Thimble for roughly turning air cylinder sleeve for ship

A cylinder and thimble technology, which is used in turning equipment, tailstock/top, tool holder accessories, etc., can solve the problems of small weight and cutting force, large outer circle cutting force in rough turning, and heavy marine cylinder liner, etc. Different wall thickness, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

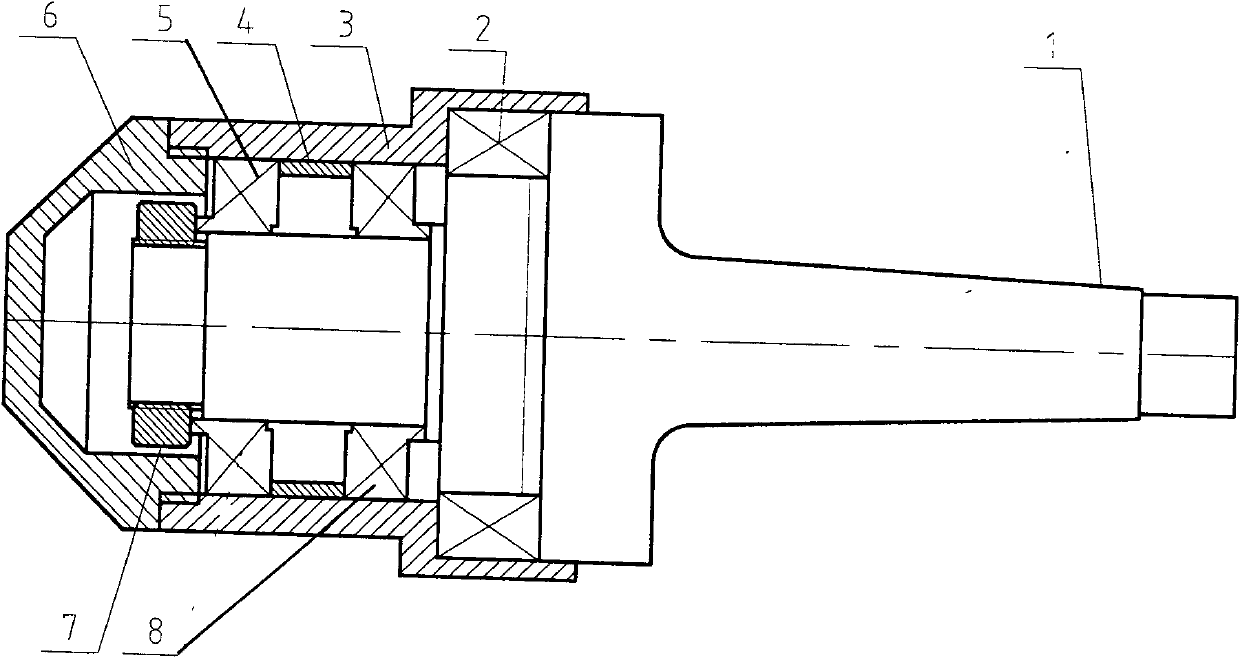

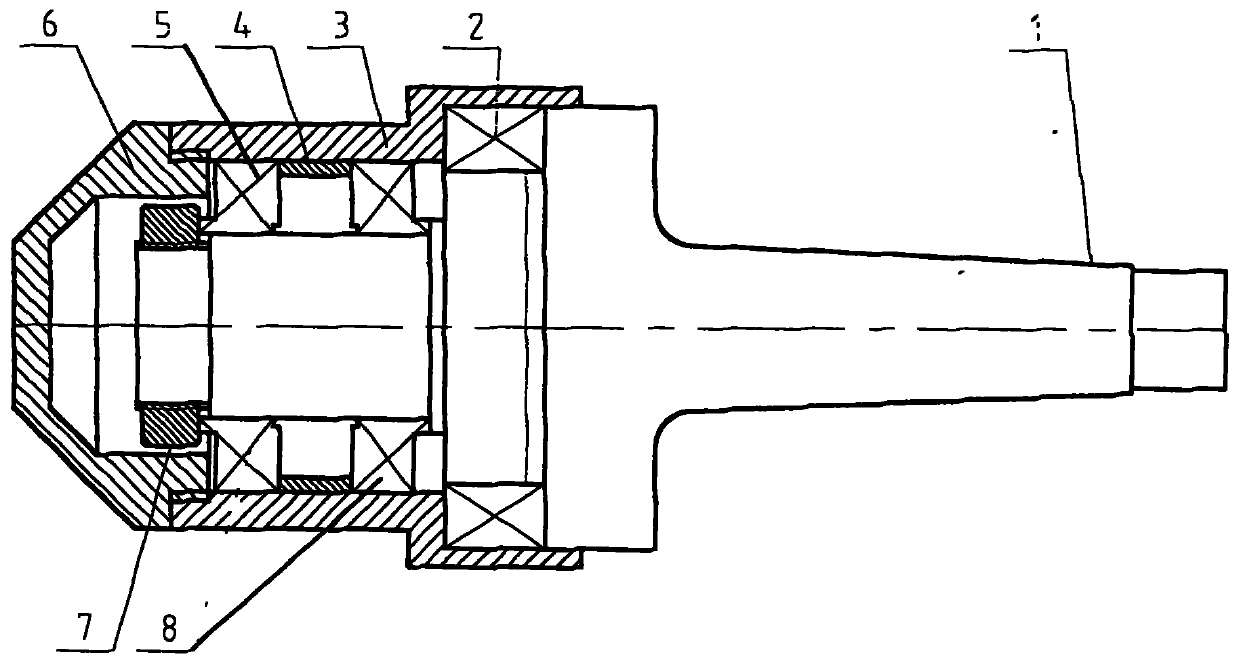

[0010] Install plane bearing 2, single row tapered roller bearing 5, bushing 4 and single row tapered roller bearing 8 on the ejector rod 1, and then install bushing 3 on plane bearing 2, single row tapered roller bearing 5, single row tapered roller bearing On the outer circle of the sub-bearing 5 and the outer circle of the push rod 1, then lock the cap 7, and then screw the bulkhead 6 and the shaft sleeve 3. When the bulkhead is in contact with the bulkhead 6, the shaft sleeve 3 and the bulkhead 6 rotate around the push rod as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com