Patents

Literature

99results about How to "Comprehensive cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

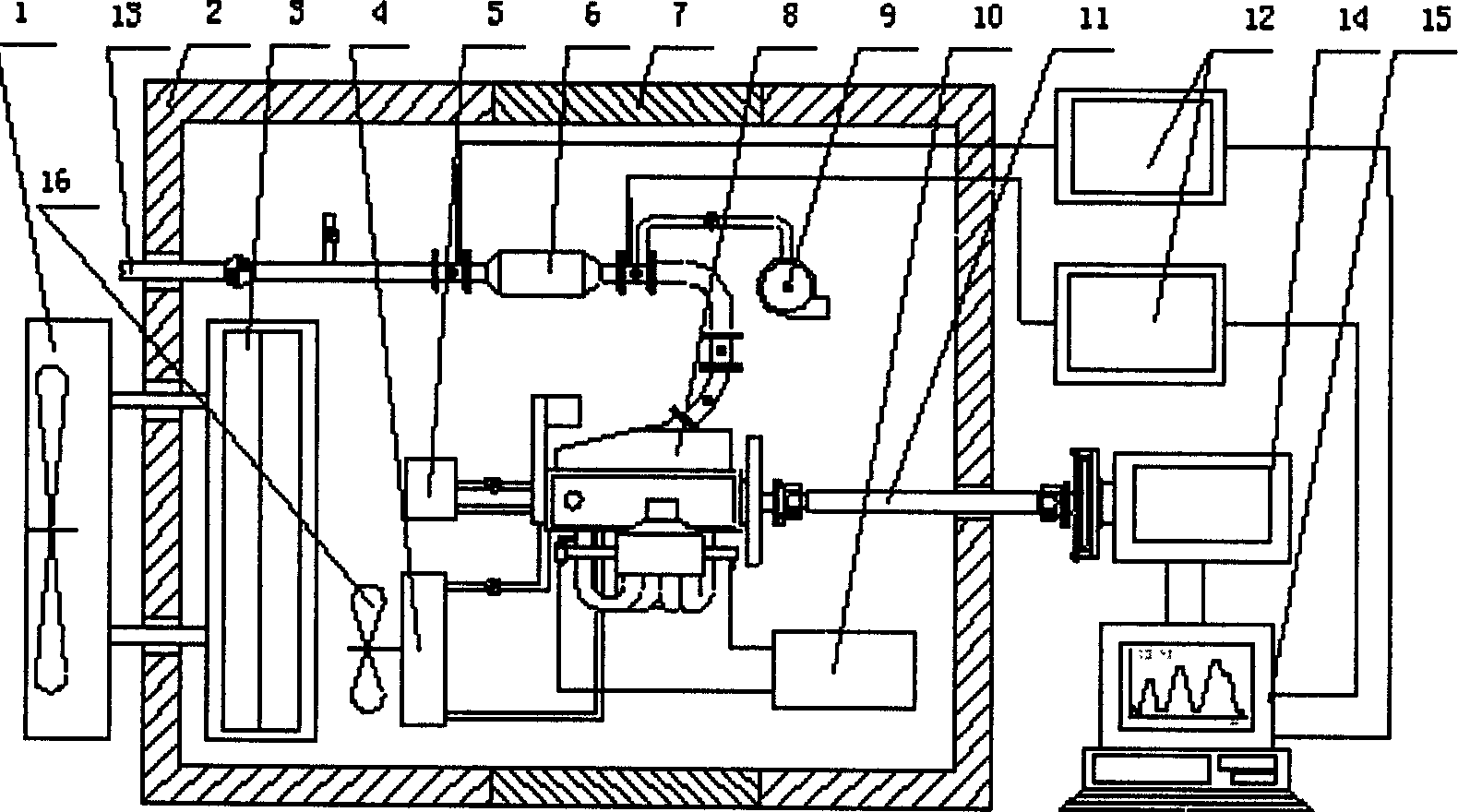

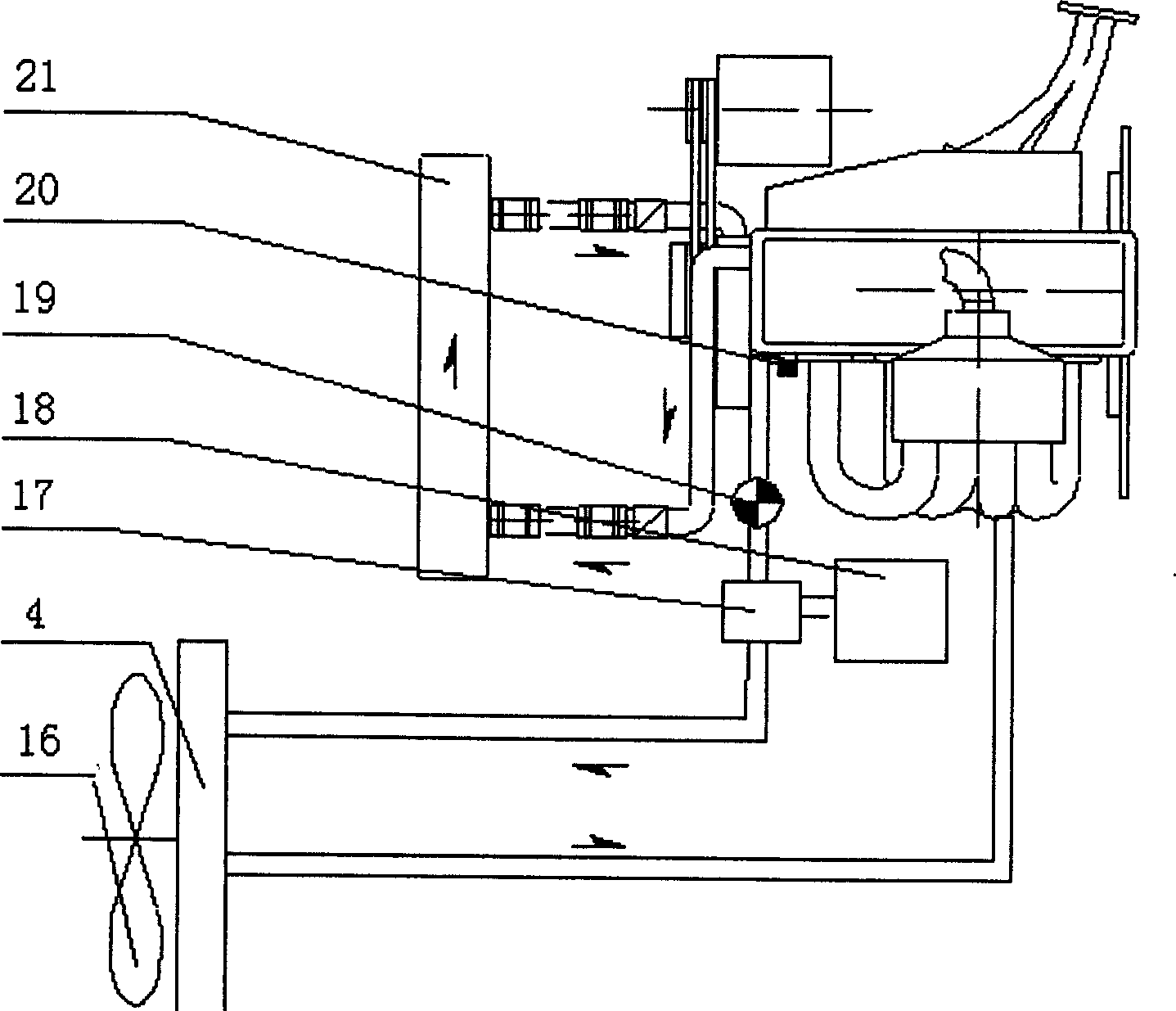

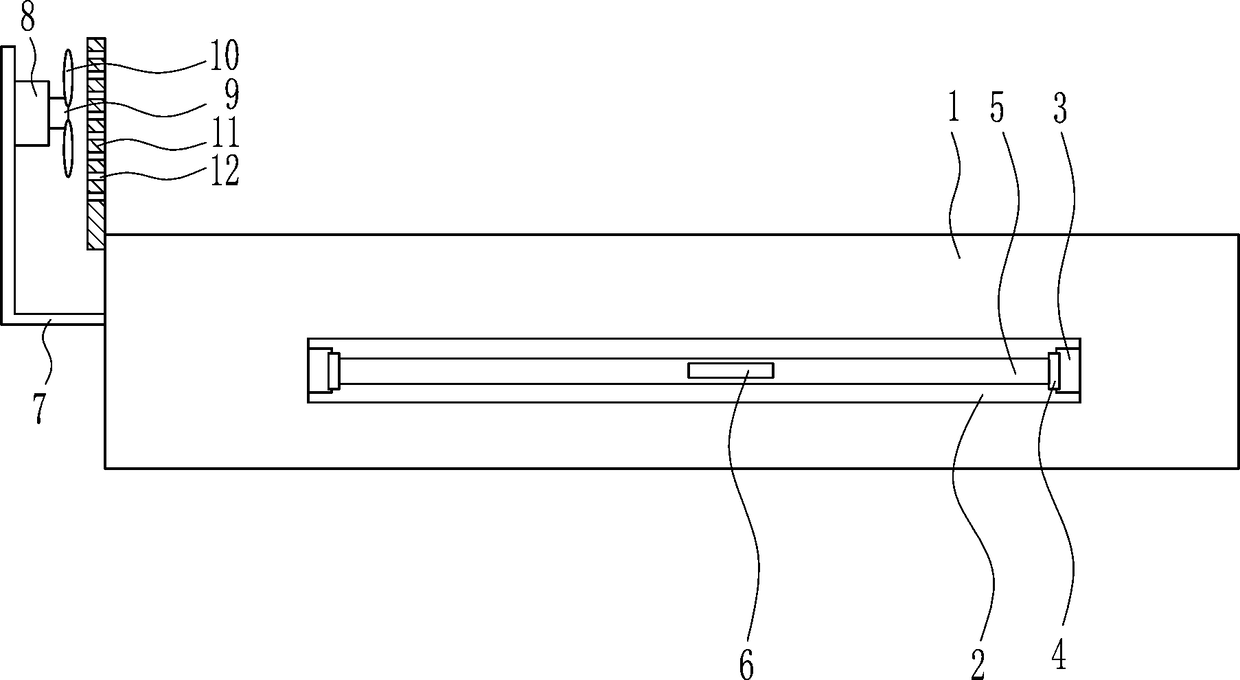

Discharge quick simulation tester for cold starting automobile engine of light car

The invention relates to a device for stimulating the cool start of the motor of the light vehicle, which applies to the motor platform for stimulating the hub test behavior of the light vehicle III, IV. Said device comprises primarily a cooling cabin, a refrigerating system, a motor intensive fast-cooling apparatus, an electric eddy current dynamometer set outside the cooling cabin, two discharging analyzer and a computer controlling and selecting system. The invention controls the cabin temperature combined with the intensive fast-cooling apparatus, and cools temperature of the motor, post handing system, accessory parts evenly and rapidly, which reduces the preparing time.

Owner:TSINGHUA UNIV

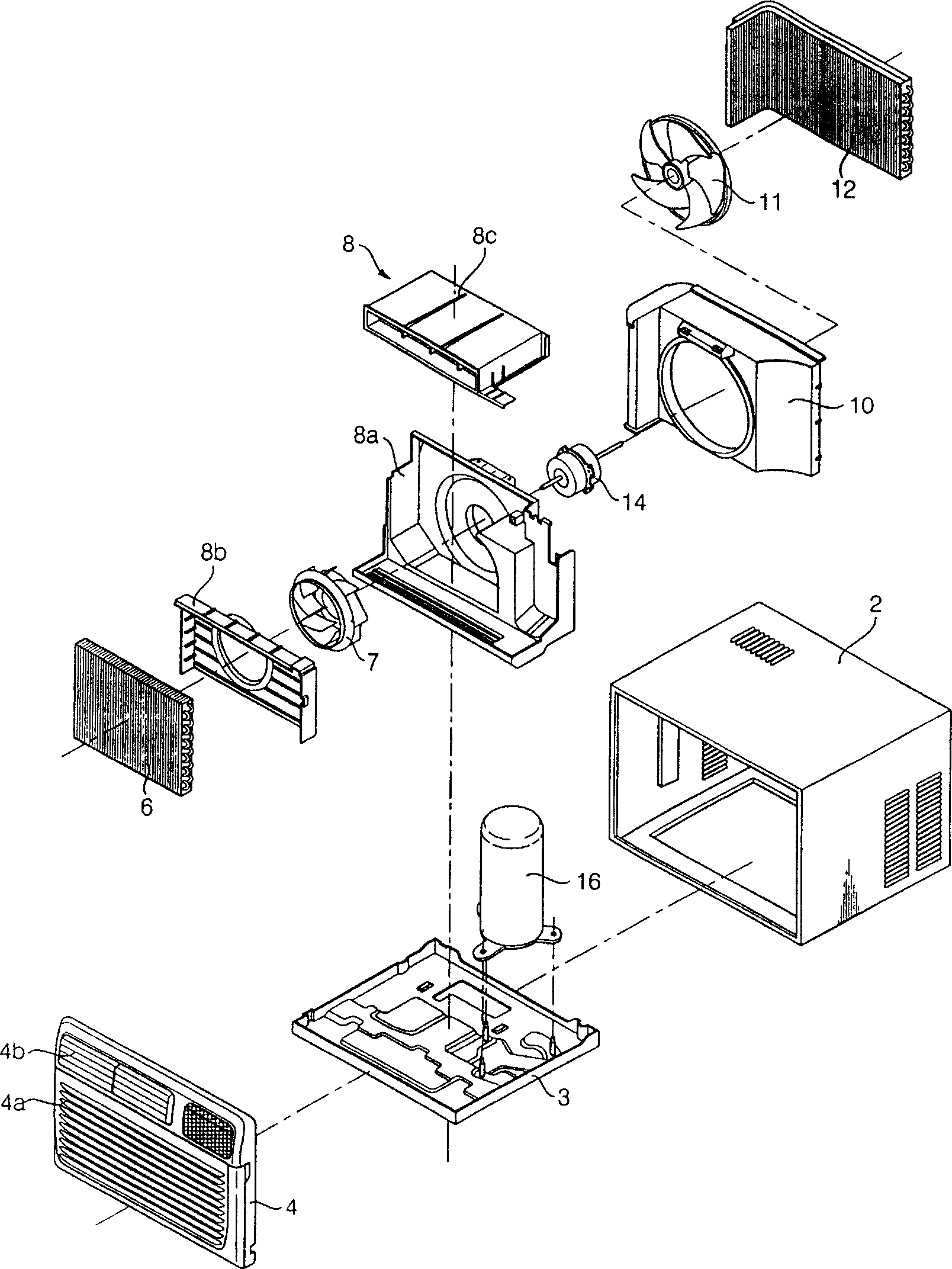

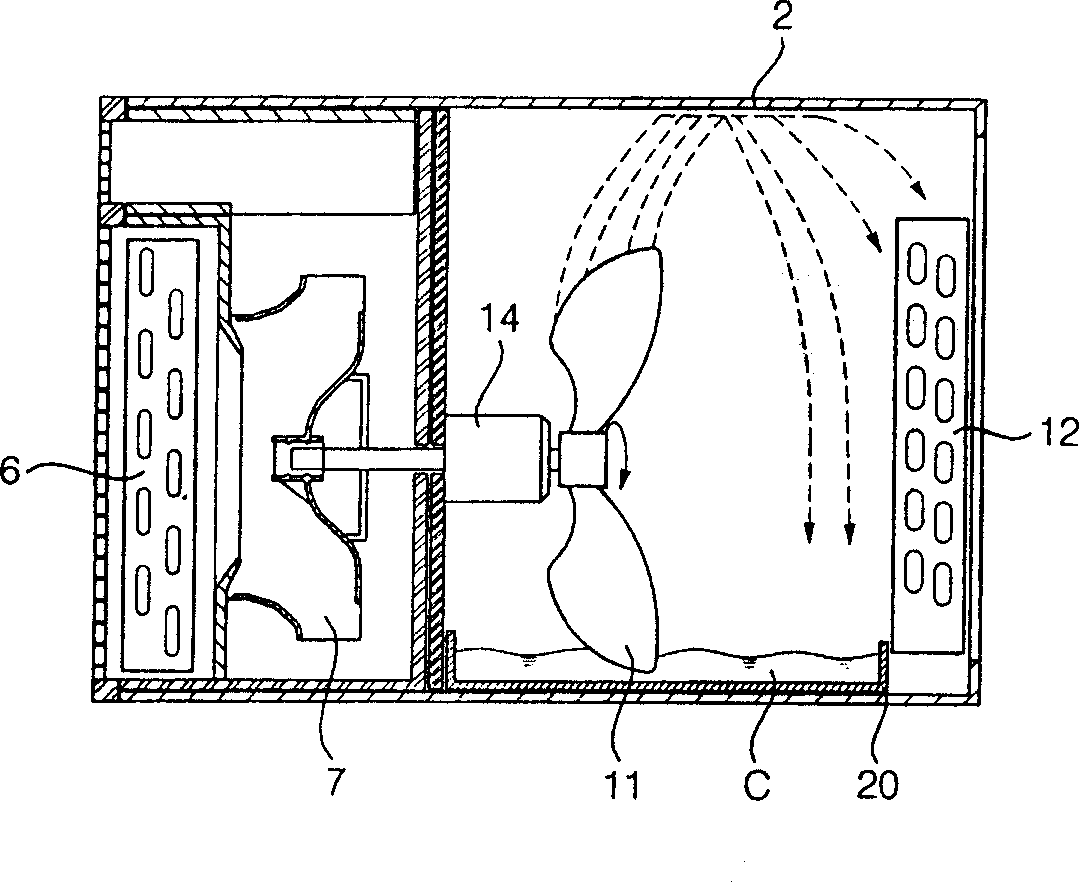

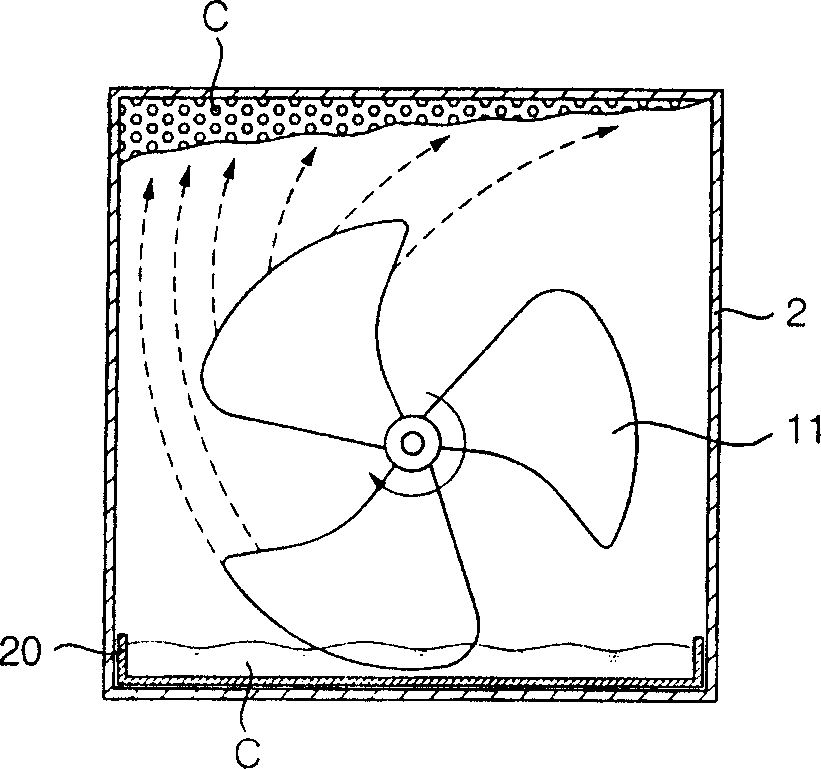

New type condenser cooling structure of window air conditioner

InactiveCN1590861APrevent fallingImprove cooling effectCondensate preventionLighting and heating apparatusEngineeringEvaporator

A cooling structure of condenser for window-type air conditioner features that the condensed water generated by evaporator is used to cool the condenser, and a condensed water guider is used to apply the water to the top surface of condenser.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

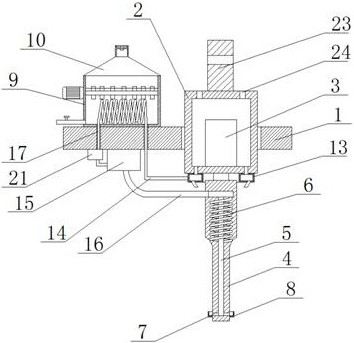

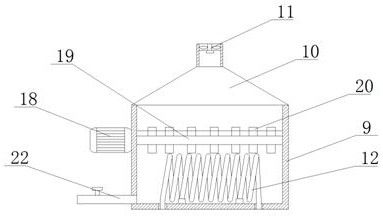

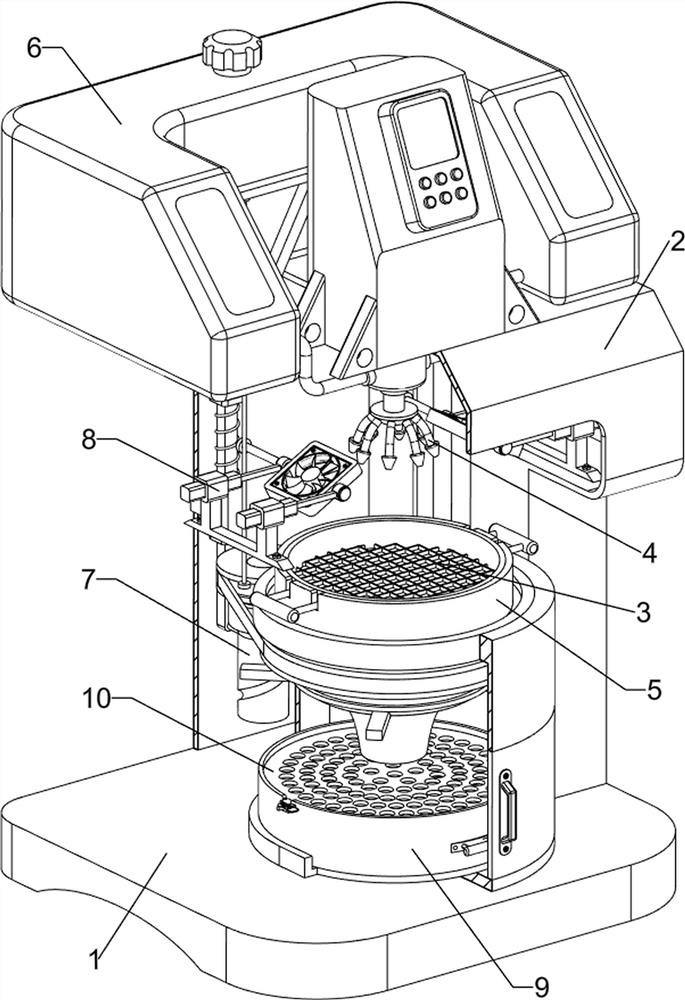

Metal material end surface quenching test machine

InactiveCN102787223AReduce heat lossGuaranteed temperatureHeat treatment process controlMetallic materialsQuenching

The invention relates to a metal material end surface quenching test machine. A prepared cylindrical sample is uniformly heated by the induction coil of a high frequency generator, the center of the upper surface of the sample is provided with a blind hole for arranging a thermocouple to collect the change of the temperature of the sample, the heating part is processed to prepare a water tank, a water injection nozzle is arranged under the sample, a cooling water tube is arranged above the sample, the water injection quenching time is controlled by a water injection control valve arranged on a middle water tube of the water injection nozzle, the water outlet time of cooling water is controlled by a cooling water control valve arranged on a cooling water tube in a cooling water tank, and a used water resource is collected in a cycle water tank and is recycled through utilizing a water pump. The machine integrates heating, quenching and cooling, and realizes the heating, the quenching and the cooling automatically, so the sample accuracy is improved.

Owner:DONGHUA UNIV

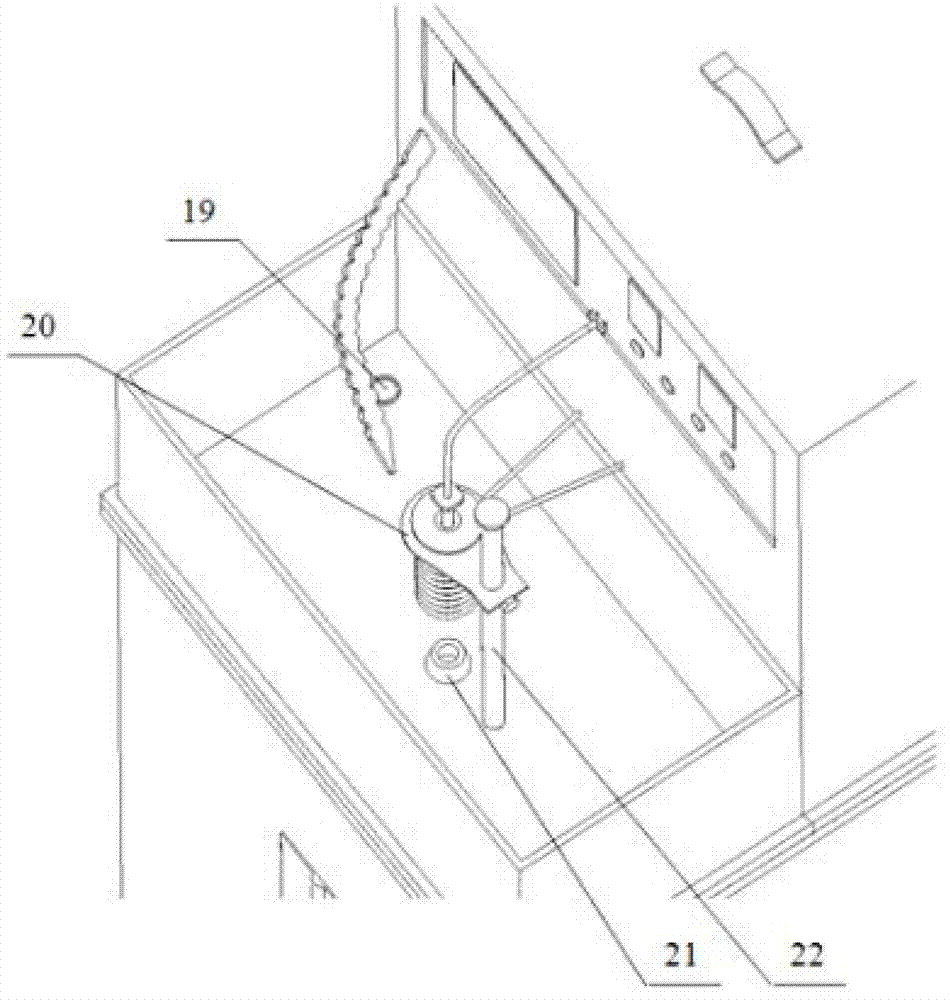

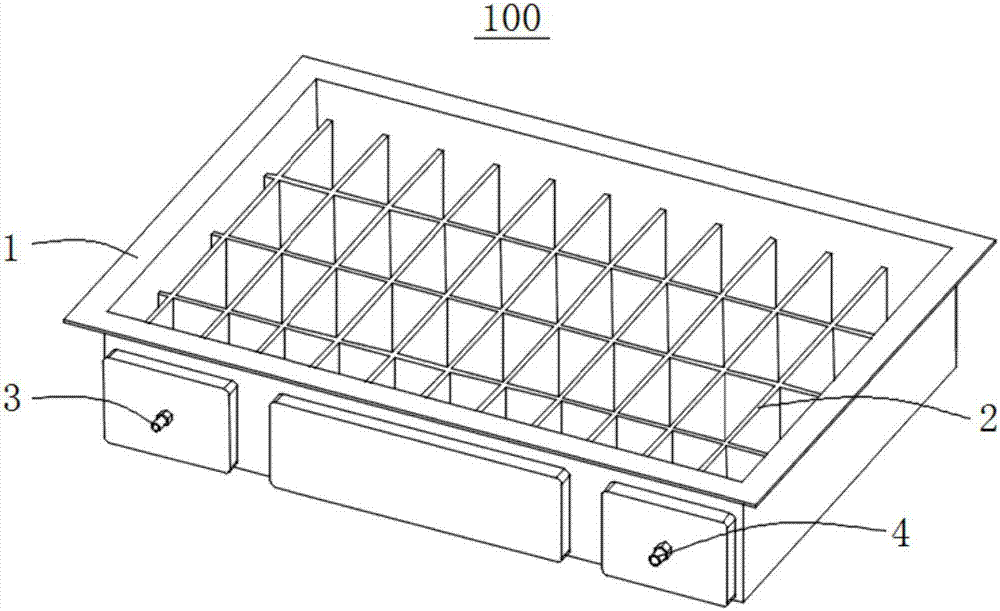

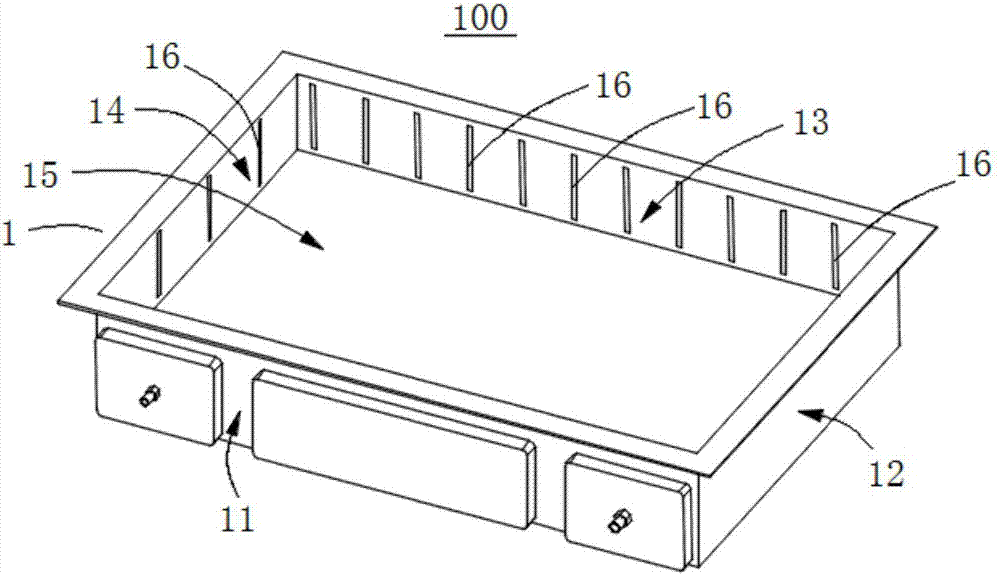

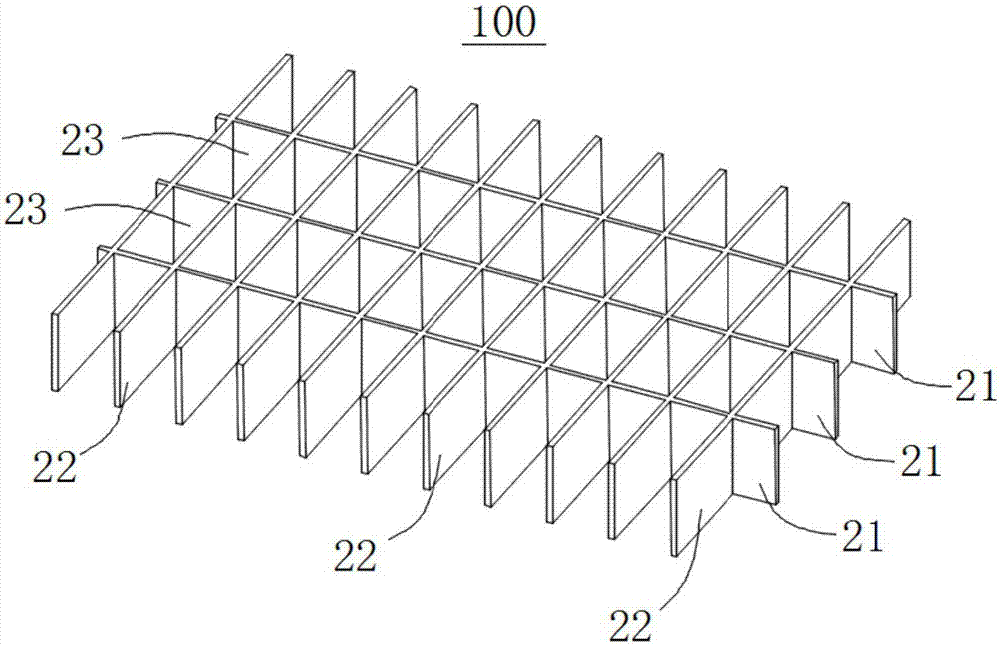

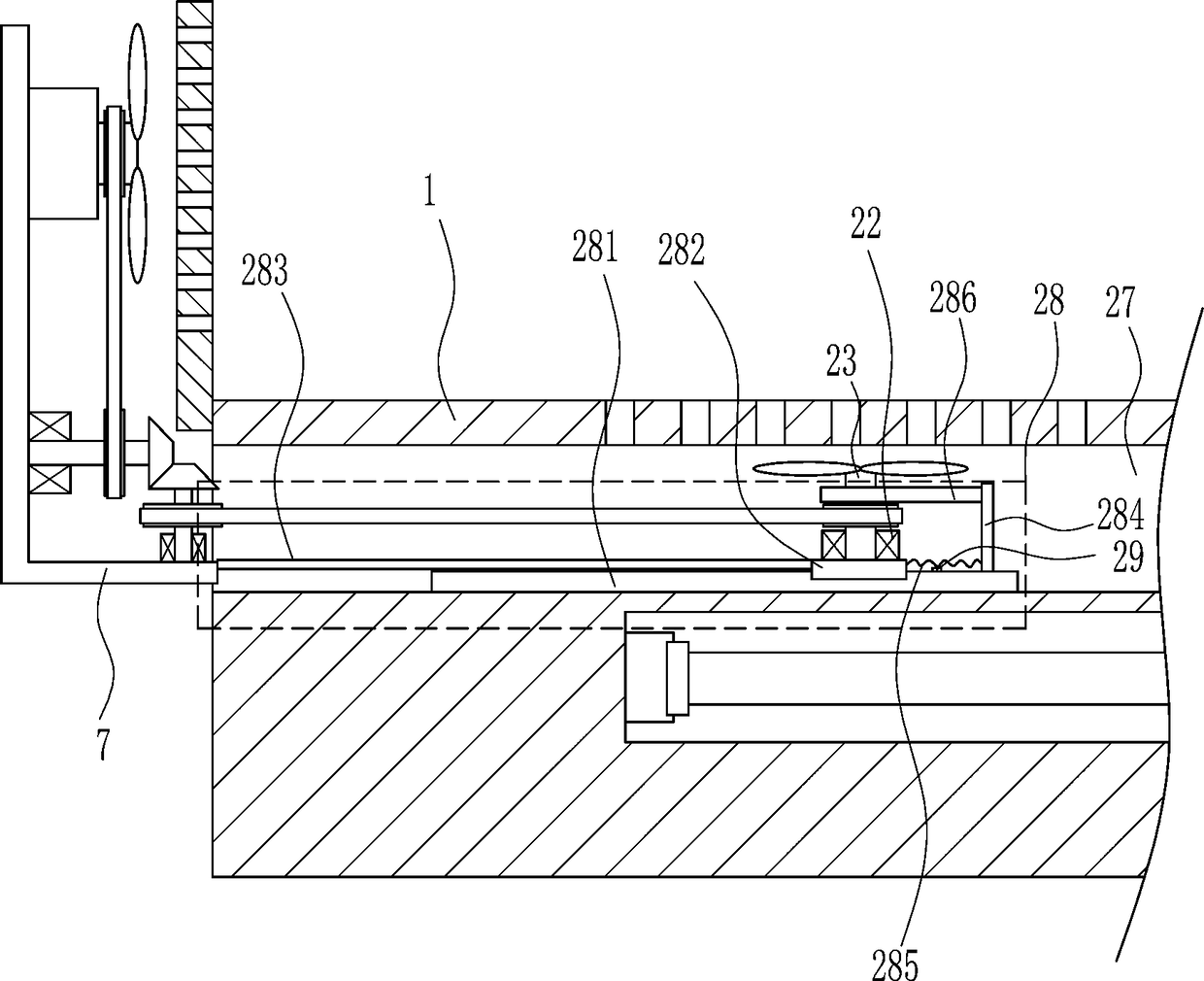

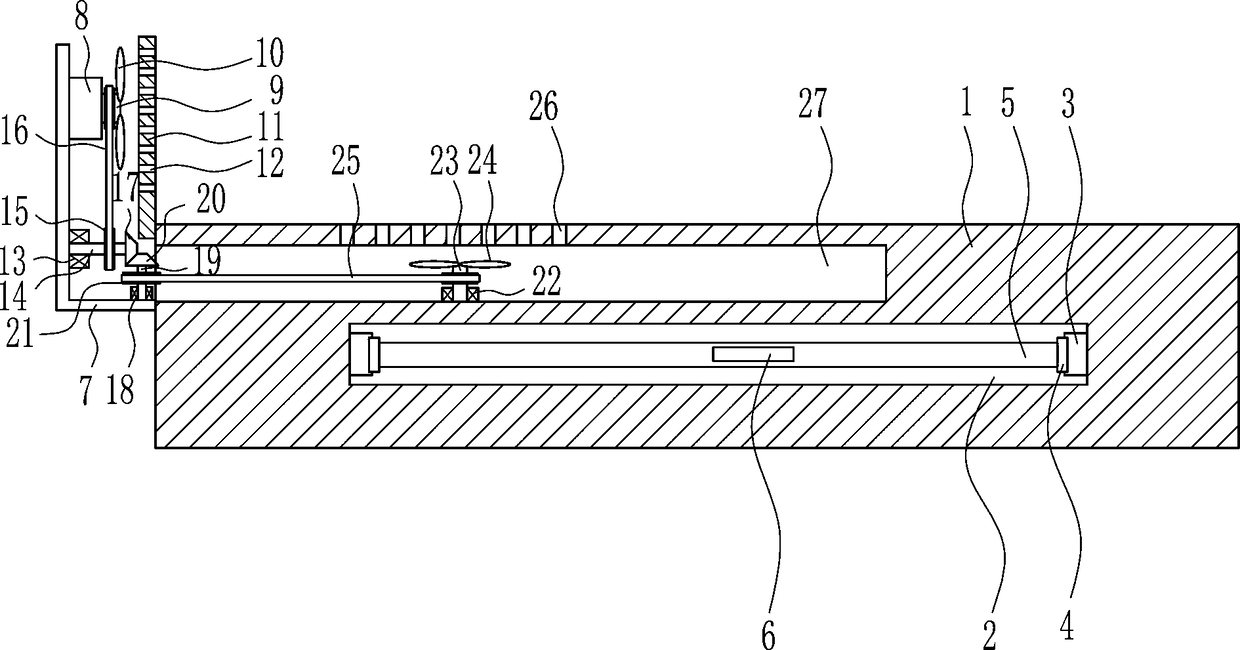

Heat dissipation device and battery module

PendingCN107394315AComprehensive coolingUniform coolingSecondary cellsCell component detailsEngineeringCooling fluid

Owner:HUATING HEFEI POWER TECH

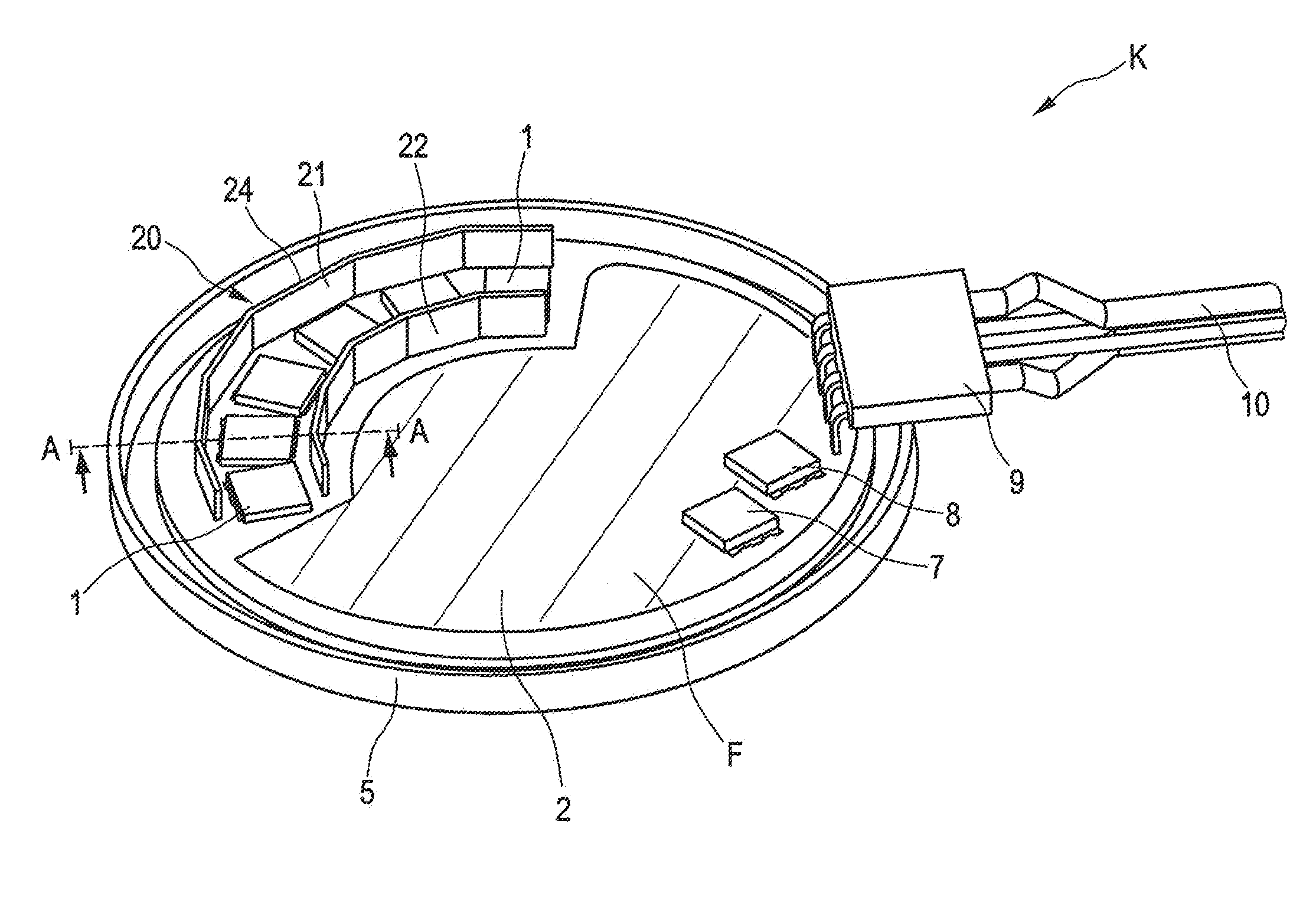

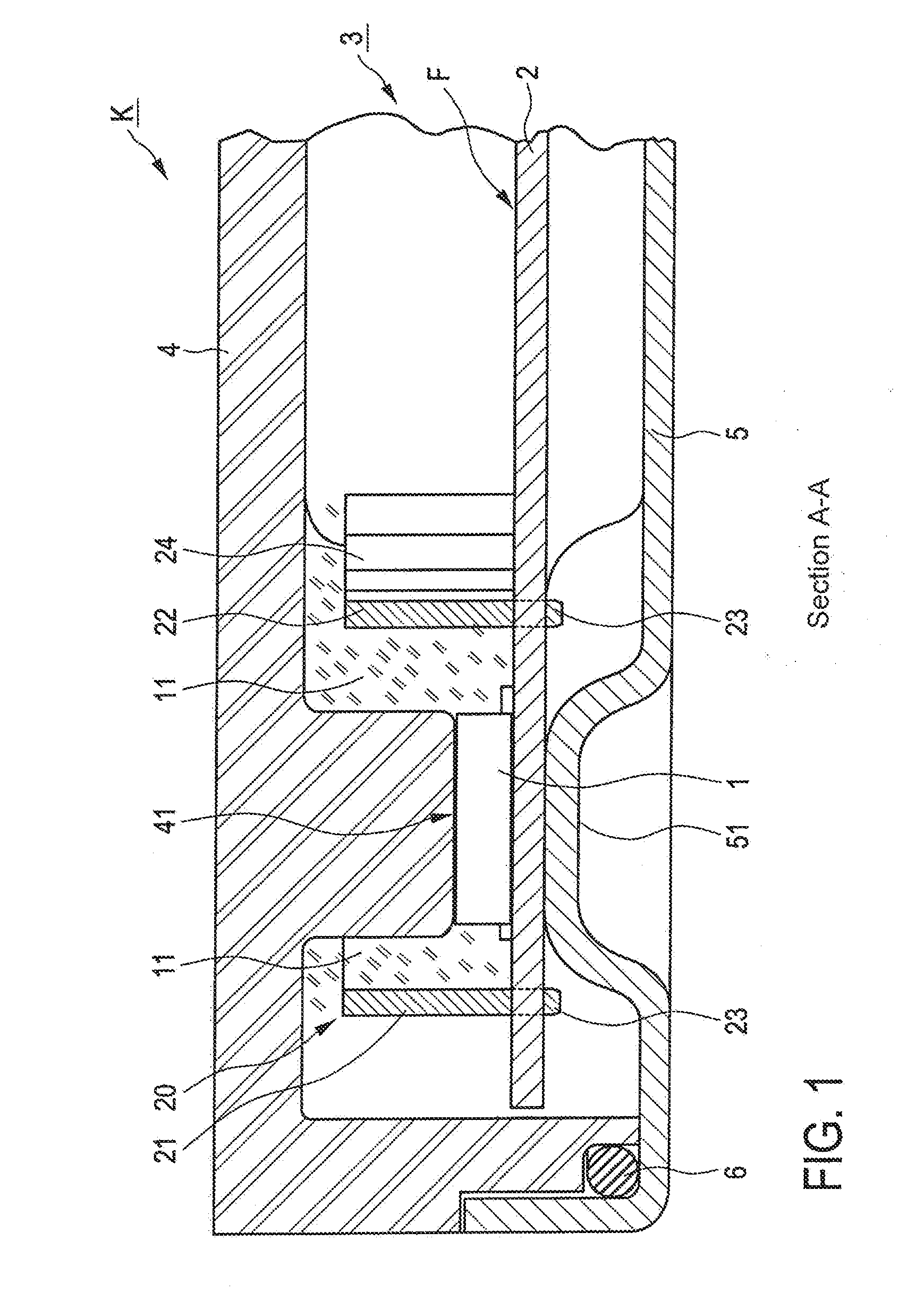

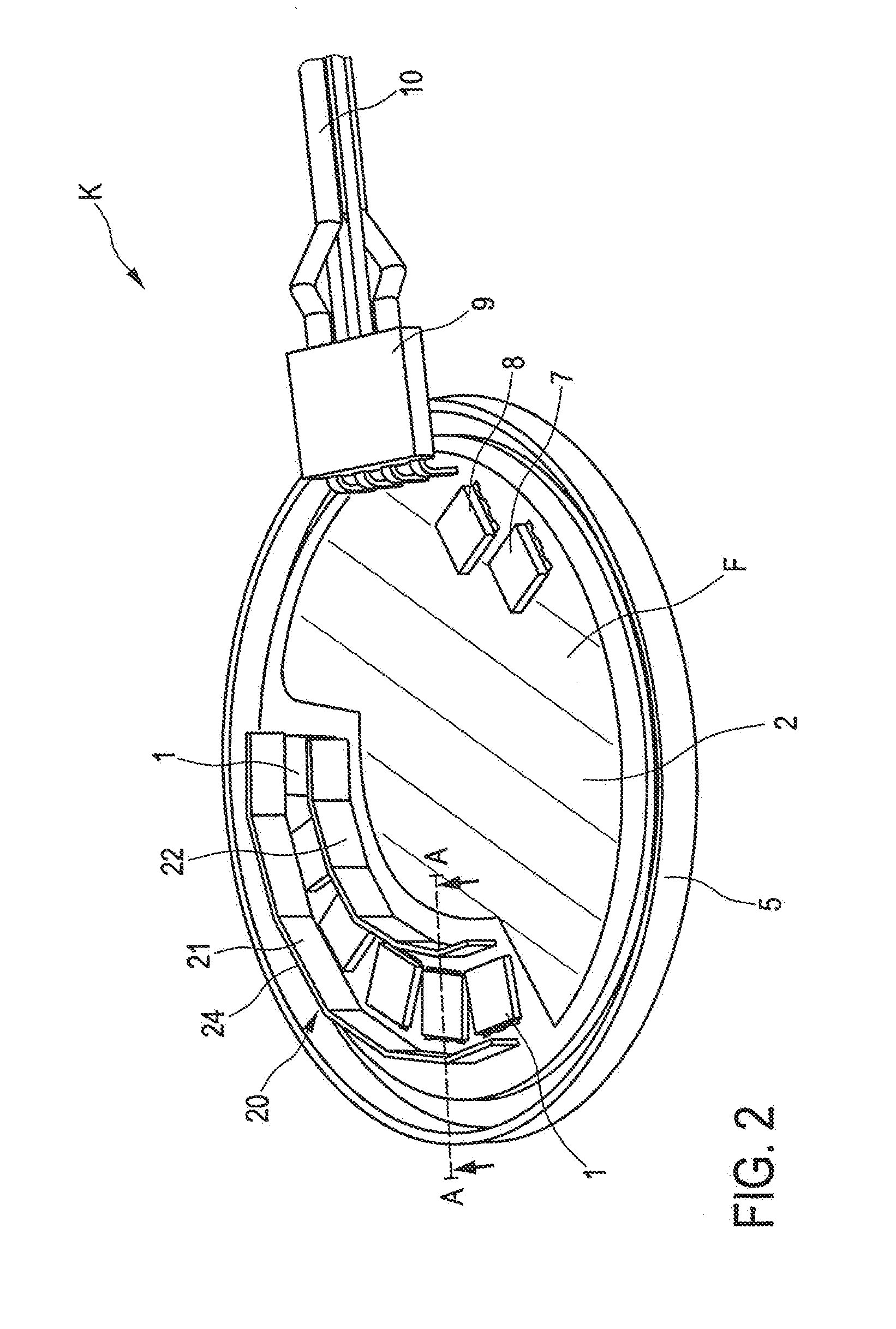

Cooling device and cooling arrangement including cooling device

ActiveUS20150257309A1Solve the lack of cooling capacityCompact designModifications by conduction heat transferHeat exchange apparatusPrinted circuit board

The invention relates to a cooling device for heat-emitting components, wherein at least one component is arranged on a printed circuit board and wherein the cooling device includes a first cooling member and a second cooling member. The two cooling members are arranged on the printed circuit board adjacent to and at a predetermined distance from the at least one component on opposite sides of the component. The invention further relates to a cooling arrangement for cooling at least one heat-emitting component arranged on a printed circuit board, wherein use is made of the cooling device.

Owner:HKR AUTOMOTIVE GMBH

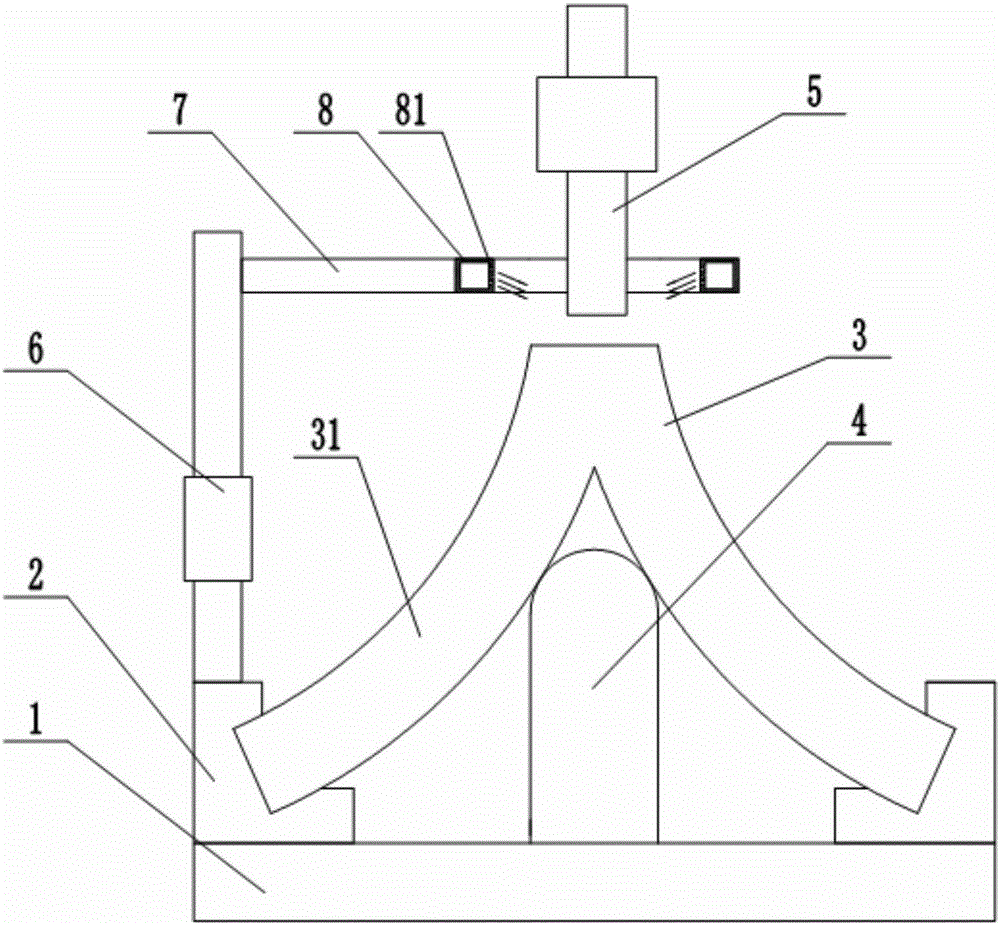

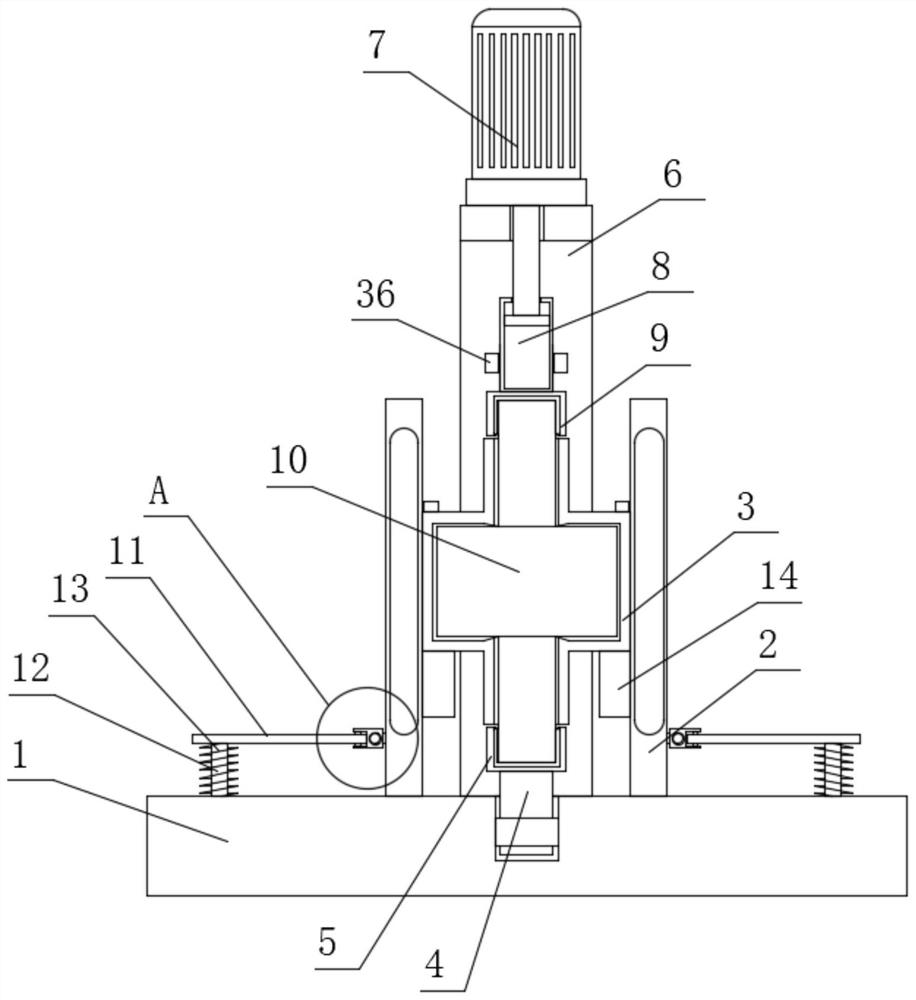

Drilling technological equipment with annular water spray cooling function

InactiveCN105312928AEasy to drillImprove support stabilityPositioning apparatusMaintainance and safety accessoriesCooling effectEngineering

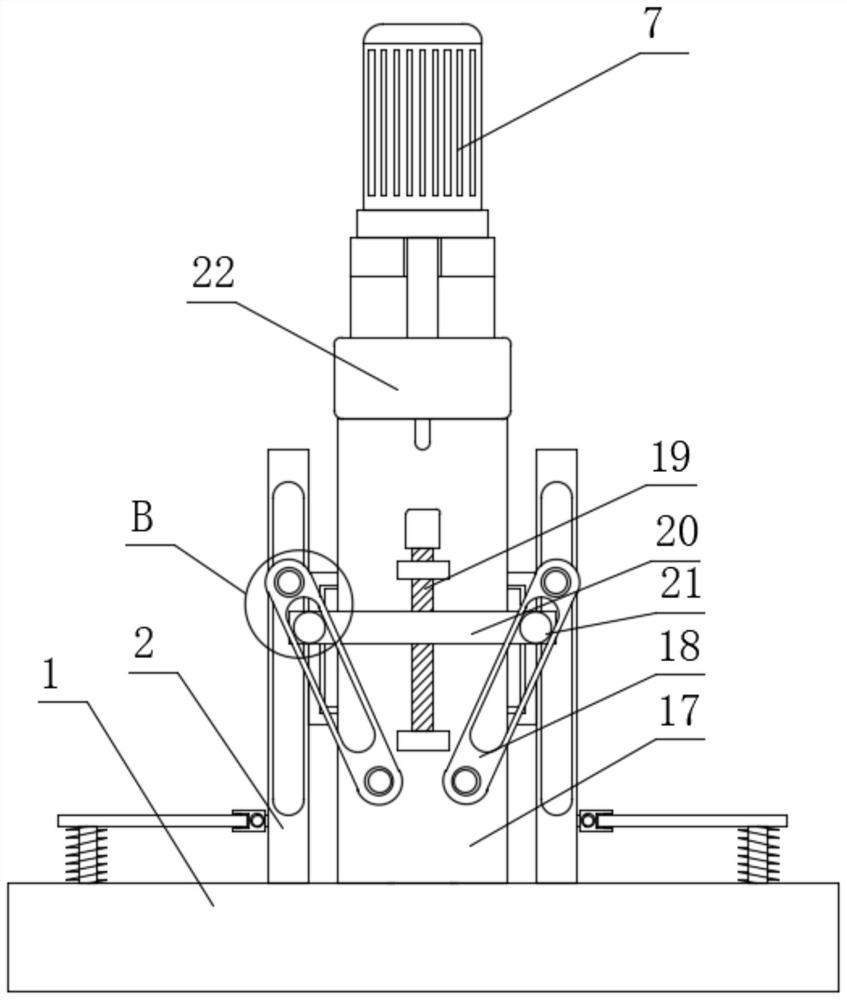

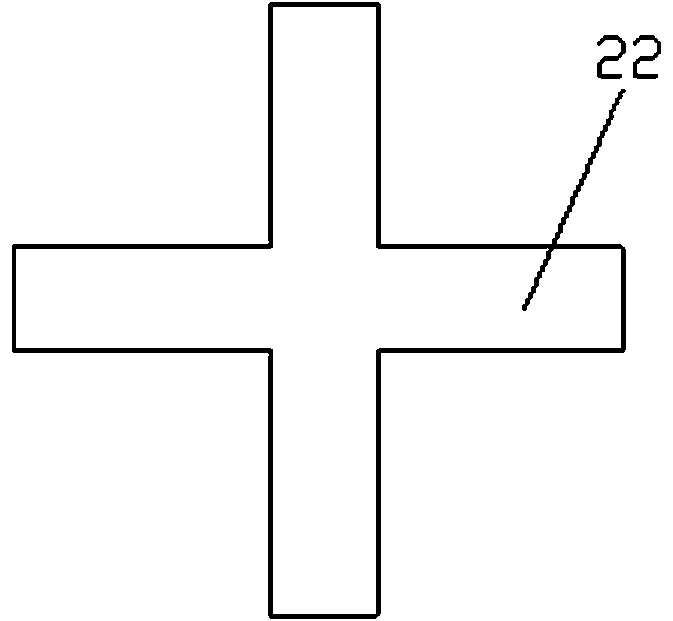

The invention relates to drilling technological equipment with an annular water spray cooling function. The drilling technological equipment with the annular water spray cooling function comprises a supporting base, wherein supporting seats are symmetrically arranged at the two ends of the upper surface of the supporting base; arc-shaped plates of two ends of a V-shaped piece are respectively arranged in the supporting seats; a supporting column is arranged in the middle of the upper surface of the supporting base; the upper end of the supporting column is leaned against the forked root of the V-shaped piece; a rotary lifting column is arranged on the supporting base of one side; a supporting plate is transversely arranged at the upper end of the rotary lifting column; water spraying rings are arranged at the end of the supporting plate; and tilted and downward spraying holes are formed in the side walls of the inner rings of the water spraying rings. The drilling technological equipment with the annular water spray cooling function has the beneficial effects that the V-shaped piece is inversely arranged on the supporting seats and the supporting column, so that the V-shaped piece has high supporting stability, thereby greatly facilitating the drilling operation of a drill bit and improving the drilling efficiency and percent of pass; and compared to a traditional water spraying head, the drilling technological equipment with the annular water spray cooling function has a comprehensive cooling effect and a relatively good effect due to the arrangement of the water spraying rings.

Owner:孙新梅

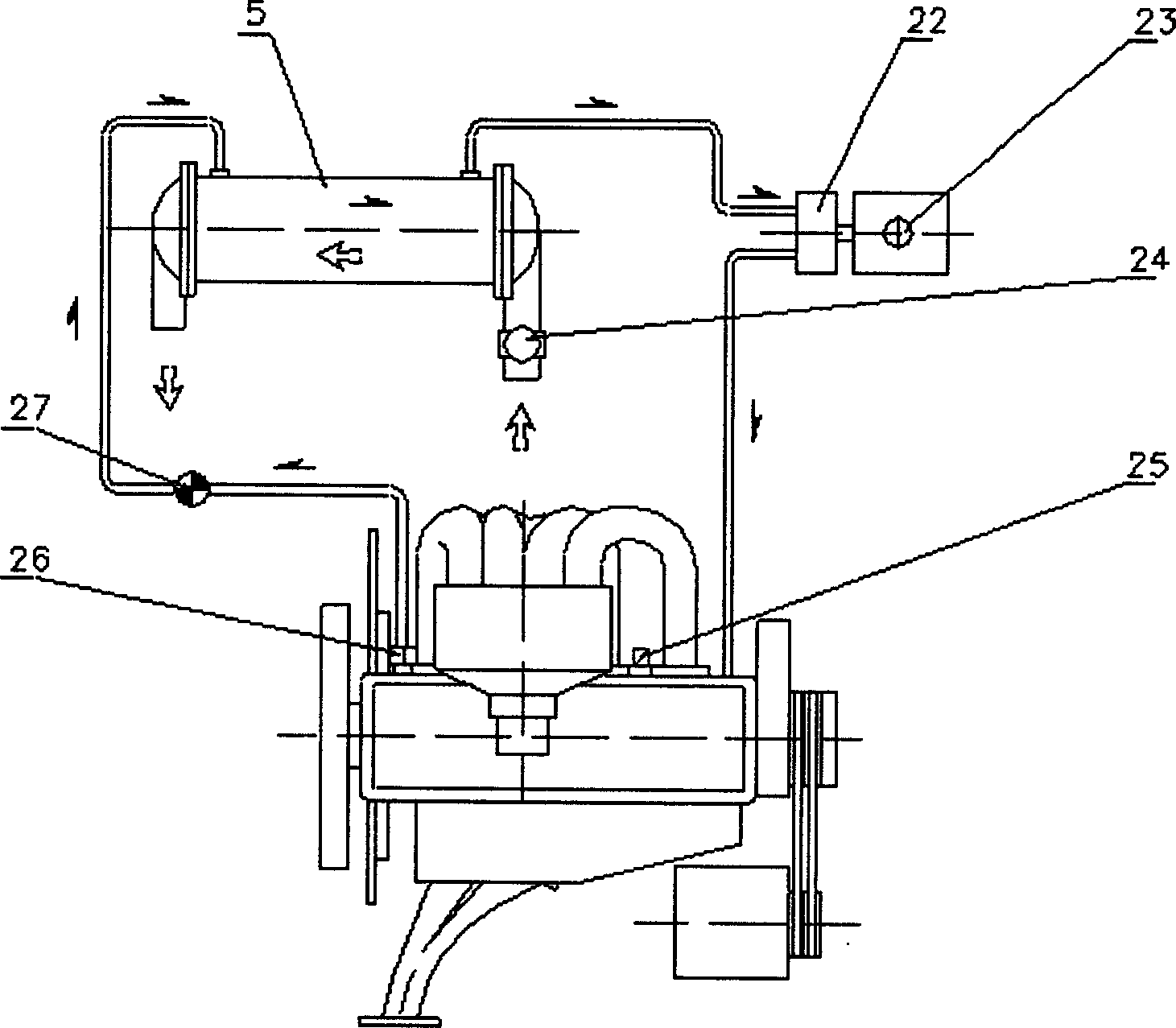

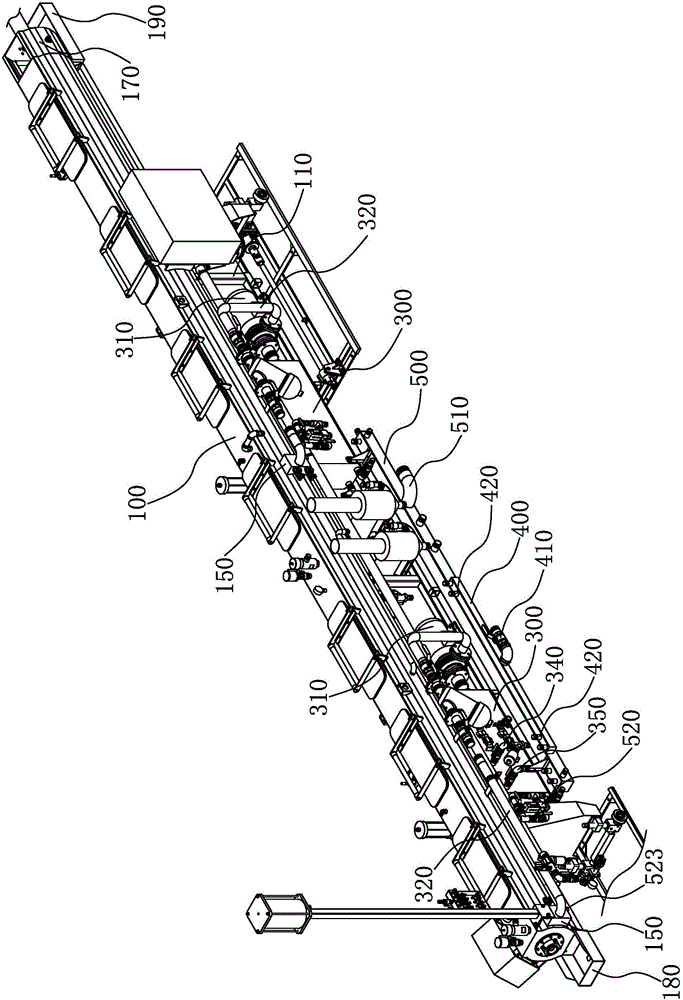

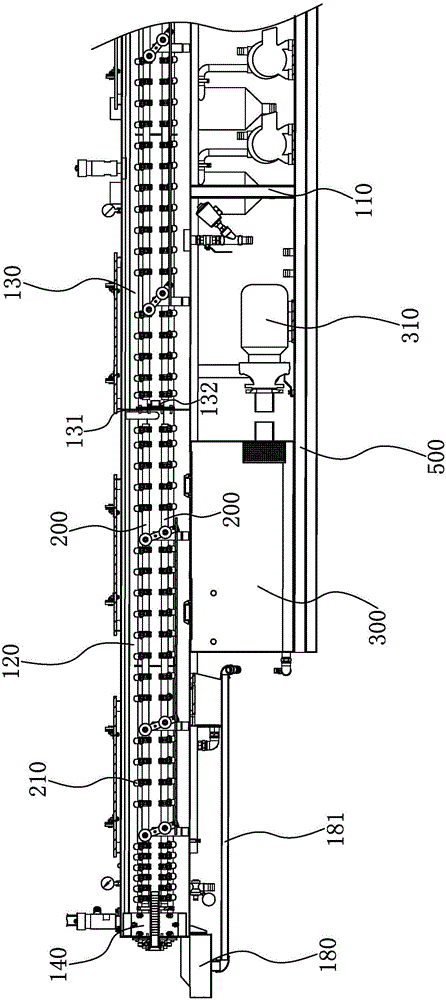

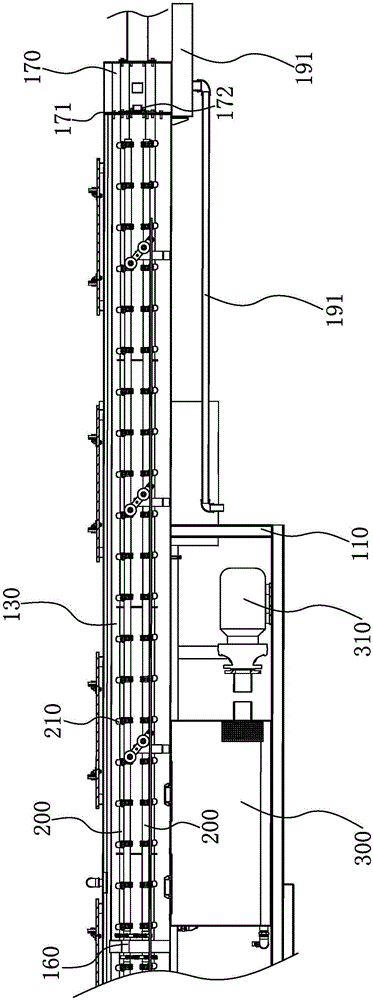

Water circulation system for vacuum setting machine

The invention provides a water circulation system for a vacuum setting machine and belongs to the technical field of pipe setting equipment. The technical problems of existing setting machines are low in water circulation efficiency, large in energy consumption and poor in pipe cooling effect are solved. The water circulation system for the vacuum setting machine comprises a box, a spraying assembly, a water supply assembly, a water feeding assembly and a water draining assembly, wherein the water feeding assembly communicates with the water supply assembly and feeds water to the water supply assembly for centralization; the water feeding assembly feeds water to the water supply assembly, and the water circulates among the water supply assembly, the spraying assembly and the box; when the water temperature of the water supply assembly reaches a preset value, part of water can be discharged through the water draining assembly; when the water temperature of the water supply assembly reaches the preset temperature value, part of high-temperature water is discharged through the water draining assembly, and cooling water feeding and high-temperature water draining are carried out simultaneously, so that the pipe cooling effect is good, water resources are effectively saved, energy consumption is small, and the use cost is controlled.

Owner:NINGBO FANGLI TECH

Hot stamping hardware mould

ActiveCN108296345AEffective coolingExtended service lifeShaping toolsMetal-working feeding devicesHot stampingPunching

The invention belongs to the technical field of hot stamping forming, and particularly relates to a hot stamping hardware mould. The hardware mould comprises a fixed frame, a telescopic air cylinder,a plunger sleeve, a spring, a plunger chip and a pusher and further comprises a platform transferring module, a punching module and a plunger cooling module, and the telescopic air cylinder is arranged on the fixed frame; the plunger sleeve is fixed below the fixed frame through a bracket; the spring is arranged inside the plunger sleeve; the plunger chip is arranged below the telescopic air cylinder; the platform transferring module is used for cooperating with the pusher to move a heated board to the lower portion of the plunger chip; the punching module is used for cooperating the plunger chip to conduct punching on the board; the plunger cooling module is used for cooling the plunger chip; the pusher is used for pushing the board to the lower portion of the plunger chip. The hot stamping hardware mould is mainly applied to carrying out the hot stamping to form holes in a hot stamping process, according to the mould, the hot stamping and hole forming are carried out on the board, the cooling protection for the plunger chip can be achieved, the service life of the plunger chip can be prolonged, and in the board transferring process, the generated scratches on the board can be reduced.

Owner:日照市锦铭机械股份有限公司

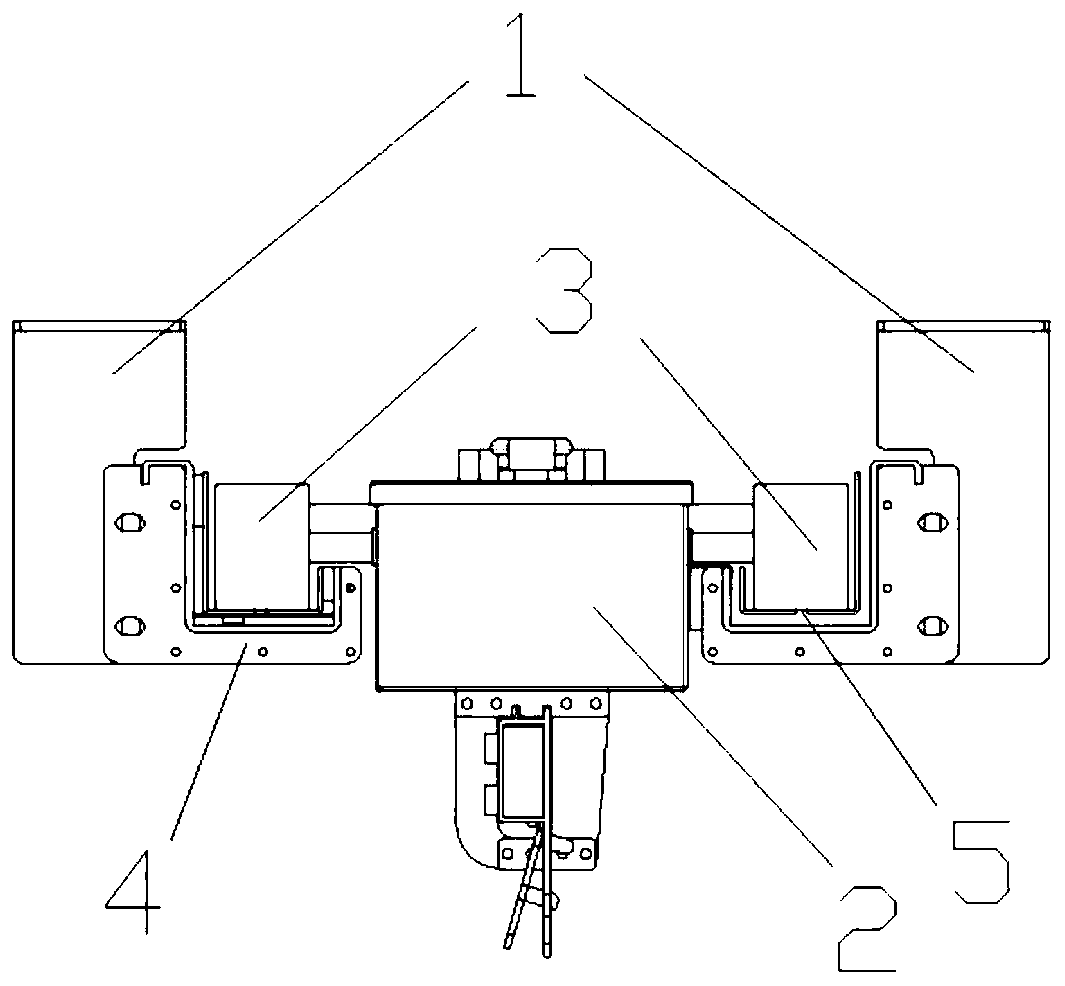

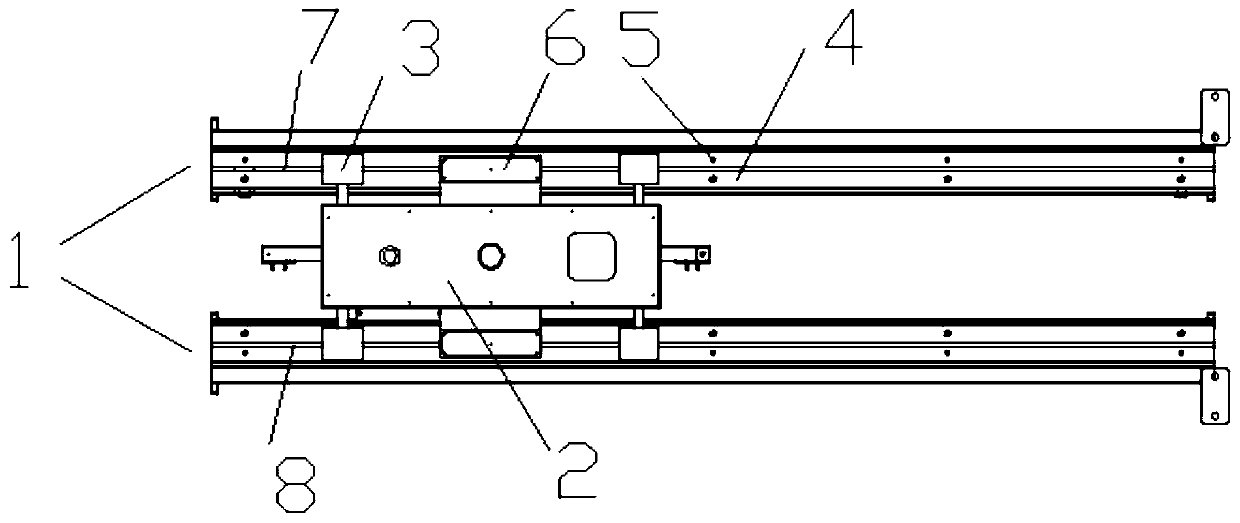

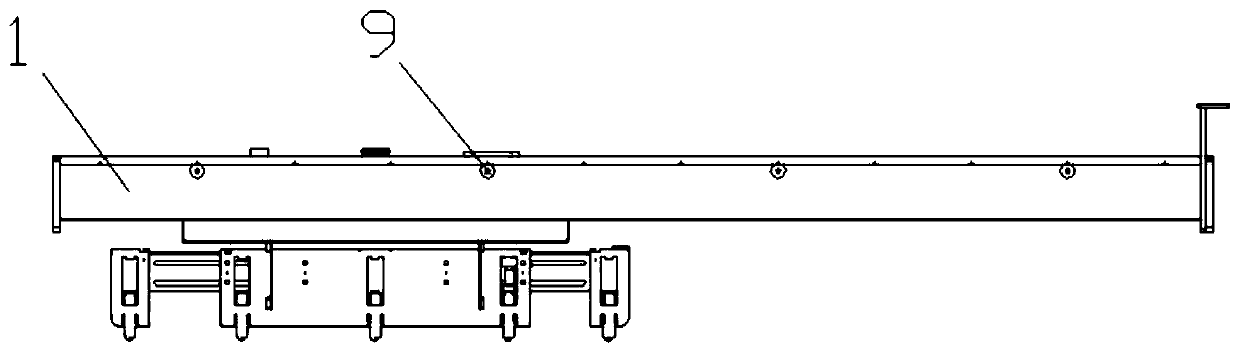

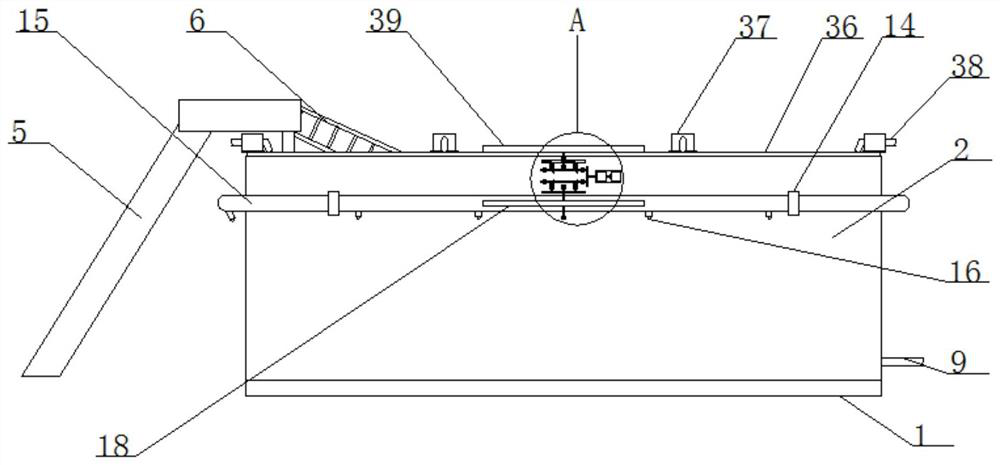

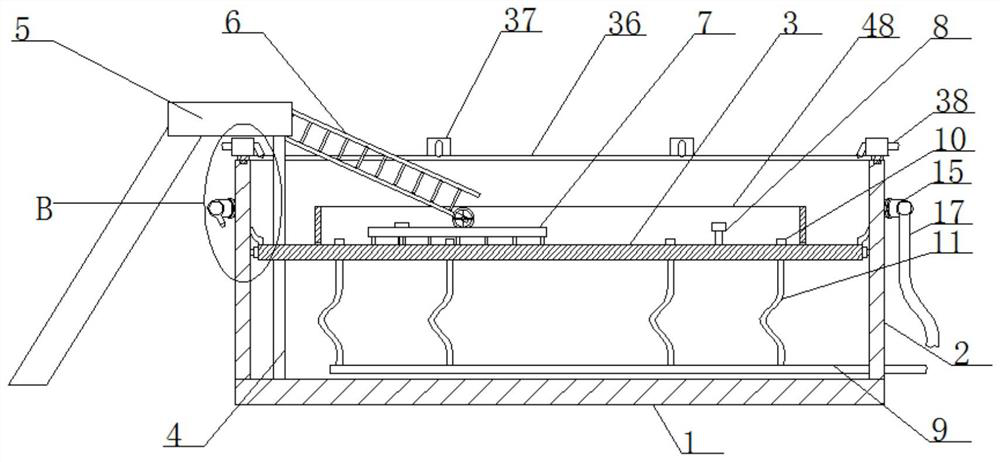

Discharging air cooling device and air cooling method for cold pilger mill

ActiveCN114345957AAvoid deformationImprove cooling effectWork treatment devicesMetal rolling arrangementsAir pumpEngineering

The invention relates to the technical field of cold rolling machining, in particular to a discharging air cooling device for a cold pilger mill and an air cooling method. The device comprises a mounting plate, the upper surface of the mounting plate is fixedly connected with a cooling cylinder, the inner wall of the cooling cylinder is fixedly connected with two sealed bearing assemblies, the inner walls of the two sealed bearing assemblies are jointly and fixedly connected with a cooling pipe, the upper surface of the cooling cylinder is fixedly connected with an air pump and a driving mechanism, and the output end of the air pump fixedly communicates with a bent pipe. The bottom end of the bent pipe fixedly communicates with the outer wall of the cooling cylinder, and the outer wall of the side end of the cooling pipe is fixedly connected with a lubricating oil cleaning mechanism. Tubes output from the cold pilger mill are comprehensively and rapidly cooled through the cooling cylinder, the situation that the tubes deform in the transportation process after cold rolling is prevented as much as possible, the quality and the qualification rate of the tubes machined by the cold pilger mill are improved, lubricating oil on the surfaces of the cooled tubes is cleaned through the lubricating oil cleaning mechanism, manual operation is not needed, and the production efficiency is improved. The labor intensity of workers is reduced, and the production efficiency is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

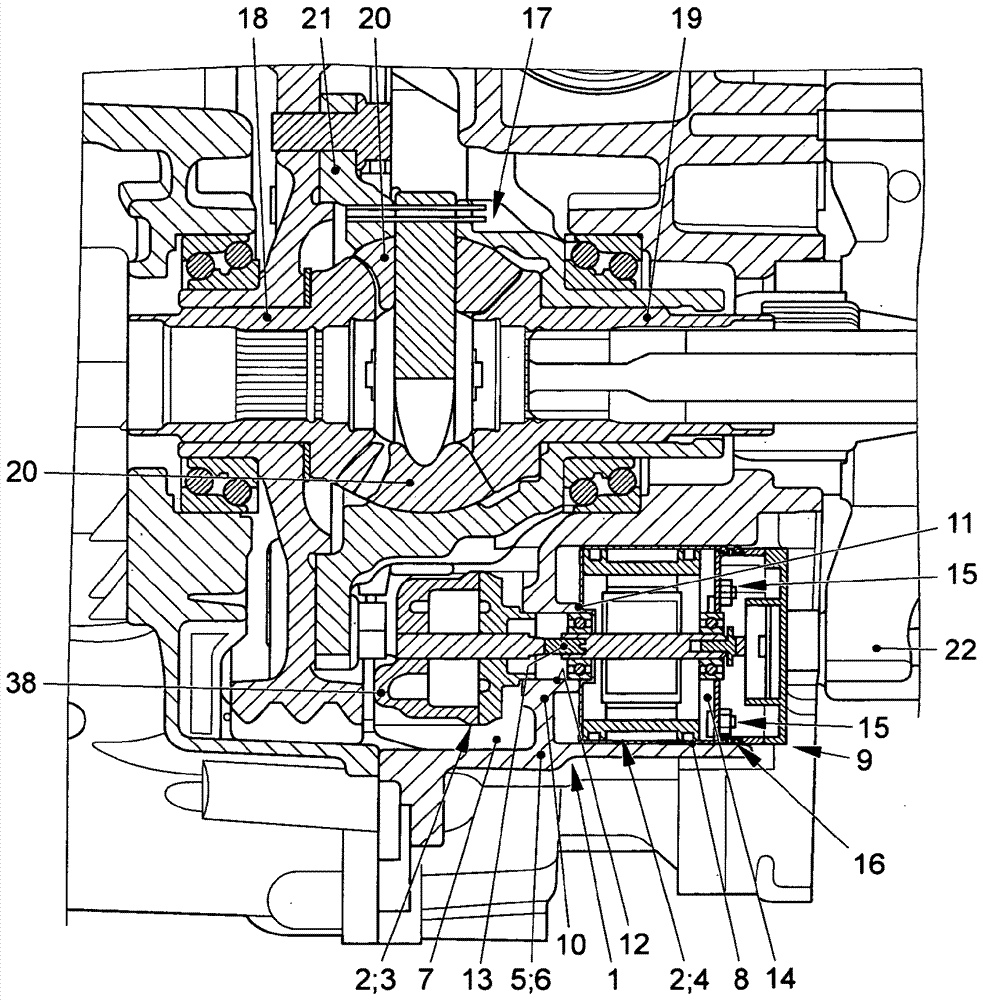

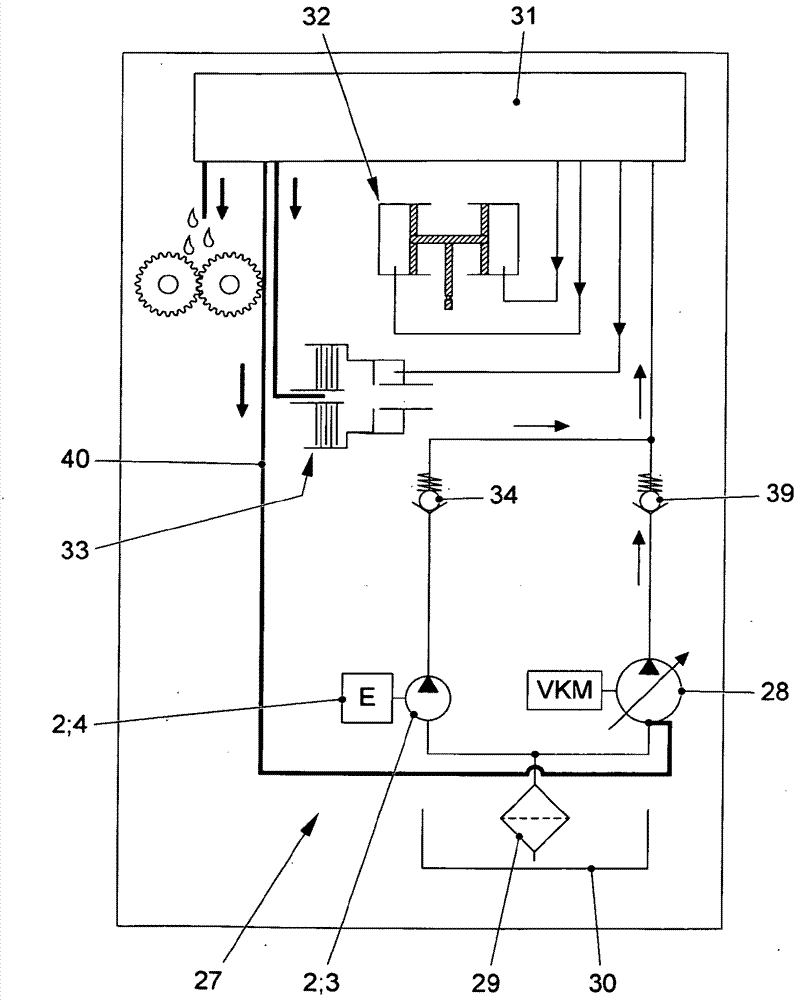

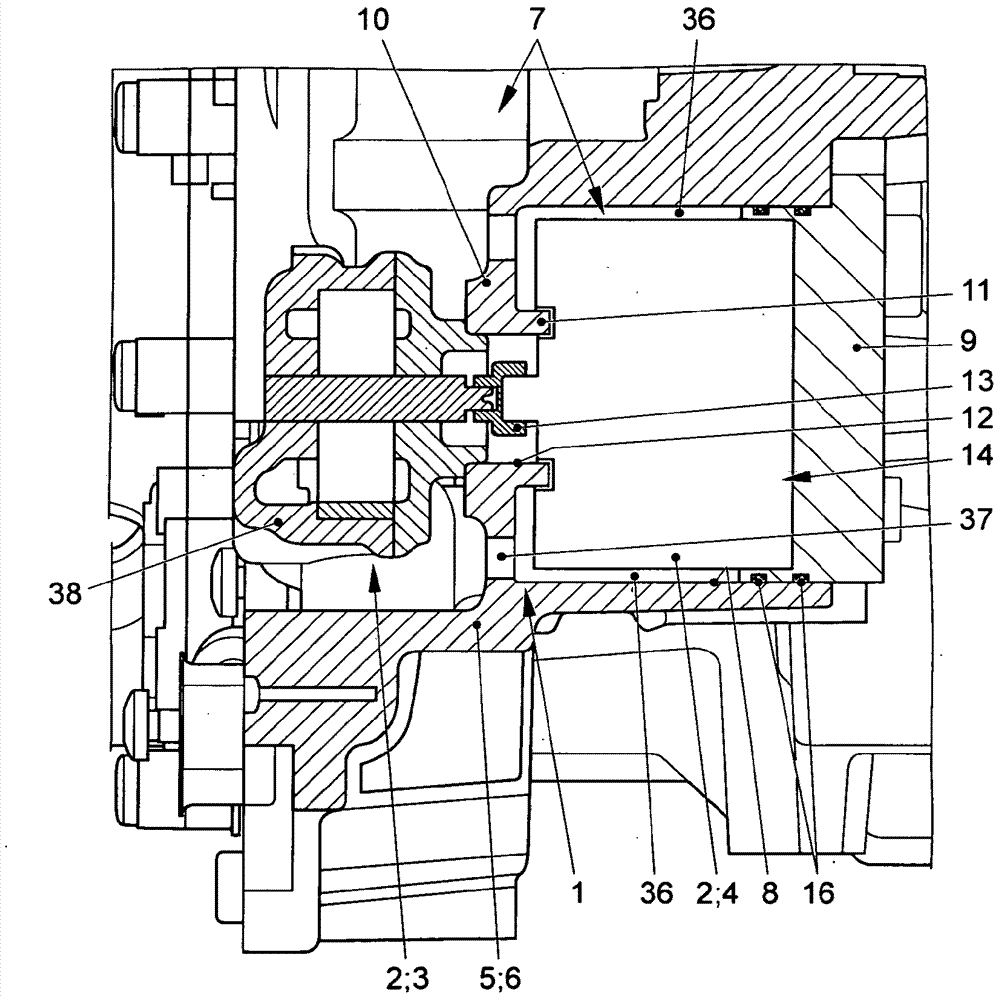

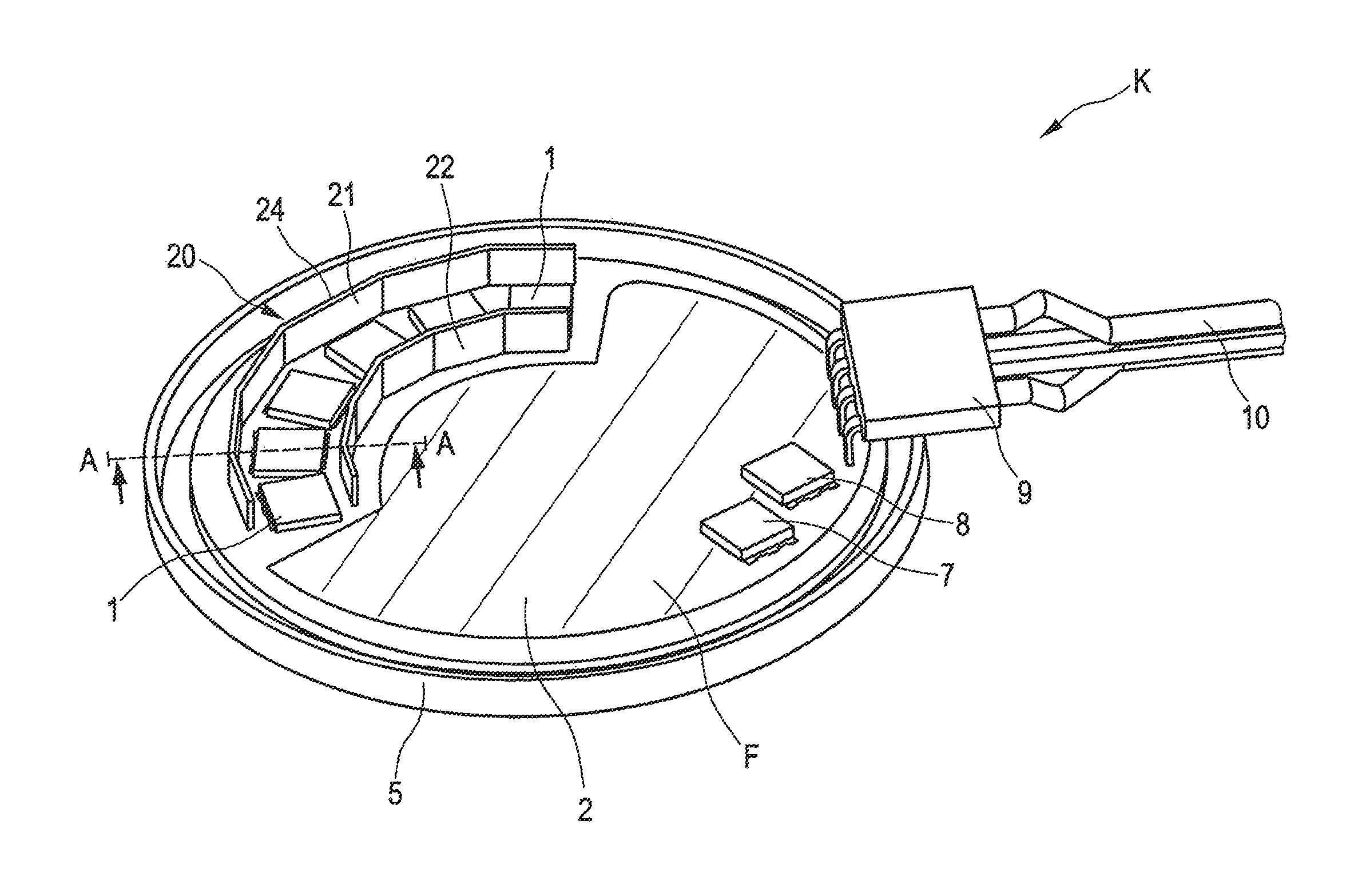

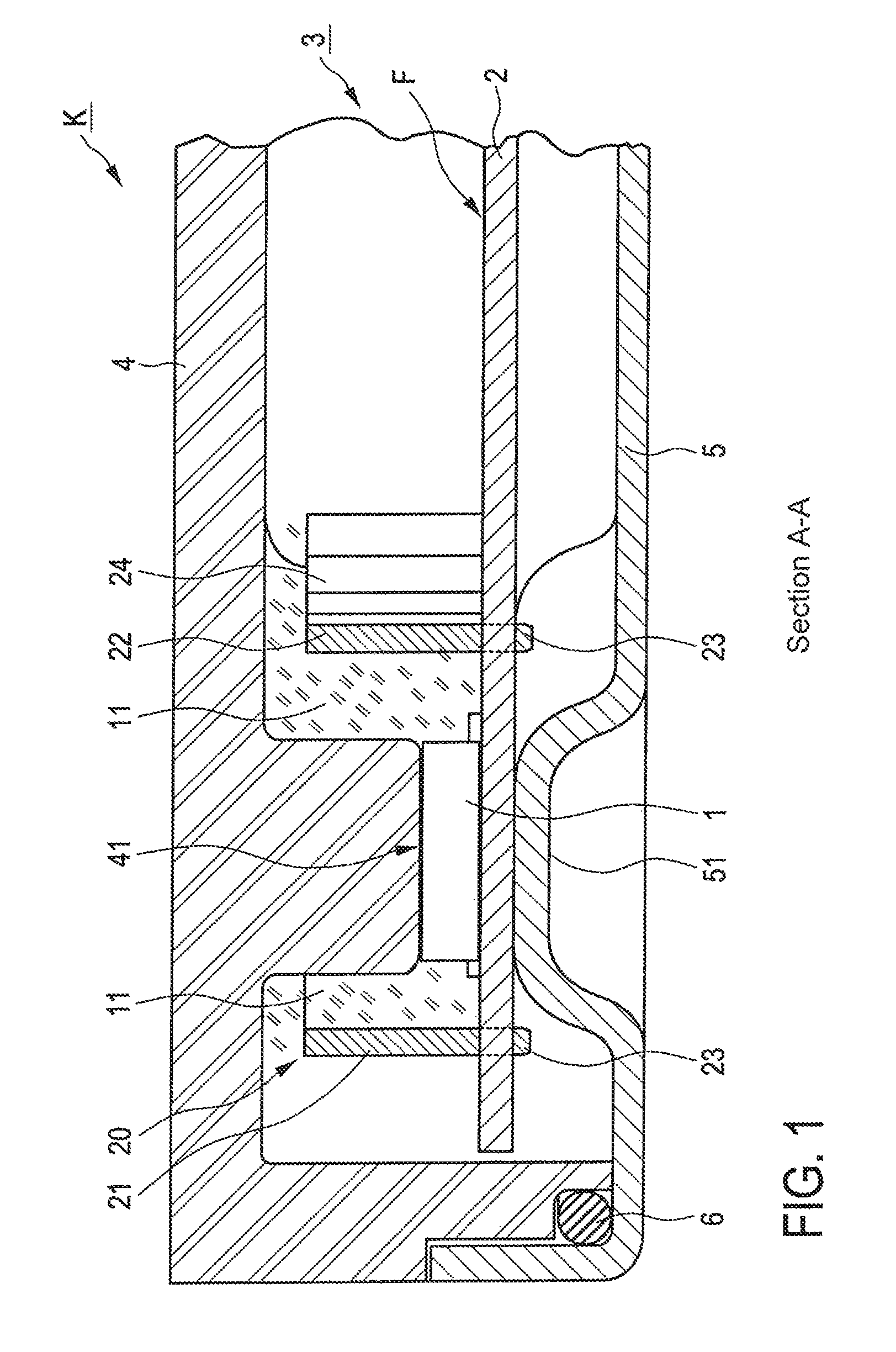

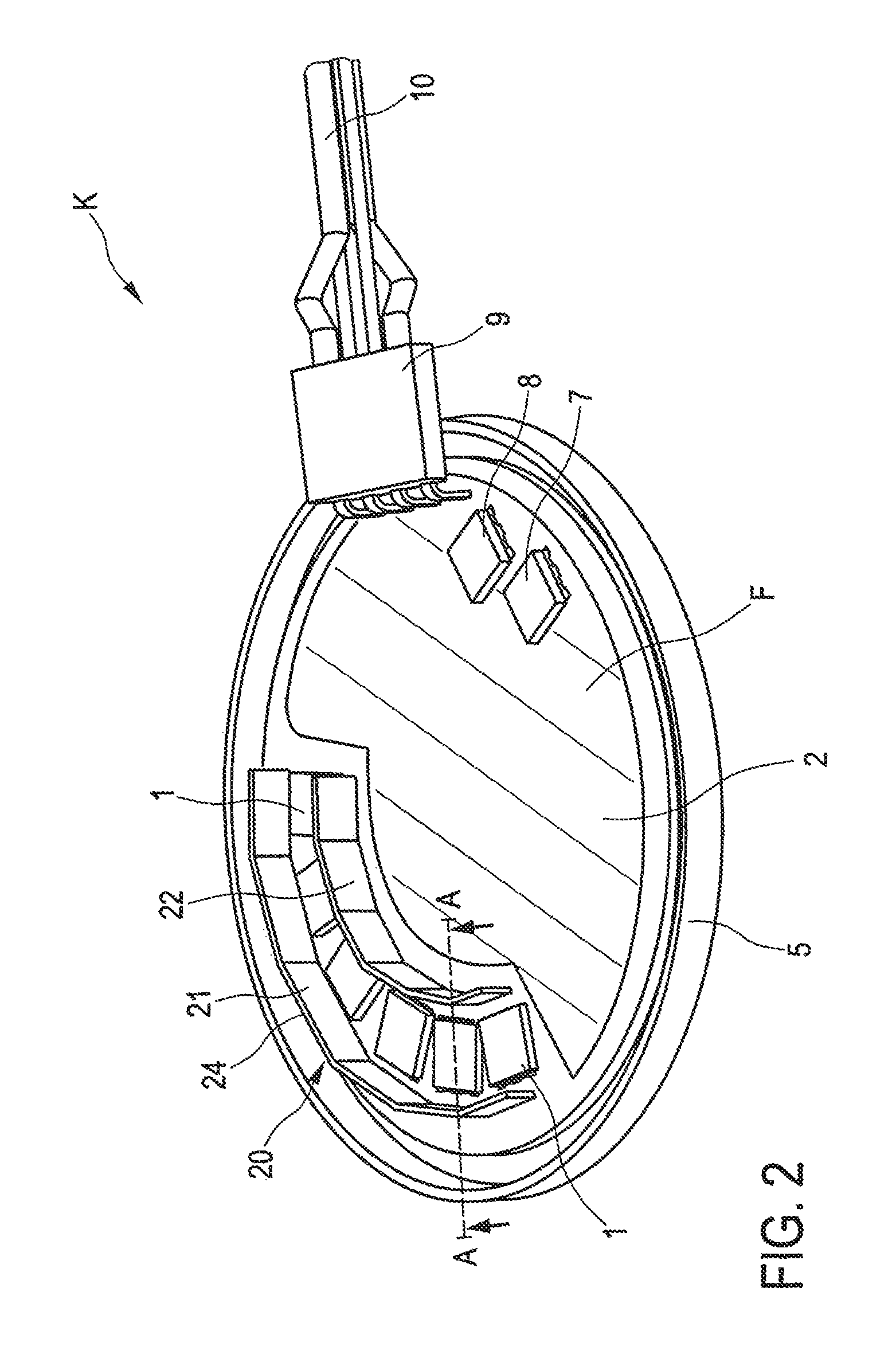

Oil pump arrangement for a motor vehicle

ActiveCN107110333AEasy to replaceSmall structural space requirementGearboxesGear lubrication/coolingEngineeringMechanical engineering

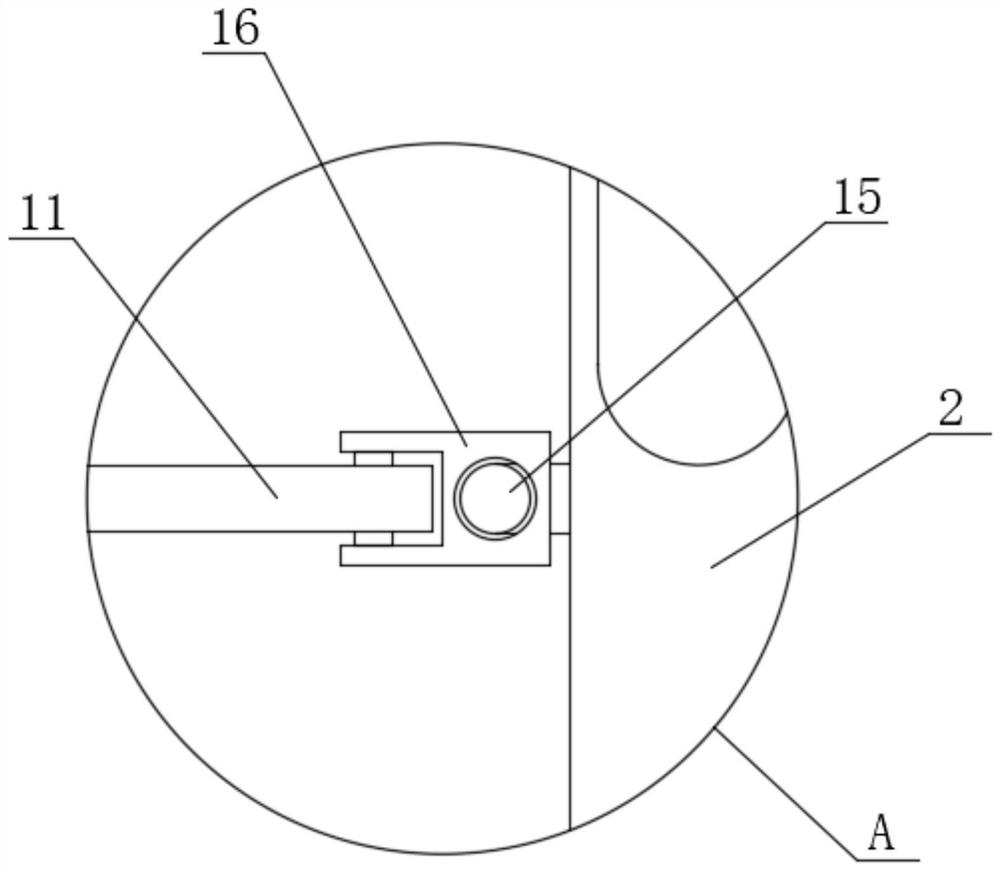

The invention relates to an oil pump arrangement (1) for a motor vehicle, comprising an oil pump (2) having a pump part (3) and an electric pump motor (4), wherein the pump part (3) is in operative connection with the pump motor (4), the pump part (3) and / or the pump motor (4) being mountable to a housing (5), the housing (5) partially delimiting an oil chamber (7). Tightness problems on the pump part (3) are prevented and the required installation space is low because the pump part (3) can be mounted within the housing (5) and the pump motor (4) can be mounted from the outside to the housing (5).

Owner:VOLKSWAGEN AG

Energy-saving auxiliary cooling device of concrete milling machine

InactiveCN107355318AComprehensive coolingImprove cooling efficiencyLiquid coolingMachines/enginesPipingFuel oil

The invention discloses an energy-saving auxiliary cooling device of a concrete milling machine. The energy-saving auxiliary cooling device of the concrete milling machine comprises a fuel oil tank, an engine and a water tank. The bottom of the fuel oil tank is provided with an oil suction opening. The top of the fuel oil tank is provided with an oil return opening. One side of the engine is connected with the oil suction opening through an oil suction pipeline, and the other side of the engine is connected with the oil return opening through an oil return pipeline. The oil return pipeline is partially arranged in the water tank. A cooling water pipe is arranged in the engine. One end of the cooling water pipe is connected with the bottom of the water tank through a water inlet pipe. The other end of the cooling water pipe is connected with the water pump through a water drawing pipeline. A water outlet of the water pump is connected with a water outlet pipeline. The water outlet pipeline is connected with a heat dissipation tank. A sprayer is installed at a pipe opening of the water outlet pipeline. A cooling box is located over the water tank. A draught fan is arranged on the top of the cooling box. The bottom of the cooling box is provided with a circulation opening. The circulation opening is connected with the water tank through a circulation pipeline. The energy-saving auxiliary cooling device of the concrete milling machine can fully utilize existing resources and achieves more complete cooling, so that cooling of the energy-saving concrete milling machine is more efficient, and energy is also saved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

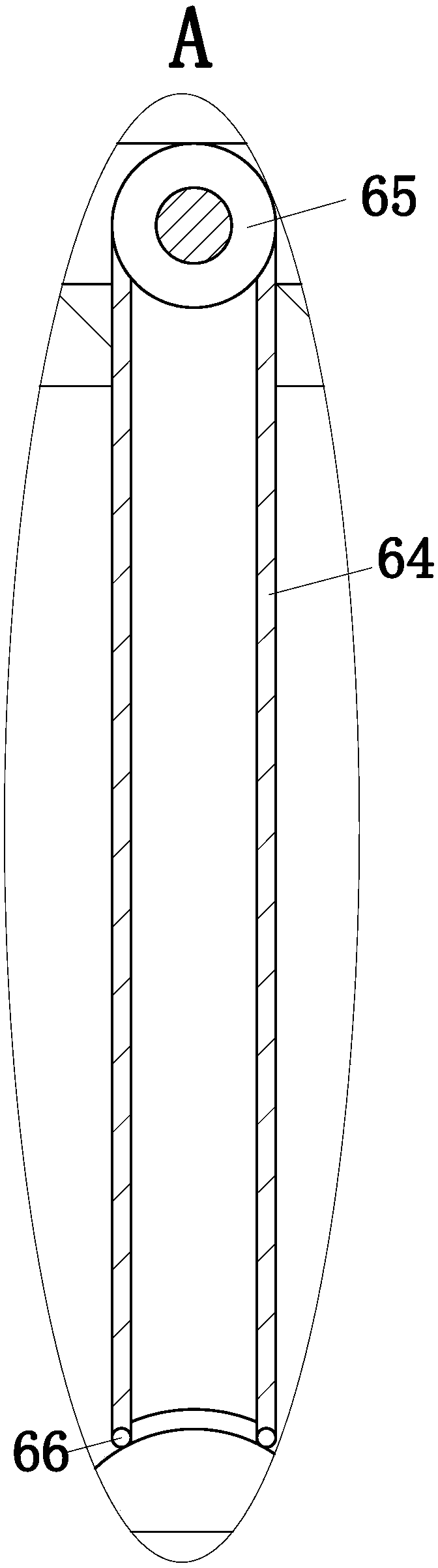

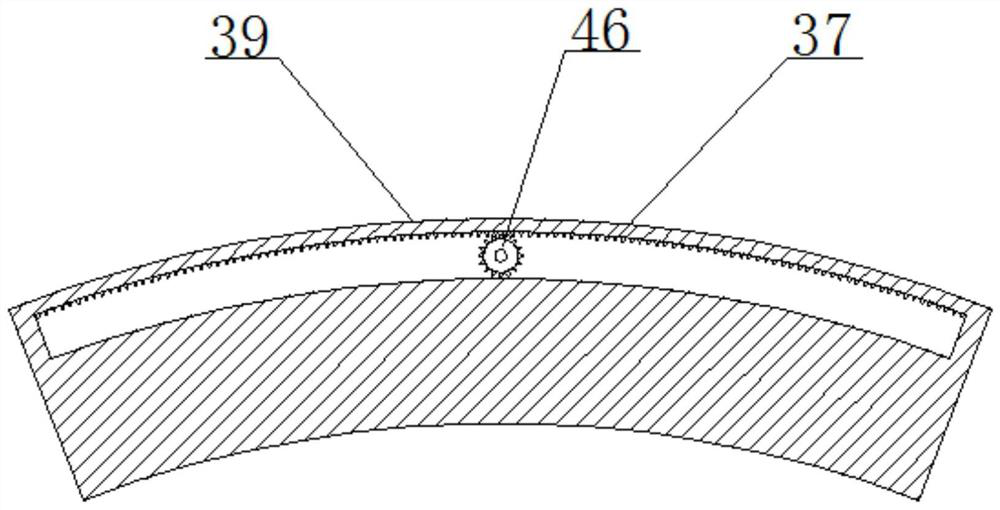

Novel guide rail

PendingCN110040455AImprove insulation performanceImprove the lubrication effectMechanical conveyorsDrive wheelEngineering

Owner:黄海

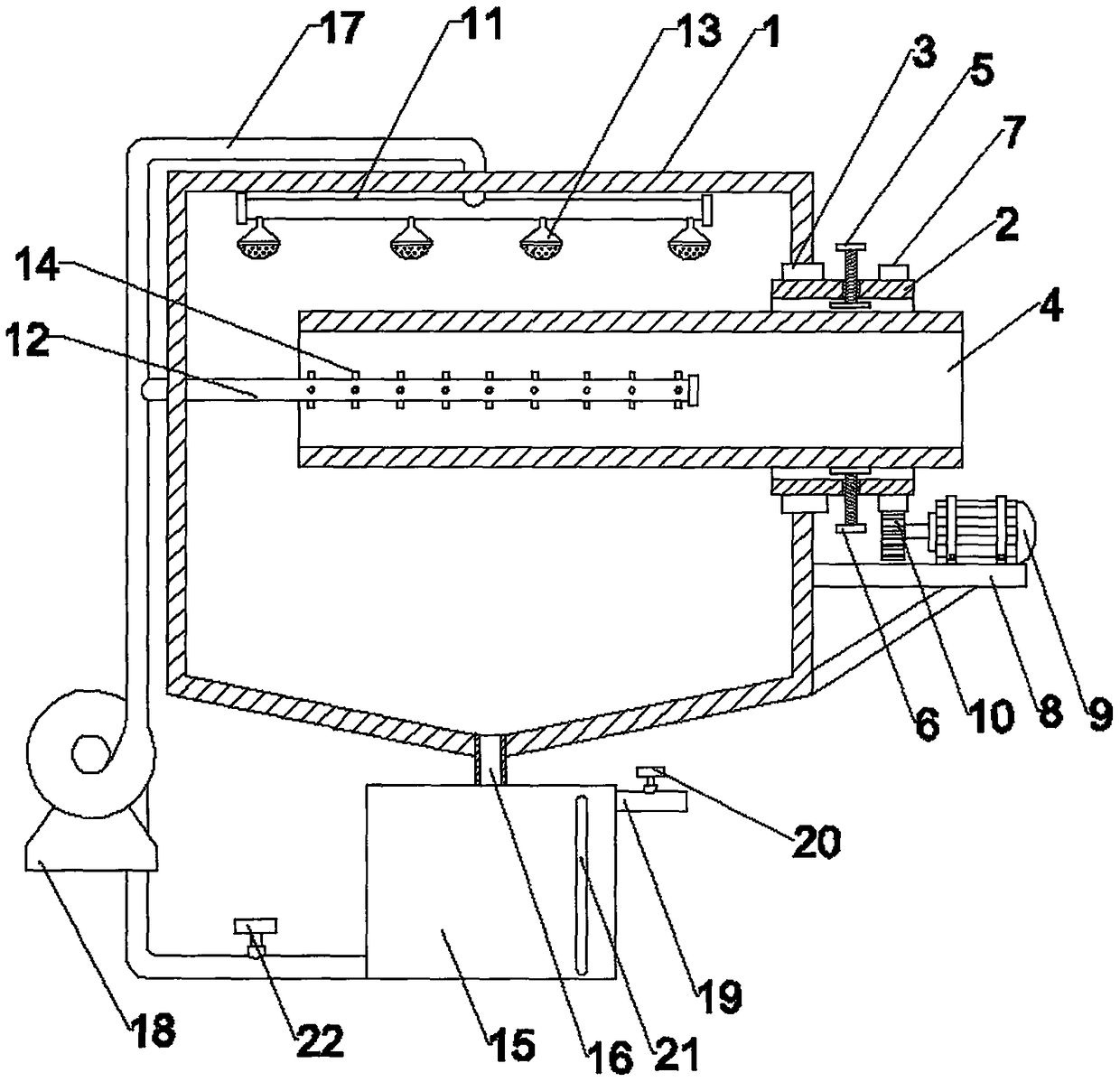

Cooling equipment for cast aluminum alloy pipes

The invention discloses cooling equipment for cast aluminum alloy pipes, and relates to aluminum alloy pipe production and processing equipment. The cooling equipment comprises a cold spraying chamber, wherein a rotating cylinder is arranged on the right side of the cold spraying chamber in a penetrating mode, a fixing bolt is arranged on the rotating cylinder, a pressing block is fixedly arrangedat the bottom end of the fixing bolt, the aluminum alloy pipe is fixedly arranged in the cold spraying chamber through the pressing block, an annular rack is arranged at the right end of the rotatingcylinder, a driving motor is arranged at the right lower end of the cold spraying chamber, a gear is arranged at the output end of the driving motor, the gear is in meshing transmission connection with the annular rack, a spraying pipe and a liquid transferring pipe are arranged at the top and the middle in the cold spraying chamber correspondingly, the spraying pipe communicates with a pluralityof spraying heads, a plurality of water outlet small pipes are arranged on the liquid transferring pipe, a liquid storage tank is arranged at the bottom end of the cold spraying chamber, the liquid storage tank communicates with the top of the cold spraying chamber through a water pipe, a top pipe of the water pipe communicates with the middle of the spraying pipe, and the left end of the liquidtransferring pipe penetrates through the cold spraying chamber and communicates with the water pipe. According to the cooling equipment, the cast aluminum alloy pipes are effectively and comprehensively cooled, waste of water resources is avoided, the recycling of the water resources after cooling is realized, and the water resources are effectively saved.

Owner:ANLU PHOENIX ALUMINUM LIMITED LIABILITY

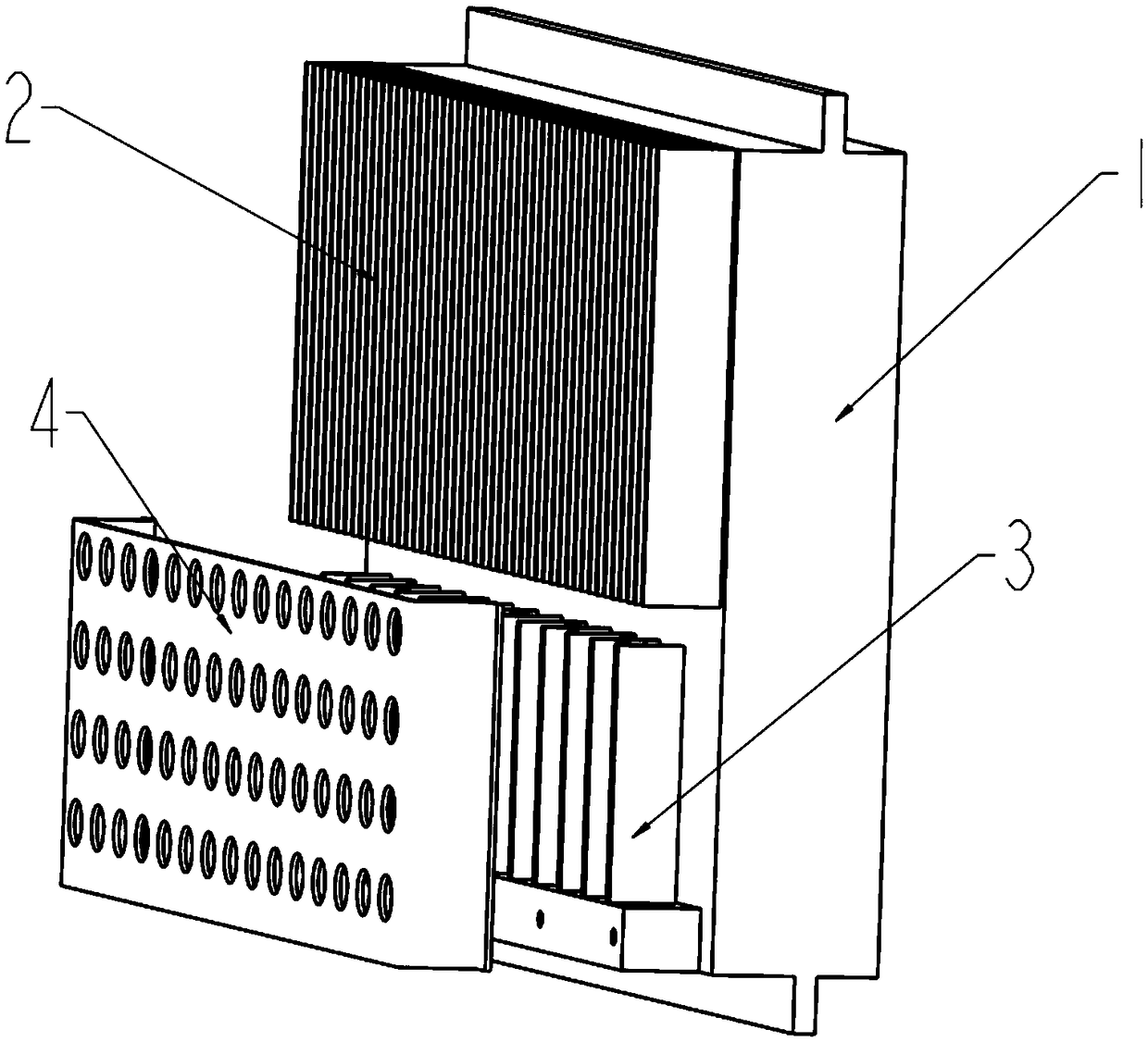

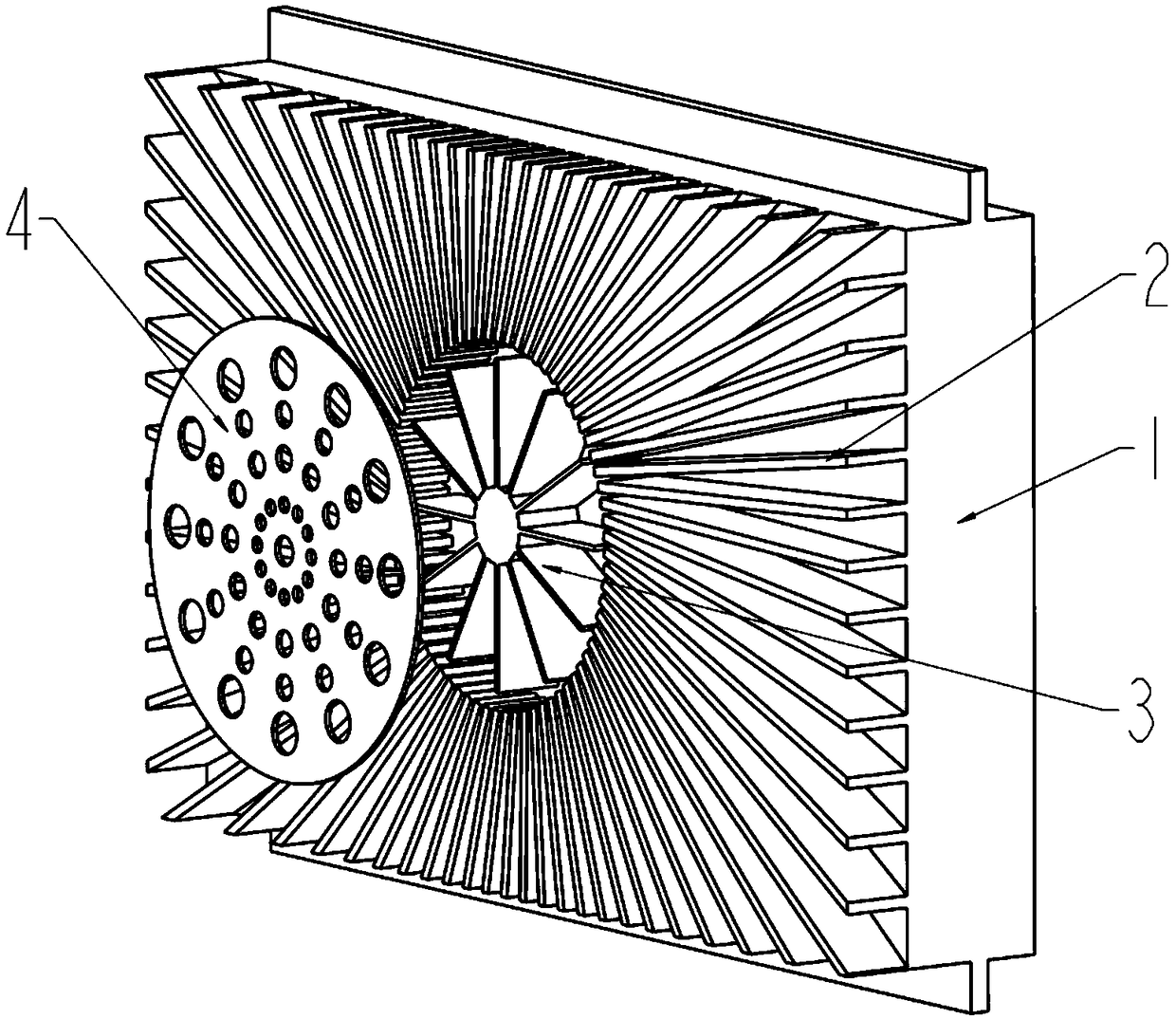

Piezoelectric fan heat dissipating closed module

InactiveCN109392291AComprehensive coolingImprove cooling efficiencyCooling/ventilation/heating modificationsLow noisePiezoelectric fan

The invention provides a piezoelectric fan heat dissipating closed module, comprising: a module; heat dissipating fins disposed on a cavity wall of the module or disposed on a cover plate of the module, used for cooling a heating component in the module; a piezoelectric fan, disposed adjacent to the heat dissipating fins, used for providing cooling airflow to the heat dissipating fins. The piezoelectric fan heat dissipating module performs air-cooling heat dissipation on the module, and does not depend on a cold plate of a chassis. Compared with a module of a traditional fan, the module has wider working temperature, small volume, and low noise, and has no electromagnetic interference. The module is exquisite in structure, and has a flexible embedded design, and can realize more efficientheat dissipation in smallest volume.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

Medical rehabilitation bed for children

InactiveCN108175592AComprehensive coolingImprove sleepingDiagnosticsNursing bedsEngineeringMedical treatment

The invention relates to rehabilitation beds, in particular to a medical rehabilitation bed for children. The medical rehabilitation bed for children aims at achieving the technical purposes that children can conveniently go to bed and get out of bed and a cool environment can be provided for children in summer. In order to achieve the technical purposes above, the provided medical rehabilitationbed for children comprises a bed body, a motor and the like; a groove is formed in the middle of the front side of the bed body, first sliding rails are disposed in the middles of the left and right walls of the groove respectively, first sliding blocks are slidingly arranged on the first sliding rails respectively, the first sliding blocks are matched with the first sliding rails, a pedal is connected between the inner sides of the first sliding blocks, and a handle is arranged in the middle of the front side of the pedal. The effects that children can conveniently go to bed and get out of bed and a cool environment can be provided for children in summer are achieved. Second blades rotate to blow out wind, and the wind passes through wind via holes to cool the backs of children so that cooling can be more comprehensively performed on children, and children can sleep better.

Owner:深圳万研科技研发有限公司

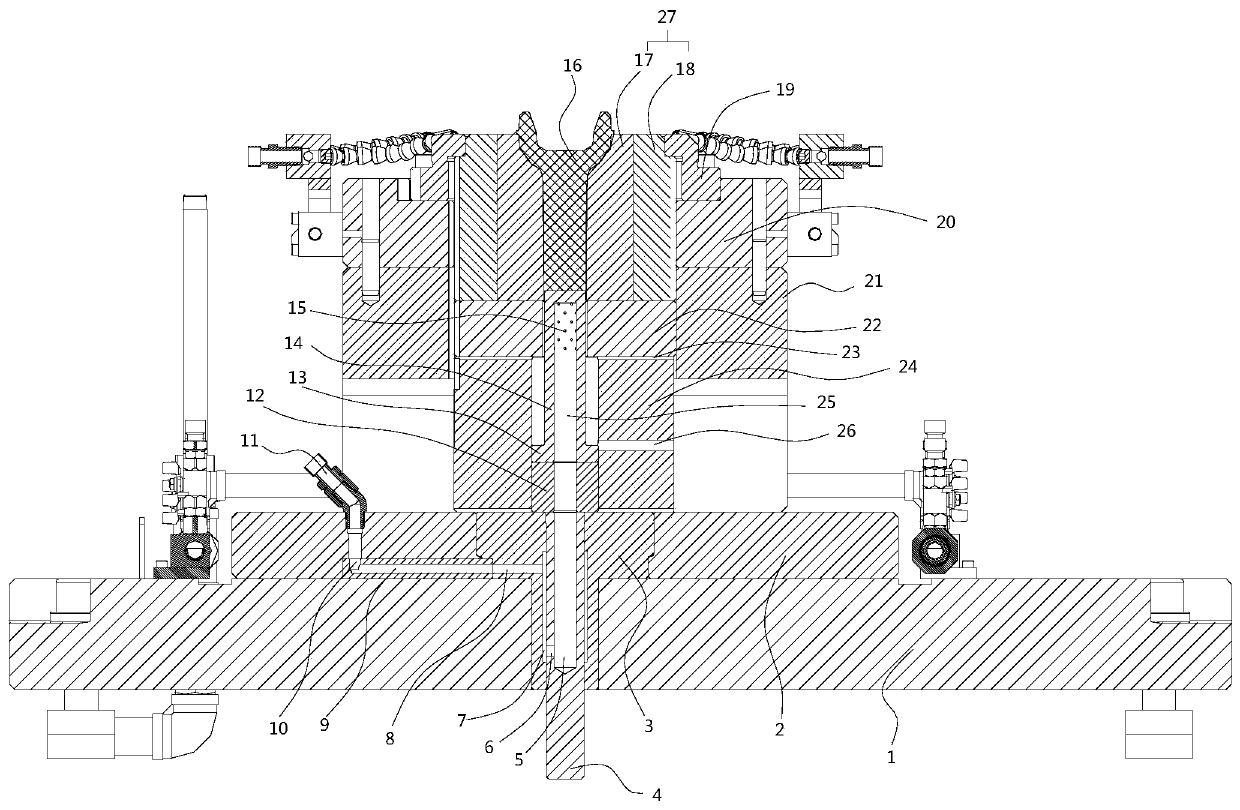

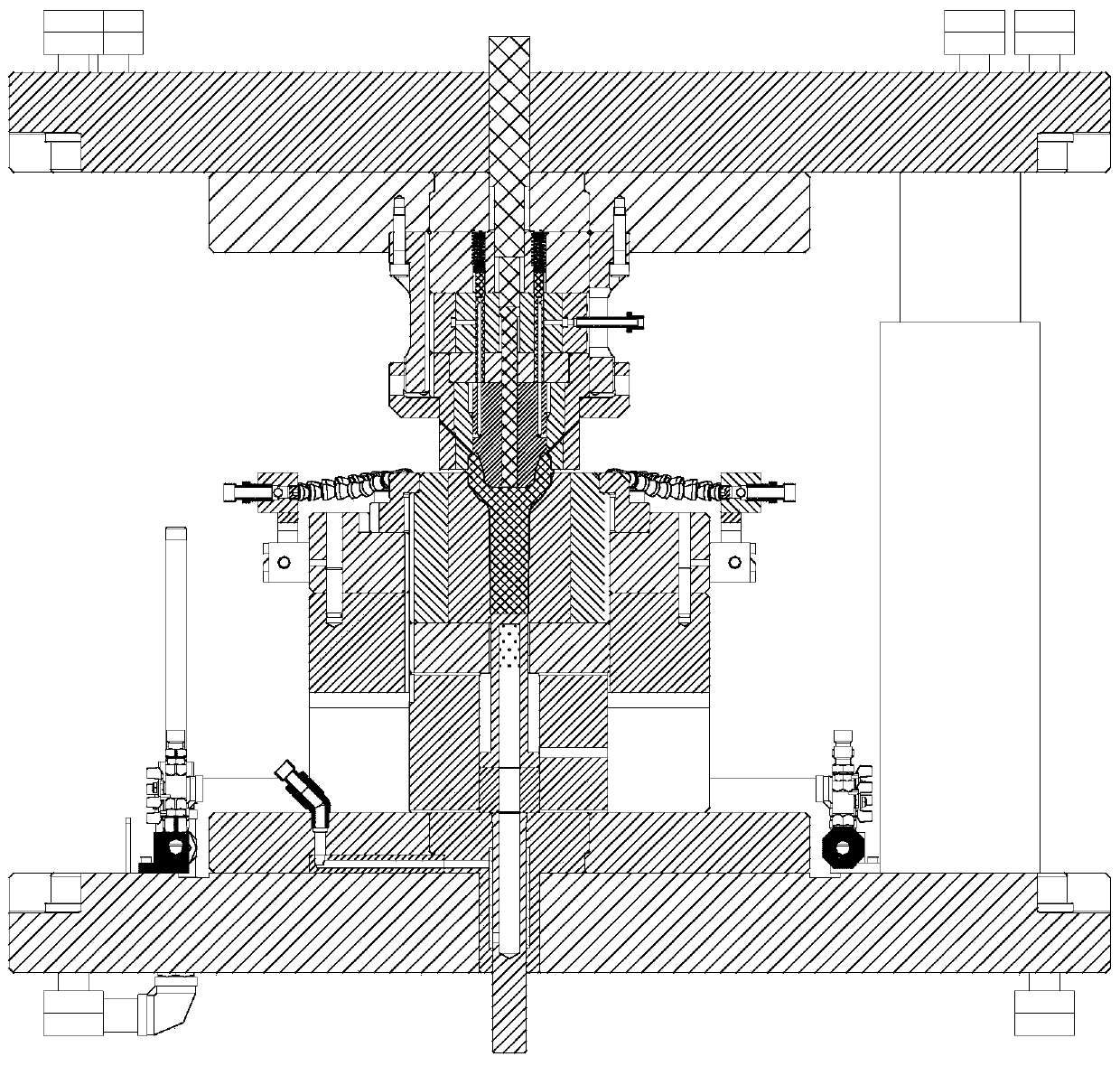

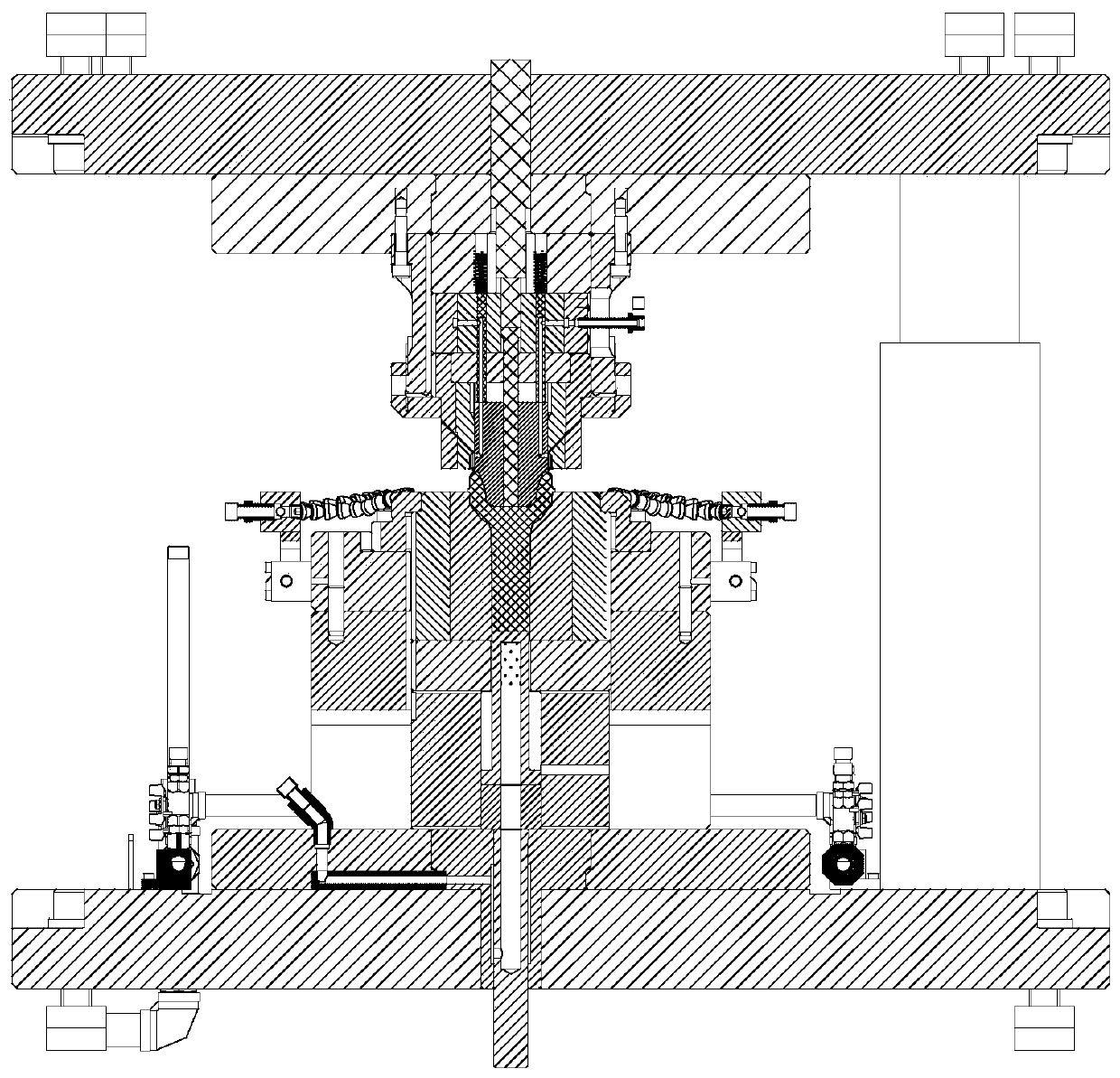

Hot-forging die lower die with internal cooling function and cooling method thereof

ActiveCN110026520AImprove cooling effectTimely coolingForging/hammering/pressing machinesHeating/cooling devicesWater flowEngineering

The invention discloses a hot-forging die lower die with an internal cooling function and a cooling method thereof. The hot-forging die lower die comprises a lower die frame, a concave die supportingcushion block mechanism, a concave die, a concave die fixing mechanism and a cooing system. The cooling method comprises the steps that water enters the cooling system, is sprayed out from water spraying holes of a lower ejection rod in a die closing state, and flows out from a side hole of a lower first cushion block; after an upper die is lifted up, the water flows out from an air hole formed between the lower first cushion block and a lower second cushion block; after the die is opened, a forge piece is carried away by a manipulator, and the water directly flows into a middle die cavity ofthe concave die; a blank is installed in the concave die through the manipulator, the redundant water in the concave die is drained out through the blank, and the water in the through hole of the lower first cushion block is drained through the side hole of the lower first cushion block; and the blank is moved downwards, the side hole of the lower first cushion block is blocked by an adjusting block, and the water in the through hole of the lower first cushion block is drained out through an air hole formed between the lower first cushion block and a lower T-shaped cushion block. According tothe hot-forging die lower die with the internal cooling function and the cooling method thereof, the concave die is cooled fully, timely, efficiently and comprehensively.

Owner:安徽康尼精密机械有限公司

Cooling structure of ultrasonic welding head

The invention relates to the technical field of ultrasonic welding, and discloses a cooling structure of an ultrasonic welding head. The cooling structure comprises a mounting base, wherein a machineshell is mounted on the mounting base, an energy converter is mounted in the machine shell, the welding head is mounted at the bottom of the energy converter, a T-shaped air conveying channel is formed in the welding head, and a spiral heat dissipation channel is formed in the welding head; the two ends of the heat dissipation channel are communicated with the air conveying channel, a plurality ofair spraying holes are annularly, evenly and equidistantly formed in the air conveying channel, the welding head located below the air spraying holes is fixedly sleeved with a flow guide cover, the upper end of the mounting base is fixedly connected with a cooling box, and an opening in the upper end of the cooling box is communicated with an exhaust hood; and an exhaust fan is mounted in the output end of the exhaust hood. According to the cooling structure, hot air near the welding head can be sucked and cooled, so that the temperature of the welding head can be rapidly decreased, the heatdissipation effect on the thick part of the welding head is better, and the welding head can be comprehensively cooled conveniently.

Owner:陕西诺盈自动化仪表有限公司

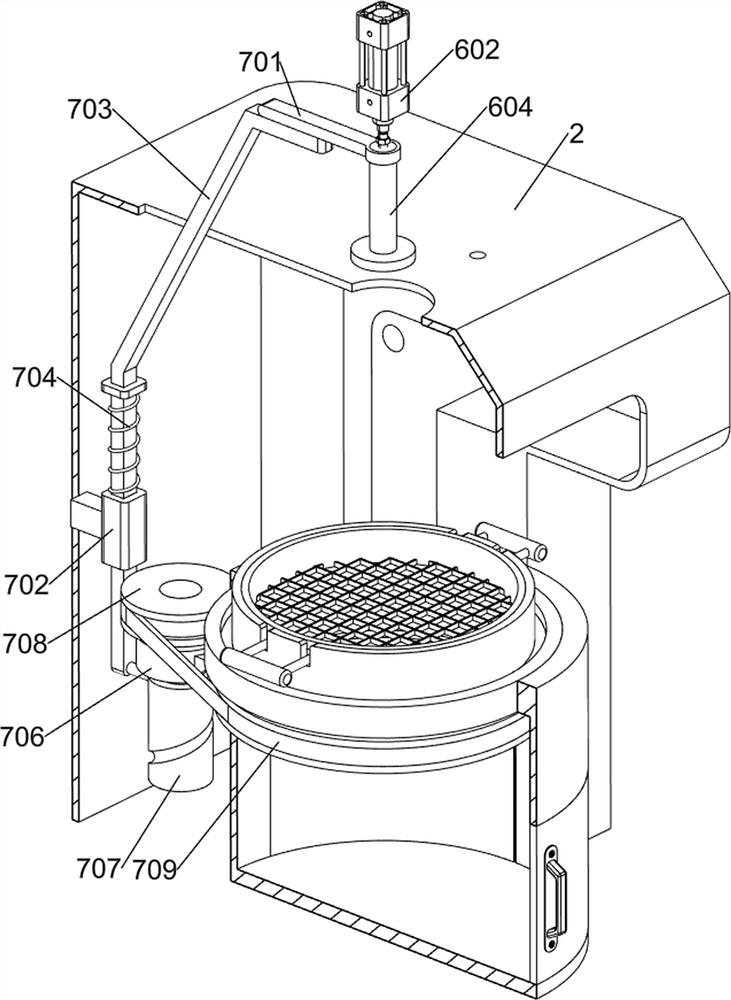

Rapid cooling equipment for sintered powder metallurgy manufactured product

PendingCN114101679ARapid coolingImprove work efficiencyIncreasing energy efficiencyMetallurgyCooling effect

The invention relates to cooling equipment, in particular to rapid cooling equipment for sintered powder metallurgy manufactured products. The invention aims to provide the rapid cooling equipment for the sintered powder metallurgy manufactured product, which is good in cooling effect and convenient to operate. According to the technical scheme, the rapid cooling equipment for the sintered powder metallurgy manufactured product comprises a base; the shell is arranged on one side of the base; the placing assembly is arranged at the upper middle part of the base; the placing net is placed on the placing assembly; the water spraying assembly is arranged on the upper side of the shell; and the spray head is arranged on the water spraying assembly. When the piston rod moves upwards, cooling liquid in the water tank can enter the piston cylinder through the water inlet pipe, and when the piston rod moves downwards, the cooling liquid in the piston cylinder can be sprayed to the metallurgical product through the spray head, so that the metallurgical product is rapidly cooled, and the working efficiency of people is improved.

Owner:肖英梅

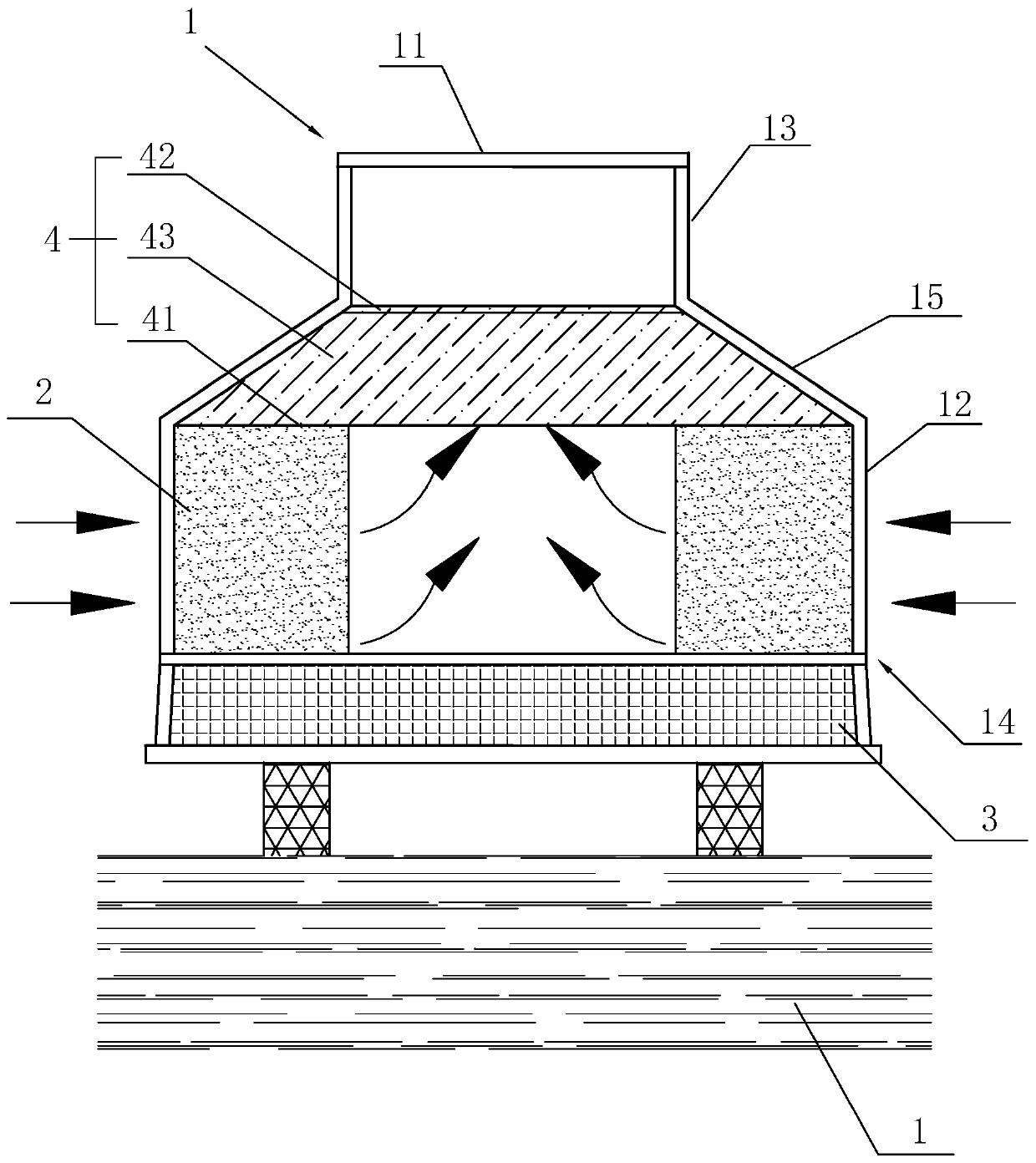

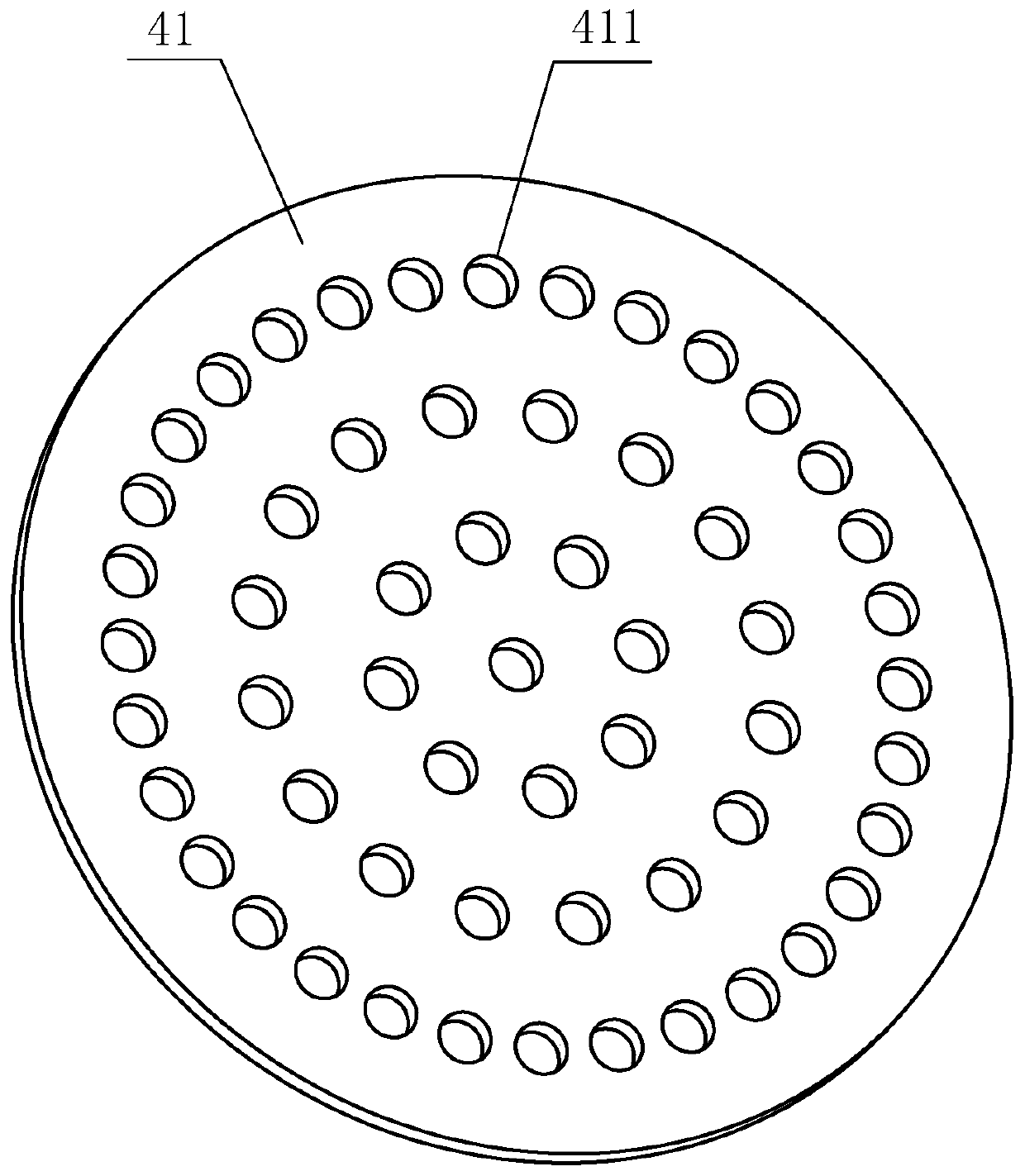

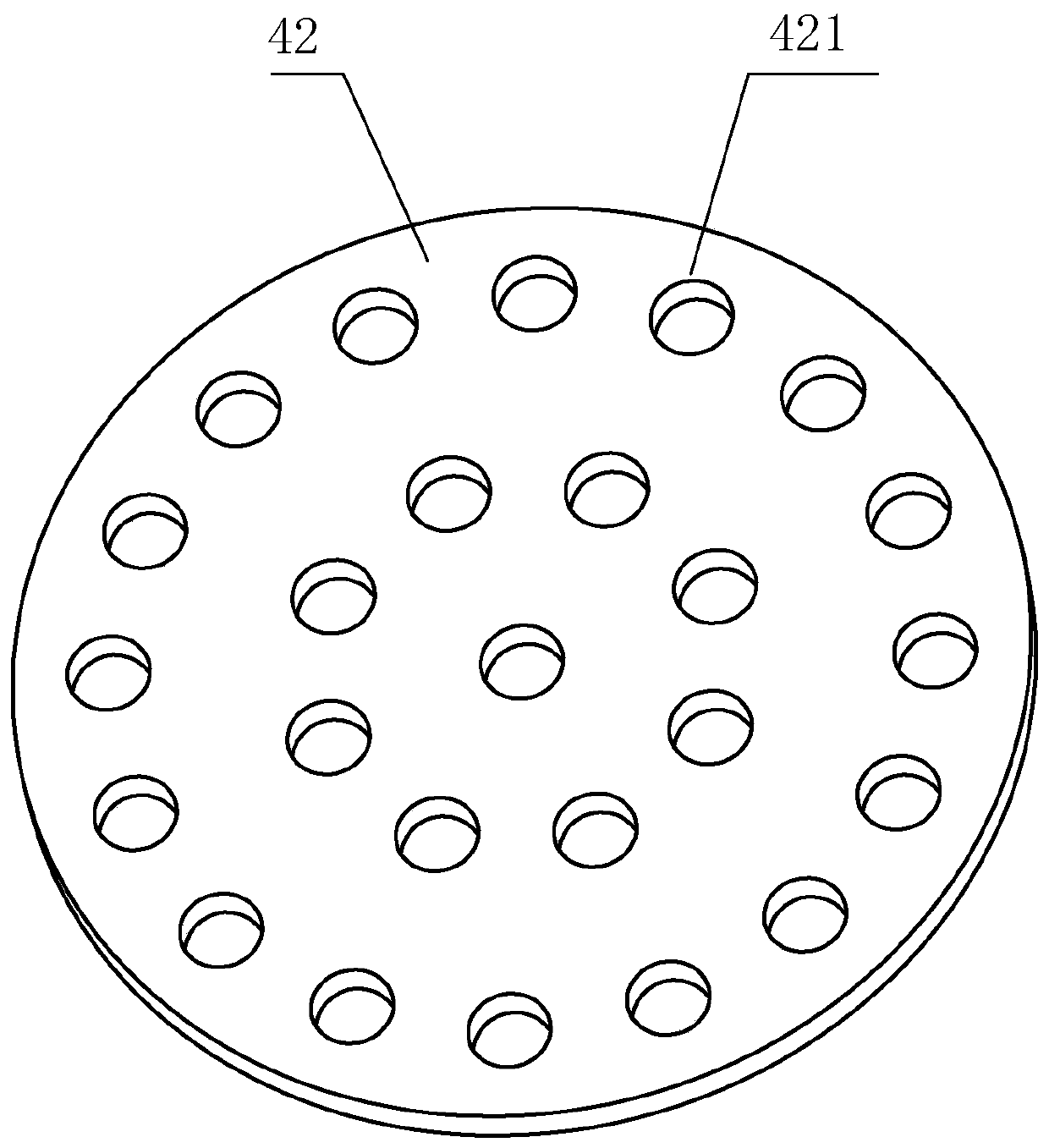

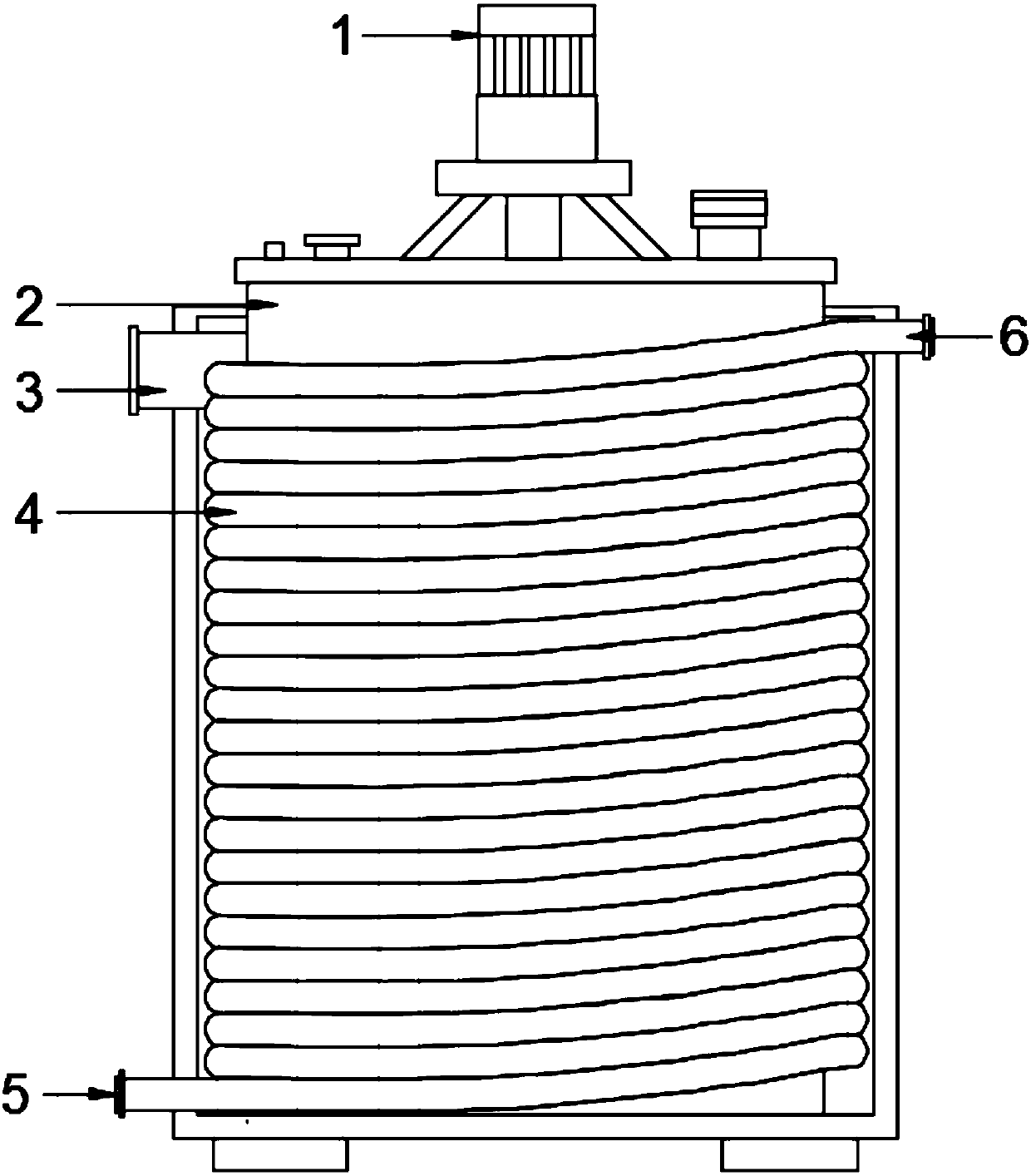

Water cooling tower and basalt fiber industrialization production line cooling system

InactiveCN111595176AReduce the temperatureEnhanced convectionCorrosion preventionIncreasing energy efficiencyProcess engineeringBasalt fiber

The invention relates to the field of basalt fiber processing devices, in particular to a water cooling tower. The tower comprises a tower body and a water collecting pool, wherein a water inlet is formed in the upper part of the tower body, the side surface of the tower body is provided with an air inlet channel, the interior of the tower body is provided with a drying layer, and the drying layeris located above the water collecting pool and corresponds to the location of the air inlet channel of the side surface of the tower body. The invention further relates to a basalt fiber industrialization production line cooling system. The system is used for cooling a kiln, and comprises the water cooling tower, wherein the water inlet of the water cooling tower is connected with a water inlet pipe, the bottom of the water collecting pool is connected with a water outlet pipe, the end, far away from the water collecting pool, of the water outlet pipe, on the outer surface of the kiln in a spiral shape, extends to the position above the kiln from the position below the kiln, and then is connected with the end, far away from the water cooling tower, of the water inlet pipe, the water outlet pipe is provided with a cold water pump, and the effects of cooling rapidly cooling water and prolonging the service life of the kiln is achieved.

Owner:潍坊中创新材料科技有限公司

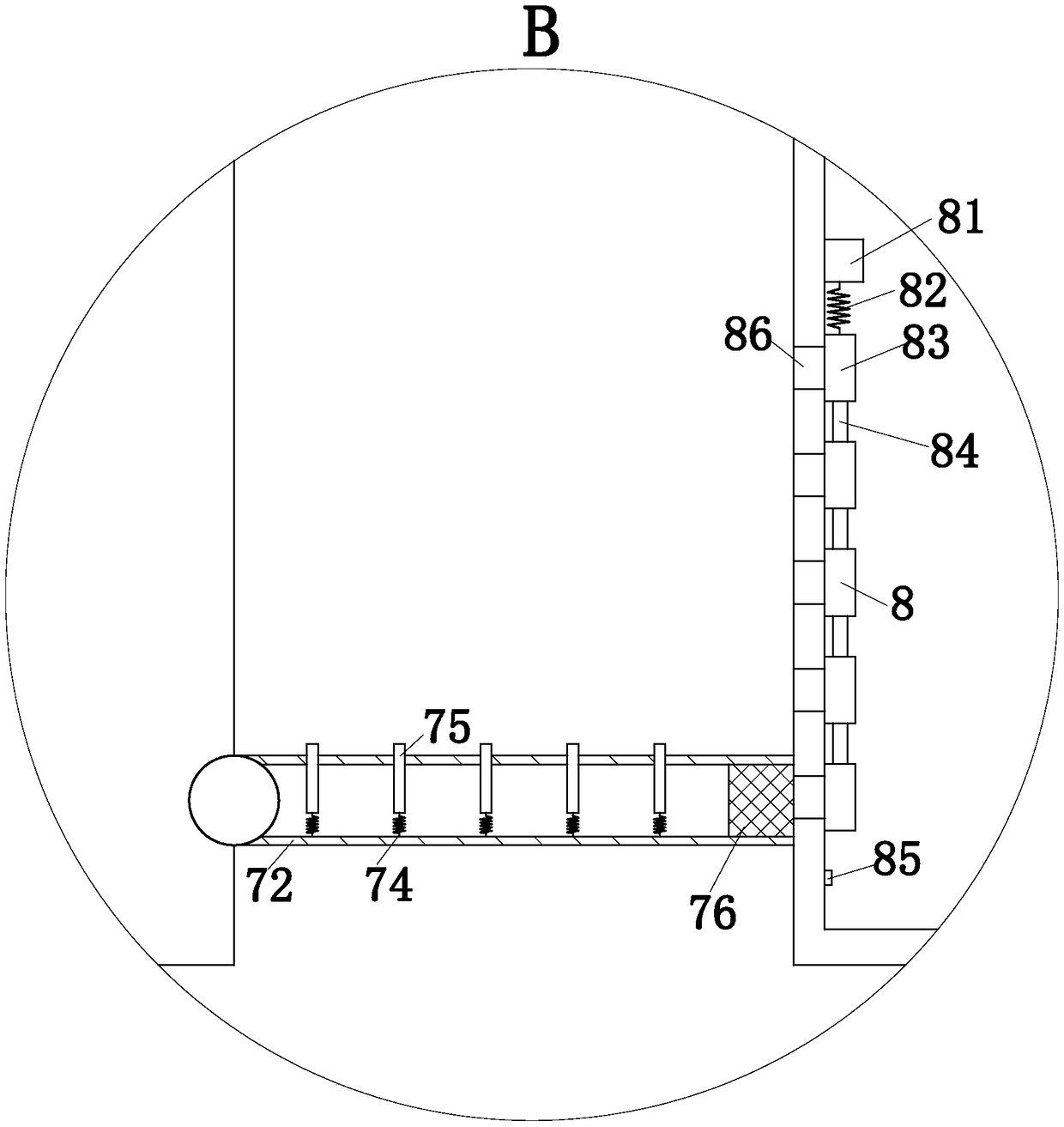

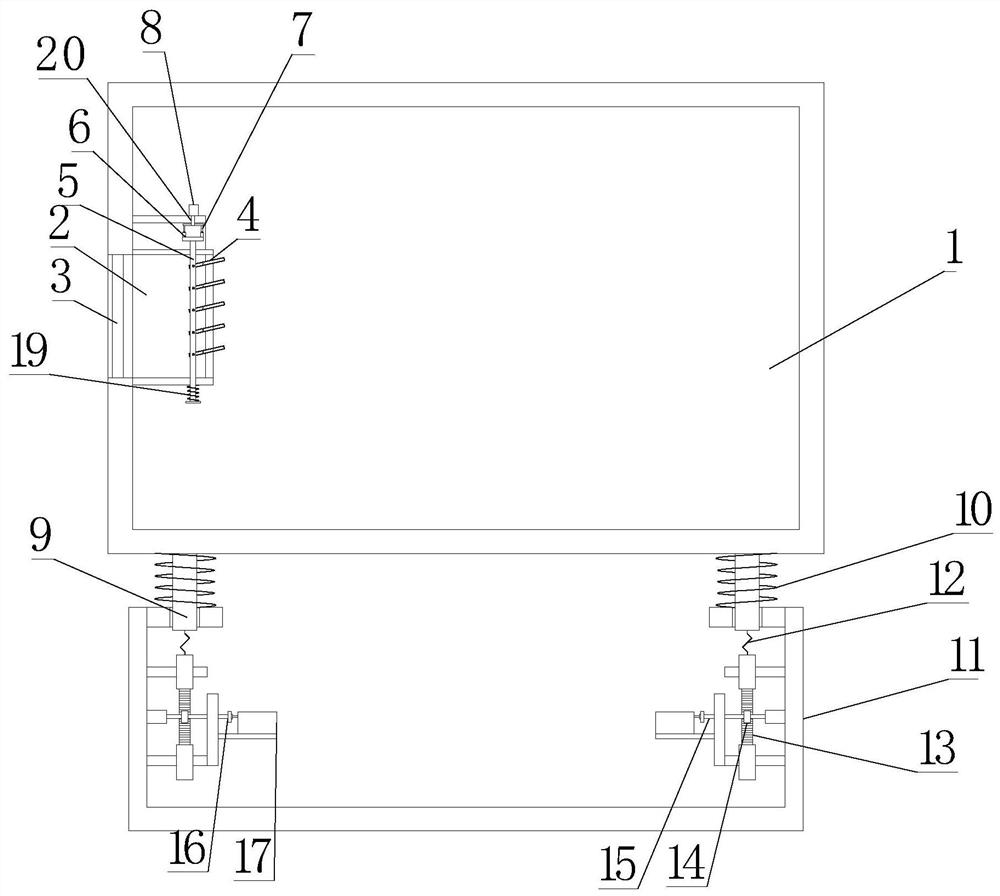

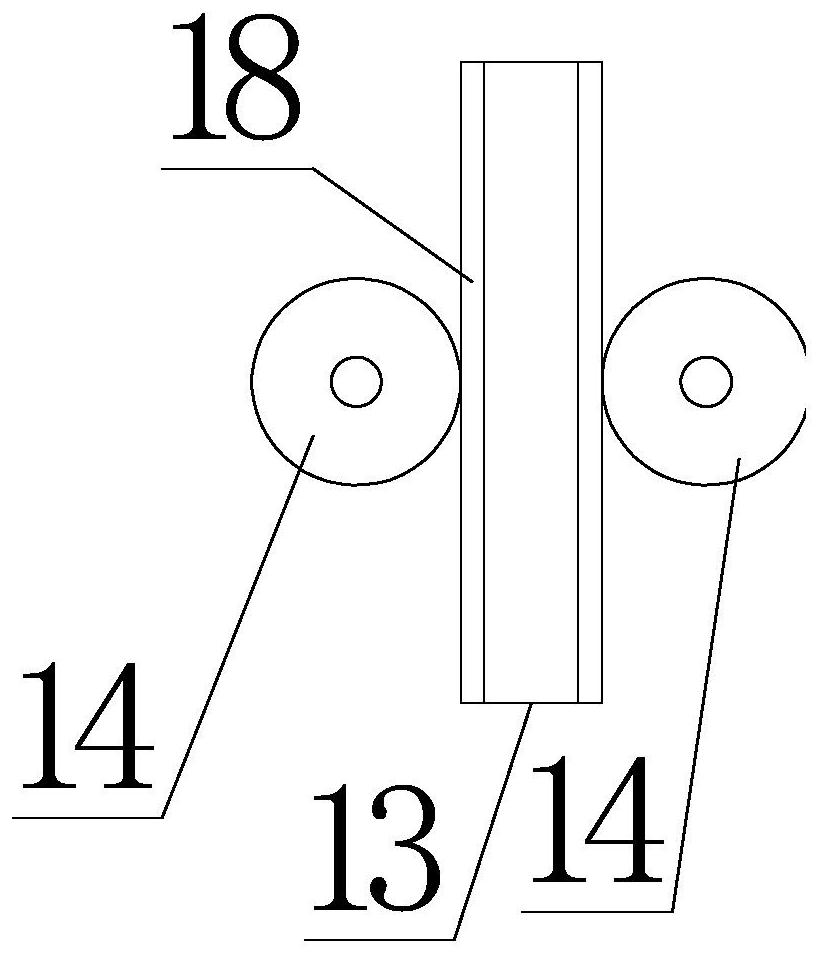

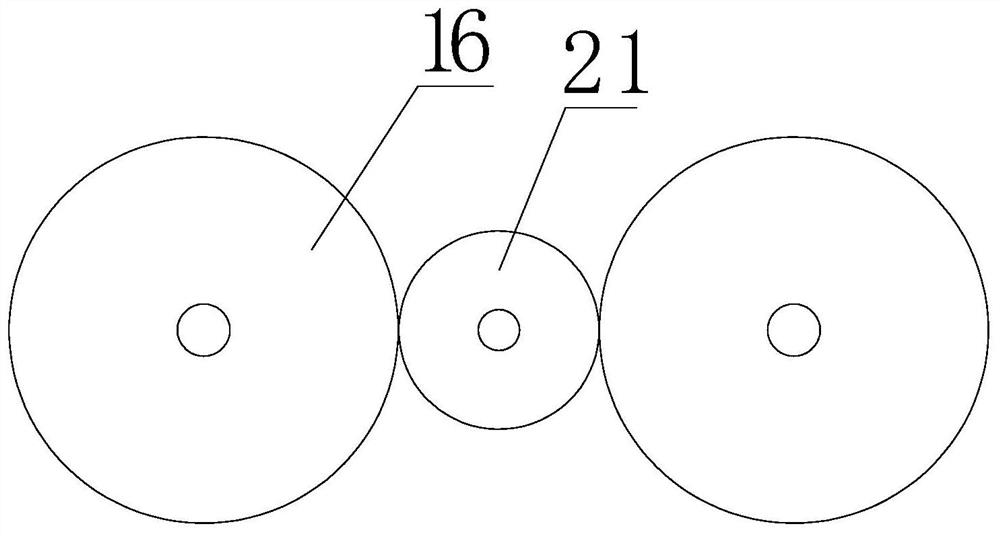

Management system of environmental sanitation vehicle

InactiveCN113090482ACool evenlyComprehensive coolingMachines/enginesMechanical power devicesAgricultural engineeringStructural engineering

The invention is applicable to the technical field of vehicle management equipment, and provides a management system of an environmental sanitation vehicle. The management system comprises a shell and a base, wherein a control part is arranged in the shell; the shell is arranged on the base; an air inlet is formed in the shell; a plurality of swinging blades which swing in a reciprocating manner are arranged at an outlet of the air inlet in an array manner, so that cooling air can swing and change the direction to enter the shell; connecting rods are fixedly arranged on two sides of the bottom of the shell; the connecting rods penetrate through sliding holes in the base; the connecting rods are elastically arranged on the base and are used for damping; the connecting rods are connected with a sliding rod which is arranged on the base in an up-down sliding manner; racks are fixedly arranged on two sides of the sliding rod; the racks on the two sides are respectively meshed with two one-way wheels; and the two one-way wheels are in transmission connection with a generator through a transmission assembly. According to the management system disclosed by the invention, vibration energy is recycled, the interior of the shell can be comprehensively cooled, and the cooling is uniform.

Owner:厦门庆丰年网络科技有限公司

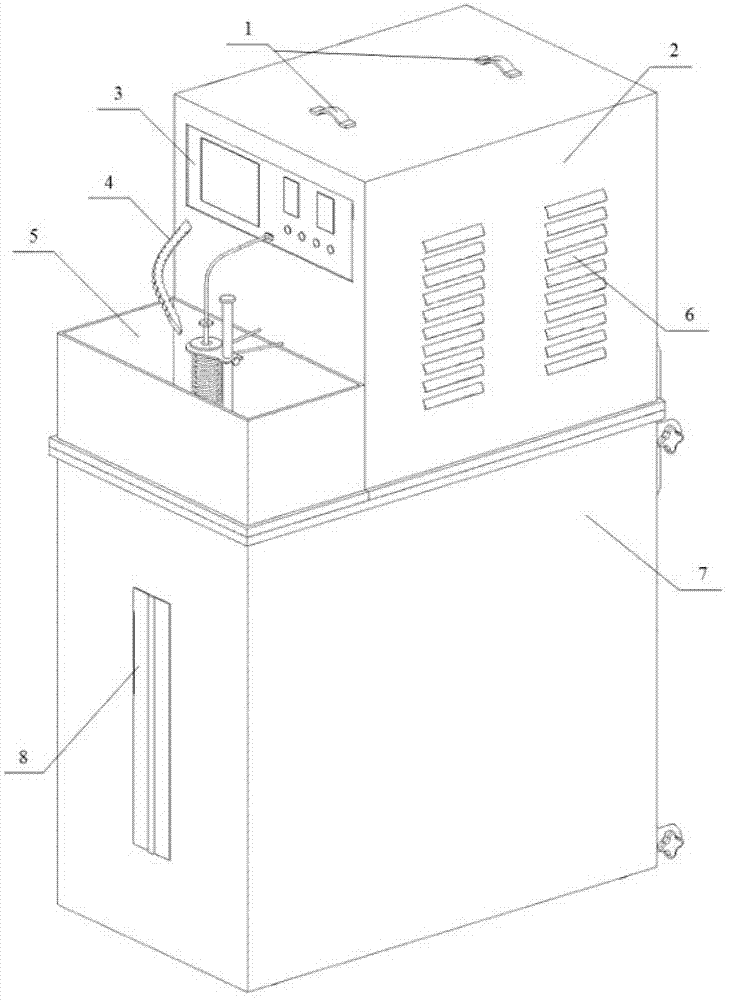

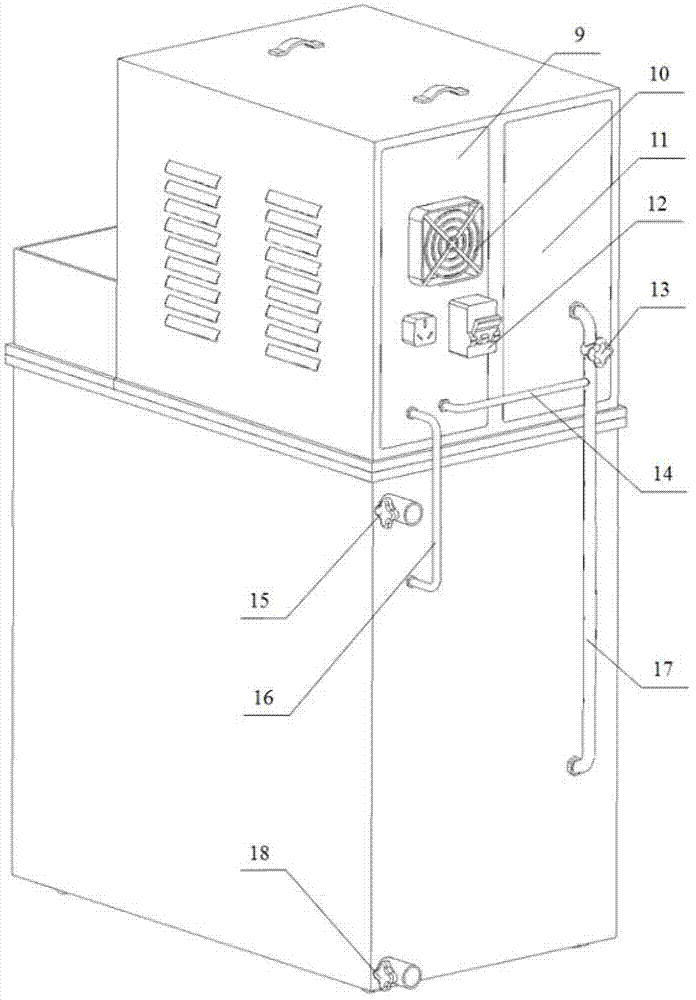

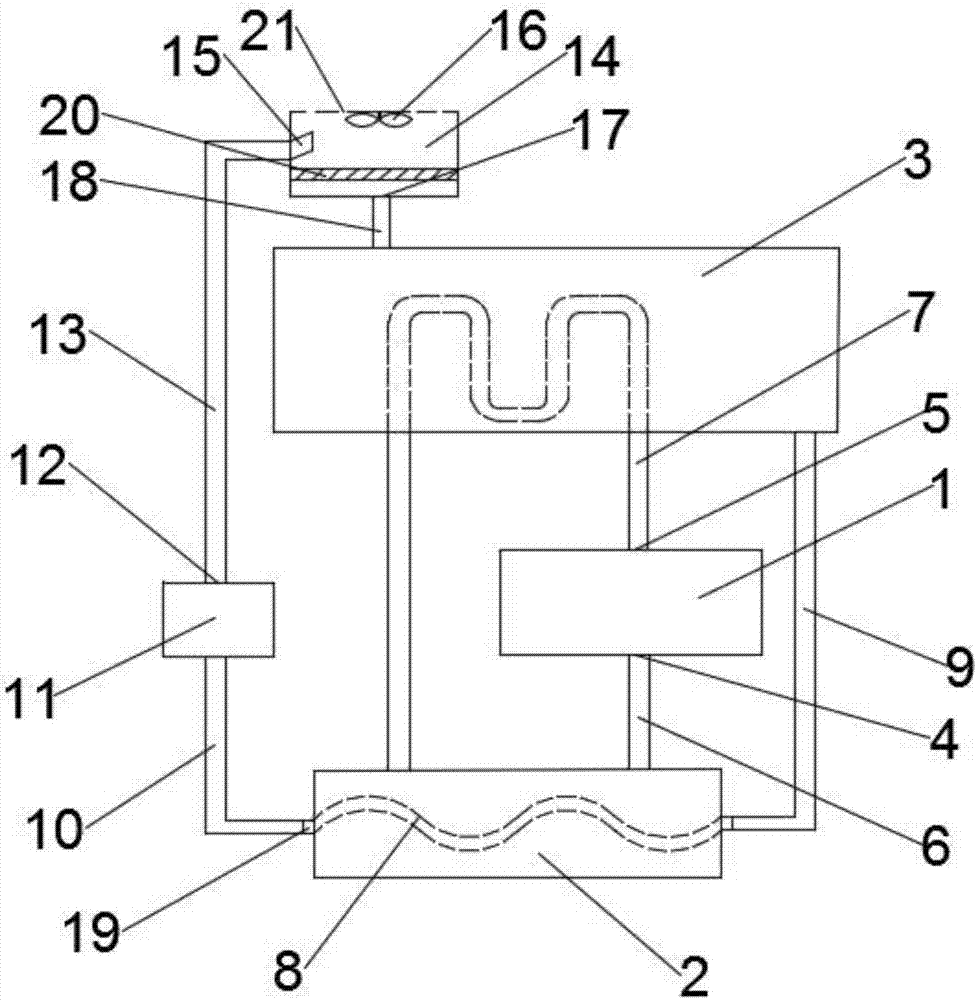

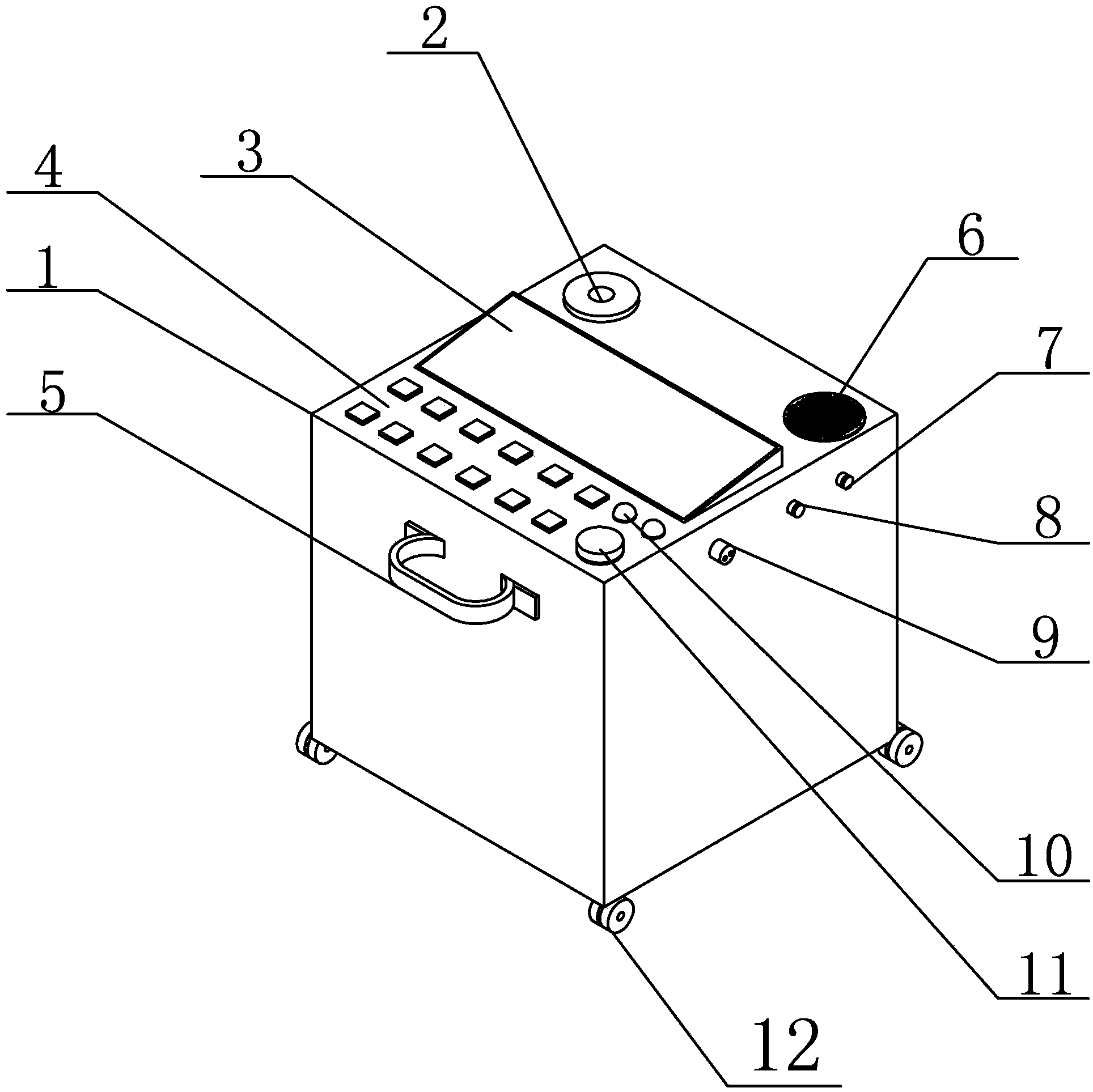

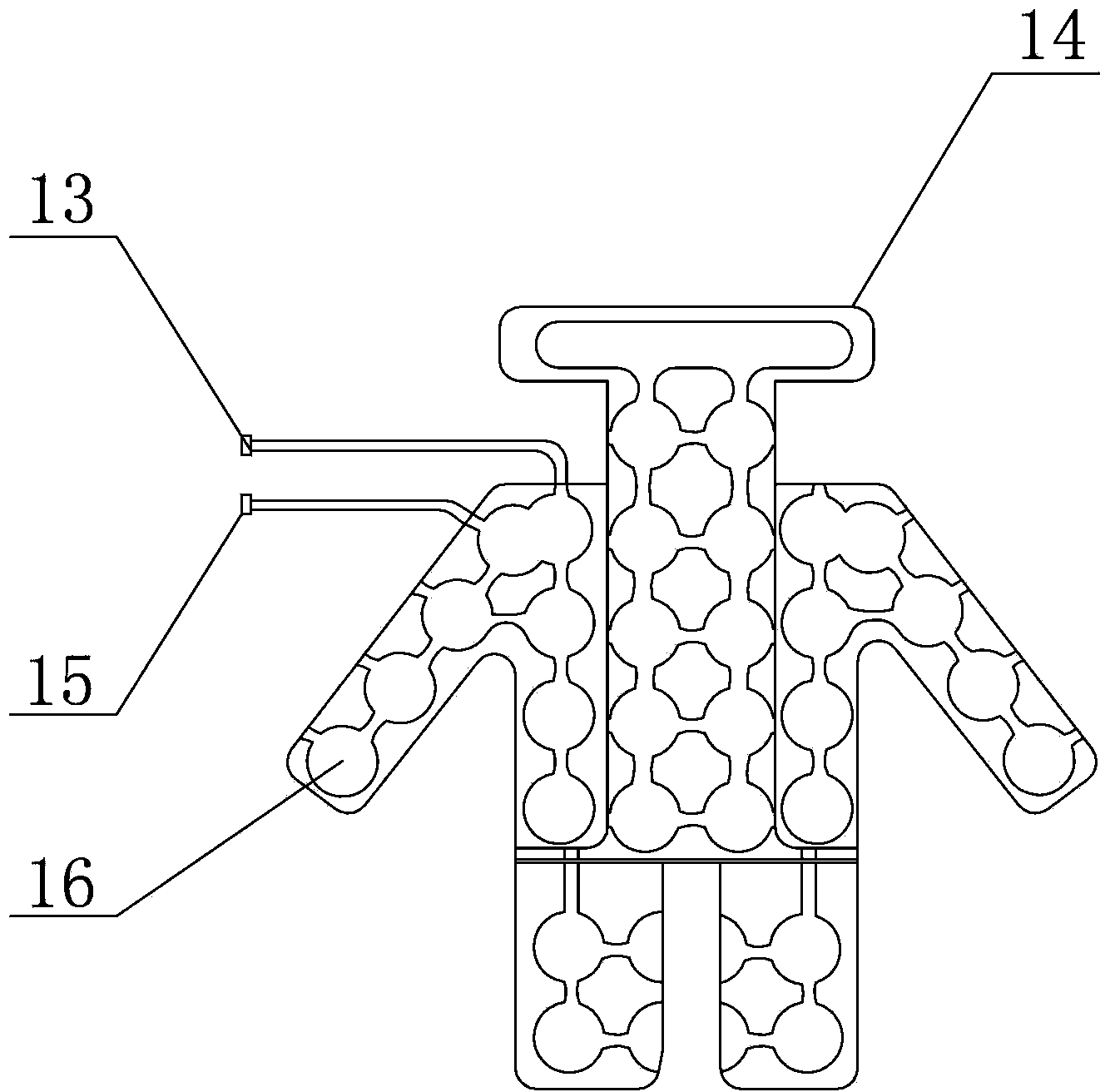

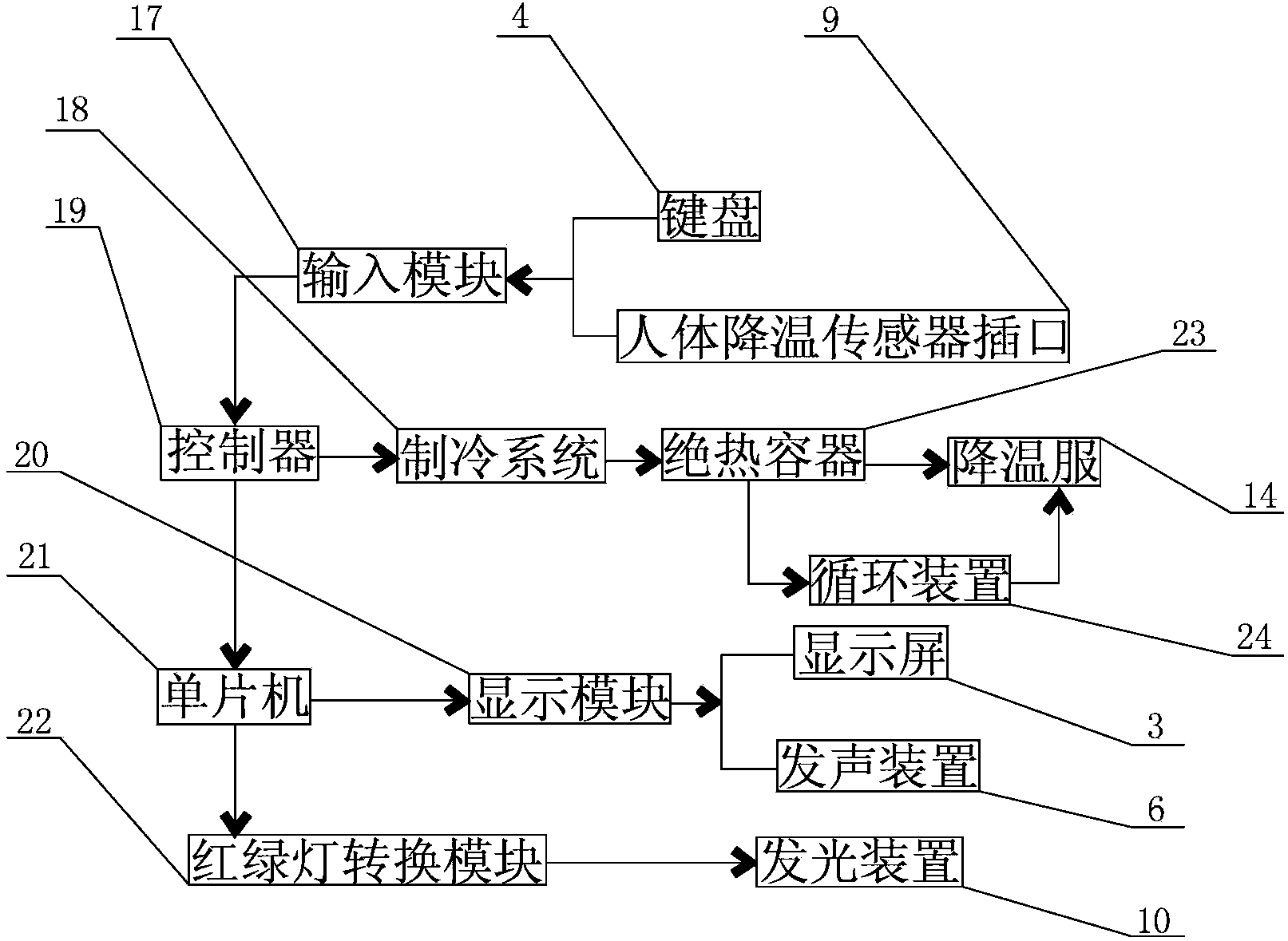

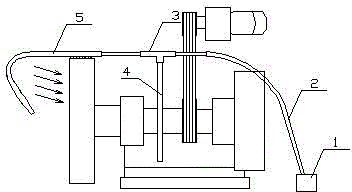

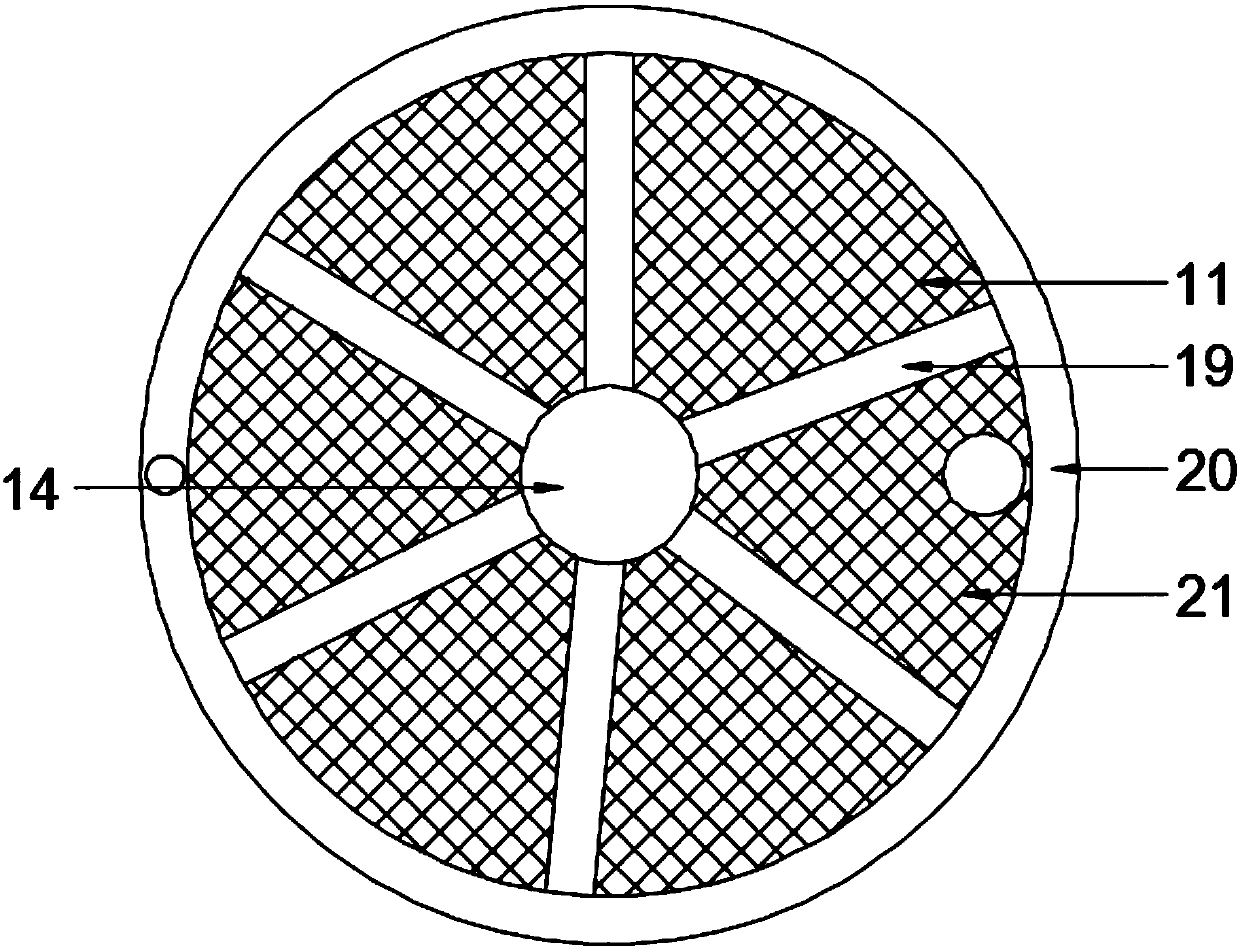

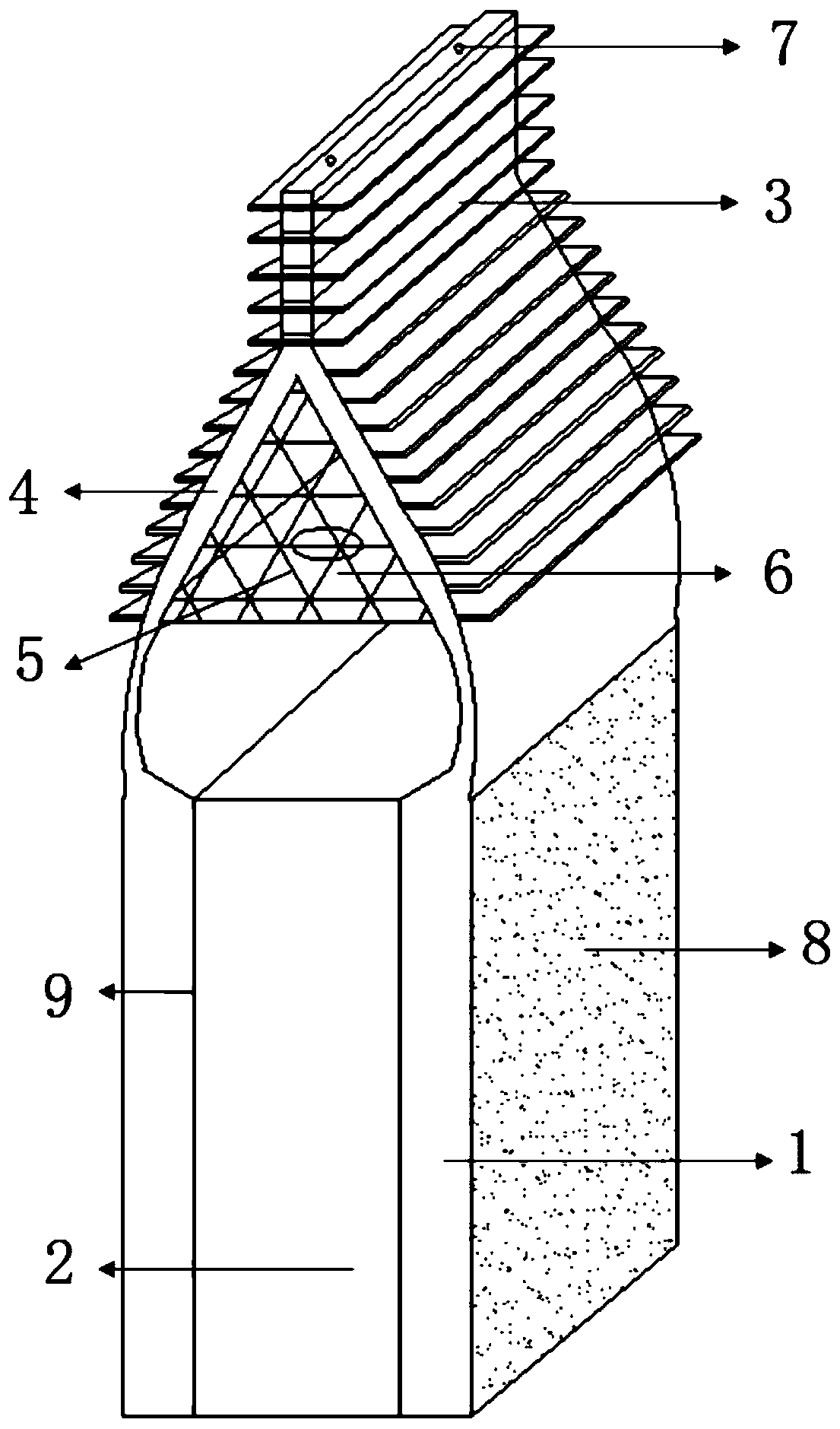

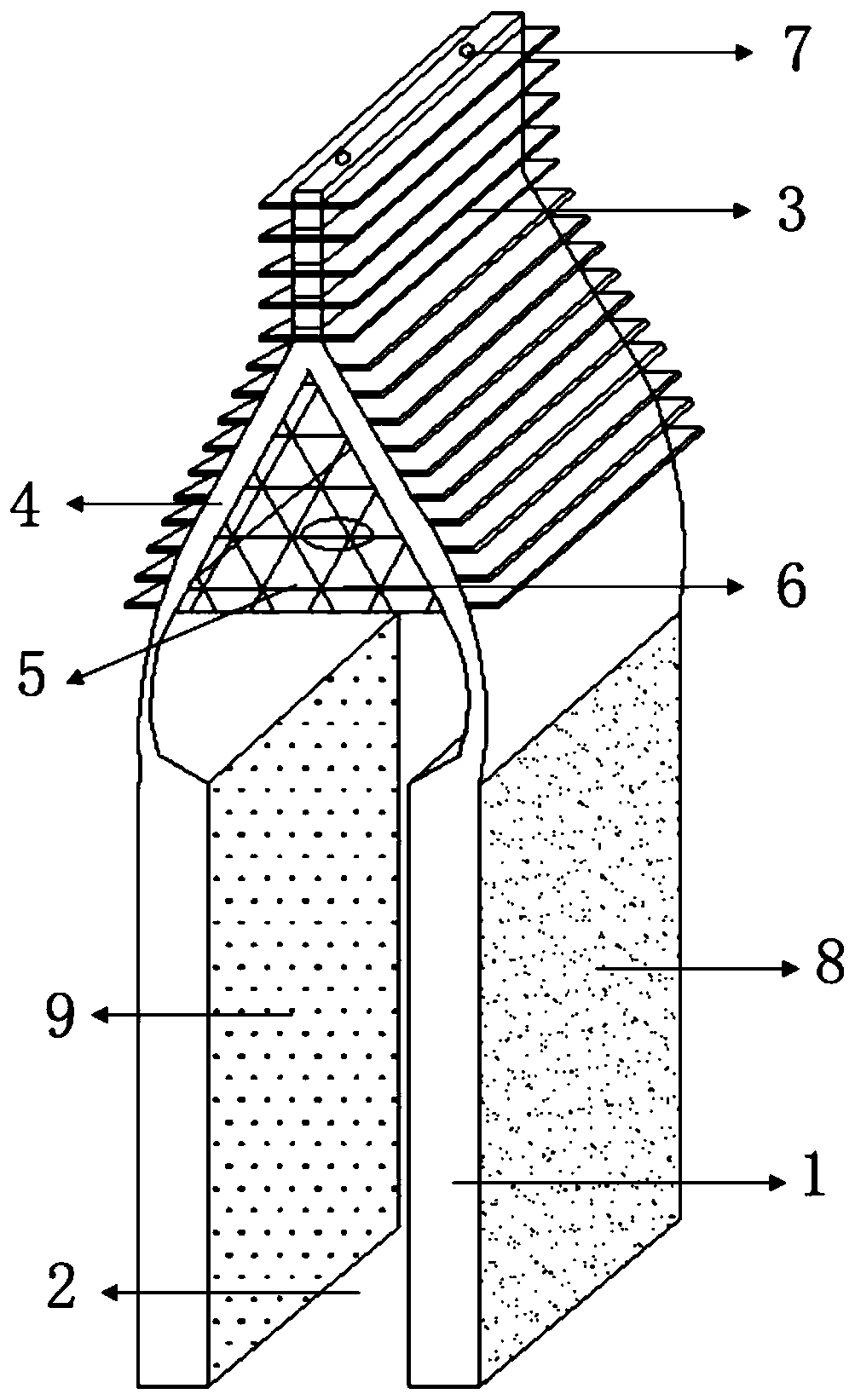

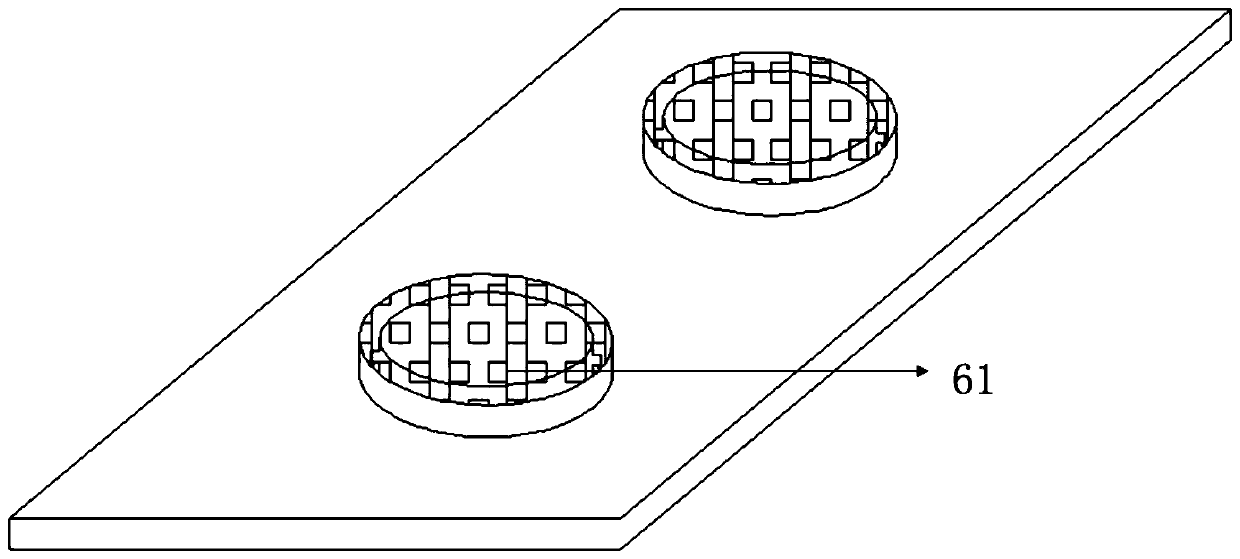

Medical human body cooling device controlled by single-chip microcomputer

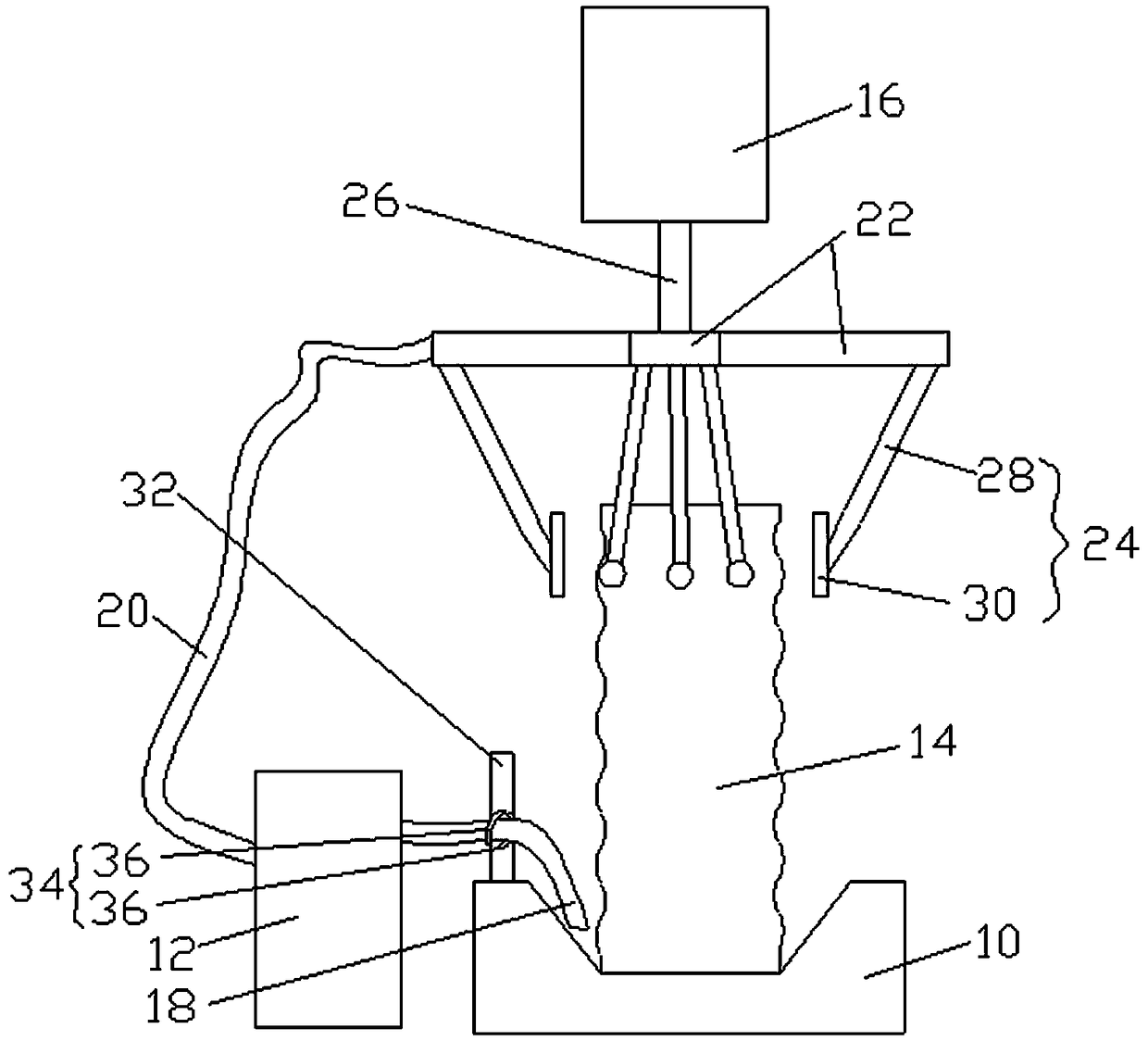

InactiveCN103800116AAdjust in timeAvoid wastingTherapeutic coolingTherapeutic heatingComputer moduleSound production

The invention relates to a medical device, in particular to a medical human body cooling device controlled by a single-chip microcomputer. The medical human body cooling device controlled by the single-chip microcomputer comprises a cooler (1) and a piece of cooling clothing (14), wherein the cooler (1) and the cooling clothing (14) are connected and embedded with a water outlet pipe (13) and a water inlet pipe (15) through a water inlet (7) and a water outlet (8) to form the human body cooling device. The medical human body cooling device controlled by the single-chip microcomputer is characterized in that the single-chip microcomputer (21) is arranged inside the cooler (1), the input and the output of the single-chip microcomputer (21) are connected with a controller (19), the output of the controller (19) is connected with a refrigerating system (18) which is connected with a heat insulation container (23), the heat insulation container (23) is connected with the cooling clothing (14) and a circulation device (24), the circulation device (24) is connected with the cooling clothing (14), the input and the output of the single-chip microcomputer (21) are connected with a display module (20), and the display module (20) is connected with a display screen (3) and a sound production device (6).

Owner:赵银香

Floating roof oil storage tank

ActiveCN114104531AReduce settingsComprehensive coolingLarge containersFire rescueElectric machineArchitectural engineering

The invention belongs to the field of floating-roof oil storage tanks, particularly relates to a floating-roof oil storage tank, and aims to solve the problems that a spraying system and a foam fire extinguishing system arranged on an existing floating-roof oil storage tank are fixedly arranged, so that the spraying system cannot comprehensively cool the oil storage tank, and the foam fire extinguishing system cannot quickly fill foams into a joint of a floating roof and an oil tank wall. In order to solve the problems that in the prior art, due to the fact that a large number of spraying heads and foam generators are arranged, equipment and funds are wasted, and meanwhile the overhaul work amount is increased, the following scheme is provided, the oil tank comprises a tank bottom, an oil tank wall and a floating roof, and a spraying system or a foam fire extinguishing system can be driven to swing by switching the rotation direction of a positive and negative rotation motor; the spraying system can comprehensively cool the oil storage tank, the foam fire extinguishing system can rapidly fill the joint of the floating roof and the oil tank wall with foam, the number of spray headers and foam generators can be reduced, and meanwhile the overhaul workload is reduced.

Owner:蓝基工程科技有限公司

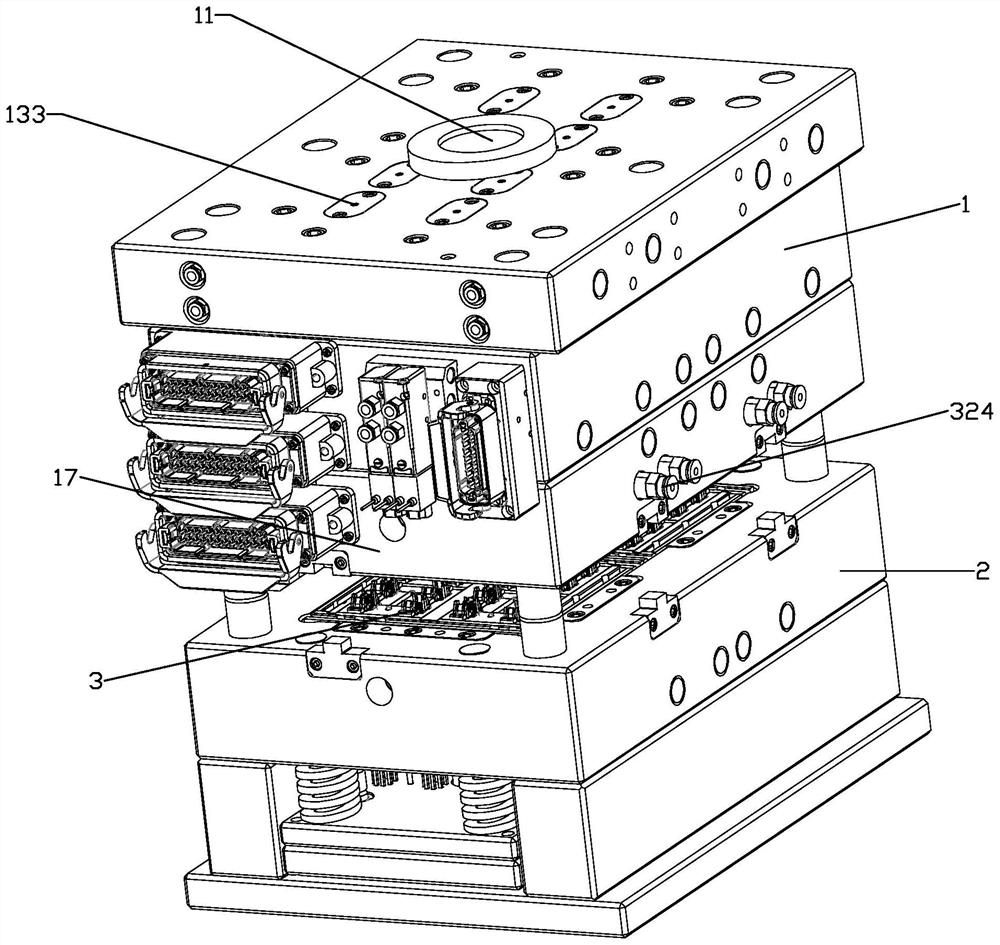

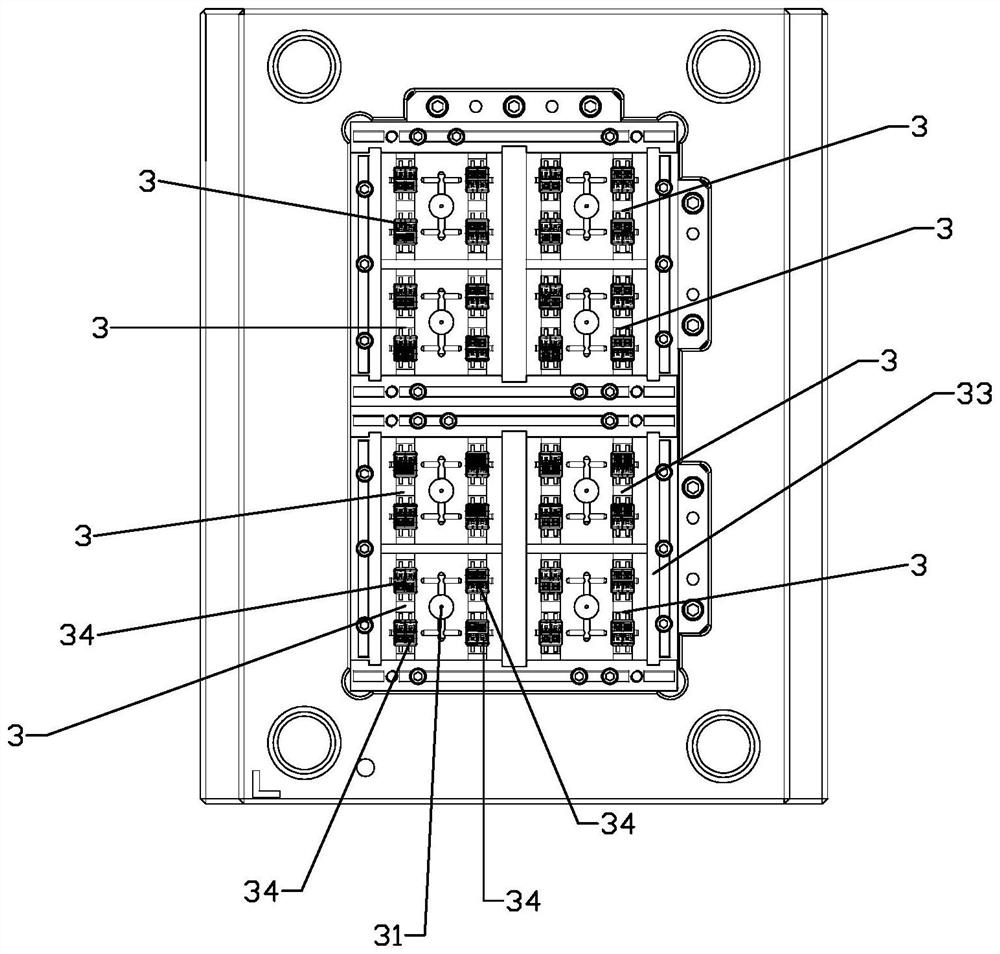

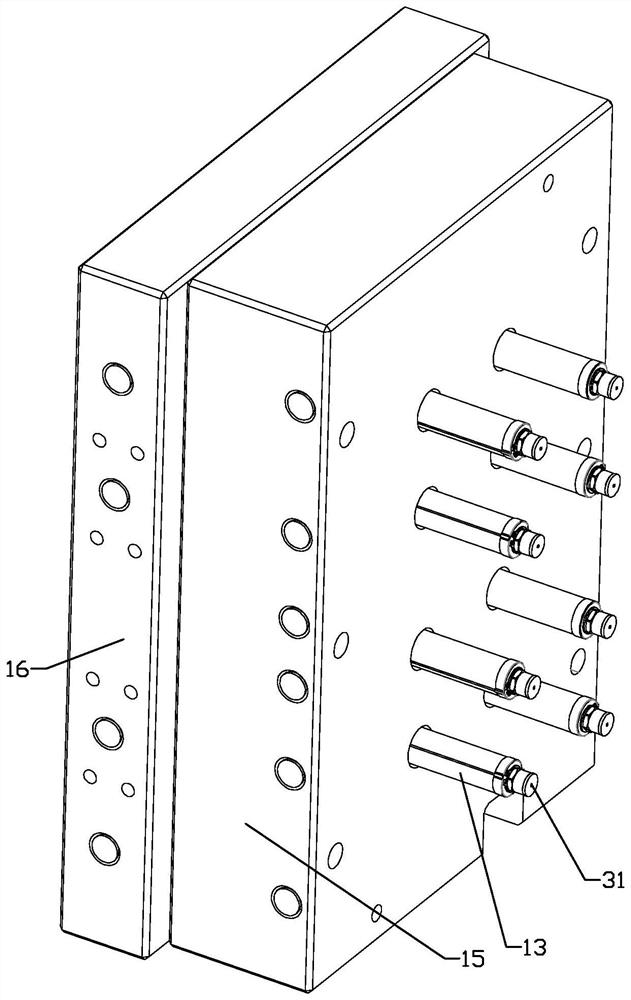

Mould with multiple glue injection ports

The invention relates to a mold with multiple glue injection ports, which comprises a front mold and a rear mold, a plurality of cavities for molding a plurality of products are arranged between the front mold and the rear mold, the front mold is provided with a glue inlet nozzle, the front mold is provided with a shunting cavity communicated with the glue inlet nozzle, and the shunting cavity is provided with a shunting valve and a heat preservation device. The flow dividing valves are in one-to-one correspondence with the cavities and enable the flow dividing cavities to be communicated with the middles of the cavities, and the heat preservation device conducts heat preservation and heating on materials in the flow dividing cavities. By adopting the scheme, the invention provides the multi-glue-injection-port mold which reduces material waste, improves the forming efficiency and reduces the design difficulty.

Owner:乐清昌德成电子有限公司

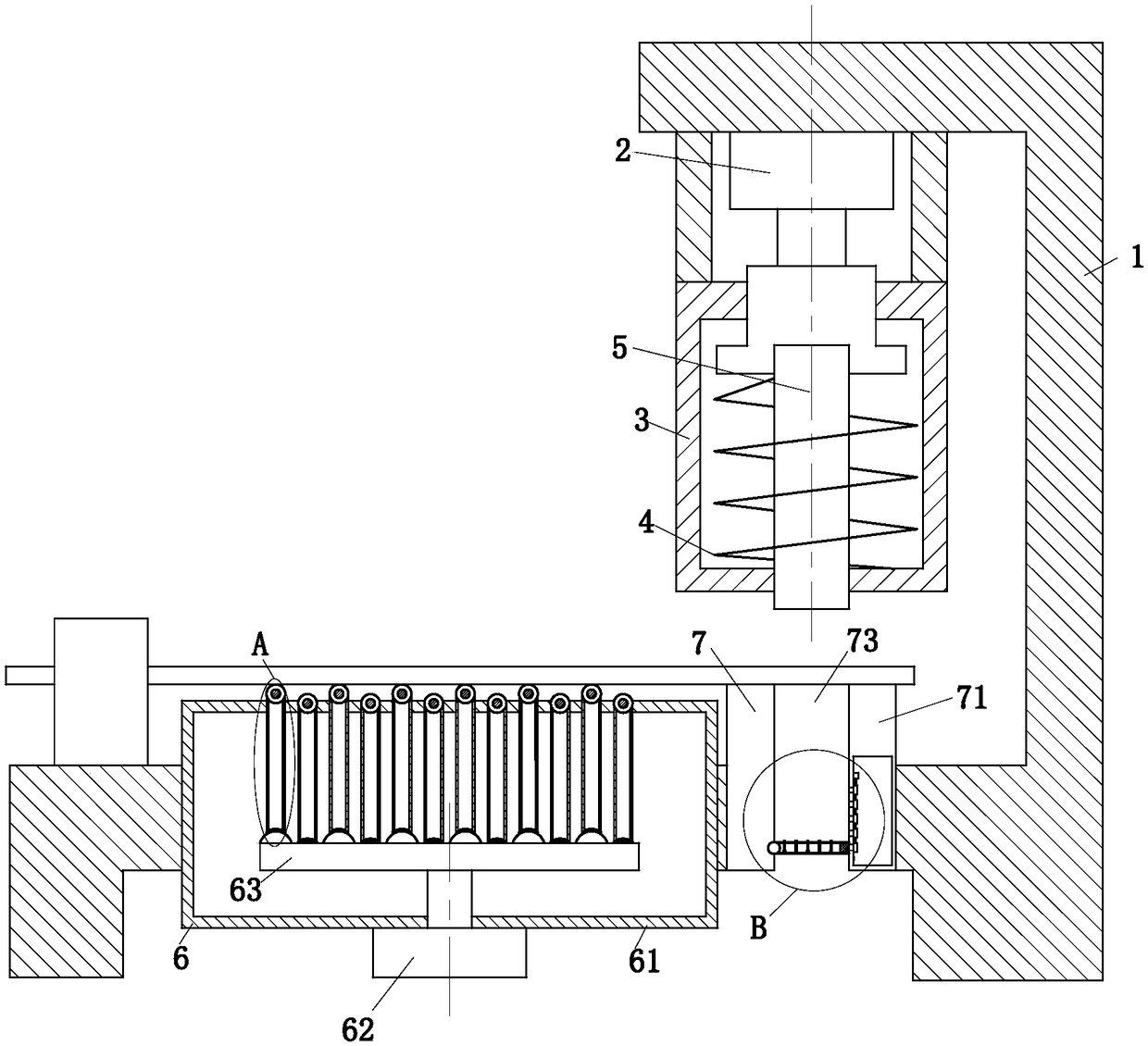

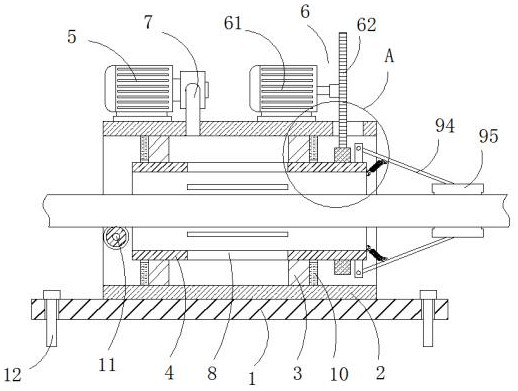

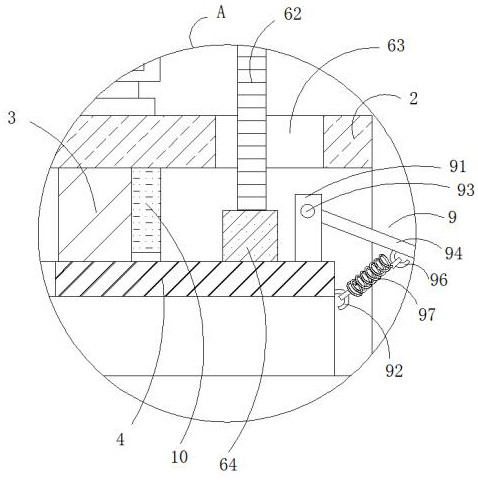

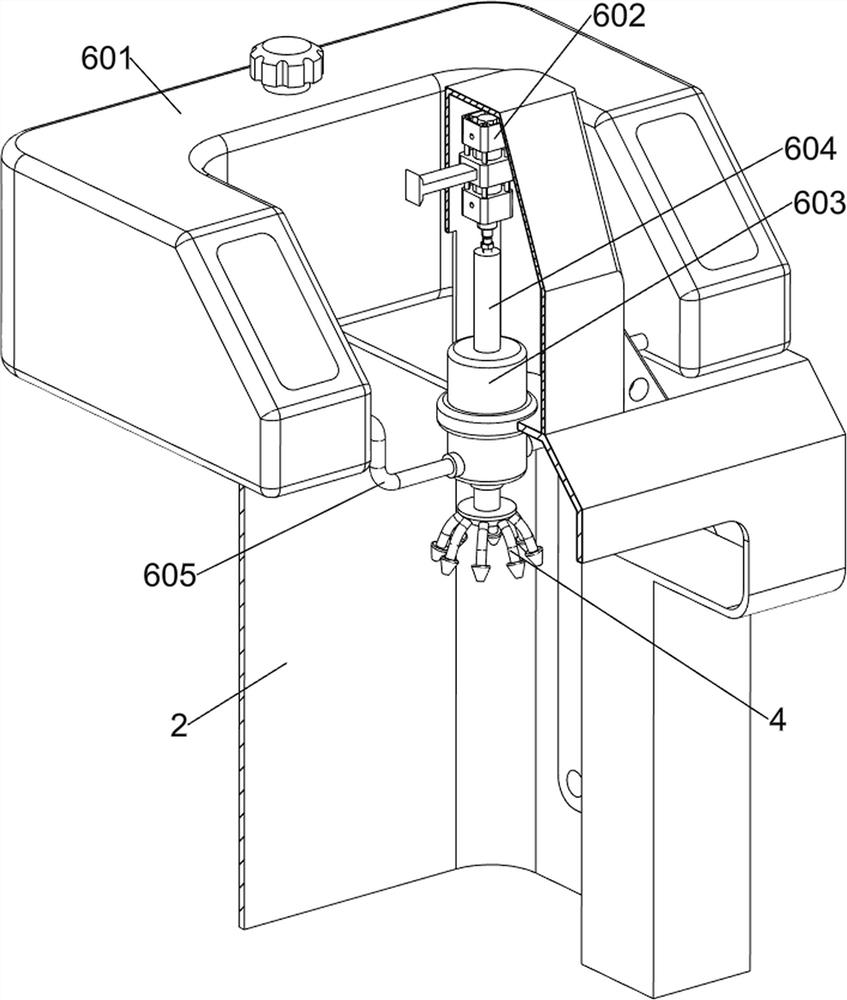

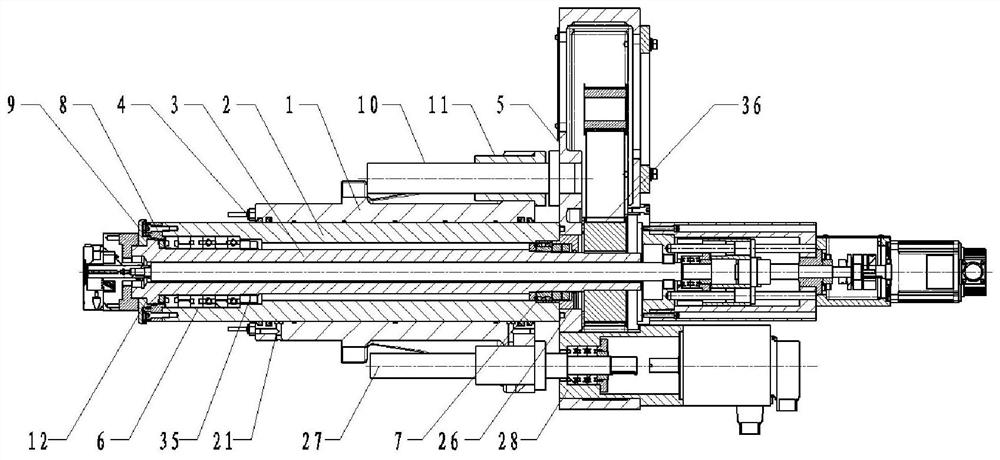

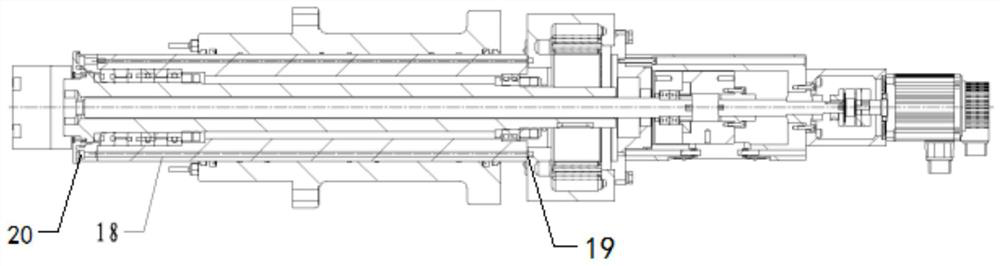

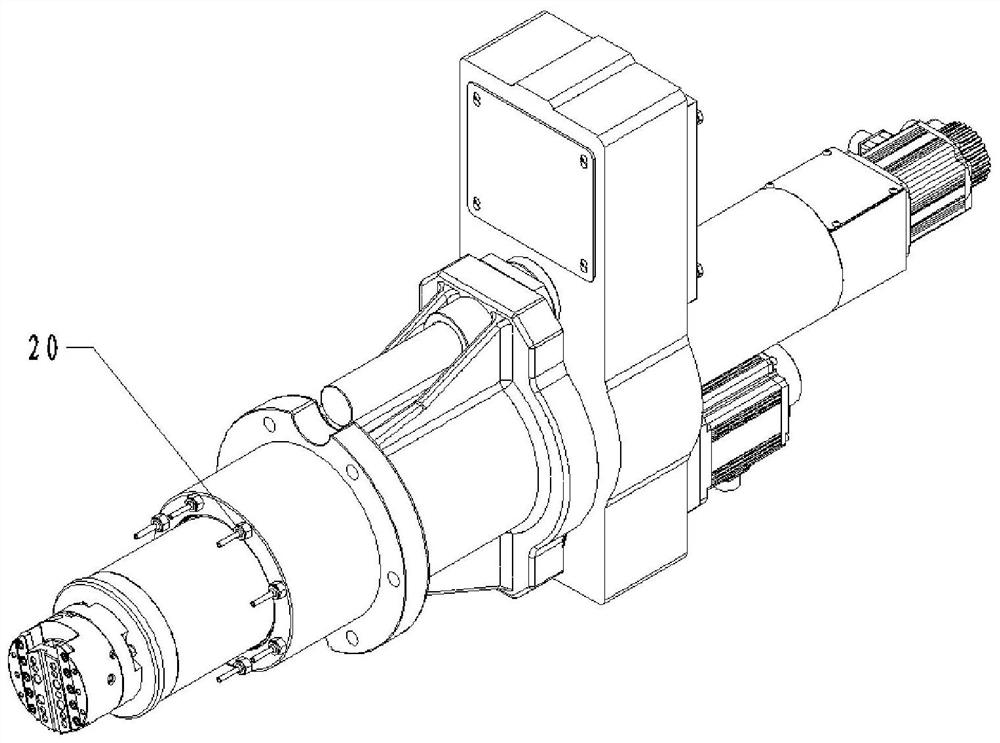

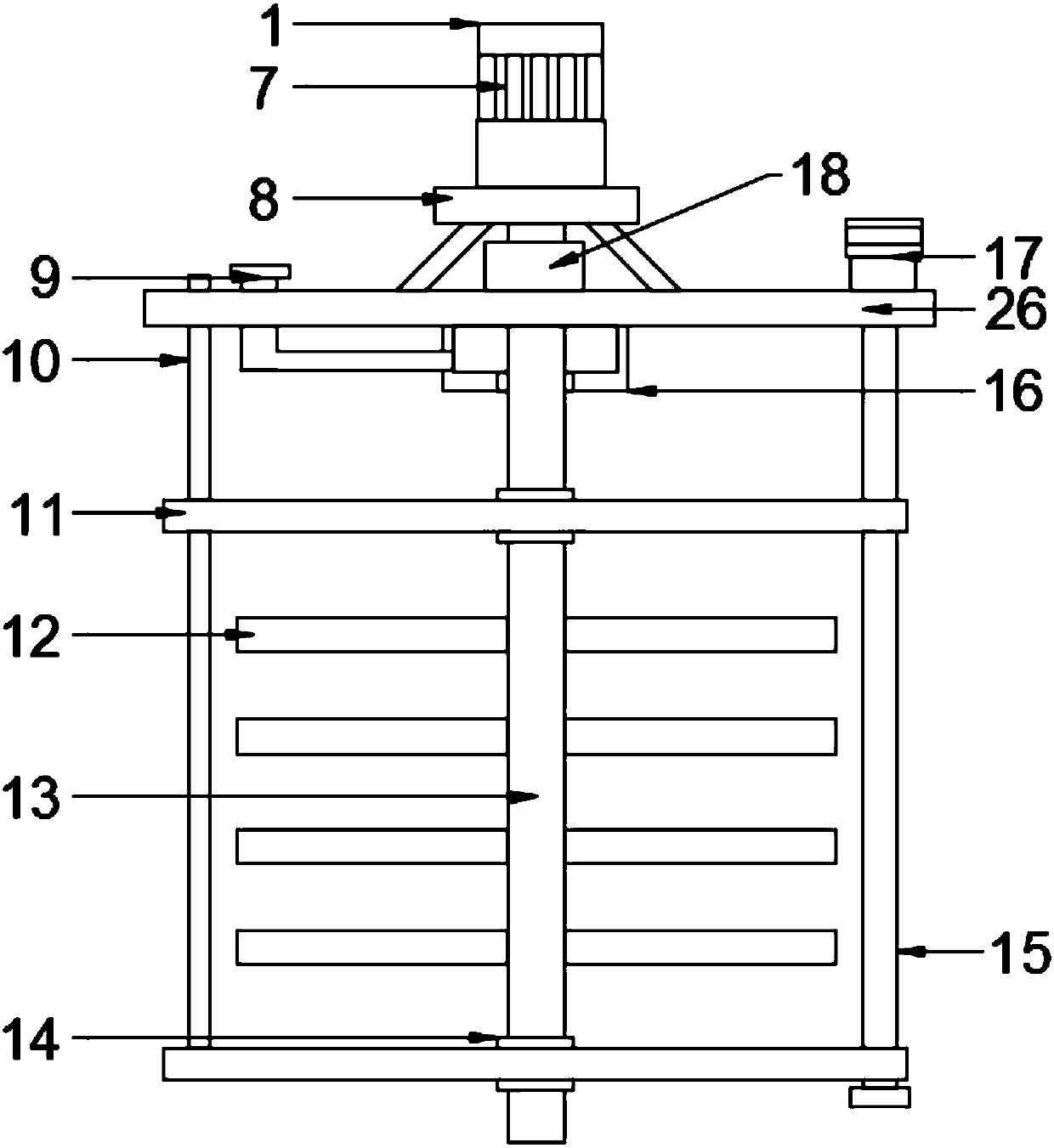

Multifunctional guide rod telescopic servo waterwheel spindle

PendingCN112264810AGuaranteed concentricityImprove carrying capacityLarge fixed membersMaintainance and safety accessoriesNumerical controlWater wheel

The invention relates to the field of numerical control machine tools, in particular to a multifunctional guide rod telescopic servo waterwheel spindle. The multifunctional guide rod telescopic servowaterwheel spindle is characterized in that a guide rod is arranged outside a shell, and meanwhile, the problems of poor cooling effect and poor air tightness of a servo spindle in the prior art are solved. the multifunctional guide rod telescopic servo waterwheel spindle comprises a guide rod, a bearing seat and a cooling system, wherein the guide rod is arranged outside the shell, the bearing seat and the cooling system are integrally designed with a motor connecting seat, the cooling system comprises a spindle unit circulating cooling system passing through the interior of a sleeve and an annular spraying type gas-liquid cooling system passing through the interior of the shell, the sleeve is arranged on the inner side of the shell, and a spindle is arranged in the sleeve, a front bearing set and a rear bearing set are fixed through bearing end covers, screws and locking nuts which are fixed to the two ends of the sleeve, a front gland is arranged on the front bearing set, a waterproof cover is connected to one side of the front gland in a clamped mode, a waterproof system combining non-contact sealing and air curtain sealing is formed between the waterproof cover and the front gland, and the guide rod is fixed to a motor support.

Owner:台州市神鹰机床有限公司

High-efficiency motor rotor grinding equipment and using method thereof

ActiveCN111958476AEasy to installFully groundedLapping machinesManufacturing stator/rotor bodiesElectric machineryControl theory

The invention discloses high-efficiency motor rotor grinding equipment and a using method thereof. The high-efficiency motor rotor grinding equipment comprises a base, wherein two moving rings are symmetrically and slidably connected to the top of the base, and U-shaped grinding plates are arranged on the sides, close to each other, of the two moving rings in a clamped mode; a supporting shaft located between the two moving rings is rotationally connected to the top of the base, a supporting cover is fixedly arranged at the top end of the supporting shaft, a motor rotor is arranged in the supporting cover in a clamped mode, and the top end of the motor rotor extends to the position above the supporting cover; and an L-shaped frame is fixedly arranged on one side of the top of the base, anda driving motor is fixedly arranged at the top of the L-shaped frame. According to the high-efficiency motor rotor grinding equipment and the using method thereof, the motor rotor can be convenientlypositioned and mounted, the motor rotor can be comprehensively ground, and the motor rotor can be synchronously cooled in the grinding process so that the situation that the motor rotor is damaged due to over-high temperature while being ground can be prevented.

Owner:温岭中昊电机配件有限公司

Cooling device for chemical treatment

InactiveCN108955082ANo need to moveSimple structureDomestic cooling apparatusLighting and heating apparatusChemical treatmentWater spray

The invention relates to a cooling device for chemical treatment. A water collecting groove, a cooling circulating water machine, a cooling tank and a lifting cylinder are included; a water inflow pipe is connected between the water collecting groove and the cooling circulating water machine; the cooling circulating water machine is connected with a water outflow pipe; a crossed pipe is arranged above the cooling tank; the water outflow pipe communicates with the crossed pipe; four water spraying mechanisms are arranged on the crossed pipe in a communicating pipe; each water spraying mechanismcomprises a plurality of water spraying assemblies; the bottom of the cooling tank is arranged in the water collecting groove; and a cylinder arm of the lifting cylinder is connected with the crossedpipe. The cooling device for chemical treatment is simple in structure and convenient to use; the cylinder is used for driving the crossed pipe to rise and fall; meanwhile, due to cooperation of thecrossed pipe and the water spraying assemblies, the cooling tank can be comprehensively cooled, cooling is uniform, the cooling tank is not needed to move, and it is guaranteed that the safety is good.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

Cooling device for centrifugal machine pouring

The invention relates to a cooling device for centrifugal machine pouring. The cooling device for the centrifugal machine pouring comprises a water pump, the water pump is connected with a regulating valve through a water inlet pipe, and the regulating valve is connected with a spray pipe located above a workpiece through a pipeline. When performing centrifugal pouring, the cooling device for the centrifugal machine pouring cools the workpiece through enabling water to pass through the spray pipe through the water pump, in order to improve the cooling effect, the spray pipe simultaneously cools the upside and lateral surfaces of the workpiece, because the workpiece rotates, the cooling device for the centrifugal machine pouring is capable of fully cooling the workpiece, and the cooling effect is good; the regulating valve can regulate the water flow rate and flow speed according to practical situations so as to guarantee the best cooling effect for the workpiece.

Owner:YANGZHOU YIFENG BRONZE PROD

Chemical solution crystallization and purification device

InactiveCN110152341ACooling crystallization effect is goodHigh crystallinitySolution crystallizationHeat exchange cooling cystallizationChemical solutionEngineering

The invention discloses a chemical solution crystallization and purification device, which comprises a cooling device and a crystallization box, wherein a cooling pipe is arranged outside the crystallization box; a water outlet is arranged at the upper end of the cooling pipe; a cold water inlet is arranged at the lower end of the cooling pipe; a feeding pipe is arranged at the upper end on the left side of the crystallization box; and the cooling device is inserted into the crystallization box. The chemical solution crystallization purification device has the advantages of complete cooling, good chemical solution cooling and crystallization effect and good purification effect, the cooling device can be carried out integrally, and crystals falling on a filter screen and crystals on a rotating shaft and a rotating rod are convenient to remove.

Owner:淮安智品企业管理有限公司

Battery safety heat management device

ActiveCN109860949AComprehensive coolingMeet the needs of useSecondary cellsFire rescueHeat managementThermal insulation

The present invention discloses a battery safety heat management device. The battery safety heat management device comprises a cooling device, a recovery device and a safety device. The cooling devicecomprises a liquid storage cabin capable of heat conduction and attached to the surface of a battery; the recovery device comprises a diversion tube connected with the liquid storage cabin and condensation fins arranged on the diversion tube, and the liquid storage cabin contains phase-change materials; and the safety device comprises a safety cabin provided with a fire extinguishing agent and arranged at the upper portion of the battery, the inner wall of the safety cabin is made of thermal insulation materials, the bottom portion of the safety cabin is provided with buckled open holes, andthe open holes can be covered with a cover plate made of fusible materials.

Owner:中能建储能科技(武汉)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com