Method and device for controlling ion implantation

A technology of ion implantation and controller, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc. It can solve problems such as the difficulty of controlling stable ion implantation, and achieve the effects of easy determination, error reduction, and optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with specific embodiment:

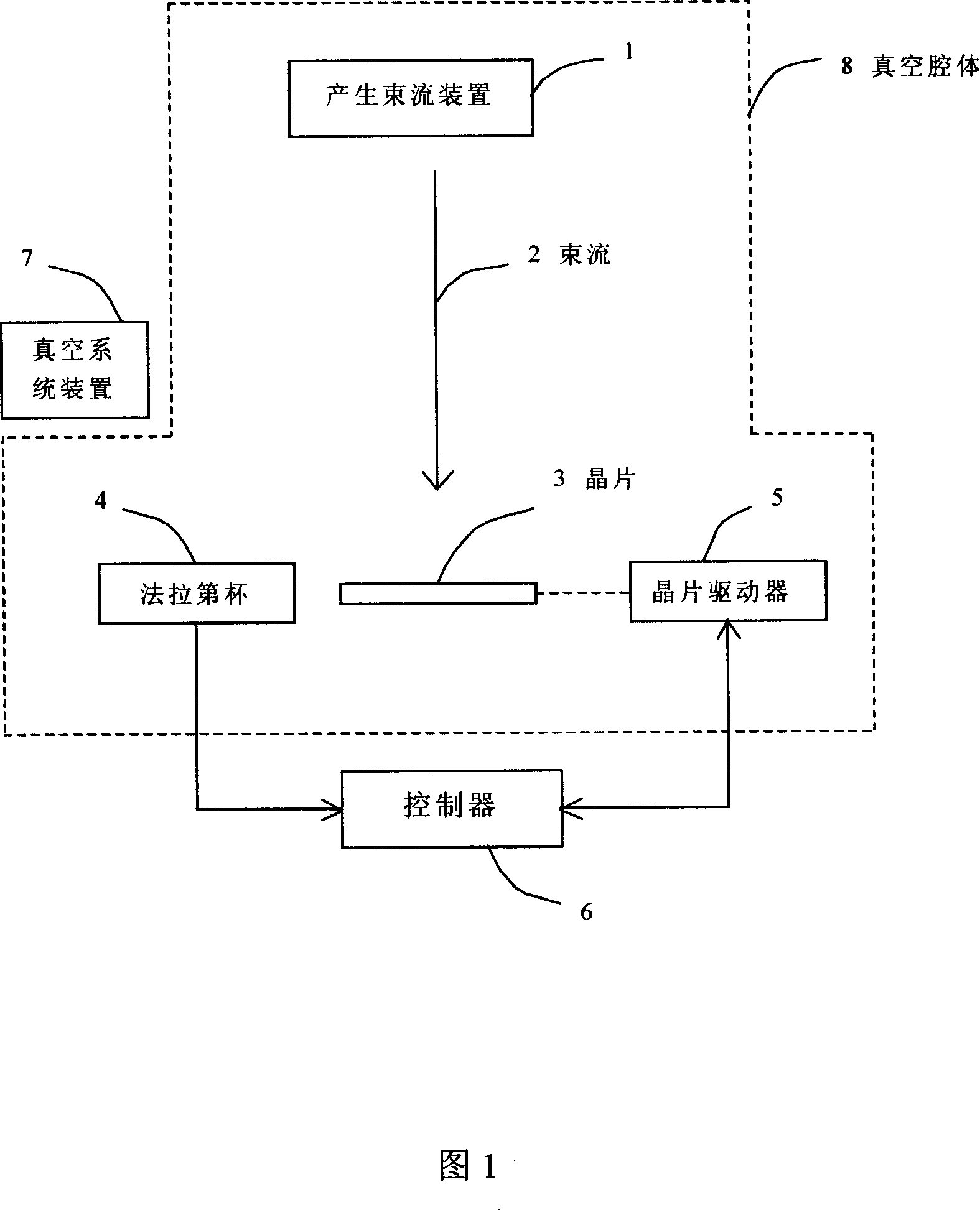

[0020] As shown in Figure 1, the device for controlling ion implantation includes generating a beam device 1, a wafer 3, a Faraday cup 4, a wafer driver 5, a controller 6, a vacuum system device 7, and a vacuum cavity 8, wherein the generating beam device 1 It is a linear beam 2 produced by ionizing the elements to be implanted through the ion source, and processed by magnetic field analysis and filtration; the beam 2 is vertically implanted into the wafer 3 after scanning, focusing, angle correction, energy acceleration, etc. ; The Faraday cup 4 is used to detect the value of the beam current 2, and outputs a signal reflecting the size of the beam current 2 to the controller 6; the controller 6 can be a general-purpose computer or a single-chip microcomputer circuit, as long as it has certain computing and storage capabilities , with simple input and output functions; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com