Expansion shaft

A technology of expansion shaft and coaxial line, which is applied in the field of expansion shaft, can solve the problems of inconvenient use and difficult maintenance of expansion shaft, and achieve the effect of easy disassembly and maintenance, not easy to break down, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

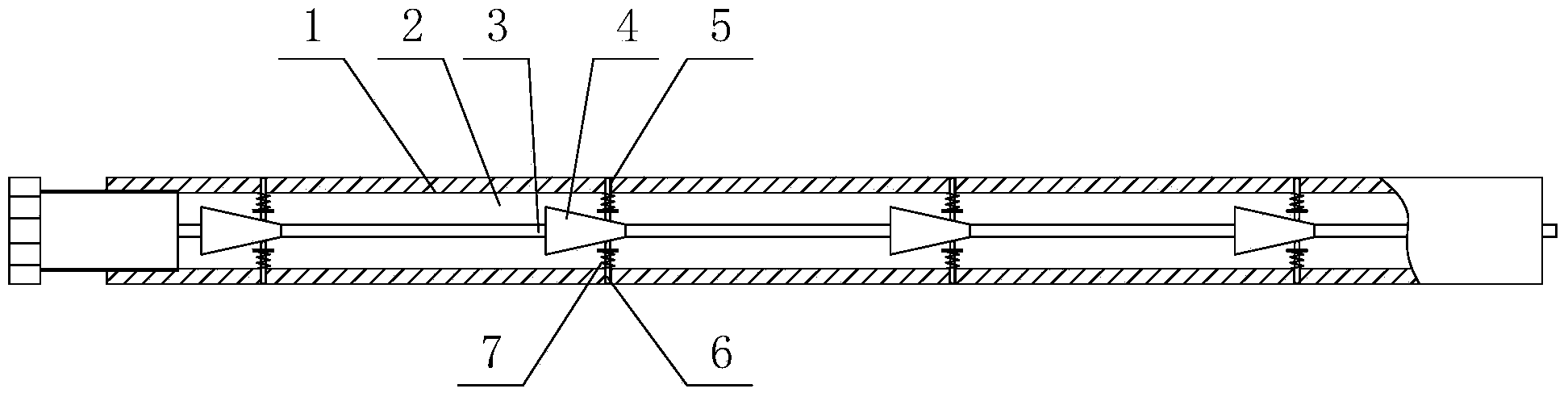

[0012] see figure 1 , an expansion shaft, comprising a cylindrical expansion shaft main body 1, the main body 1 has a hole 2 coaxial with the main body 1, and the hole 2 is provided with a top coaxial with the hole Rod 3, one end of the ejector rod 3 is inserted on the main body 1, and the other end of the ejector rod 3 is connected to the end of the main body 1 through threads. In this embodiment, one end of the main body 1 is provided with a The other end of the main body 1 has an internal thread connecting the end of the ejector rod 3, one end of the ejector rod 3 is inserted into the small hole, and the other end of the ejector rod 3 has a The top of one end where the push rod 3 and the main body 1 are threadedly fitted has a part that f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com