Product through hole etching defect detection method

A technology of through-hole etching and detection methods, which is applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., to achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Attached below Figure 5-13 , the specific embodiment of the present invention will be further described in detail.

[0038] It should be noted that, in the following embodiments, a 55nm logic product is taken as an example for illustration, and the etching success rate of the through hole of the connection layer between the semiconductor device layer and the first metal layer of the product is tested. test module.

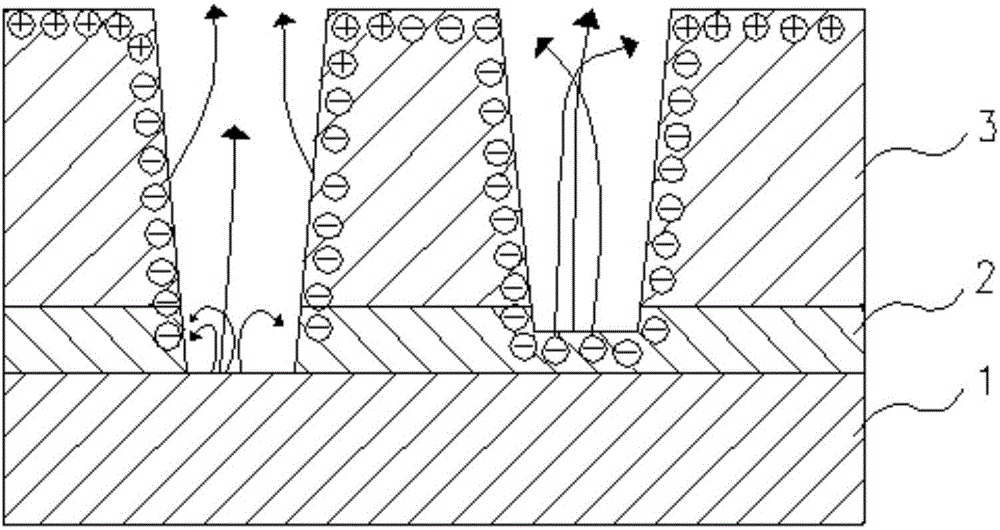

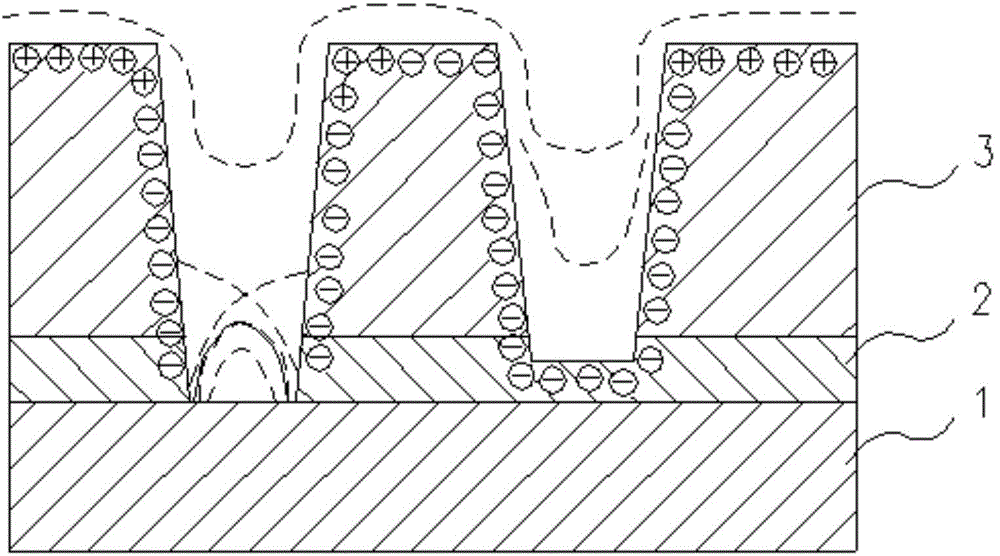

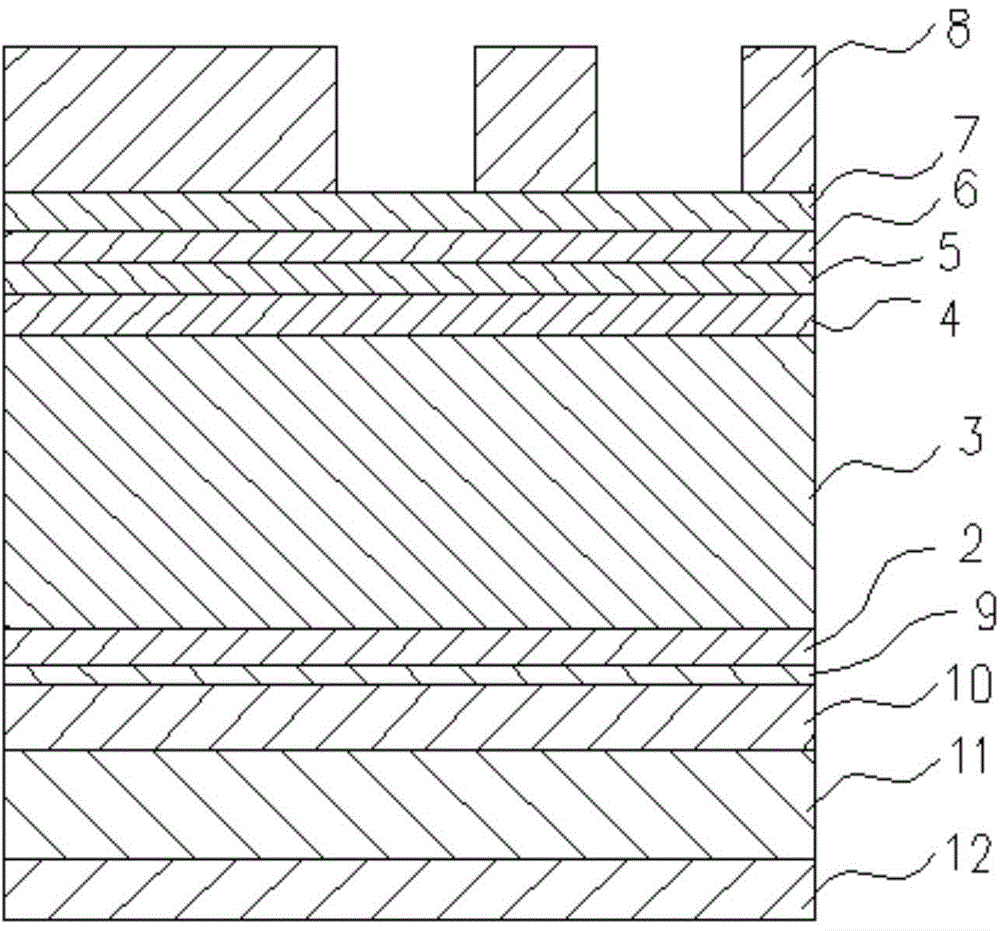

[0039] see Figure 5 , Figure 5 It is a flow diagram of a detection method for product through hole etching defects in the present invention; it illustrates a detection method for product through hole etching defects, the product includes a semiconductor device layer and the semiconductor device layer during etching A metal silicide layer 9, a barrier layer 2, an insulating layer 3, an oxide film layer 4, a hard mask layer 5, a silicon oxide layer 6, an antireflection layer 7 and a photoresist layer 8 are sequentially formed; the semiconductor device la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com