Expansion fixture device

A technology of expanding and clamping, applied in the direction of expanding the mandrel, etc., can solve the problems of inner hole surface damage, part cracks, outer circle deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

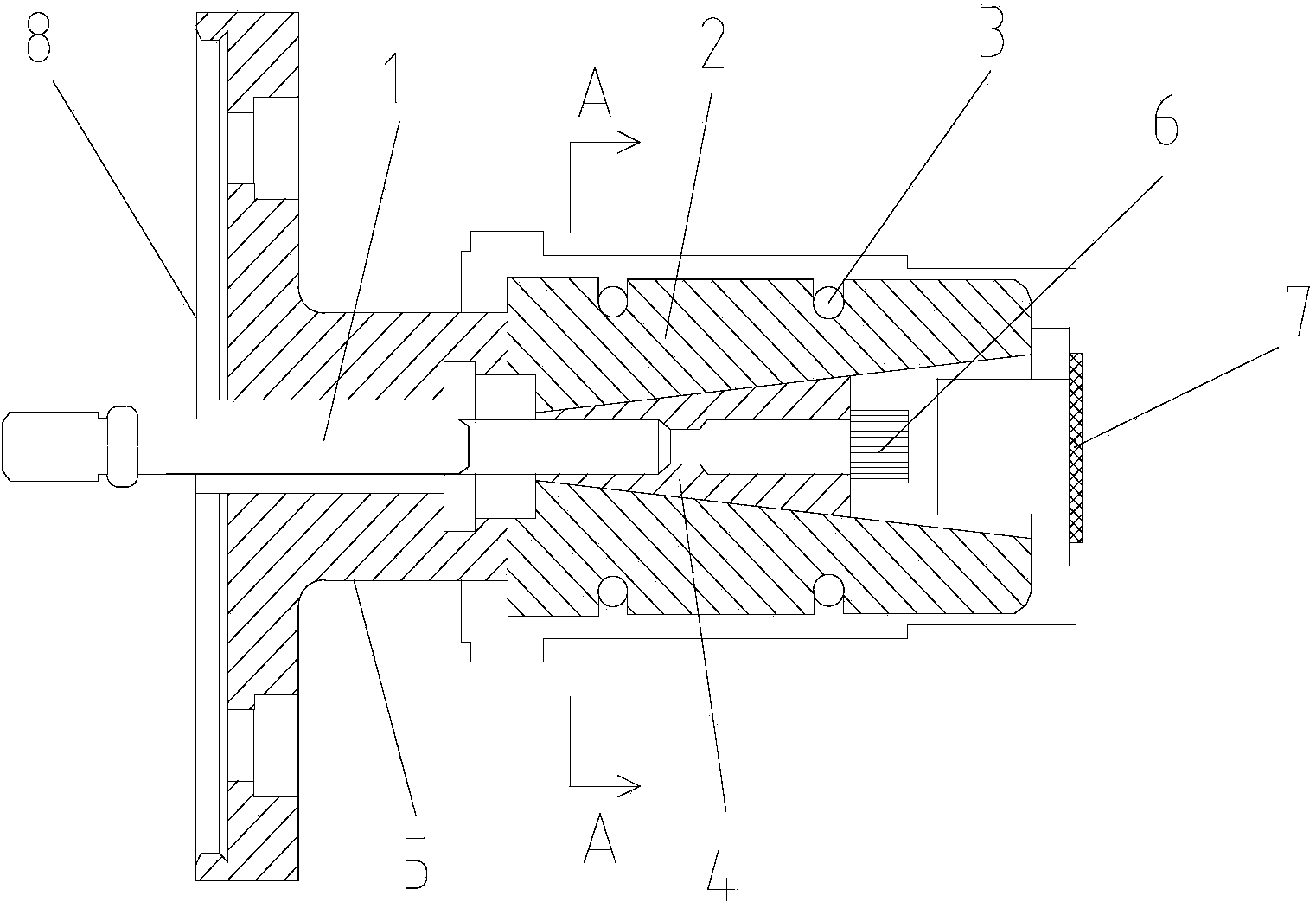

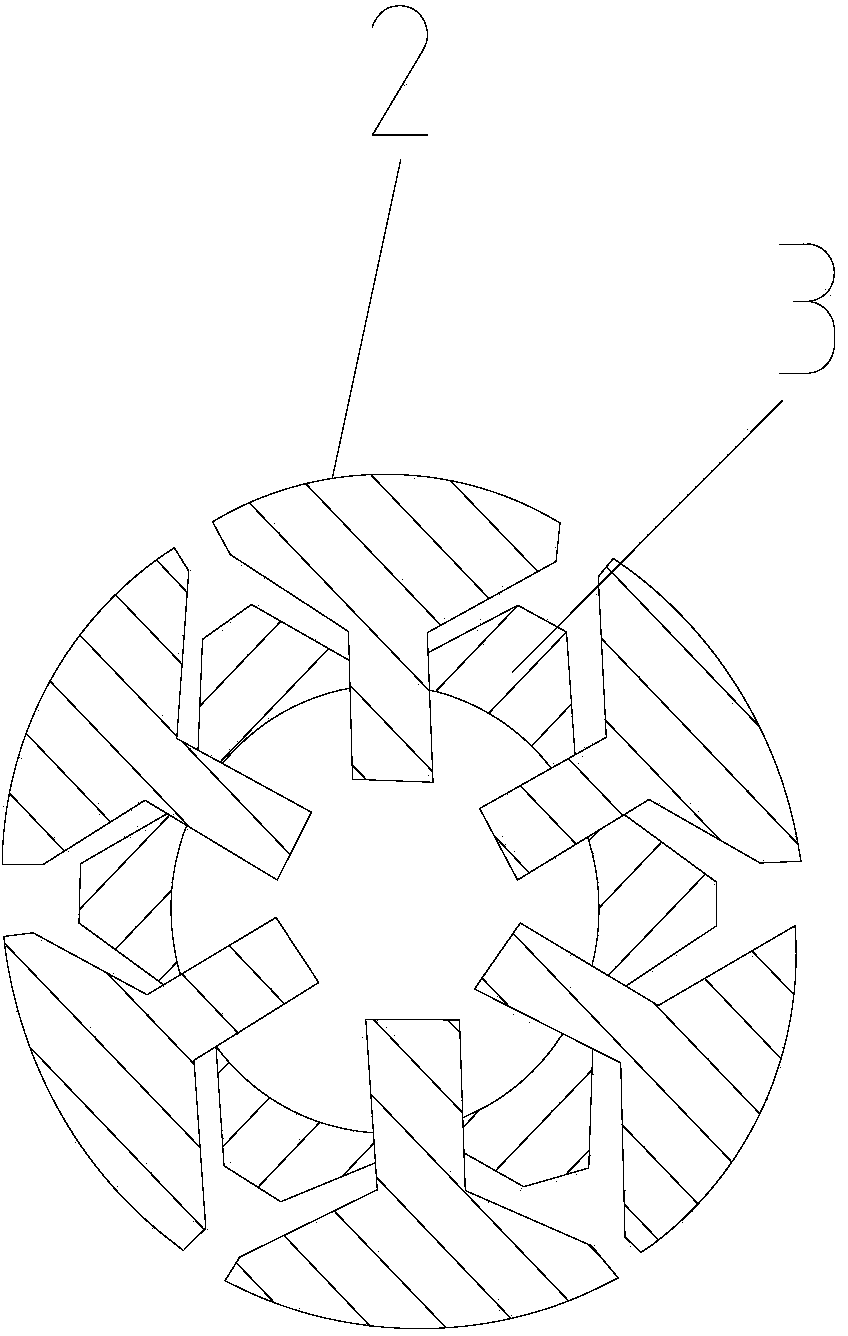

[0012] As shown in the figure, the external expansion fixture device consists of a pull rod 1, a flat petal body 2, a tension spring 3, a wedge block 4 and a clamp body 5. The clamp body 5 is provided with a central through hole, and the pull rod 1 is provided with a central through hole. Inside, six uneven axial long grooves are milled on the outer surface of the right side of the clamp body 5, and six flat petals 2 that can form a full circle are arranged in the axial long grooves. The full circle shape can ensure the surface quality of the inner hole of the workpiece. The flat petal body 2 is provided with a groove for a set tension spring 3, and the tension spring 3 is arranged in the groove, and the two tension springs 3 compress the six flat petal bodies 2 together without separation, and the flat petal body 2 The lower surface is provided with a tapered surface, the wedge-shaped block 4 is placed in the center hole of the clamp body, and is threadedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com