Transferable drill bit deep hole drilling, processing method and application

A processing method and deep hole drilling technology, which is applied in the field of aerospace, can solve the problems of easy blockage of drill pipes and low processing efficiency, and achieve the effects of low probability of blockage, high processing efficiency, and reduced probability of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

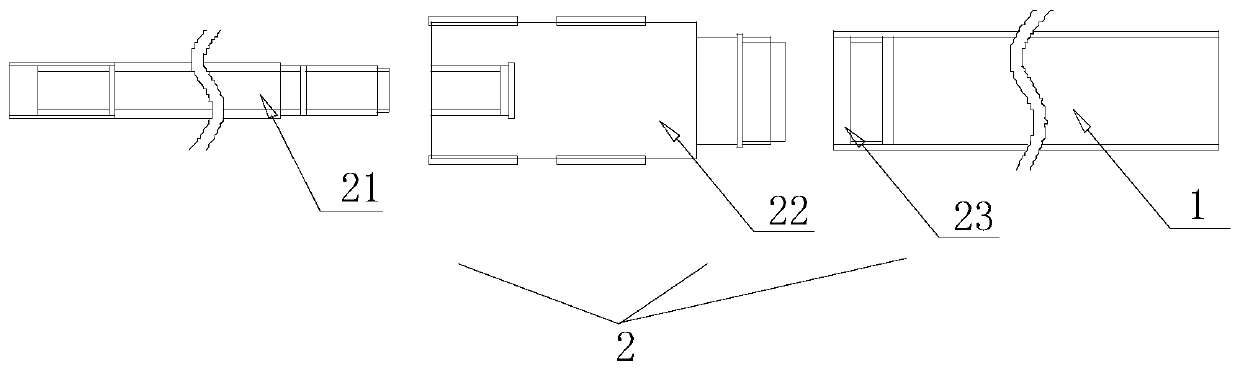

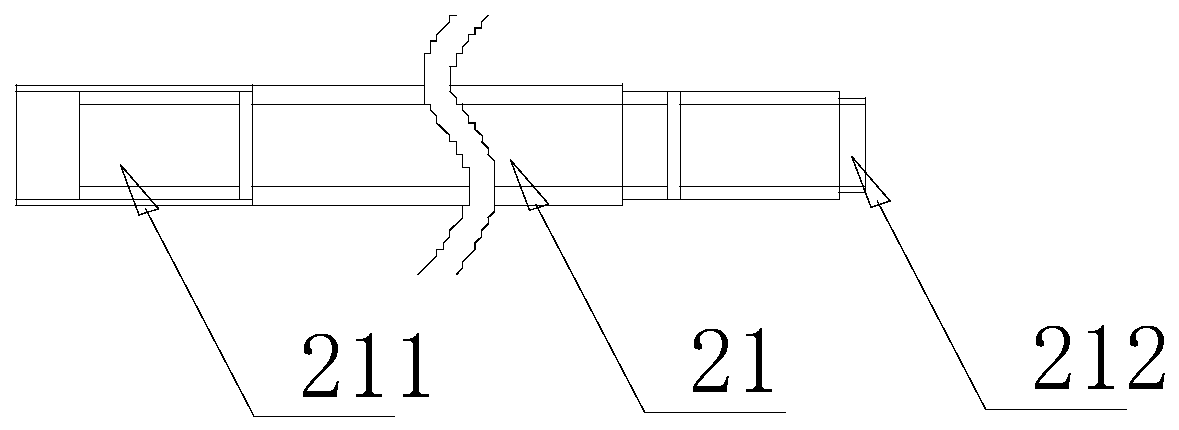

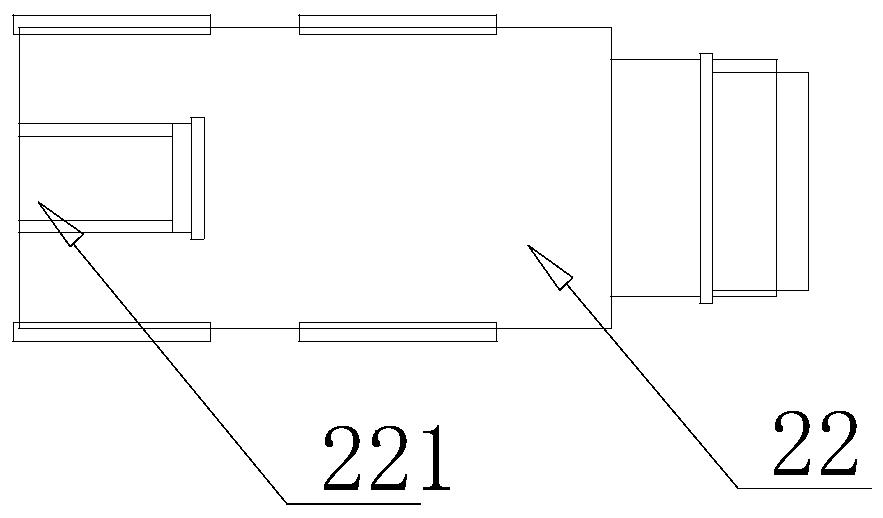

Image

Examples

Embodiment 1

[0042] 1. Drill bit selection, according to the size of the step hole to be processed on the long axis of the power, determine the radial size of the large-diameter drill bit 3 and the radial size of the small-diameter drill bit 4, the radial size of the large-diameter drill bit 3 is 25.8mm, and the small-diameter drill bit The radial dimension of 4 is 15.2mm.

[0043] 2. Processing speed, the feeding speed of the large-diameter drill bit 3 is 0.14mm / rev, and the feed speed of the small-diameter drill bit 4 is 0.12mm / rev, so as to ensure the smooth discharge of debris and avoid the blockage of the drill pipe 1.

[0044] 3. Positioning, mark the center point of the step hole to be processed on the long axis of the power to ensure the accuracy of the drilling position. When marking the center point, ensure that the drill bit is perpendicular to the step hole of the power long axis to ensure the smooth discharge of debris and reduce the wall thickness difference of the power long...

Embodiment 2

[0052] 1. Drill bit selection, according to the size of the step hole to be processed on the long axis of the power, determine the radial size of the large diameter drill bit 3 and the radial size of the small diameter drill bit 4, the radial size of the large diameter drill bit 3 is 40mm, and the small diameter drill bit 4 The radial dimension is 18mm.

[0053] 2. Processing speed, the feeding speed of the large-diameter drill bit 3 is 0.15 mm / rev, and the feed speed of the small-diameter drill bit 4 is 0.12 mm / rev, so as to ensure the smooth discharge of debris and avoid the blockage of the drill pipe 1.

[0054] 3. Positioning, mark the center point of the step hole to be processed on the long axis of the power to ensure the accuracy of the drilling position. When marking the center point, ensure that the drill bit is perpendicular to the step hole of the power long axis to ensure the smooth discharge of debris and reduce the wall thickness difference of the power long axis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com