Full-bracket track-bogie bearing and moving device and construction method for installing steel box girders

A technology of steel box girder and trolley, which is applied in the field of full-support rail trolley camel shifting device, can solve the problems of time-consuming and material-consuming, large safety hazards, increased construction costs, etc., and achieve investment cost savings, high safety, and easy operation. Fast and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

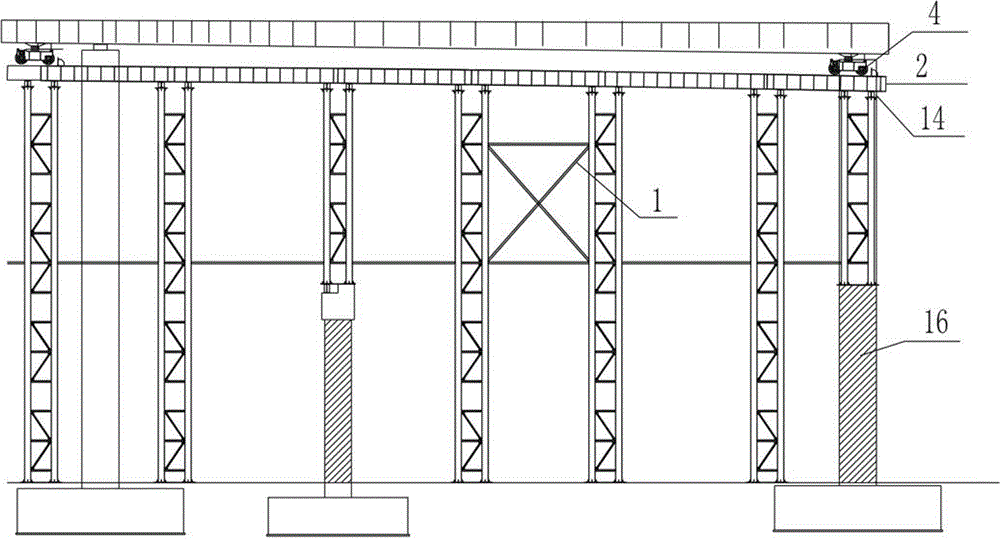

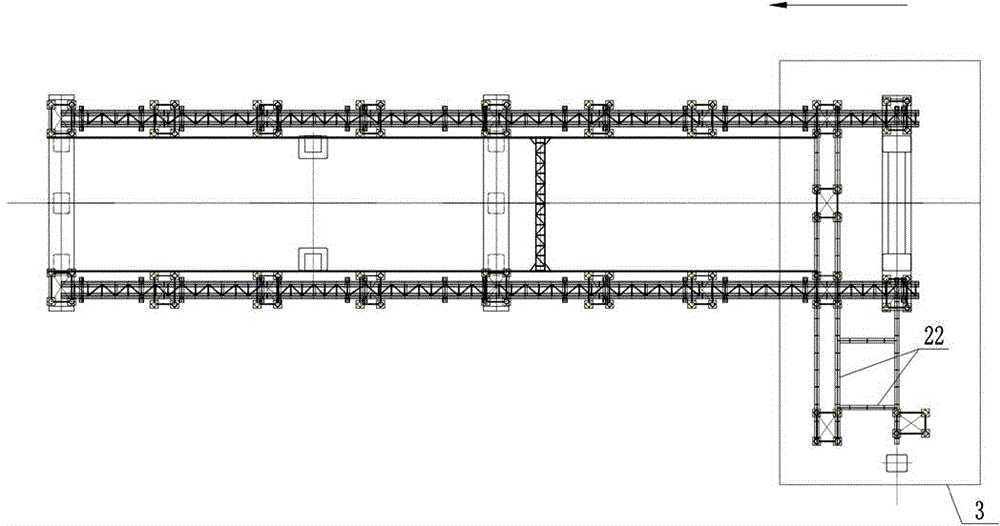

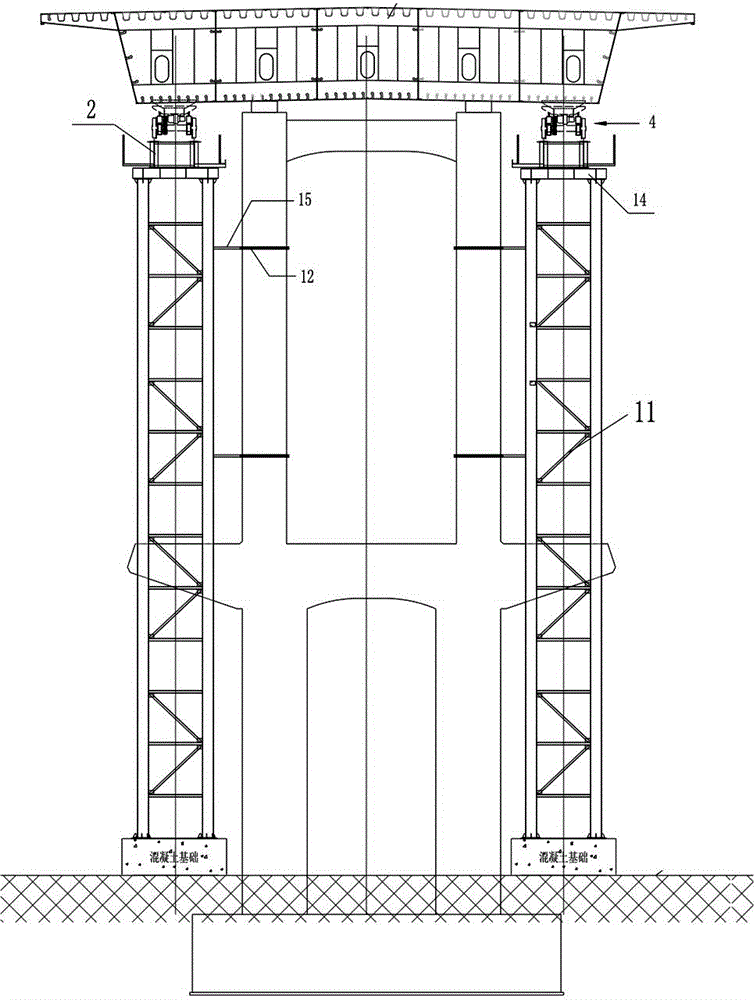

[0036] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 8 As shown, the present invention is composed of a support system 1, a slide rail longitudinal beam system 2, an assembled platform 3, and a traction system 4.

[0037] The support system 1 is composed of a steel pipe pier 11, a tightening device 12, a support frame 13 between columns, an upper beam 14 and a connector 15. The device 12 is surrounded by the pier column 16, and a rubber layer is arranged between the clamping device 12 and the pier column 16; the steel pipe pier 11 and the steel pipe pier 11 are connected by an inter-column support frame 13 to form a whole; the steel pipe pier 11 top An upper crossbeam 14 is provided, on which a slideway longitudinal beam system 2 is placed, and one end of the slideway longitudinal beam system 2 is provided with an assembly platform 3;

[0038] The slideway longitudinal beam system 2 mainly includes double slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com