Automatic expansion core clamp for thin-walled cylinder parts

A technology for thin-walled tubes and parts, which is applied in the field of automatic core-expanding turning fixtures for thin-walled tube parts, can solve problems such as high labor intensity, low labor productivity, and complicated installation, so as to improve rationality, reliability, and labor productivity , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

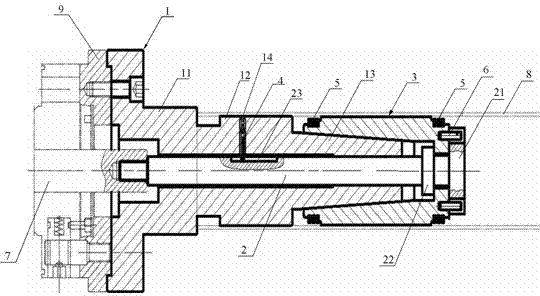

[0030] The automatic expansion core clamp for thin-walled cylindrical parts of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

[0031] Such as figure 1 As shown, an automatic expansion core fixture for thin-walled cylindrical parts, including a core shaft 1 forming a central through hole, a connecting shaft 2 and an expansion sleeve 3,

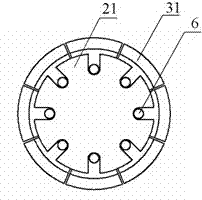

[0032] Such as figure 2 , 3 , 4, the mandrel 1 is composed of a fixed part 11, a limiting part 12 and a tapered shaft part 13 from left to right, one end of the fixing part 11 forms a flange and is fixed to the chuck 9 of the machine tool, and the limiting part A radial positioning hole 14 is formed on the 12, and the tapered shaft portion 13 is in the shape of a truncated cone with a taper on the outer peripheral surface;

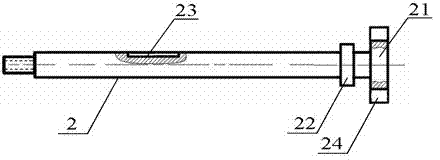

[0033] The connecting shaft 2 extends into the central through hole of the mandrel 1, one end is threadedly connected with the piston rod 7 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com