Thin-wall round pipe turning and clamping device

A clamping device and a technology for round tubes, applied in the field of mechanical processing, can solve problems such as difficulty in ensuring and controlling the size of thin-walled round tubes, affecting dimensional accuracy and shape tolerance, thermal deformation of thin-walled round tubes, etc., achieving low production costs and high processing accuracy , Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

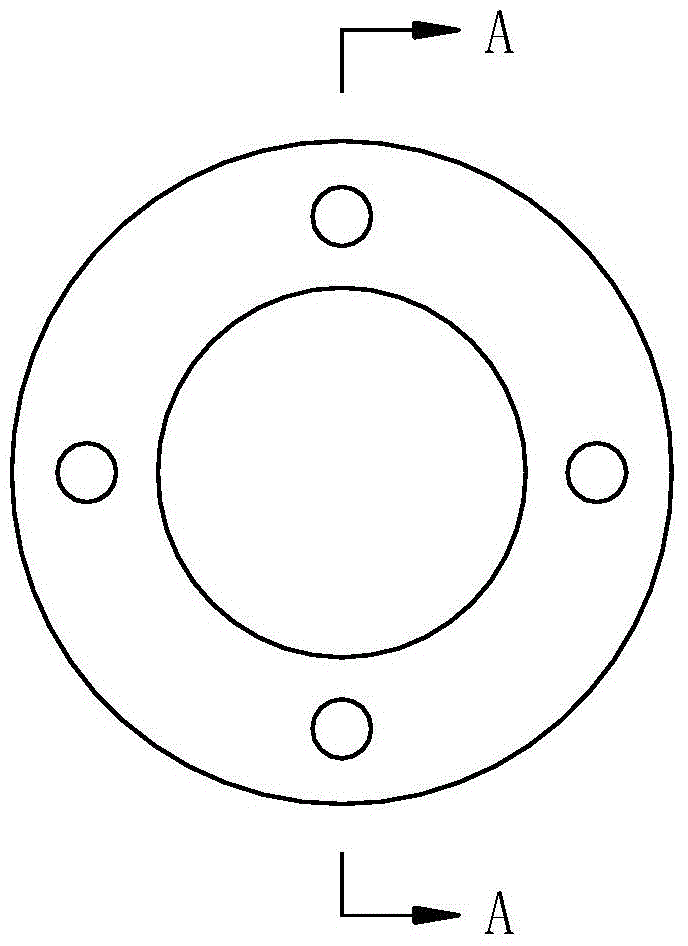

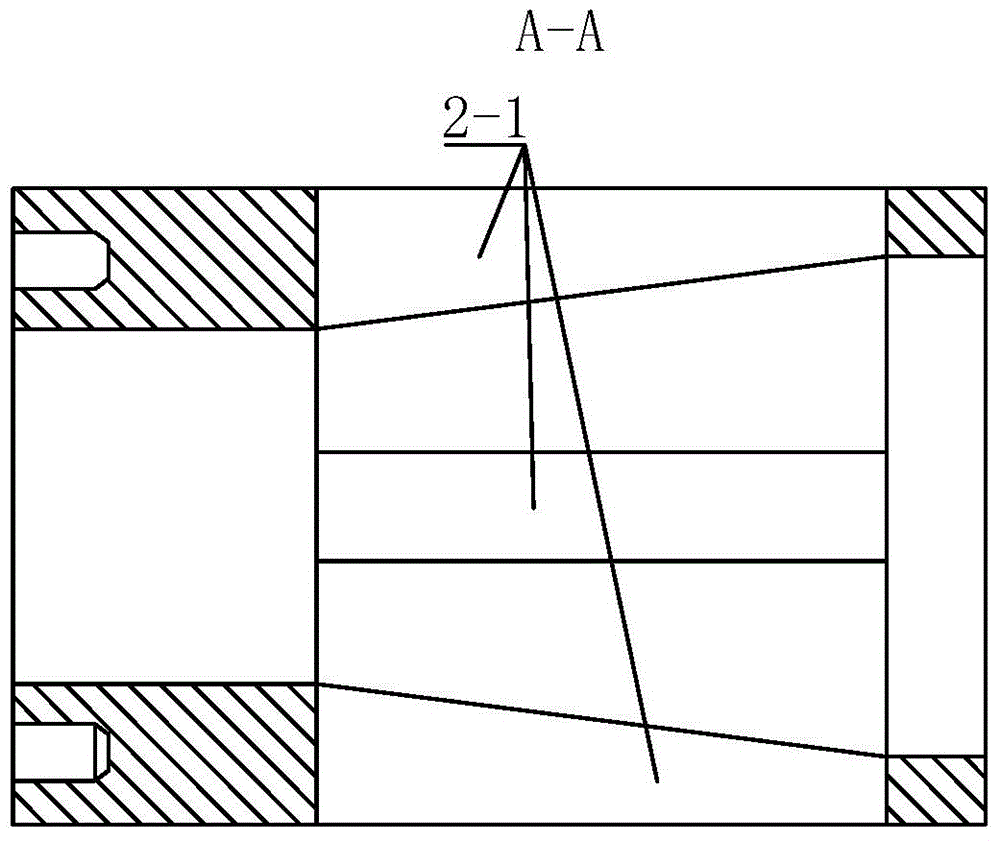

[0020] Such as Figure 1-Figure 3 The shown clamping device for turning a thin-walled circular tube includes a slider bracket 2 for slidingly installing the inclined-plane slider 4, a screw rod 7 for slidingly installing and supporting the tapered sleeve 5, and a screw rod 7 for driving the slider bracket 2 and The clamping base 1 that the screw rod 7 rotates with the main shaft of the lathe also includes an inclined plane slider 4 and a taper sleeve 5 with the same taper; the slider bracket 2 and the screw rod 7 are fixedly installed on the clamping base At one end of the seat 1, a taper sleeve 5 is slidably installed on the screw rod 7, and at least two installation chutes for installing the inclined-plane slider 4 are evenly distributed around the axis of the screw rod 7 on the slider bracket 2 2-1, each of the installation chute 2-1 is slidably installed with the tapered sleeve 5 to tighten the workpiece 3 from the inside of the inclined slider 4, each of the inclined slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com