Dual-reel coiler

A coiler and double drum technology, applied in the field of forming, can solve the problems of increasing the floor space and equipment, increasing the amount of equipment maintenance and equipment failure sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

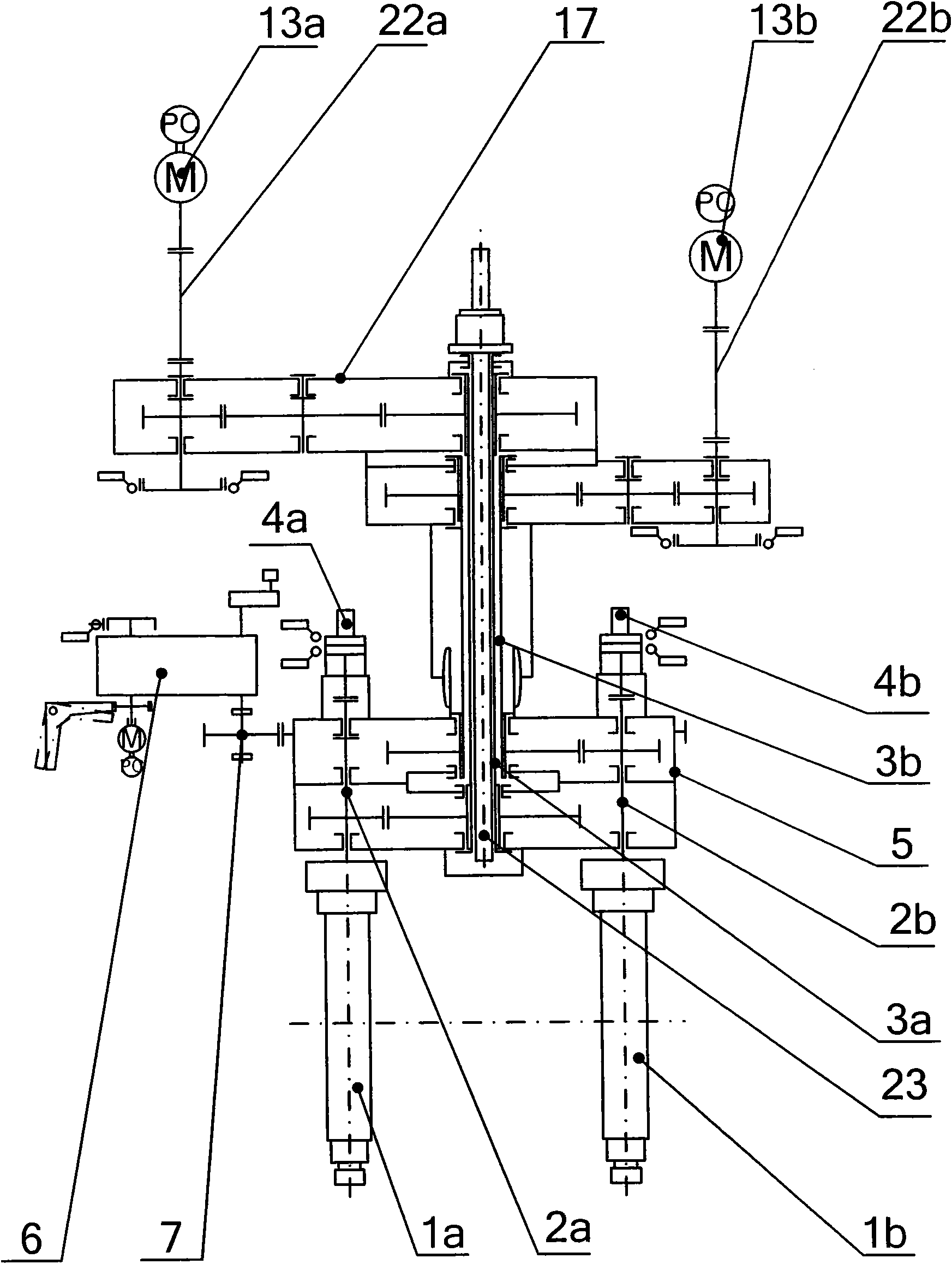

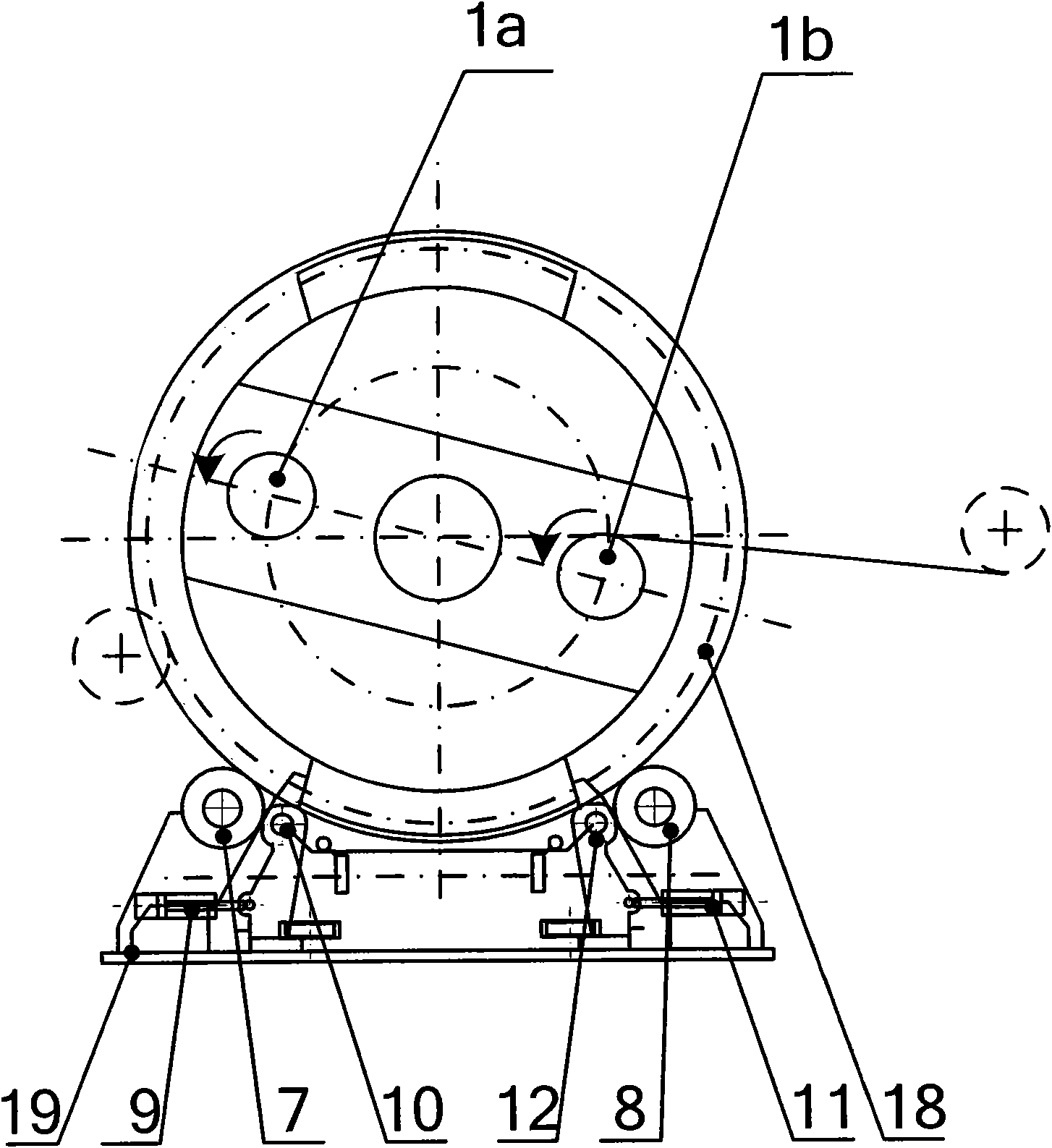

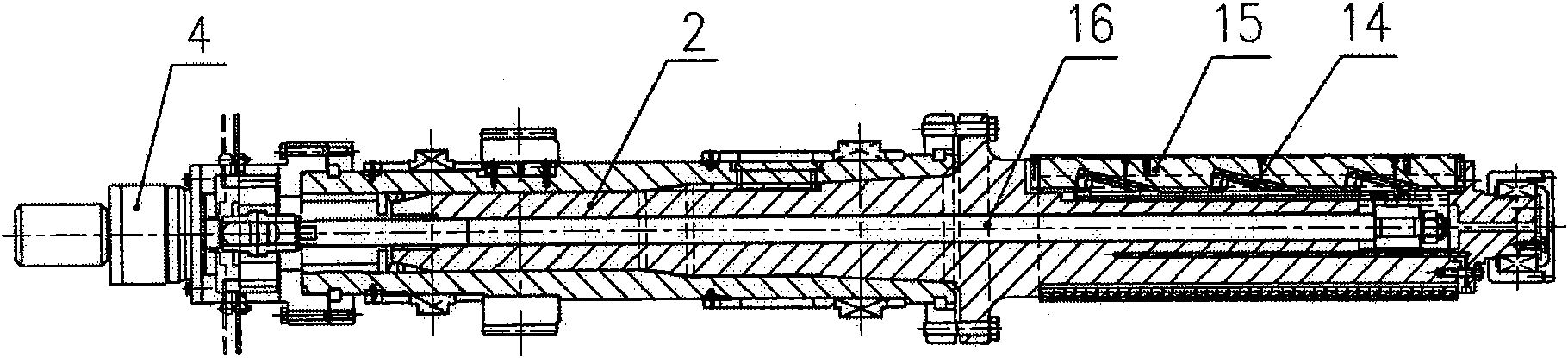

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] Depend on figure 1 , figure 2 As shown: two hydraulically controlled expandable reels 1a and 1b are arranged in a common rotary box (turntable) 5, and the reels 1a and 1b rotate around their respective mandrels 2a and 2b, and the mandrels 2a and 2b are respectively driven by Two hollow shafts 3a and 3b with a common axis are input into the drive, and the reels 1a and 1b are driven by the rotary hydraulic cylinders 4a and 4b to achieve expansion and contraction; the rotary box 5 is driven by the drive device 6 through the gear 7, and the turntable 5 is driven by the guide roller 8 supports; the rotary box 5 is braked by the brake hydraulic cylinder 9 to drive the brake 10, and the clamping device 12 is driven by the clamping hydraulic cylinder 11 to achieve clamping; the reels 1a and 1b are decelerated by separate motors 13a and 13b through gears The system transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com