Method and device for accurately detecting and correcting parallelism of ion beam

A technology of parallelism and ion beams, which is applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems that the injection angle cannot be precisely controlled, and cannot meet the requirements of the semiconductor device manufacturing process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

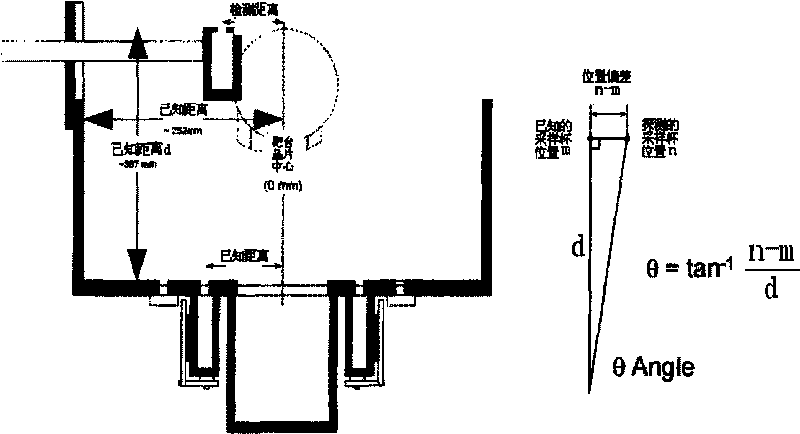

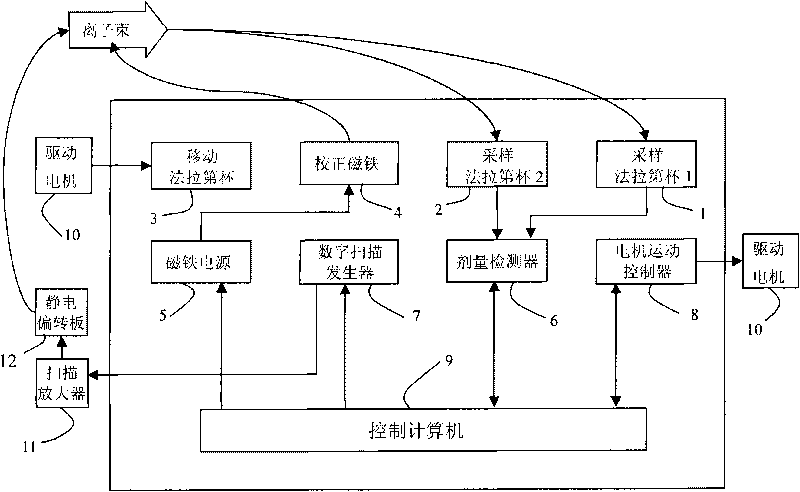

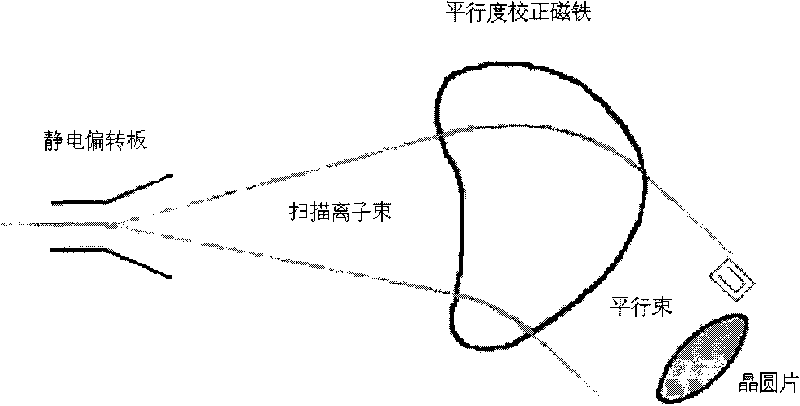

[0041] A set of scanning ion beam parallelism detection and correction data was recorded according to the above method, as shown in Table 1 below. In the embodiment, the ion implanter injects B+ ions, the implantation energy is set to 50keV, and the ion beam current is adjusted between 1mA~5mA. First, the ion source system and beamline system are automatically adjusted, and the required ion beam current is set. Then use a method and device for accurately detecting and correcting the parallelism of the scanning ion beam according to the present invention to detect and correct the parallelism of the scanning ion beam, obtain the correction data value of the parallelism of the scanning ion beam, and adjust the current setting of the magnet power supply . It can be seen from Table 1 that the parallelism of the scanning ion beam generally undergoes 3 to 5 repeated calibration processes, and the angle of each incident point of the scanning ion beam can be within 90°±0.7°, Δθ=θ 1 -θ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com