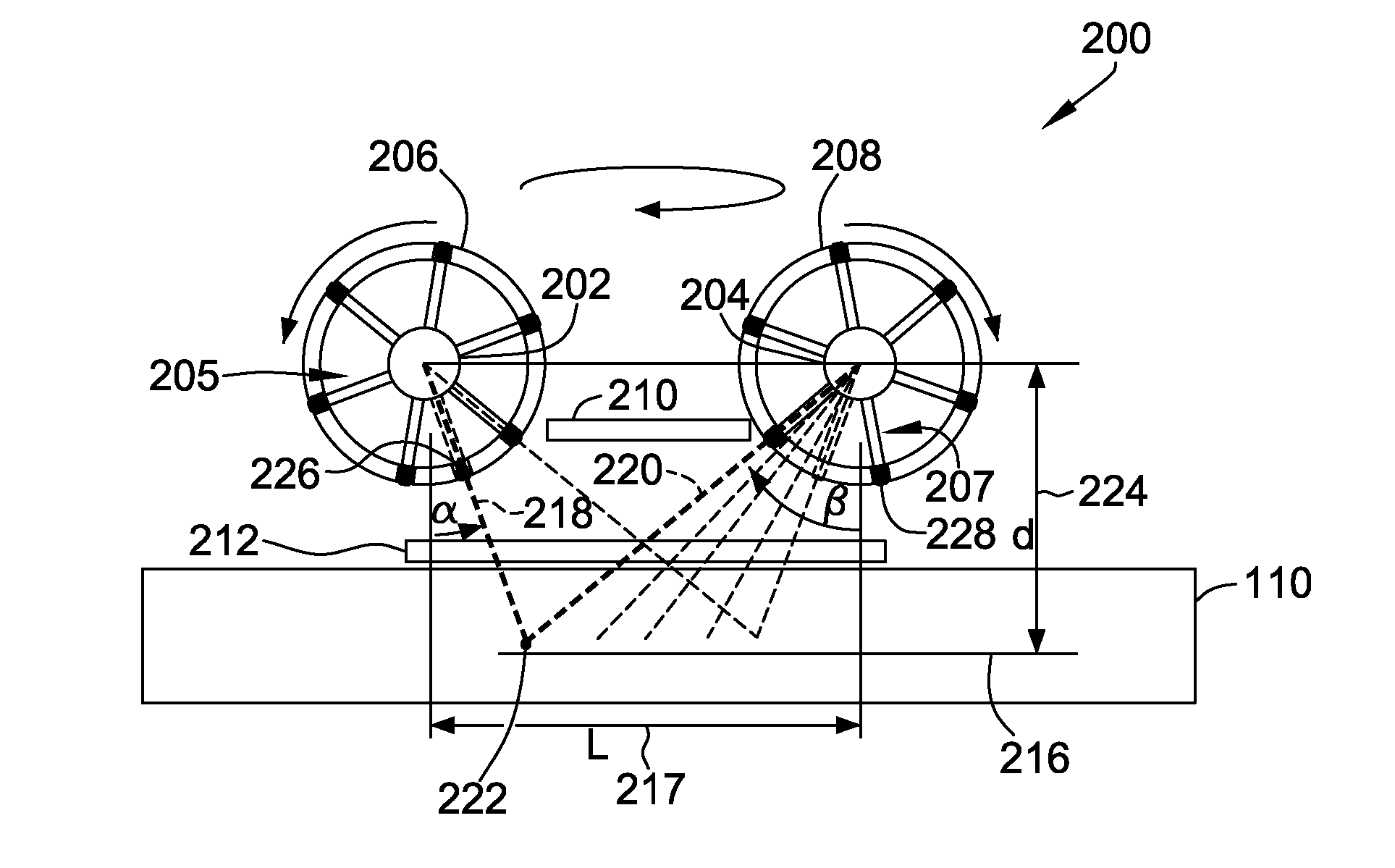

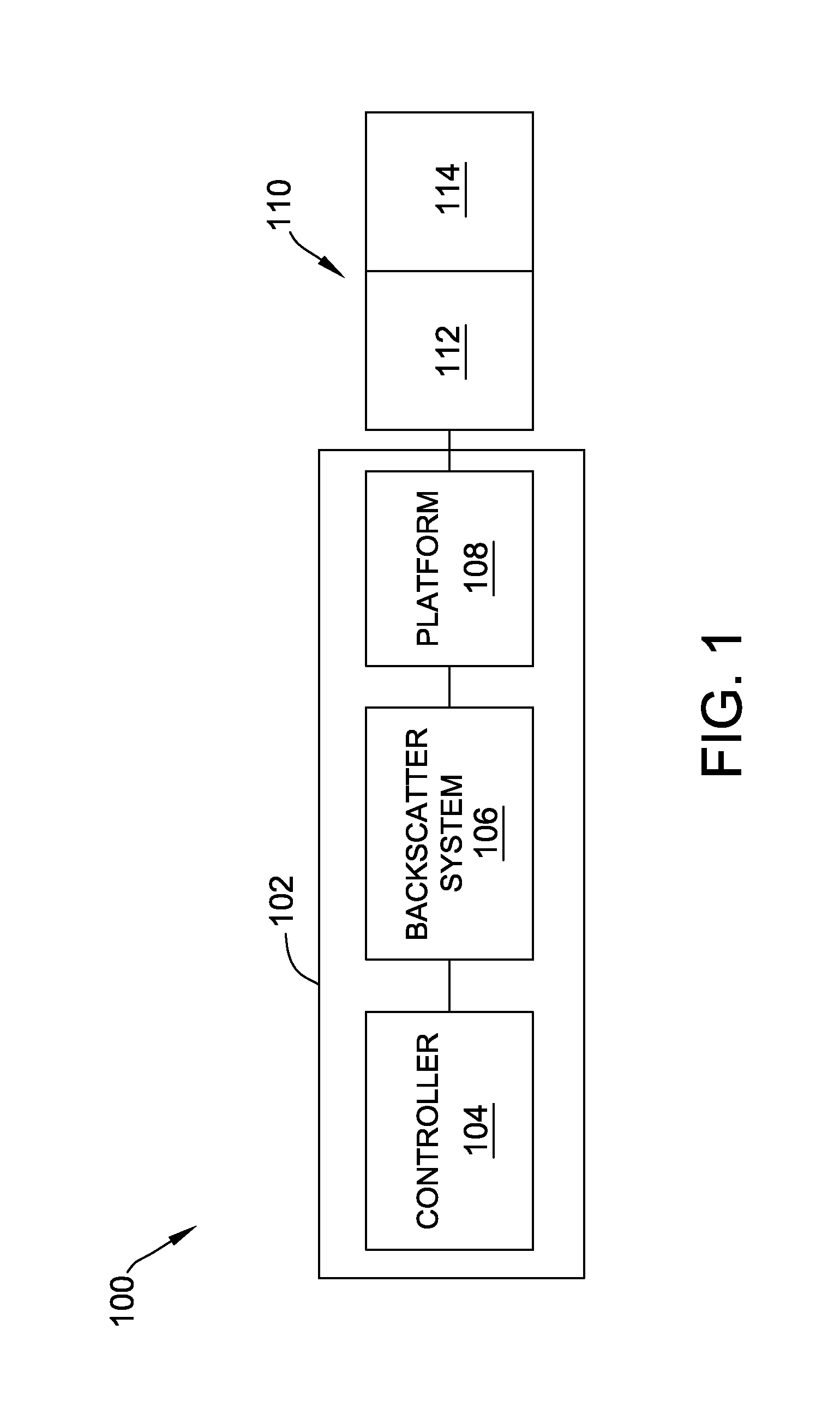

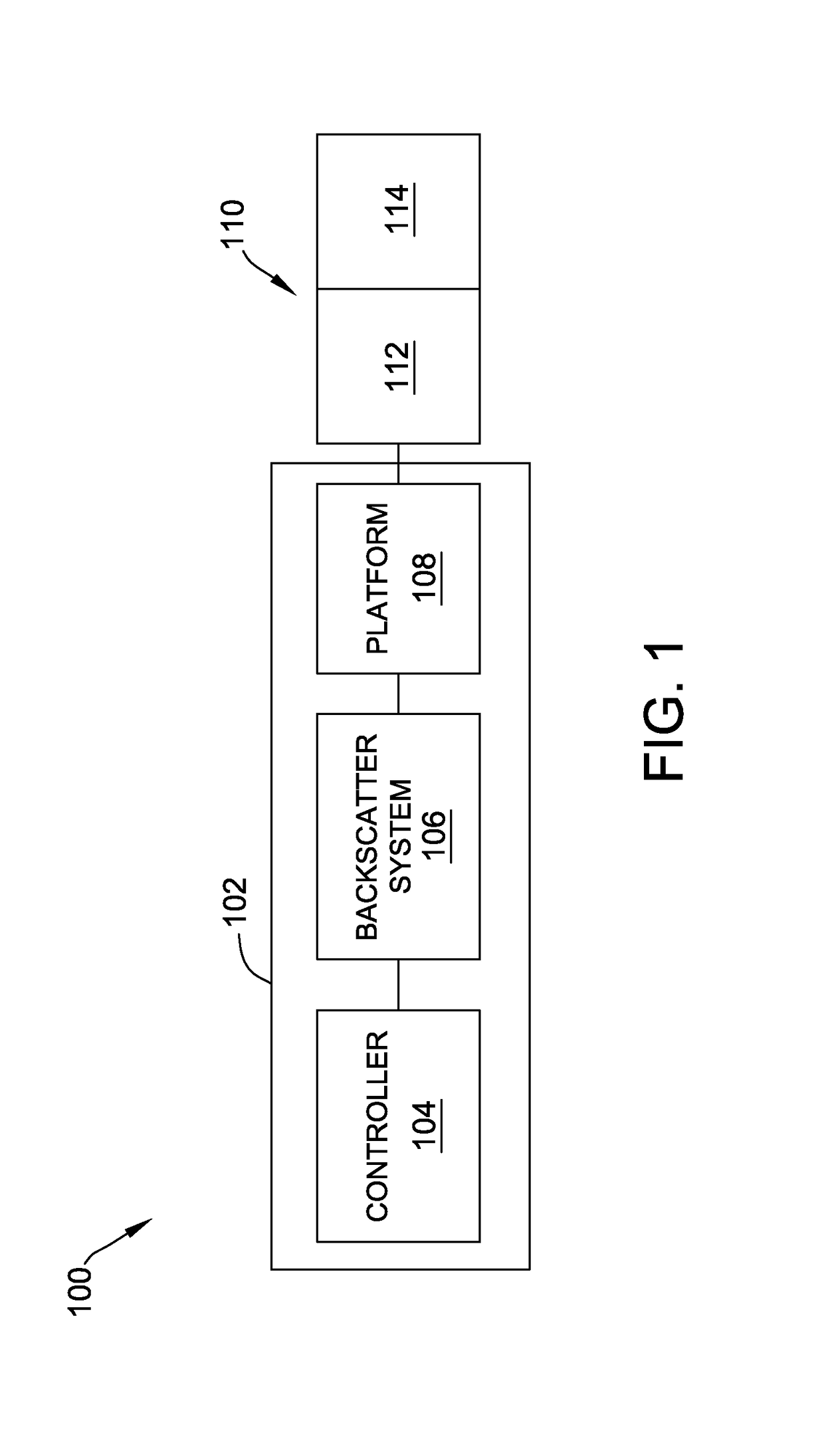

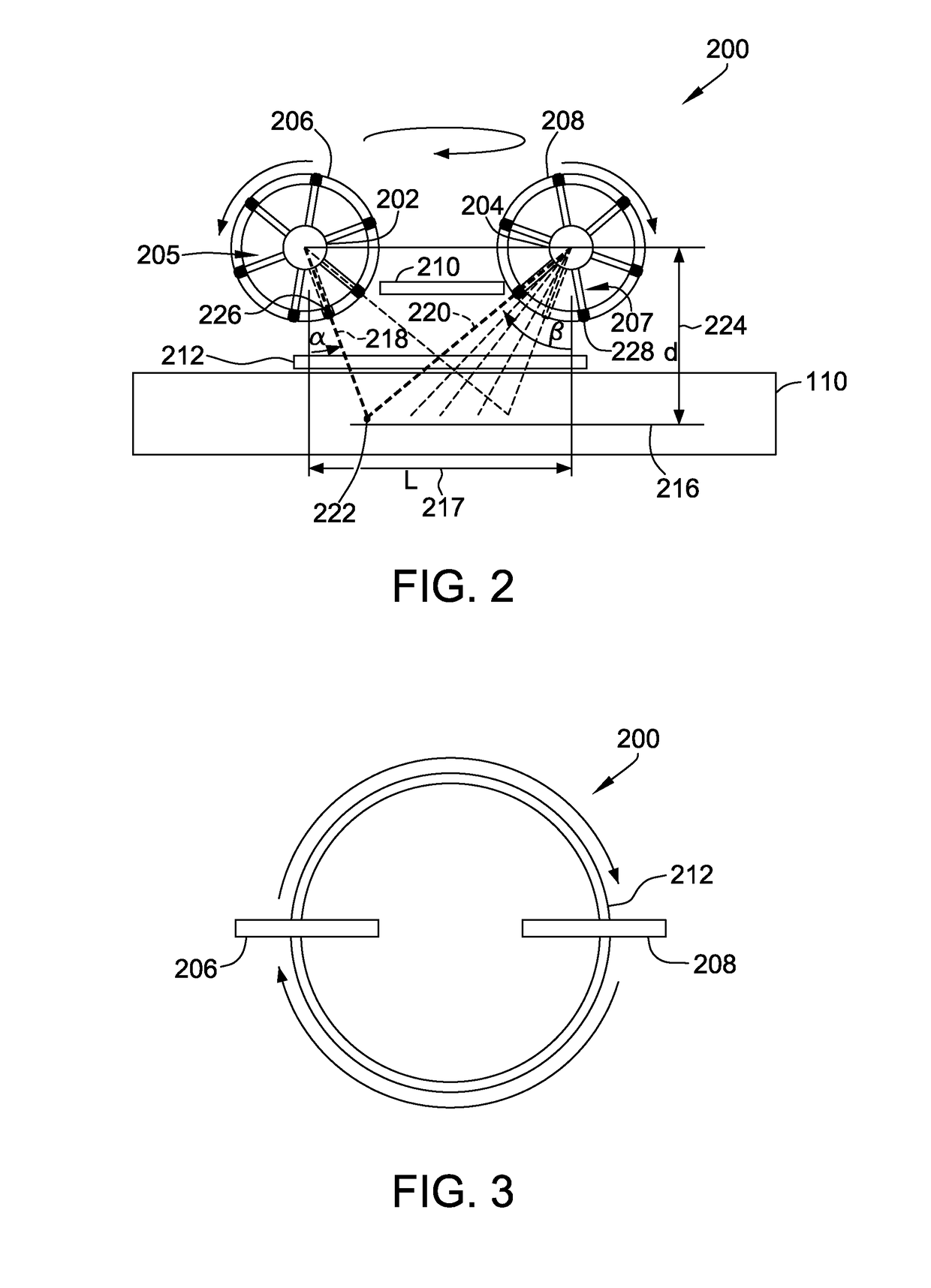

An imaging system for generating three dimensional image data using X-ray backscattering from one side of a structure is provided. The imaging system includes at least one X-ray source, at least one rotating collimator coupled to the at least one X-ray source, an X-ray detector, and a controller coupled to the at least one X-ray source, the at least one rotating collimator and the X-ray detector. The controller is configured to emit X-rays from the at least one X-ray source through the at least one rotating collimator towards the one side of the structure. Additionally, the controller is configured to detect backscattered X-rays from the one side of the structure, using the X-ray detector, at a plurality of depths within the structure. Additionally, the controller is configured to generate three dimensional image data of the structure based on the detected backscattered X-rays.

Owner:THE BOEING CO

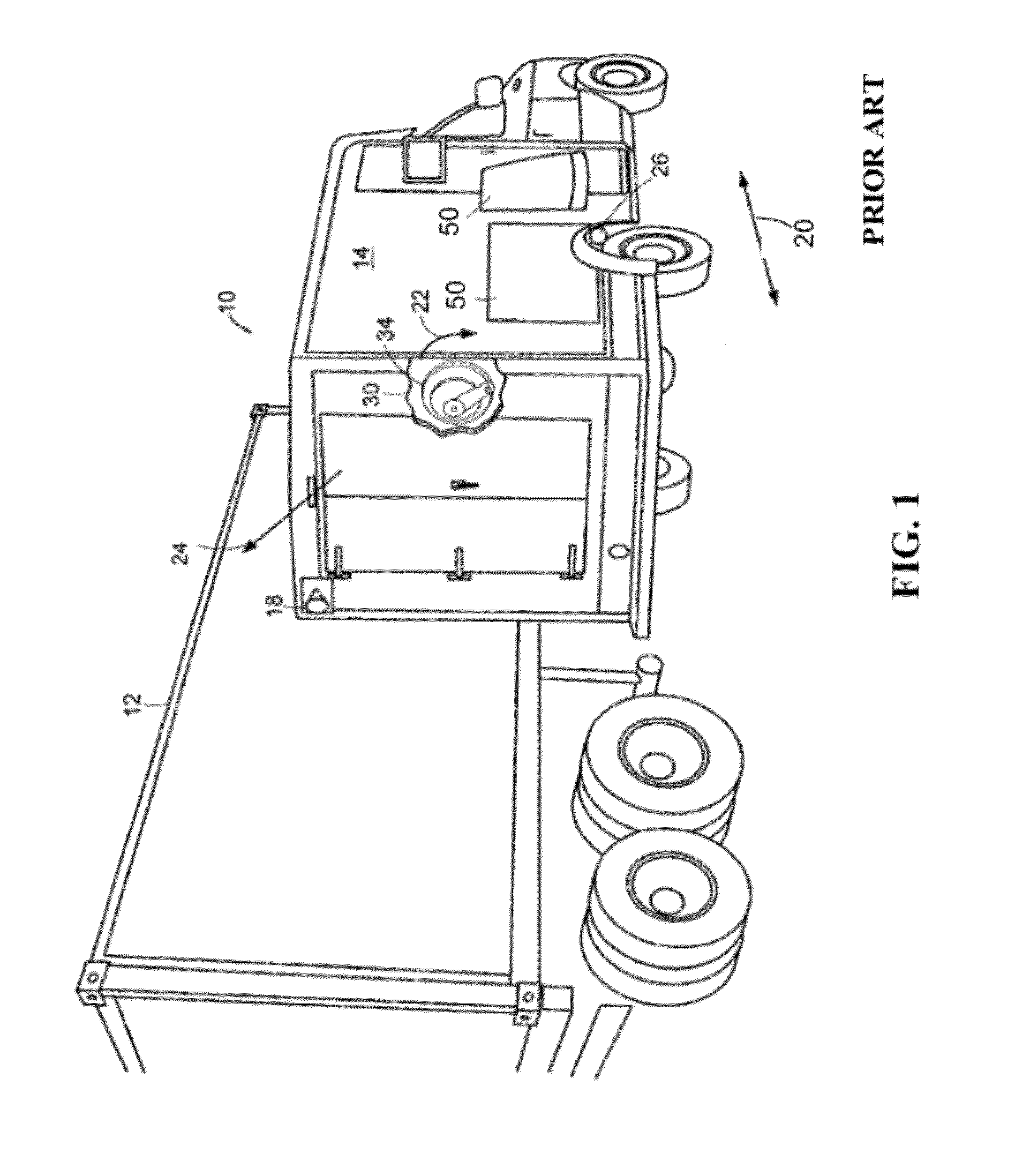

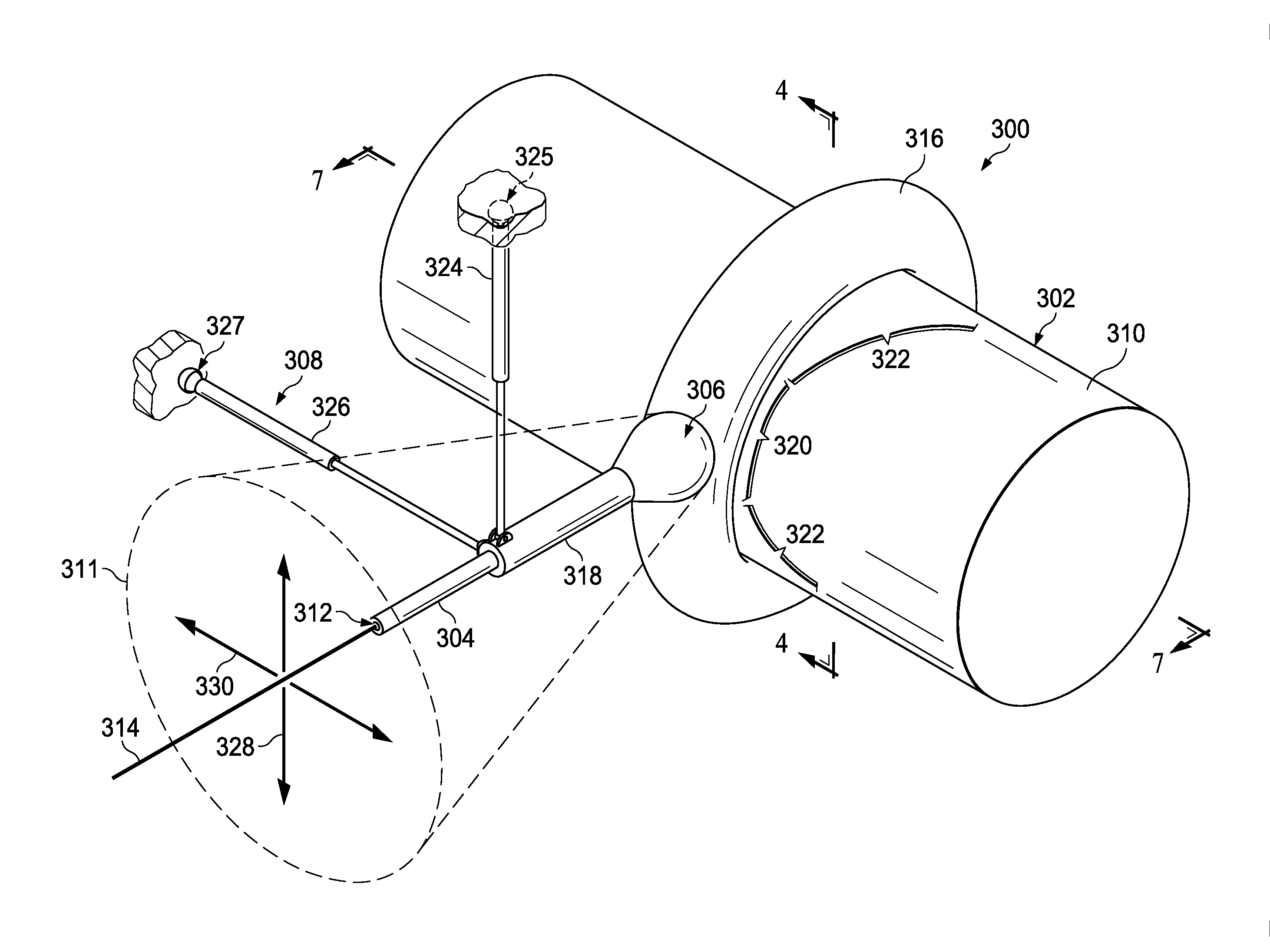

Single Beam Backscatter X-Ray System

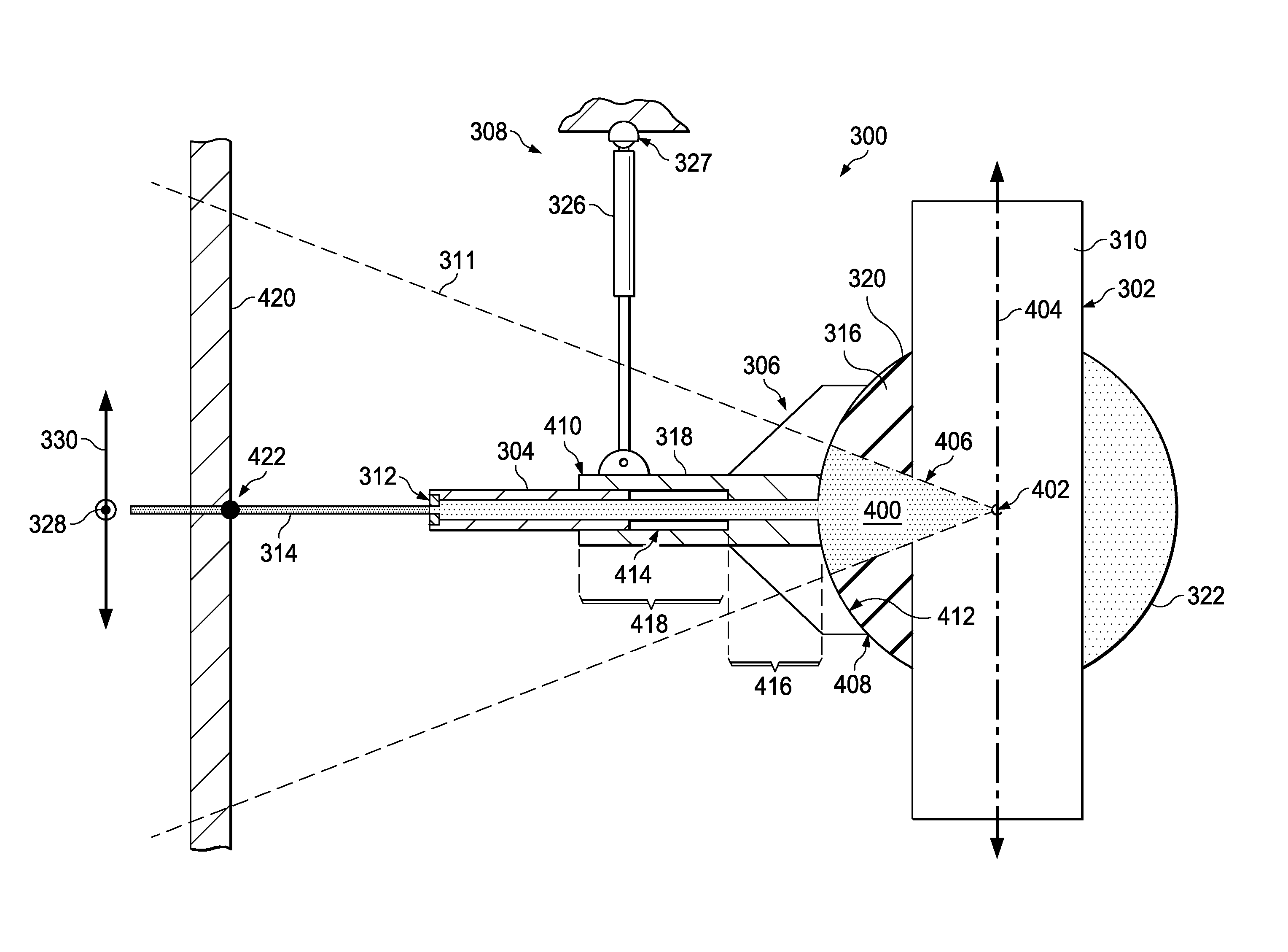

ActiveUS20130287169A1Thermometer detailsHandling using diaphragms/collimetersBackscatter X-rayLight beam

A method and apparatus for inspecting an object is present. Radiation is emitted from a radiation source. A beam is formed from a portion of the radiation emitted by the radiation source using a collimator. The collimator is connected to the radiation source by a bearing system comprising a first structure associated with the radiation source and a second structure connected to the first structure. The second structure is configured to hold the collimator. The second structure of the bearing system is moved using a movement system such that the second structure rotates in one of a plurality of directions substantially about a center point in the radiation source while the radiation source remains stationary relative to the second structure. Rotation of the second structure substantially about the center point in the radiation source changes a direction in which the beam is directed.

Owner:THE BOEING CO

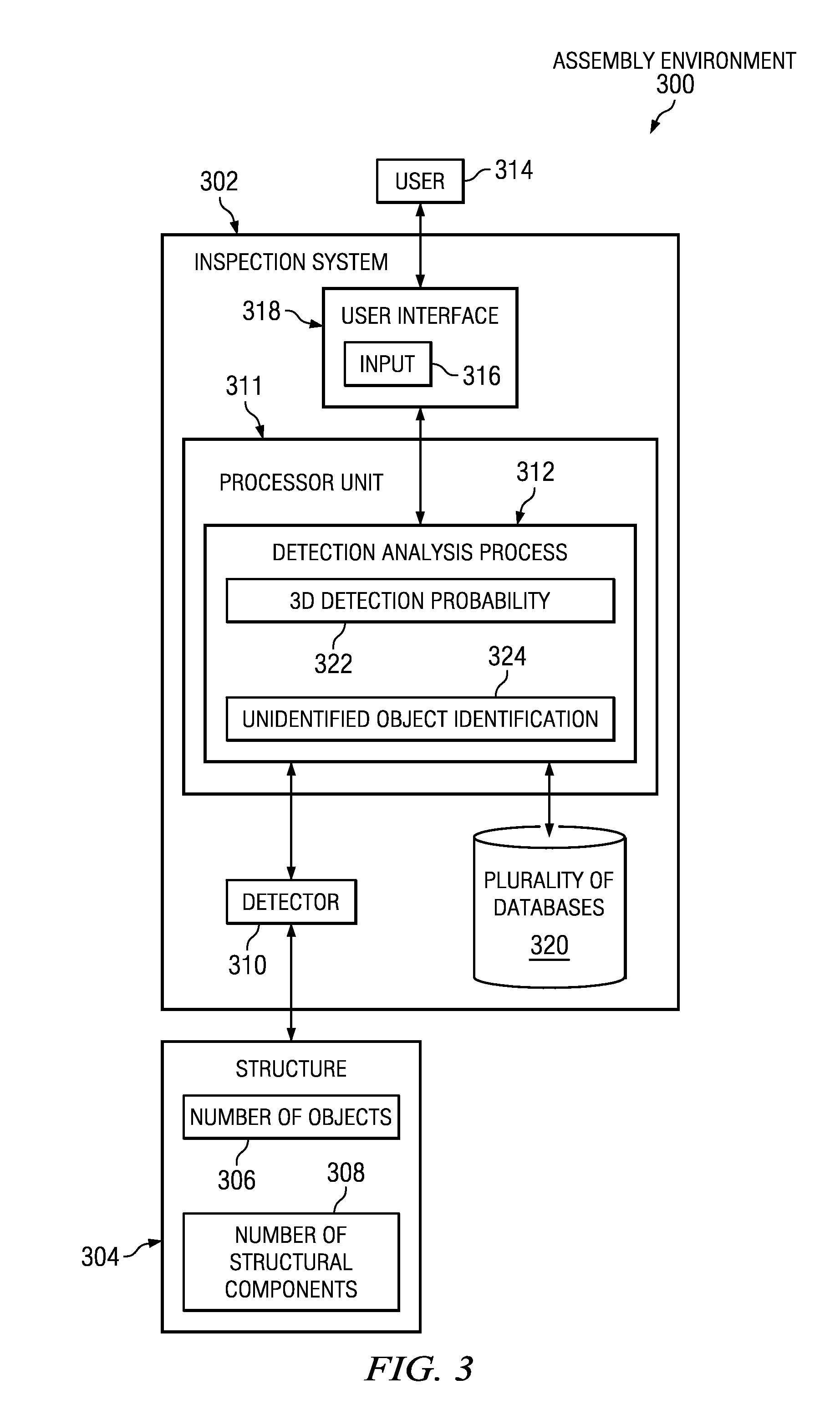

Method and system to predict detectability and identify foreign objects

ActiveUS7983387B1Using wave/particle radiation meansMaterial analysis by transmitting radiationBackscatter X-rayForeign object

The different advantageous embodiments provide a system for identifying a likelihood of detecting objects with a backscatter x-ray system comprising a structure having a number of objects, a plurality of databases, and a processor unit configured to execute a detection analysis process. The processor unit executes the detection analysis process to identify the number of objects, identify a number of densities associated with each of the number of objects, determine a likelihood of detecting each of the number of objects with the backscatter x-ray system, and generate a three-dimensional diagram of the likelihood of detecting each of the number of objects.

Owner:THE BOEING CO

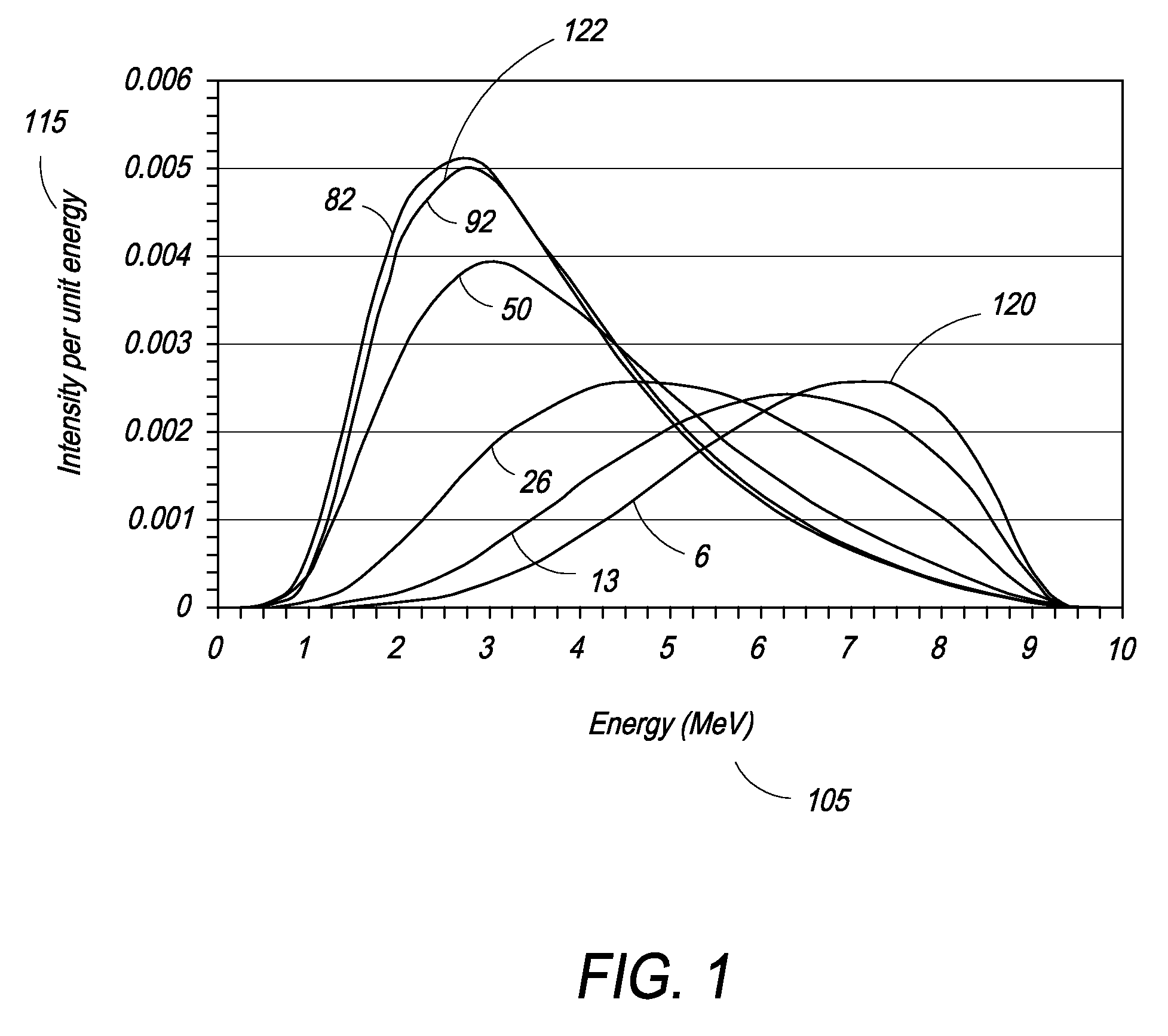

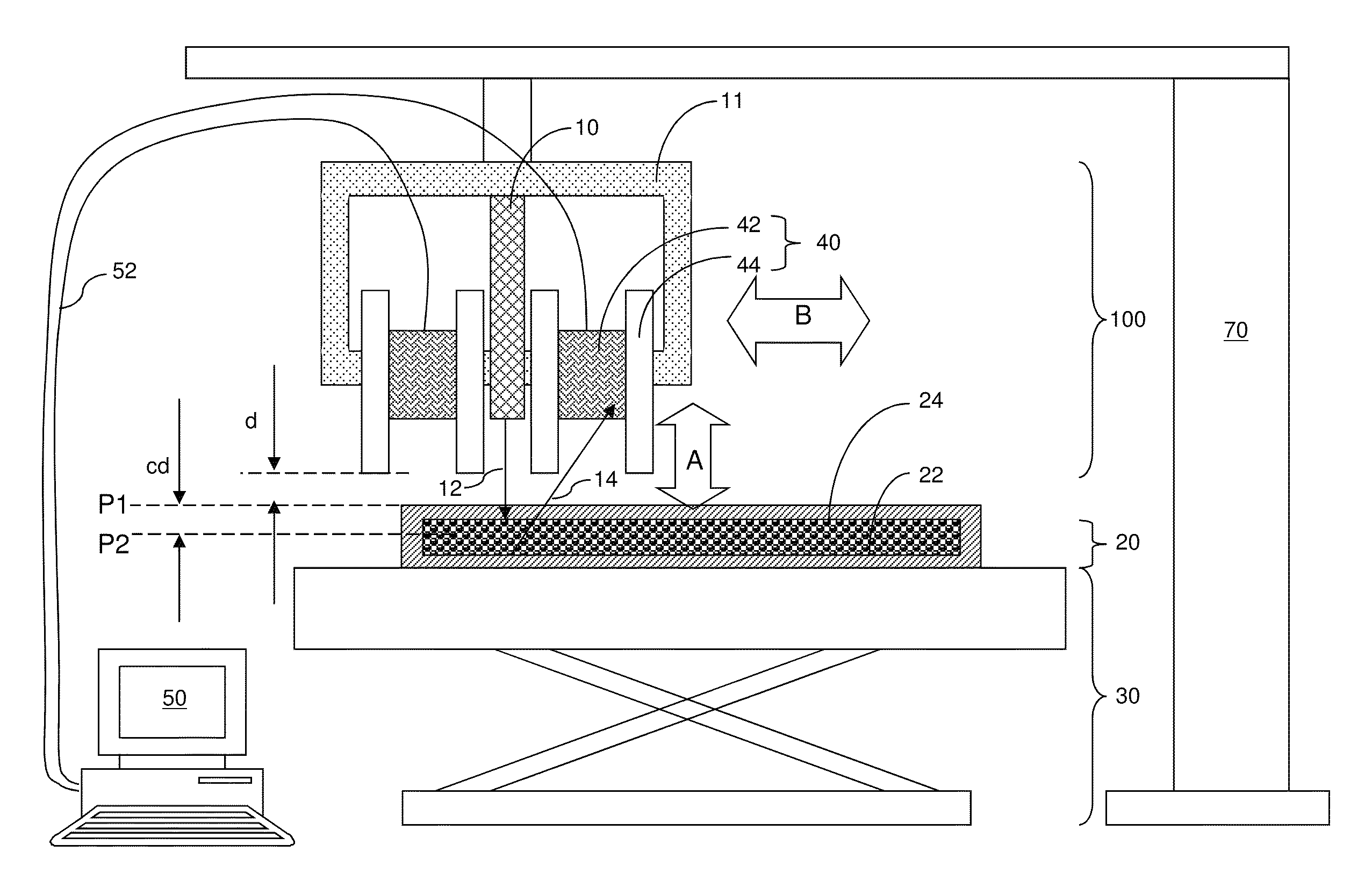

X-ray backscatter imaging of nuclear materials

ActiveUS8848871B2Material analysis using wave/particle radiationUsing wave/particle radiation meansBackscatter X-rayX-ray

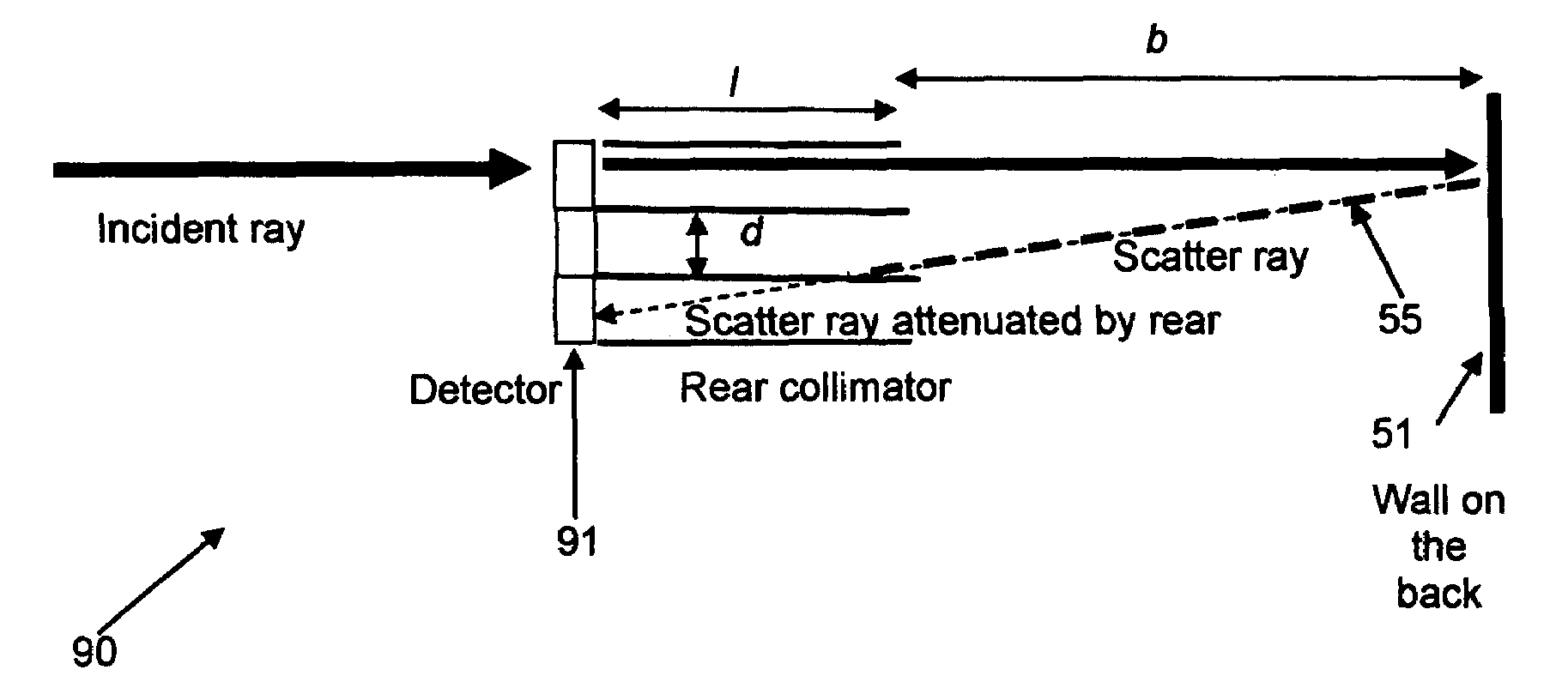

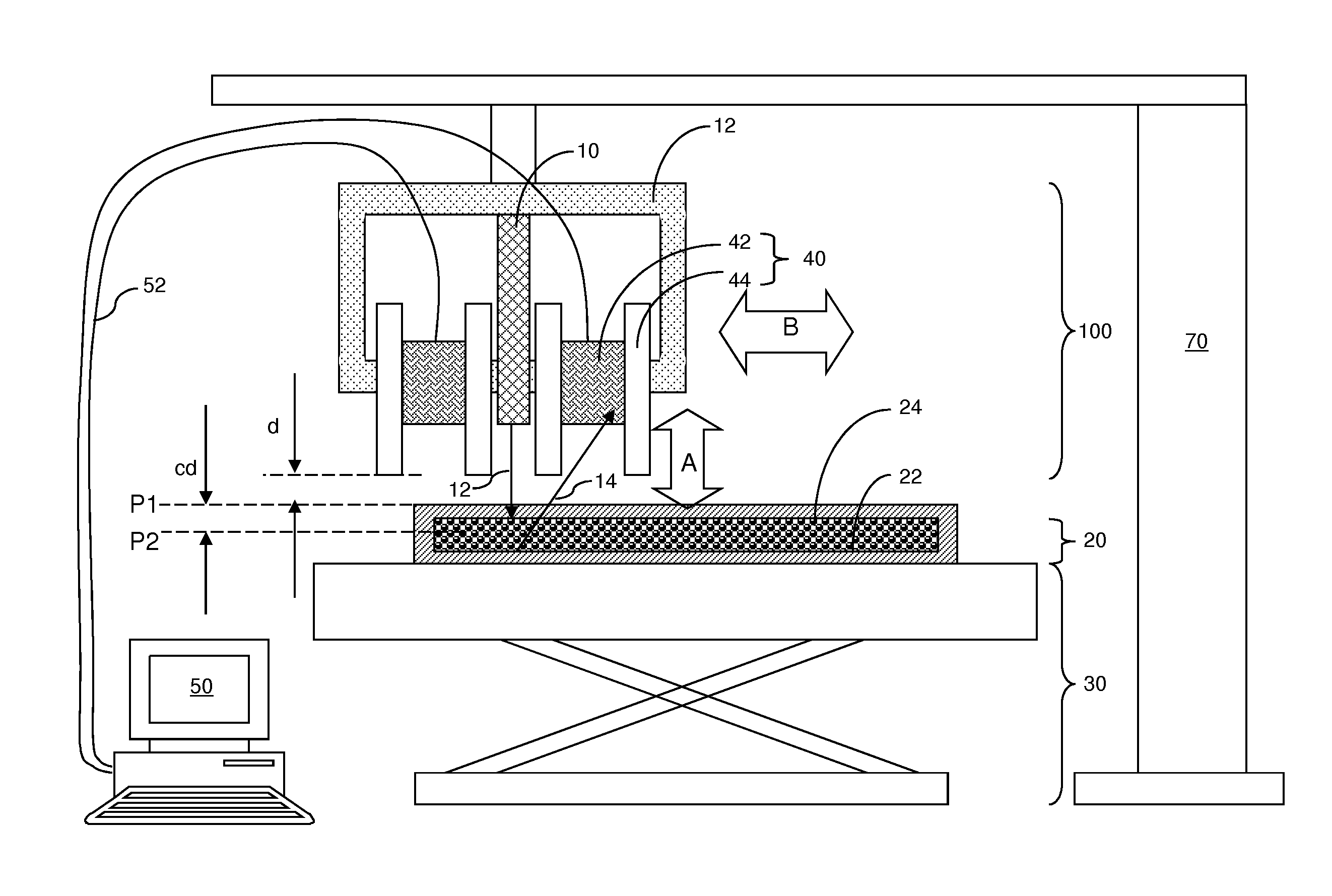

The energy of an X-ray beam and critical depth are selected to detect structural discontinuities in a material having an atomic number Z of 57 or greater. The critical depth is selected by adjusting the geometry of a collimator that blocks backscattered radiation so that backscattered X-ray originating from a depth less than the critical depth is not detected. Structures of Lanthanides and Actinides, including nuclear fuel rod materials, can be inspected for structural discontinuities such as gaps, cracks, and chipping employing the backscattered X-ray.

Owner:UT BATTELLE LLC

Single beam backscatter x-ray system

InactiveUS9123450B2Thermometer detailsHandling using diaphragms/collimetersBackscatter X-rayLight beam

A method and apparatus for inspecting an object is present. Radiation is emitted from a radiation source. A beam is formed from a portion of the radiation emitted by the radiation source using a collimator. The collimator is connected to the radiation source by a bearing system comprising a first structure associated with the radiation source and a second structure connected to the first structure. The second structure is configured to hold the collimator. The second structure of the bearing system is moved using a movement system such that the second structure rotates in one of a plurality of directions substantially about a center point in the radiation source while the radiation source remains stationary relative to the second structure. Rotation of the second structure substantially about the center point in the radiation source changes a direction in which the beam is directed.

Owner:THE BOEING CO

Methods and systems for enhancing backscatter X-ray foreign object debris detection

ActiveUS8542876B1Material analysis using wave/particle radiationCharacter and pattern recognitionForeign matterBackscatter X-ray

A method for detecting an anomaly associated with a structure is described. The method includes obtaining a baseline scan of the structure, changing at least one condition associated with the structure which is intended to impart a movement of the structure or a movement of objects within the structure, obtaining a secondary scan of the structure, the secondary scan obtained from a same position, with respect to the structure, as the baseline scan, determining any differences between the baseline scan and the secondary scan, and identifying at least one of a foreign object proximate the structure and a structural anomaly associated with the structure based on any differences between the baseline scan and the secondary scan.

Owner:THE BOEING CO

Digital X-ray detector assembly

The invention relates to a digital X-ray detector assembly. In one embodiment, a digital X-ray detector (22) is provided with a detector assembly (46) that includes a support panel (72), a digital detector array (54) with a rear side of the detector array (54) being secured to a front side of the support panel (72), a backscattered X-ray and reflected light absorption layer disposed between the detector array (54) and the support panel (72), a rear shock absorbing structure secured to a rear side of the support panel (72), and a front shock absorbing structure (52) secured to a front side of the detector array (54). The digital X-ray detector further includes a shell assembly (34) surrounding the detector assembly (46) and secured to the rear shock absorbing structure.

Owner:GENERAL ELECTRIC CO

Visible X-ray indication and detection system for X-ray backscatter applications

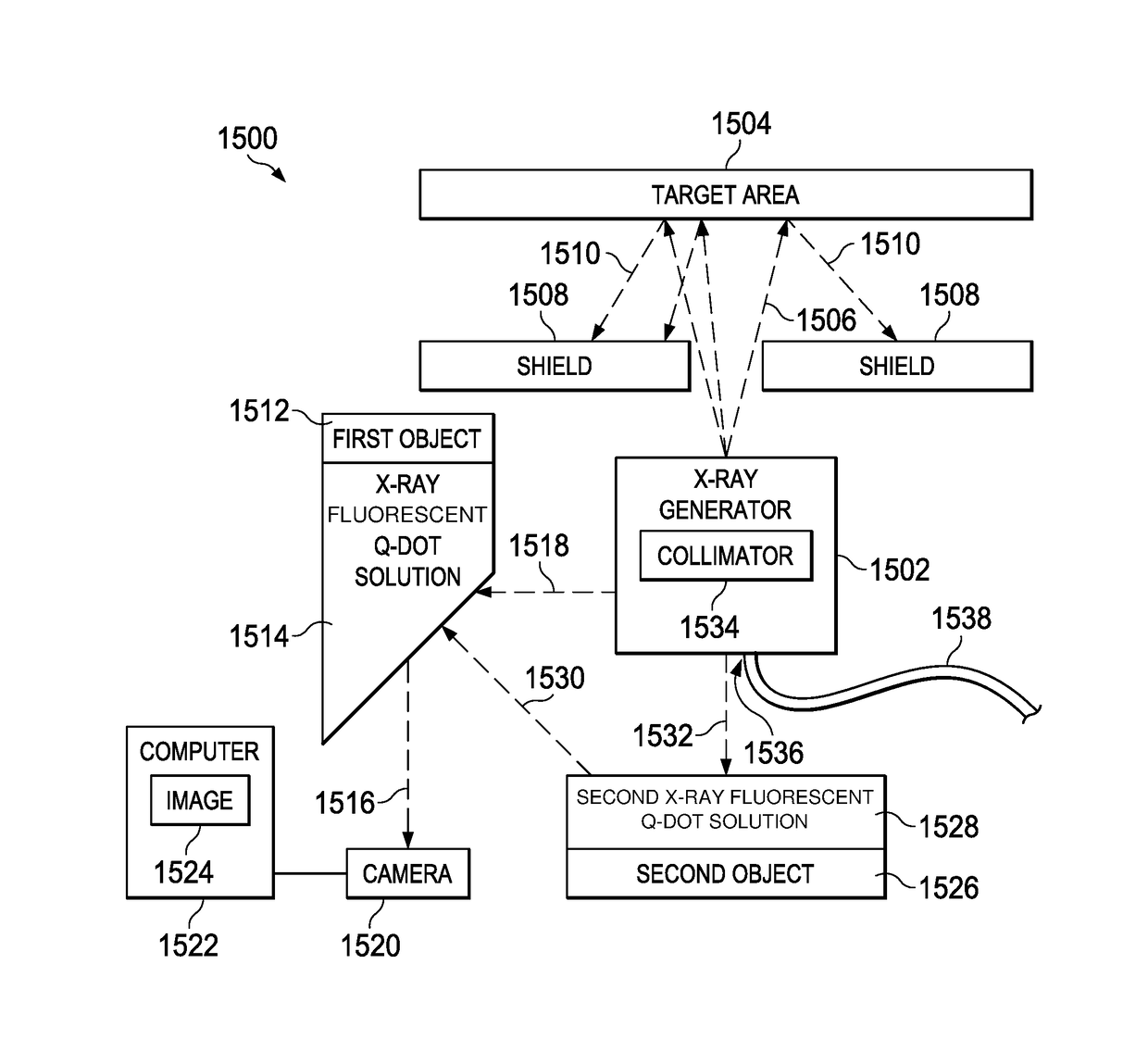

ActiveUS9594033B2Material analysis using wave/particle radiationChemical dosimetersSoft x rayBackscatter X-ray

An X-ray backscatter indication and detection system, including an object disposed with respect to a target area targeted by X-rays, such that X-rays that backscatter from the target area strike the surface of the object. The surface of the object includes an X-ray sensitive indicator substance that fluoresces with a visible light when contacted by backscattered X-rays.

Owner:THE BOEING CO

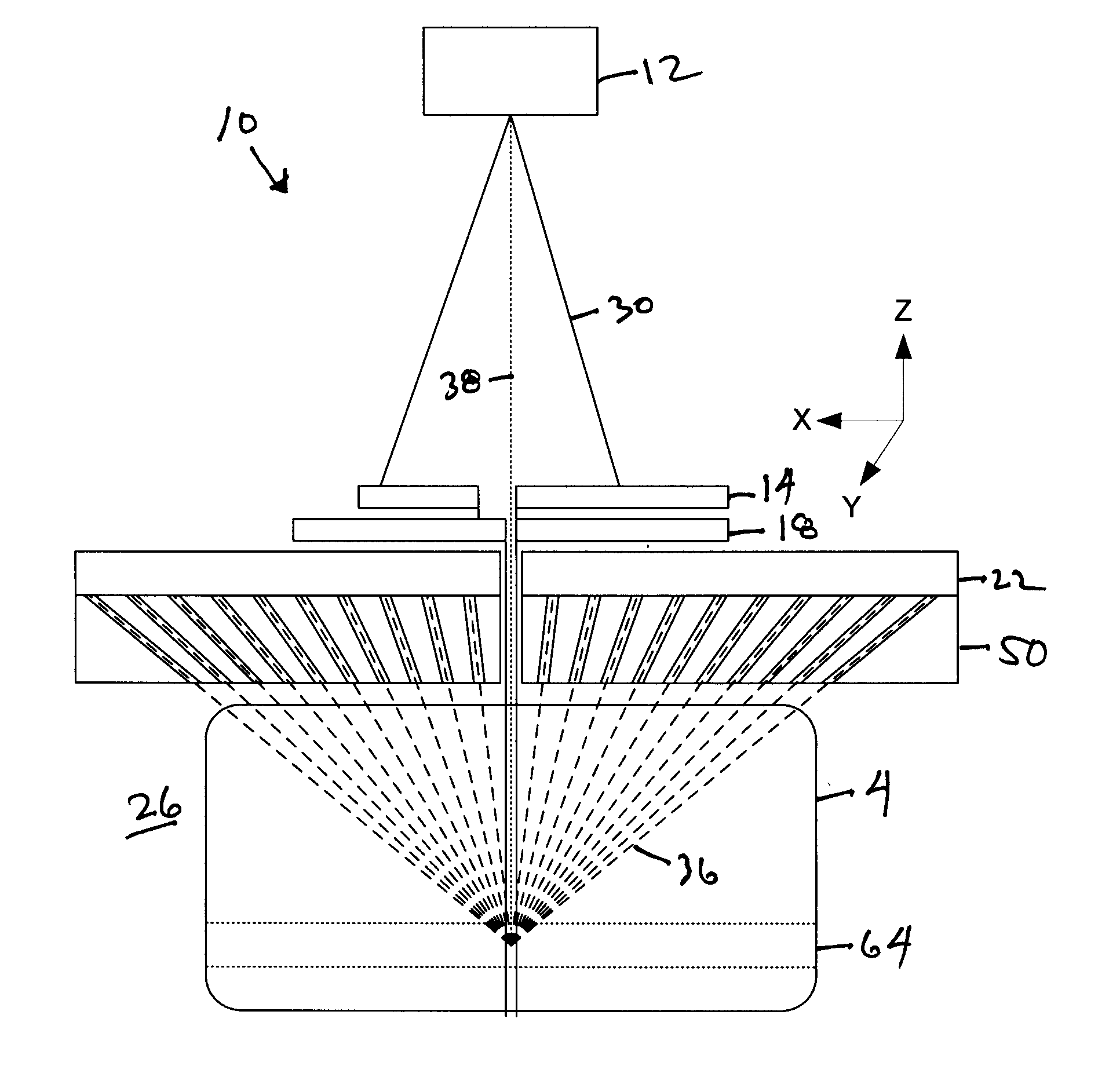

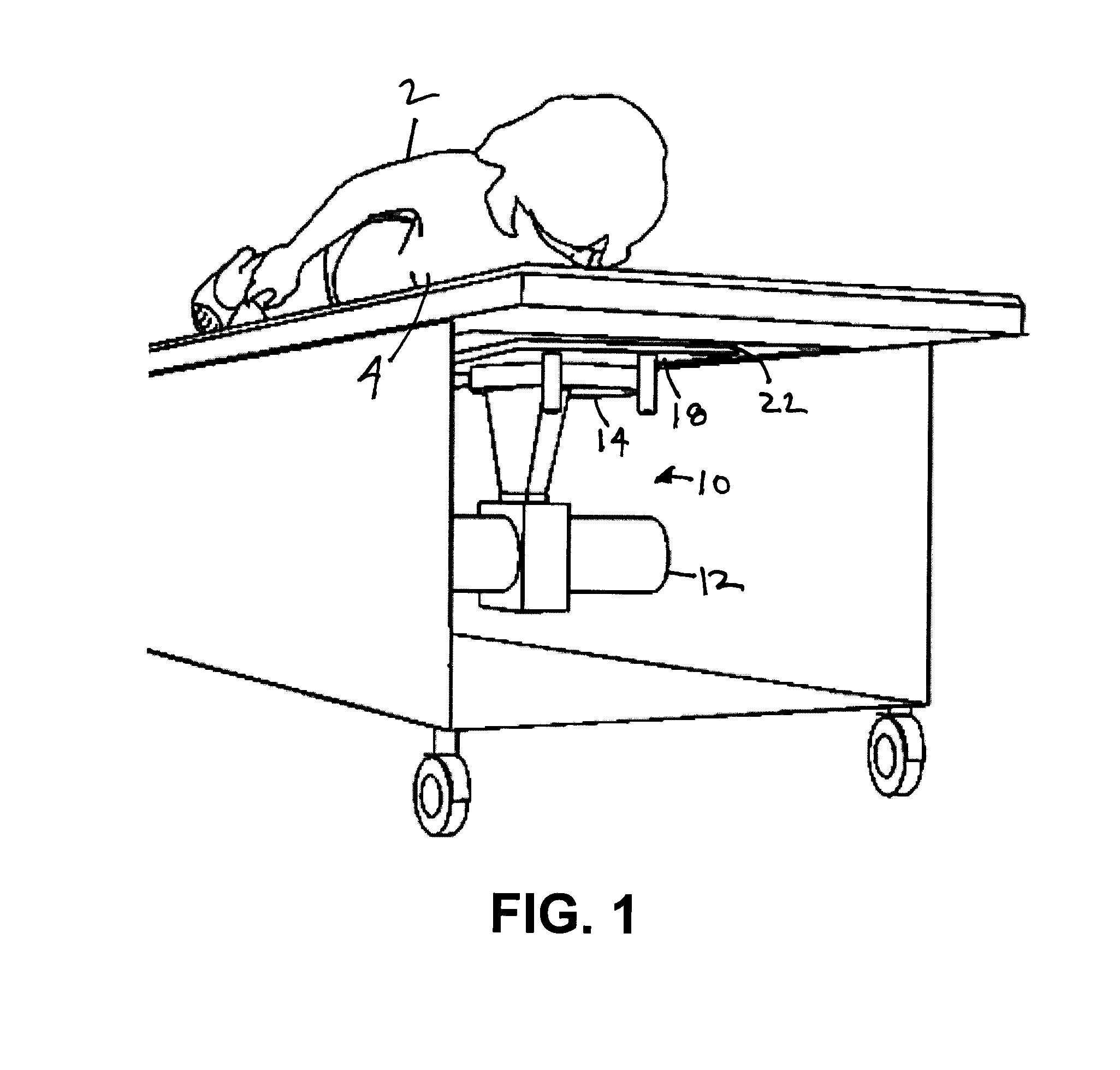

Low-dose x-ray backscatter system for three dimensional medical imaging using a conventional x-ray tube

InactiveUS20150297156A1Material analysis using wave/particle radiationPatient positioning for diagnosticsBackscatter X-rayConventional X-Ray

An x-ray source emits a cone beam to a rotating, x-ray-opaque disc with radial slots. The slots break the cone beam into fan beams that are emitted to an x-ray-opaque plate that produces a scanning x-ray pencil beam as each fan beam moves across a slit in the plate. A backscatter detector is adjacent to the plate. A collimator is adjacent. The pencil beam enters the object space through slits in the detector and collimator. The pencil beam moves rapidly in the y direction in the object space, producing backscatter x-rays from the object. The collimator only passes backscattered x-rays at a selected distance from the detector. Simultaneously, the assemblage of x-ray source, disc, plate, detector, and collimator moves slowly in the x and z directions. The backscattered x-rays passed by the collimator are processed to form planar images at various depths in the object space.

Owner:MARTIN ANNIS PATENT TRUST - 2009

X-ray backscatter imaging of nuclear materials

The energy of an X-ray beam and critical depth are selected to detect structural discontinuities in a material having an atomic number Z of 57 or greater. The critical depth is selected by adjusting the geometry of a collimator that blocks backscattered radiation so that backscattered X-ray originating from a depth less than the critical depth is not detected. Structures of Lanthanides and Actinides, including nuclear fuel rod materials, can be inspected for structural discontinuities such as gaps, cracks, and chipping employing the backscattered X-ray.

Owner:UT BATTELLE LLC

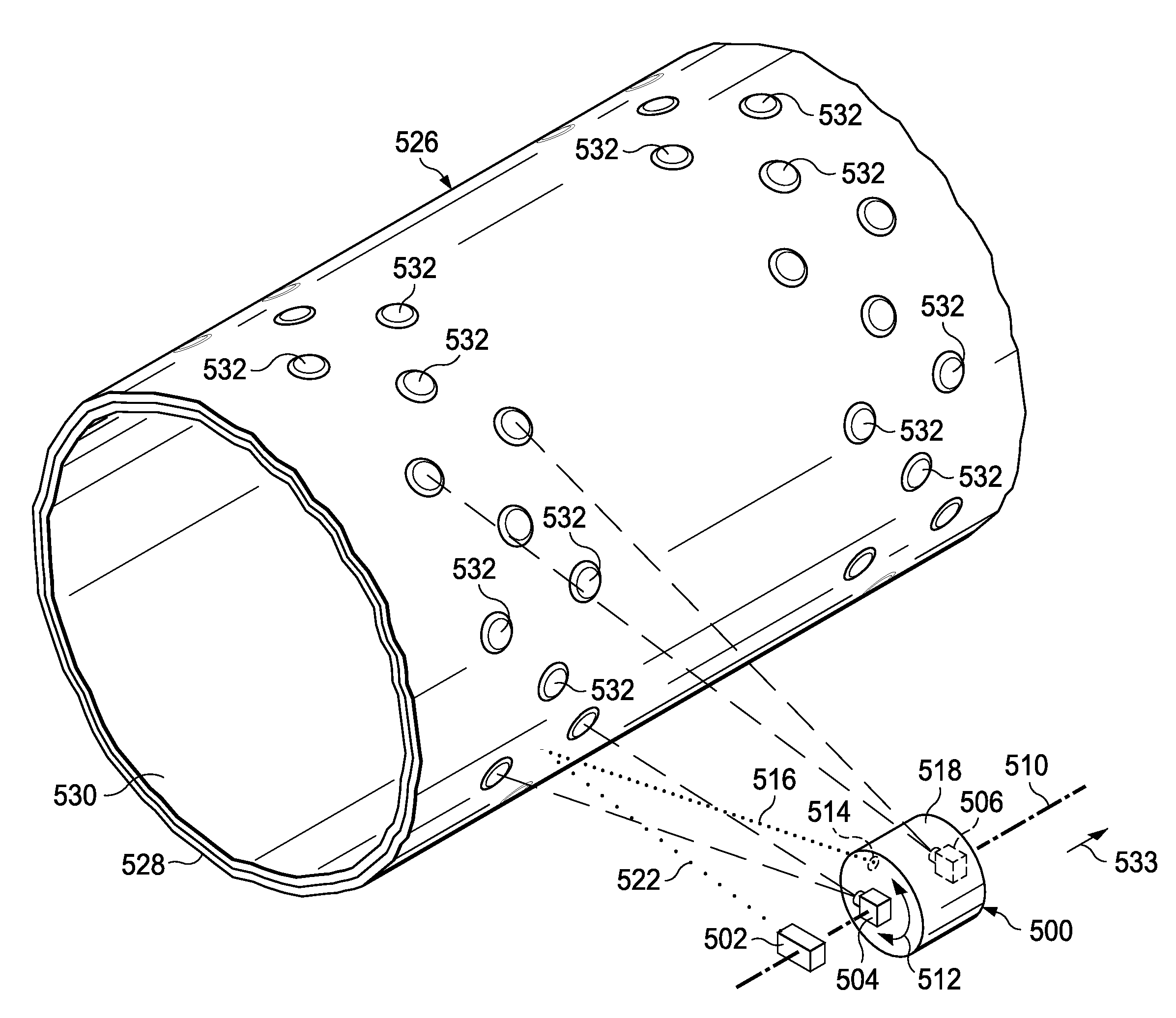

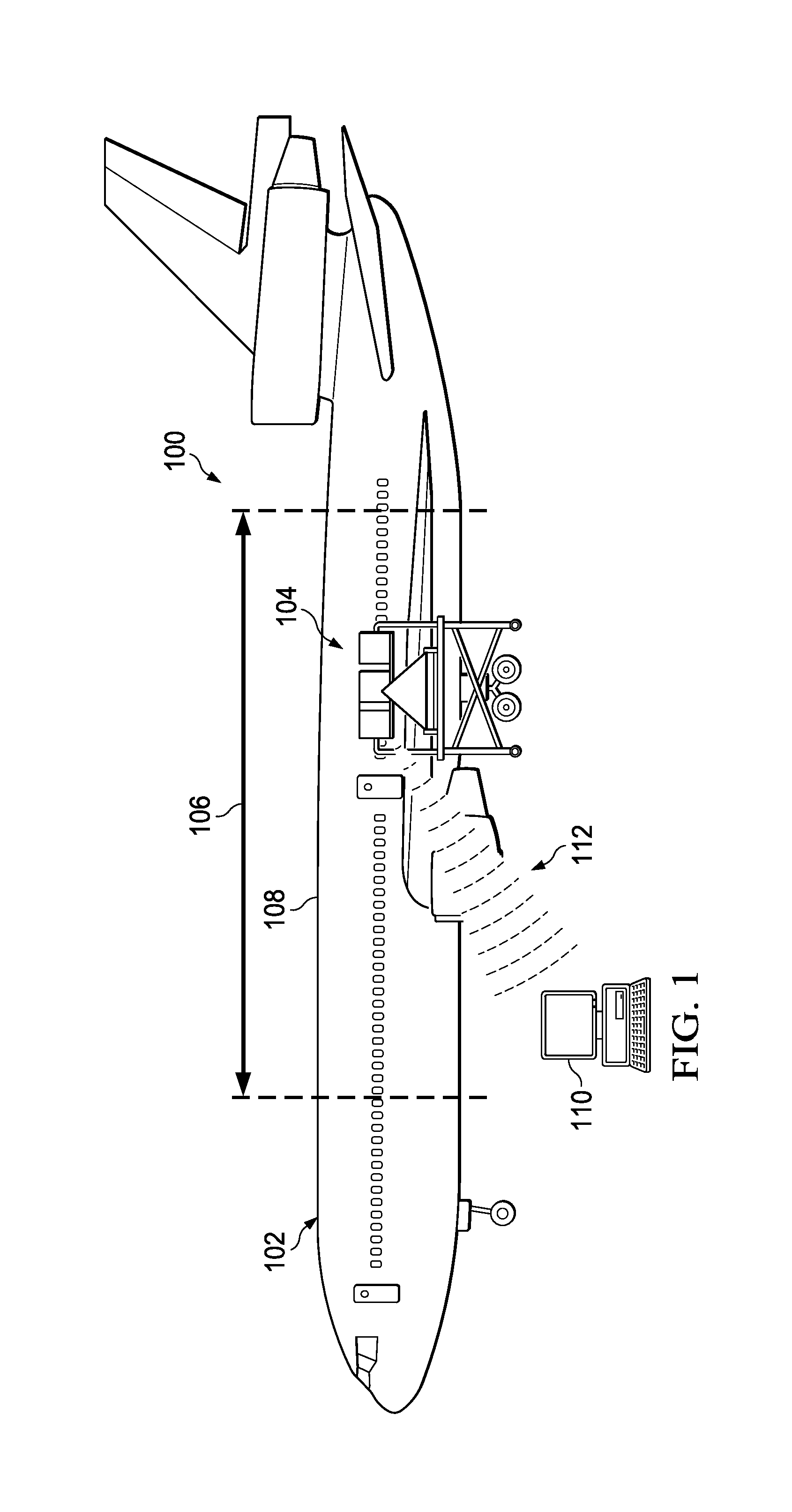

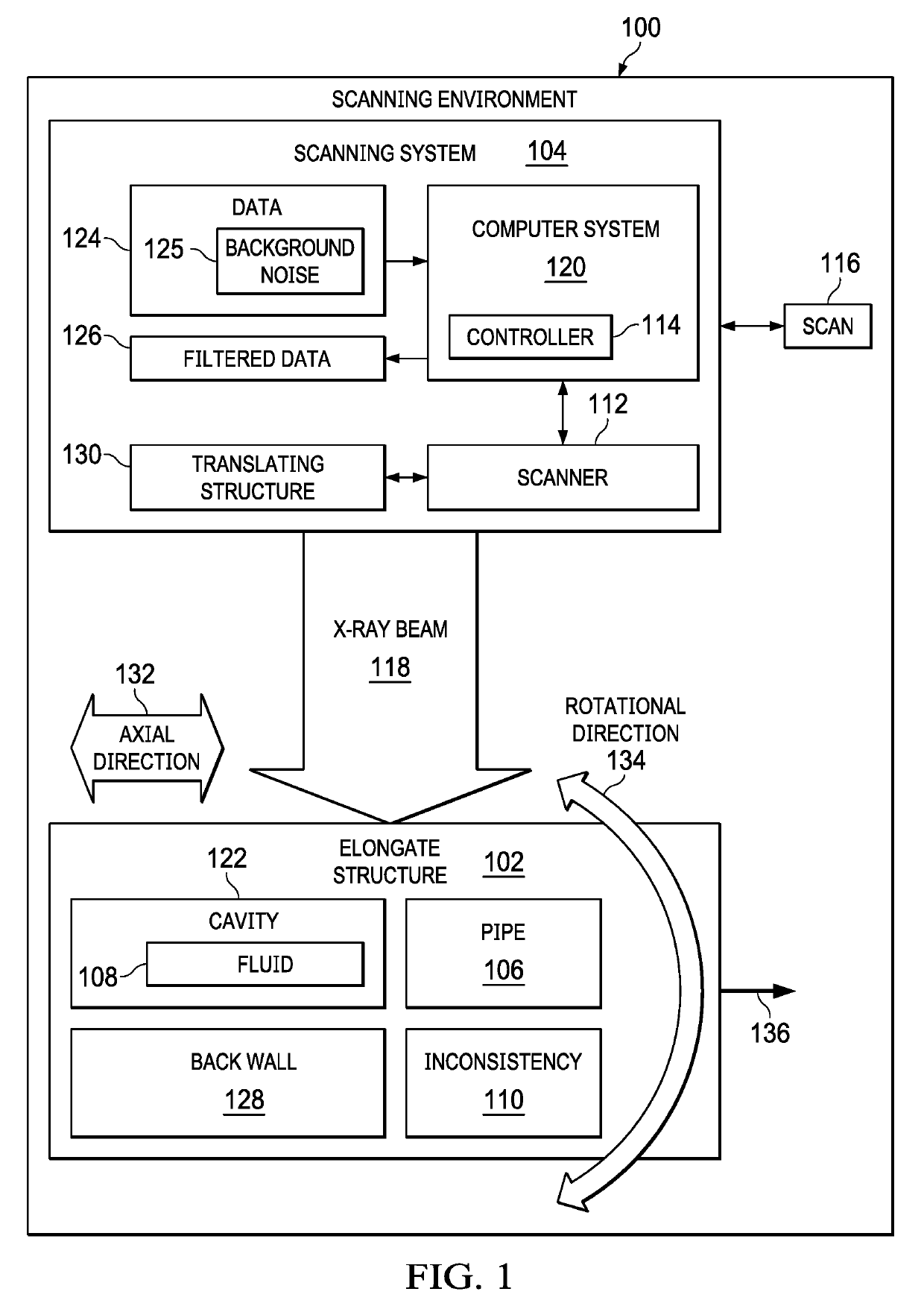

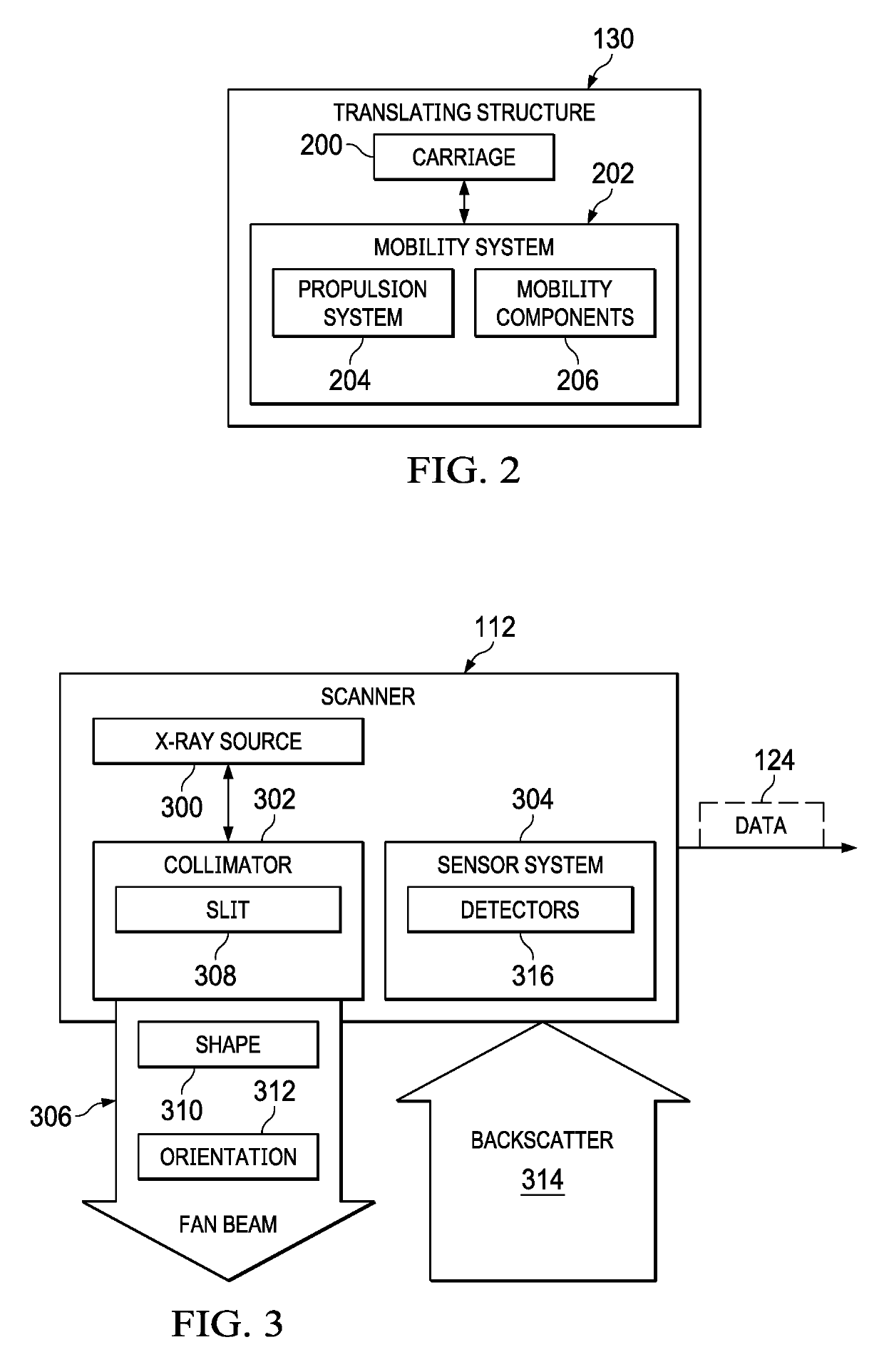

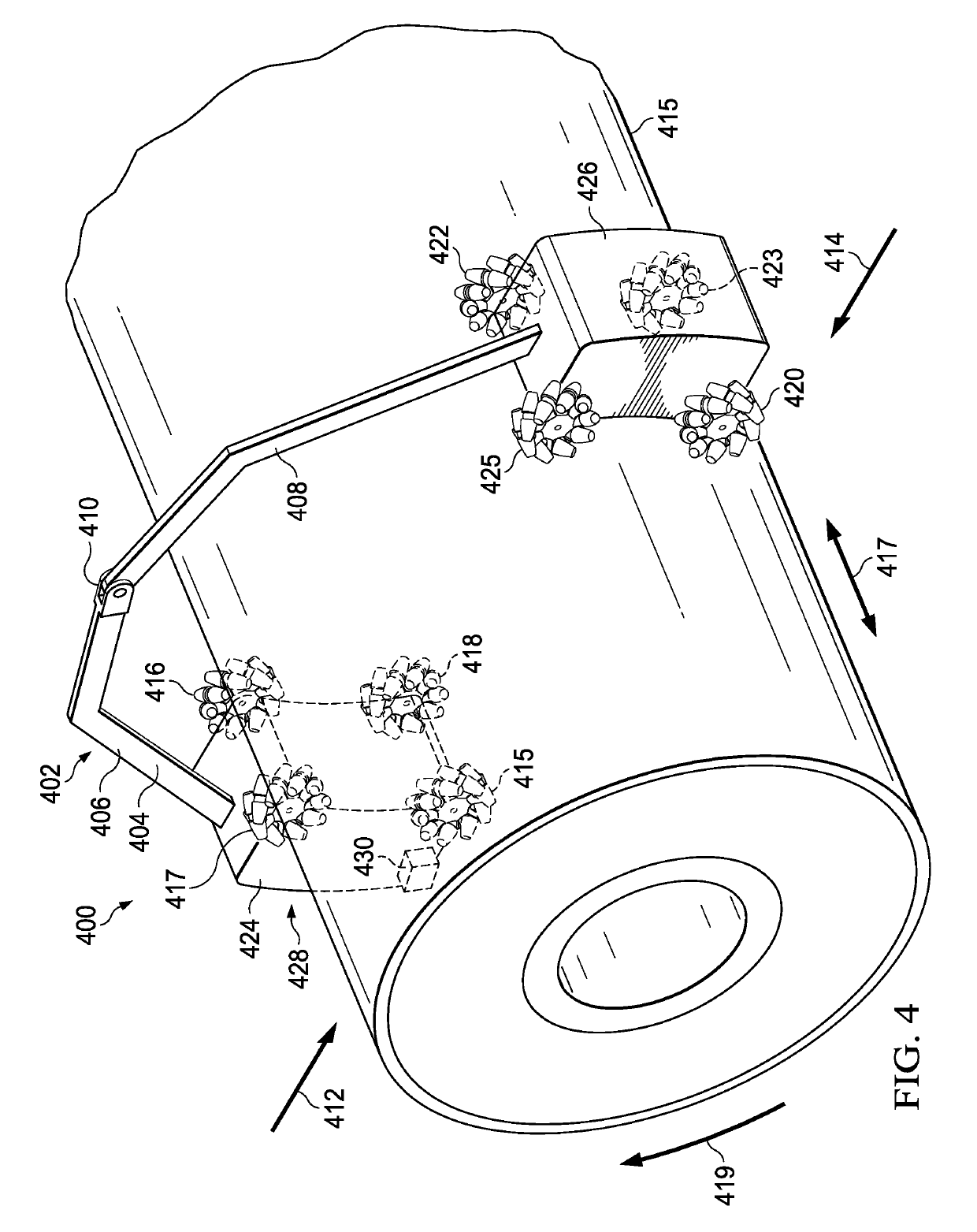

Backscatter X-Ray Inspection System for Pipes

A method and a system for scanning an elongate structure. A scan of the elongate structure with a fluid in a cavity of the elongate structure is received. The scan is generated by a scanner using an x-ray beam. Data in the scan is filtered to remove a portion of the data in the scan attributable to the fluid to form filtered data, enabling detecting an inconsistency on a wall of the elongate structure in the filtered data.

Owner:THE BOEING CO

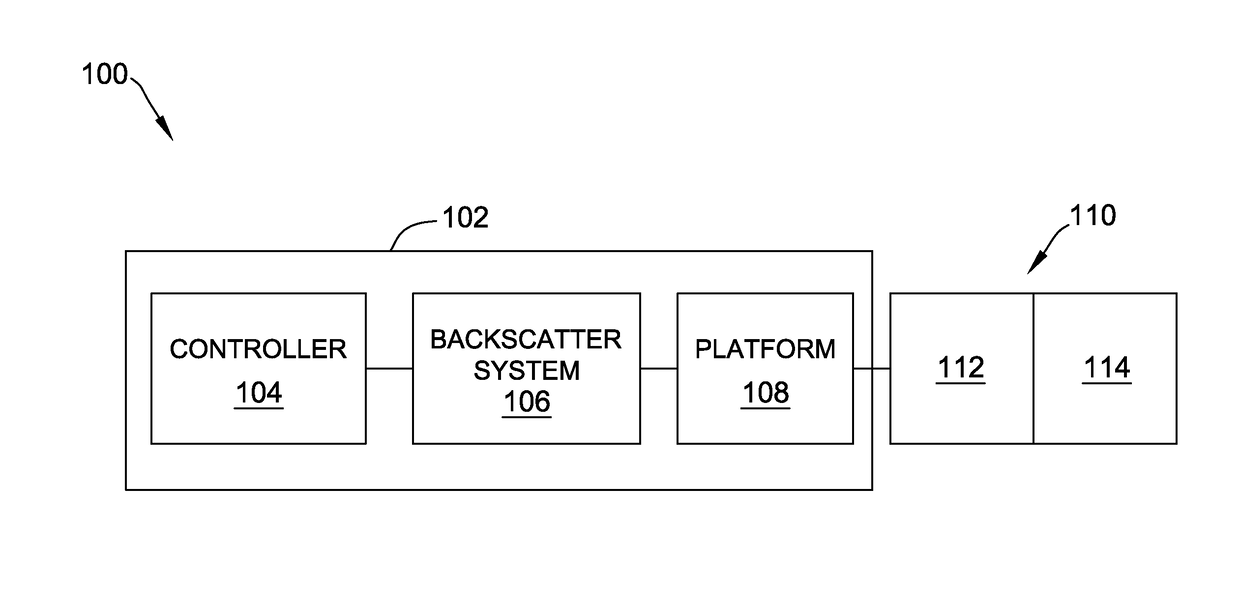

Systems and methods for performing backscatter three dimensional imaging from one side of a structure

An imaging system for generating three dimensional image data using X-ray backscattering from one side of a structure is provided. The imaging system includes at least one X-ray source, at least one rotating collimator coupled to the at least one X-ray source, an X-ray detector, and a controller coupled to the at least one X-ray source, the at least one rotating collimator and the X-ray detector. The controller is configured to emit X-rays from the at least one X-ray source through the at least one rotating collimator towards the one side of the structure. Additionally, the controller is configured to detect backscattered X-rays from the one side of the structure, using the X-ray detector, at a plurality of depths within the structure. Additionally, the controller is configured to generate three dimensional image data of the structure based on the detected backscattered X-rays.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com