Jump detector for grinding wheel circle

A technology of circular runout and measuring instrument, which is applied in the direction of measuring devices, instruments, and electric devices, etc., can solve the problem of low measurement efficiency of grinding wheel circular runout parameters, achieve good market prospects and social significance, avoid human errors, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

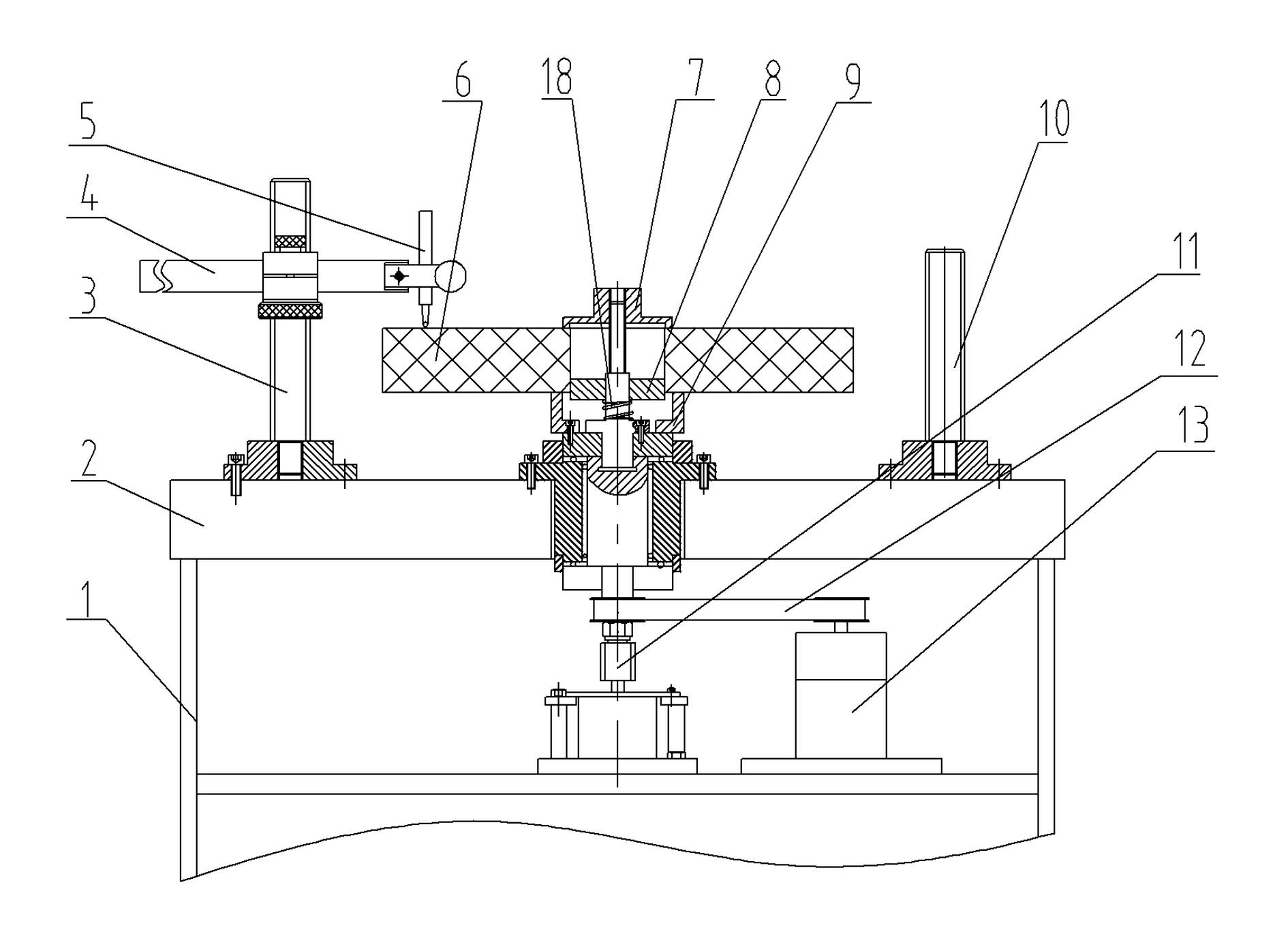

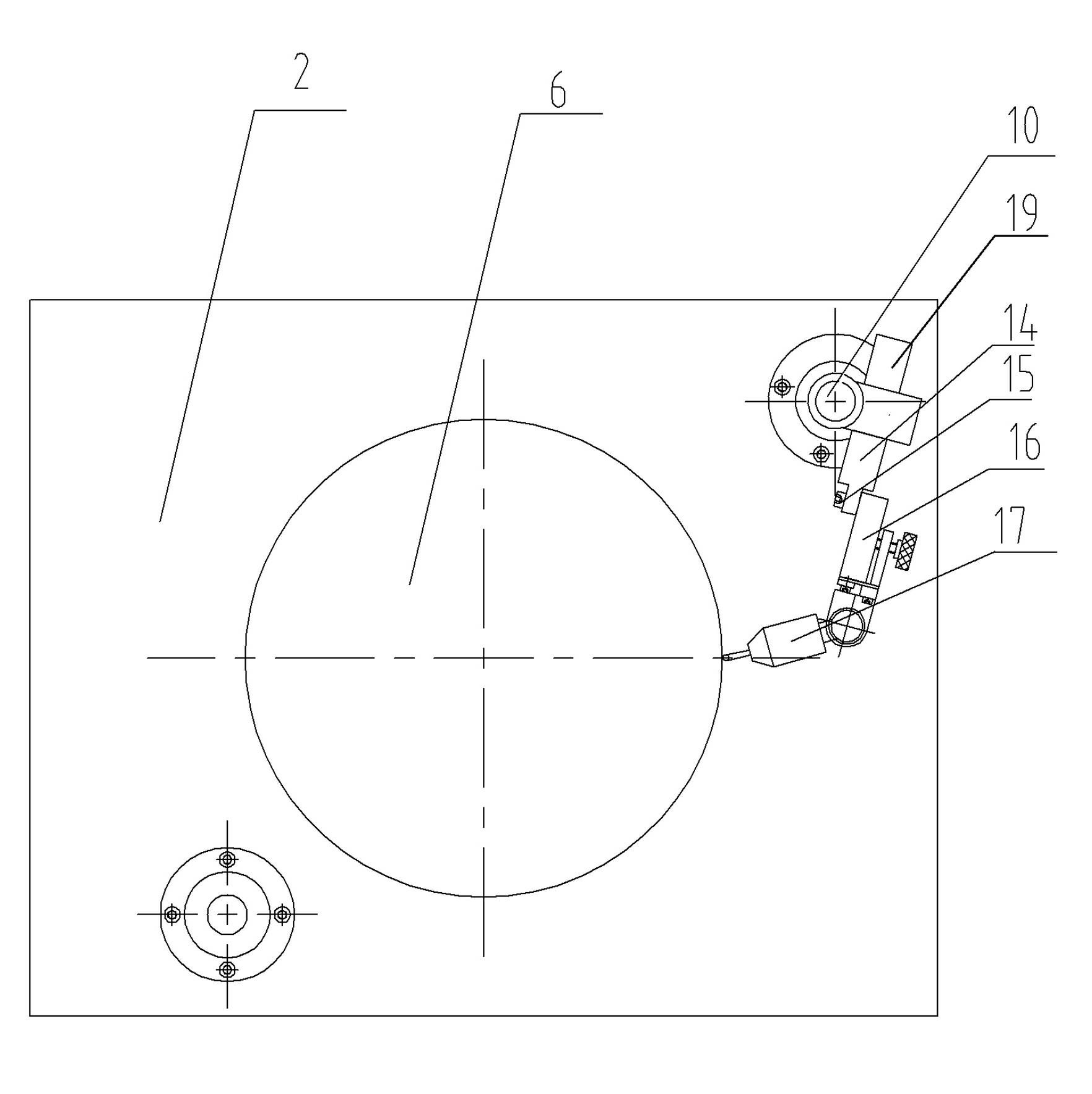

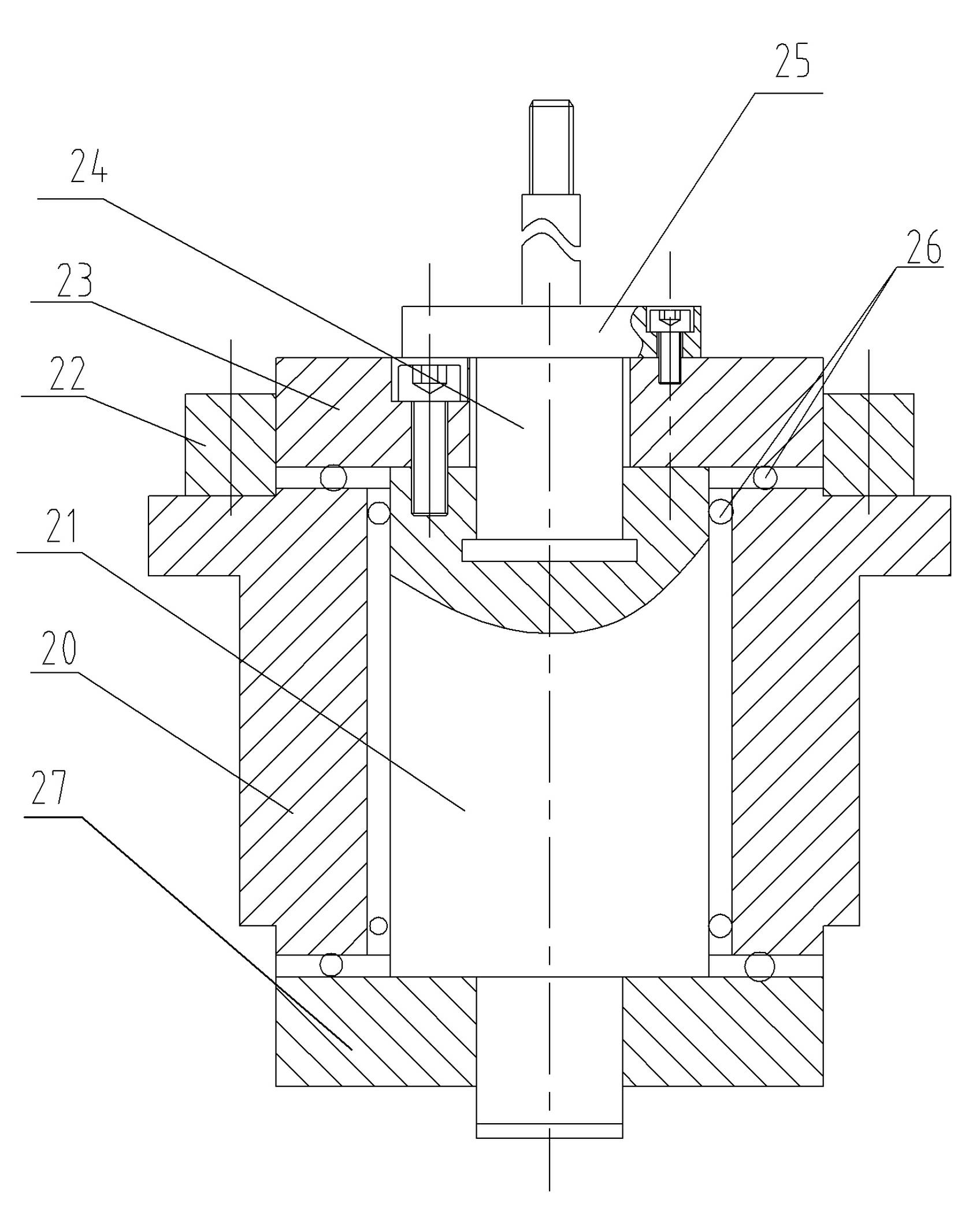

[0022] Such as Figure 1 to Figure 4 As shown, a grinding wheel runout measuring instrument includes a frame 1, a workbench 2 is arranged on the frame 1, and a rotating fixture is installed on the workbench 2. The rotating fixture includes a rotating shaft, and a useful The mandrel part coaxially plugged with the center hole of the tested grinding wheel 6, the rotating shaft in this embodiment includes a main shaft that is rotated on the workbench 2, and the main shaft is driven to rotate by the drive system. The core set on the said rotating shaft The shaft part is a conical mandrel 8 coaxially rotating on the main shaft, the outer peripheral surface of the conical mandrel 8 is a circular table surface, and the upper end of the conical mandrel is a small diameter end. The drive system in this embodiment includes a synchronous motor 13 And the synchronous belt 12 that is used to drive and connect the synchronous motor and the main shaft is coaxially fixed with a tray 9 for hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com