Glass kiln transition roller machining method

A processing method and glass furnace technology, applied in the field of mechanical processing, can solve the problems of difficult to eliminate casting stress, difficult to guarantee processing accuracy, insufficient gravity bearing, etc., and achieve the effects of eliminating casting stress, improving processing accuracy and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

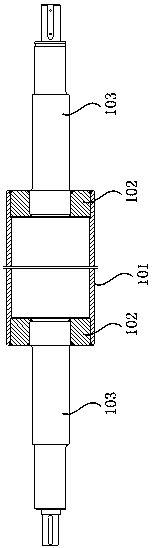

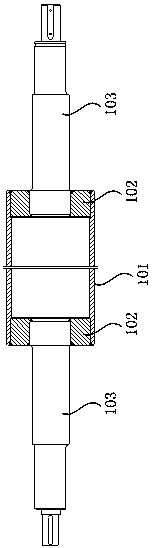

[0017] The glass kiln transition roller processing method of the present embodiment includes:

[0018] Step 1: Processing the roll body of the transition roll, turning the periphery of the centrifugally casted roll body, and at the same time, boring and washing the inner hole of the roll body. Specifically, turning is performed on the periphery of the roller body multiple times, and at the same time, boring and washing are performed on the inner hole of the roller body for many times, and the amount of turning and boring is gradually reduced. The casting material of roller body 101 is usually ZG4Cr25Ni20 to achieve high temperature and heat resistance. It is completed by centrifugal casting process. Due to the relatively large internal stress of centrifugal casting, the method of adding 15mm to the outer diameter of the casting blank and subtracting 15mm from the inner wall is used. Later, the casting stress was eliminated by using multiple processing methods to leave a margin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com