Electrostatic sensing experimental system and particle frictional charge measuring method

An experimental system and electrostatic sensor technology, applied in measurement devices, measurement of electrical variables, measurement of current/voltage, etc., can solve the problems of inaccurate results and difficulty in ensuring the reliability of the monitoring system, and achieve accurate measurement results, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

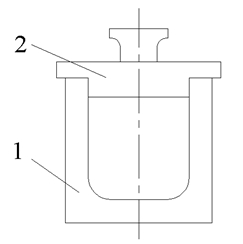

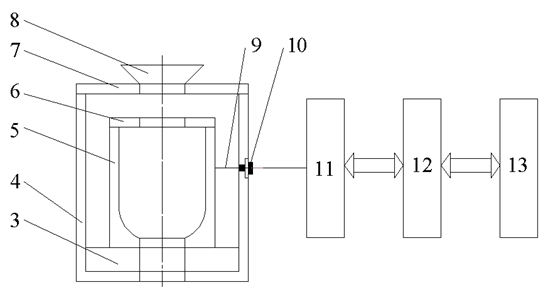

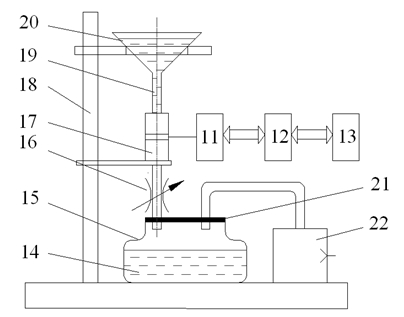

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0031] In the present invention, the frictional contact between particles and solid materials in the air carries a certain amount of charge through experiments to simulate the charge of abrasive particles in the process of friction and wear. The theoretical voltage amplitude is obtained by measuring the charge, and then the charge The electric particle is injected into the liquid medium, and the pulse amplitude is detected when the particle passes through the electrostatic sensor. The relationship between the initial theoretical voltage value of the particle and the actual voltage value measured after the particle interacts with the liquid medium will reflect the interaction between the particle and the liquid medium mechanism. At the same time, uncharged particles can be directly injected into the liquid medium, and the pulse amplitude is also detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com