Floating roof oil storage tank

An oil storage tank and floating roof technology, which is applied to tank cars, transportation passenger cars, railway car body parts, etc., can solve the problems of inability to foam filling, waste of equipment and funds for foam generators, and inability to cool the oil storage tank, reducing the number of settings. , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

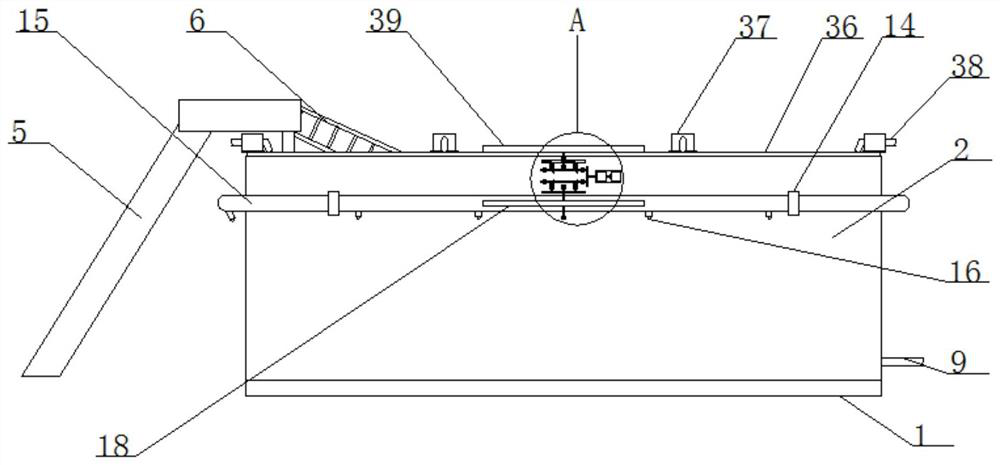

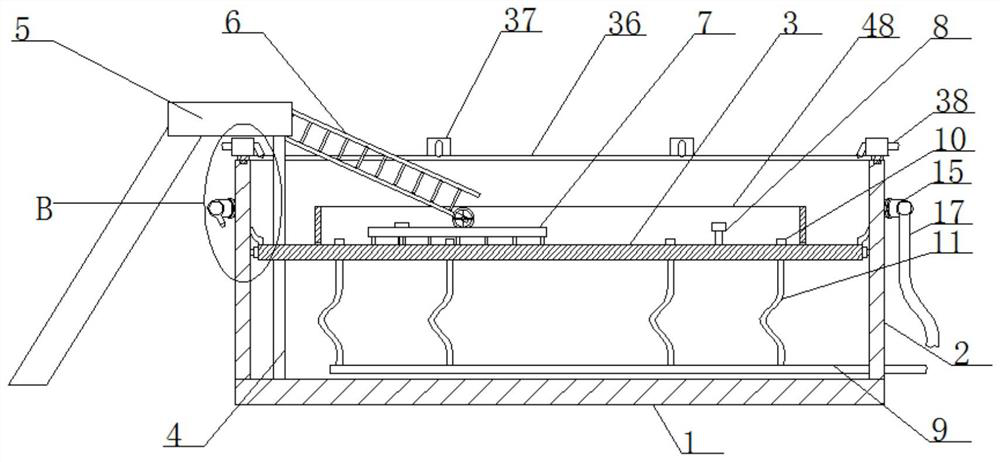

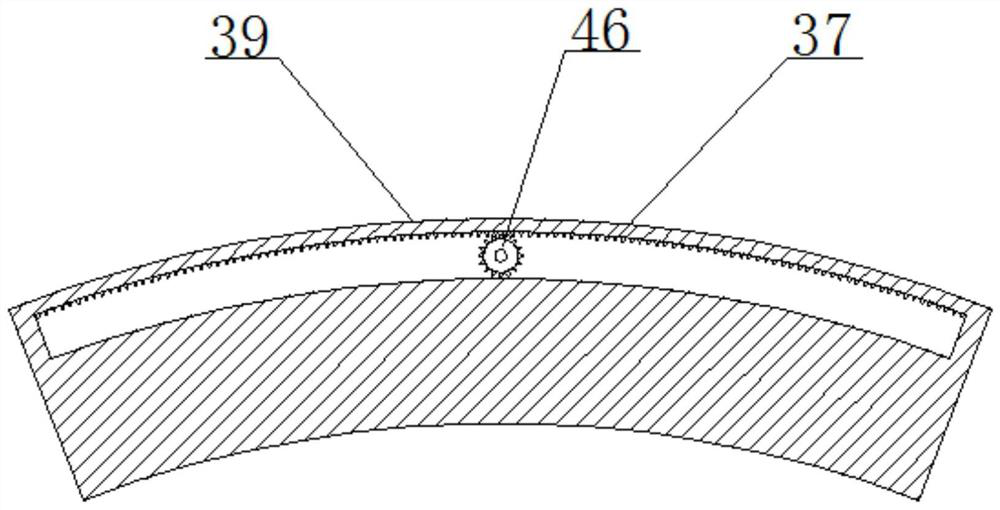

[0031] refer to Figure 1-8, a floating roof oil storage tank, comprising a tank bottom 1, an oil tank wall 2 and a floating roof 3, the oil tank wall 2 is fixedly arranged on the top of the tank bottom 1, the floating roof 3 is arranged in the oil tank wall 2, and the floating roof 3 The outer side of the floating roof 3 is provided with a ring sealing ring, the top of the floating roof 3 is provided with a tongue-shaped sealing ring, the floating roof 3 is provided with a sliding hole, and the sliding hole is provided with an oil dipping pipe 4, and the bottom end of the oil dipping pipe 4 is connected to the tank bottom 1. A ladder 5 is arranged on the outside of the top of the oil dipping pipe 4, and the ladder 5 is arranged on the outside of the oil tank wall 2. The ladder 5 is rotatably connected with a movable ladder 6, and the top of the floating roof 3 is fixedly connected with a track platform 7 by welding, and the movable ladder 6 The bottom end is slidably installe...

Embodiment 2

[0042] The difference from Embodiment 1 is that it includes a tank bottom 1, an oil tank wall 2 and a floating roof 3, and is characterized in that the oil tank wall 2 is fixedly arranged on the top of the tank bottom 1, and the floating roof 3 is arranged on the oil tank In the wall 2, a ring sealing ring is provided on the outside of the floating roof 3, a tongue-shaped sealing ring is provided on the top of the floating roof 3, a sliding hole is provided on the floating roof 3, and an oil dipping pipe 4 is arranged in the sliding hole, and the bottom of the oil dipping pipe 4 The end is connected to the bottom of the tank 1, and a ladder 5 is arranged on the outside of the top of the dipstick 4, and the ladder 5 is arranged on the outside of the tank wall 2. A movable ladder 6 is connected to the ladder 5 in rotation, and a track platform 7 is fixedly connected to the top of the floating roof 3. , the bottom end of the movable ladder 6 is slidingly installed on the track pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com