Rapid detection method and rapid detection device of non-metallic inclusions in metal

A technology of non-metallic inclusions and detection methods, applied in the field of metallurgy, can solve the problems of subjective error, time-consuming metallographic method, false particle size report of metallographic method, etc., to achieve the effect of fast and convenient process, ensure accuracy and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

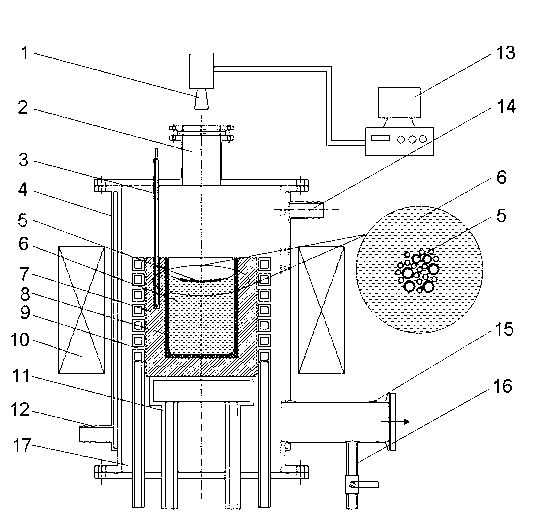

[0036] Use a sampler or turning method to prepare a regular metal sample, use physical grinding and chemical cleaning methods to clean the oxide skin, impurity dust on the surface of the metal sample, and use tweezers to clamp the metal sample and place it on a clean room with inner and outer walls. in the sample container of the melting furnace.

[0037] A method for rapidly detecting non-metallic inclusions in metals, comprising the steps of:

[0038] a. Heating and melting the metal sample: the clean metal sample is quickly melted in a high oxygen-free environment to form a molten metal, and the molten metal is kept warm;

[0039] b. Separation of inclusions: Then the molten metal is rotated, and various non-metallic inclusions in the molten metal are quickly floated up and gathered in the center of the surface of the molten metal by centrifugal force and gravity;

[0040] c. Detection of the total amount and size of inclusions: for various non-metallic inclusions accumula...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, especially in that:

[0049] In this embodiment, the high-speed camera 1 accurately measures the rotational speed of the molten metal 6, forms a signal feedback to the rotating magnetic field generator 10, and further controls the output frequency and the generated magnetic field strength of the rotating magnetic field generator 10, so as to control the inclusions fully. Floating and separation, improve detection accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com