Inside and outside beam system bridge fabrication machine for small radius curve concrete box girder construction and construction method thereof

A technology of concrete box girder and small radius curve, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in turning during construction and travel, and achieve the effect of convenient maintenance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

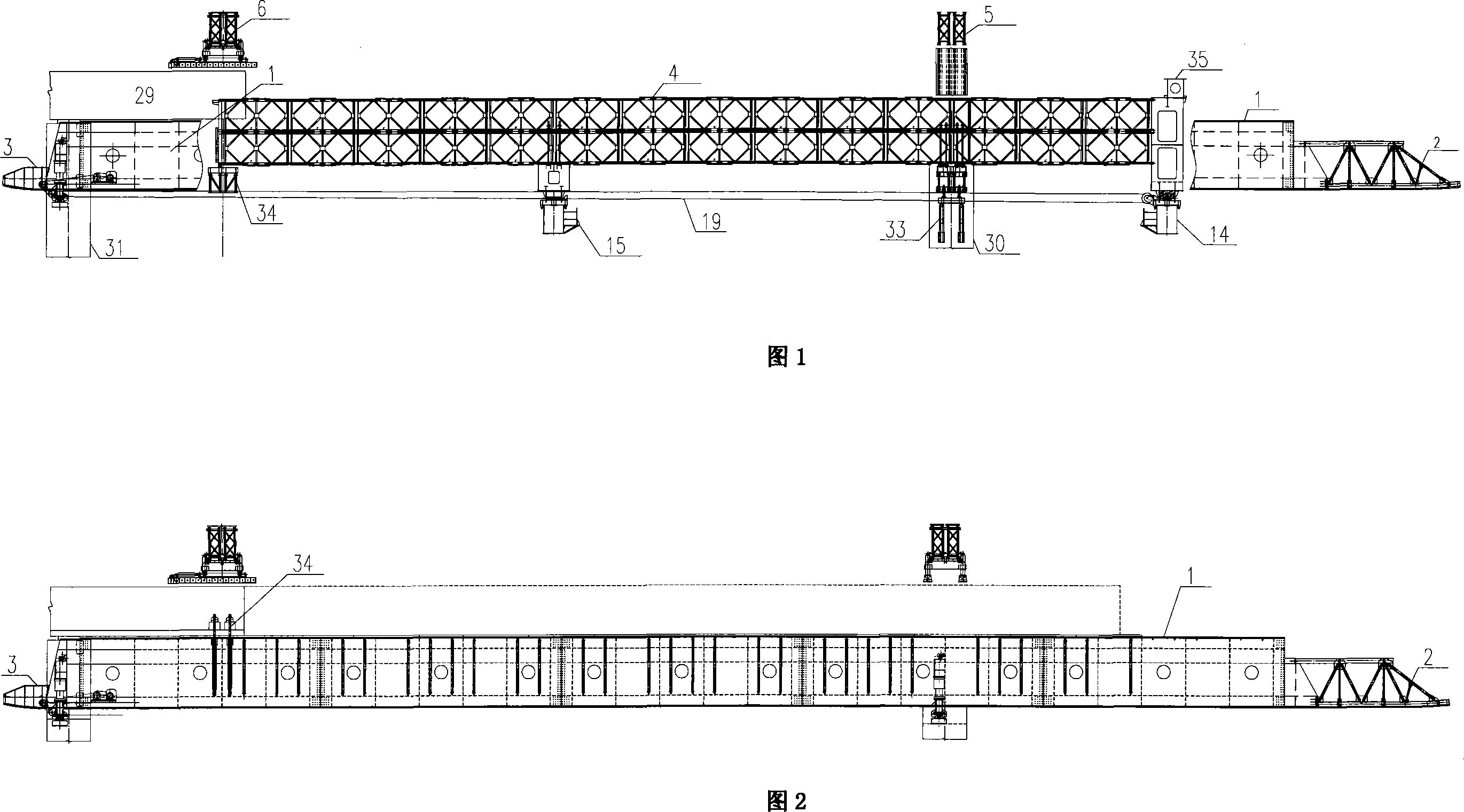

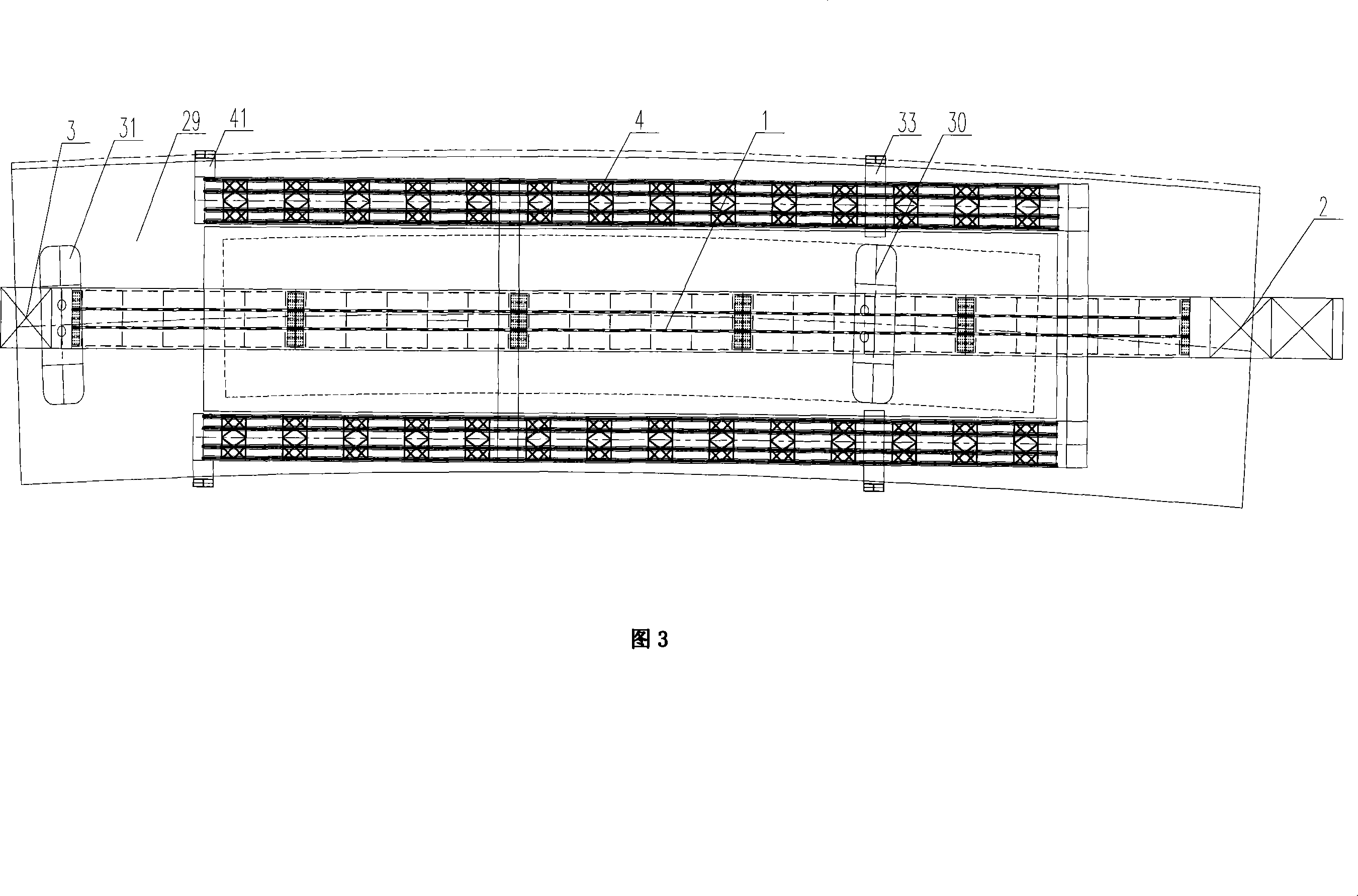

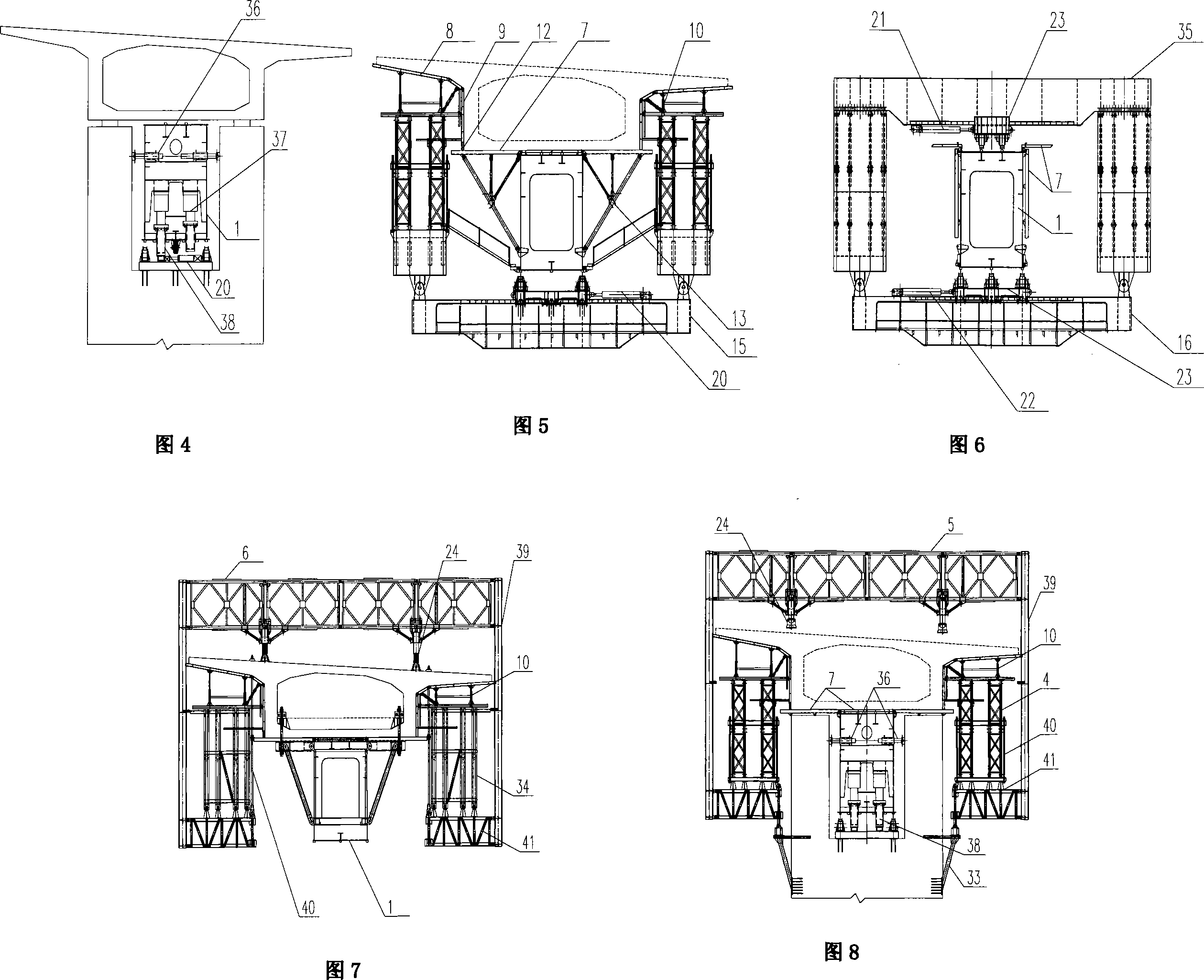

[0048] 1-10 , the bridge building machine is composed of an inner beam system, an outer beam system 2 , a template system 3 , a running system 4 , and an auxiliary structure 5 .

[0049] The inner beam system is composed of a steel box beam 1, a front nose frame 2, and a rear nose frame 3. The inner beam is supported on the front pier body 30 and the rear pier body 31. bolt butt,

[0050] External beam system: the double beam structure 4 is made of Bailey beam group, the front fulcrum is on the front joist 14, the middle fulcrum is the pier side corbel 33, and the rear fulcrum is hung on the cantilever end 29 through the end structure 34 and the hook beam 41 Above, the horizontal connection between the double beam structures 4 is composed of a front connecting gantry 5 and a rear connecting gantry 6 .

[0051] Formwork system: consists of bottom mold 7, wing mold 8, and side mold 9. Bottom mold 7 is on inner beam steel box girder 1, wing plate mold 8 and side mold 9 are on Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com