Lathe fixture

A lathe jig and clamping body technology, applied in the direction of expanding the mandrel, etc., can solve the problems of not reaching the inner hole surface, rough inner hole, unsatisfactory effect, etc., and achieve the effect of ensuring the difference in wall thickness

Inactive Publication Date: 2013-06-12

陶晓明

View PDF0 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The effect is not ideal. Due to the rough inner hole of the blank, the expansion sleeve form cannot guarantee the wall thickness difference between the inner and outer circles of sleeve parts, and cannot meet the ideal requirements of the inner hole surface.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

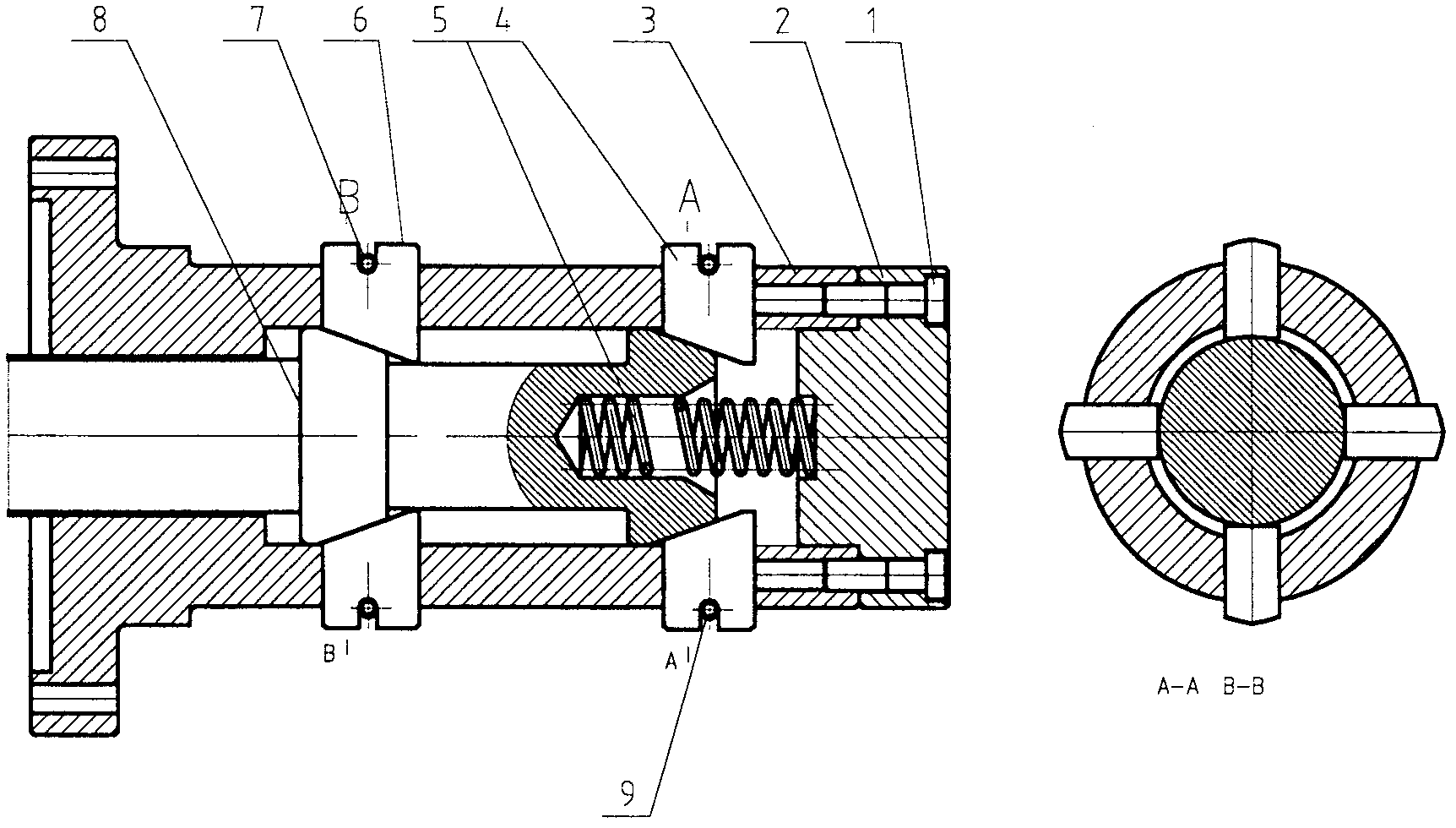

[0011] After loading the inner hole of the blank into the mandrel, open the hydraulic cylinder at the spindle end, move the movable cone head 8 to the right, and move the movable cone head 8 to the right to push the arc expanding claw 4 and the arc expanding claw 6 to move upward to tighten the blank. On the contrary, the blank is loosened.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A lathe fixture is particularly suitable for manufacturing and using sleeve parts. Eight points support an inner hole of a sleeve part blank; an angle between the front four points and the rear four points is 90 DEG; the fixture has high manufacturing precision, accuracy for positioning, and long service life; the wall thickness difference of the sleeve part is small; and the fixture can be effectively controlled in a specified range. The lathe fixture has the advantages that through the fixture, the wall thickness difference of the inner circle and the excircle of the sleeve part can be ensured.

Description

technical field [0001] The invention relates to a lathe fixture, which is especially suitable for mass production of sets. Background technique [0002] At present, most domestic machinery manufacturers use inner hole positioning for rough machining production of sleeve parts, and the fixtures are double-fold expansion sleeves or single-valve expansion sleeves. The effect is unsatisfactory. Due to the rough inner hole of the blank, the expansion sleeve form cannot guarantee the wall thickness difference between the inner and outer circles of sleeve parts, and cannot meet the ideal requirements of the inner hole surface. Contents of the invention [0003] In order to overcome the deficiencies of existing expansion sleeves, the present invention provides an 8-point support fixture. [0004] The technical method adopted by the present invention to solve the technical problem is to adopt 8 points to support the inner hole of the part blank, the front 4 points and the rear 4 p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B31/40

Inventor 陶晓明

Owner 陶晓明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com