Converter for manufacturing environment-friendly material activated carbon

An environmentally friendly material and activated carbon technology, which is applied in the direction of furnaces, furnace components, and discharged materials, can solve the problems of floating in the air and the low efficiency of concentrated cooling inside activated carbon, and achieve a comprehensive cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

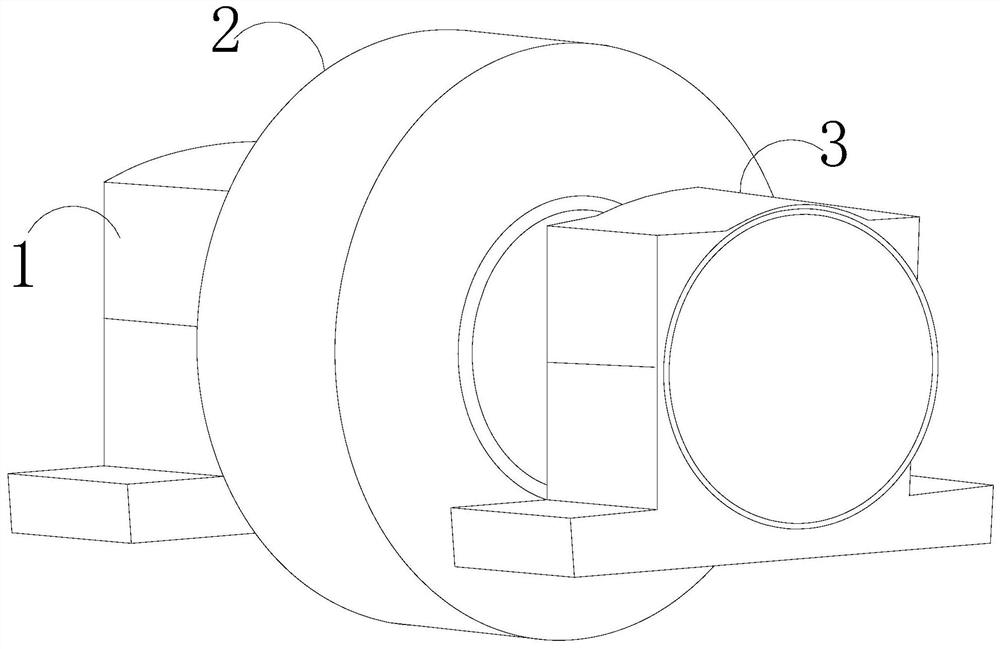

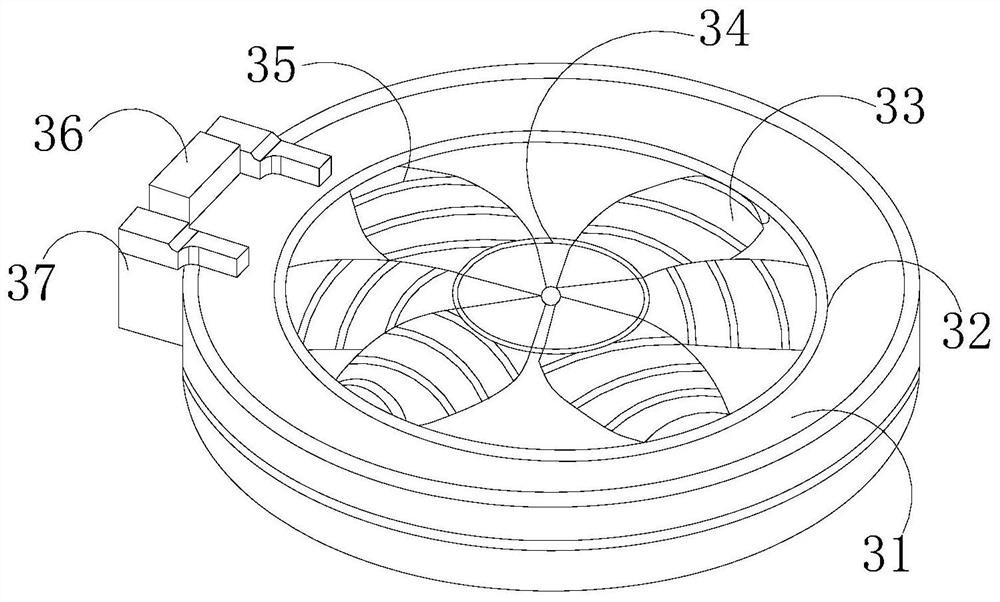

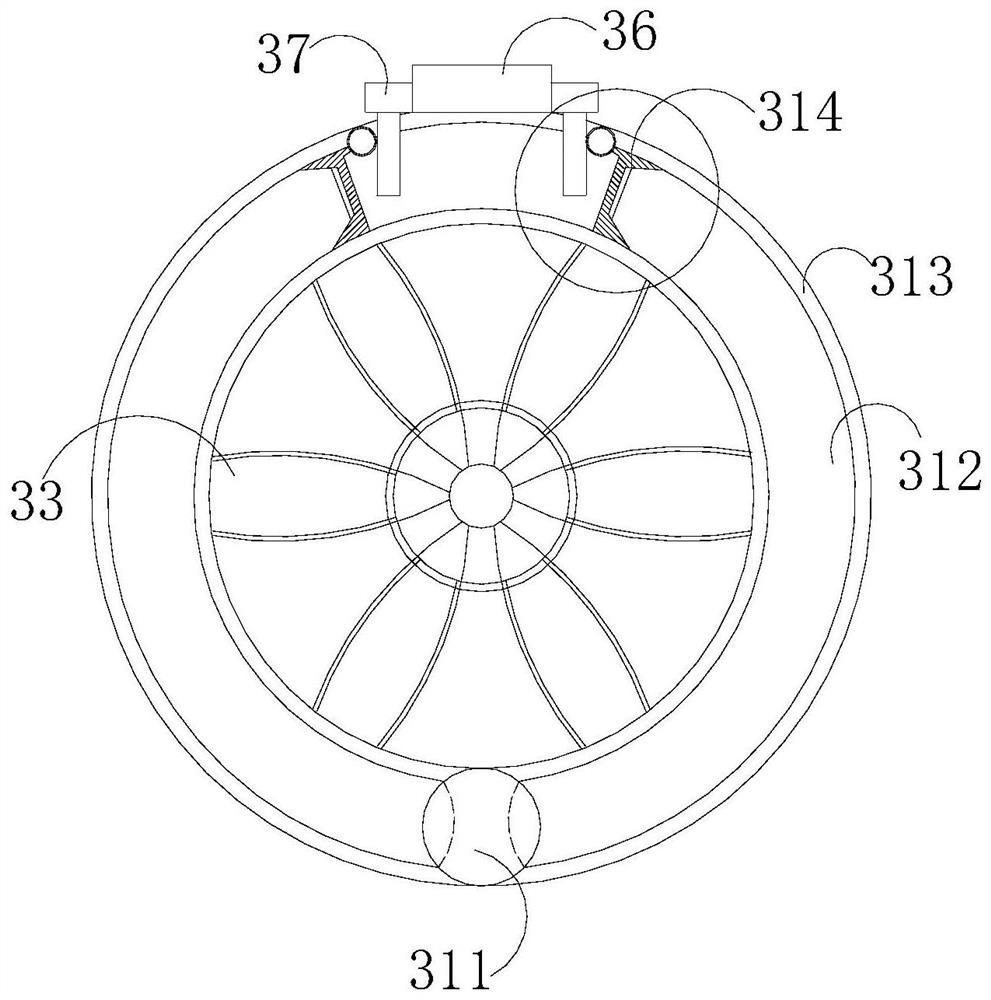

[0030] Such as Figure 1-Figure 8 As shown, the present invention provides a kind of environmental protection material active carbon converter, and its structure comprises inlet 1, body of furnace 2, cooling device 3, and described inlet 1 is connected in body of furnace 2 inside, and body of furnace 2 and cooling device 3 In cooperation, the cooling device 3 includes a receiving tray 31, a holding tray 32, a cooling cavity 33, a material distribution port 34, a refrigeration belt 35, a mounting seat 36, and a drive motor 37. 34 is coaxially installed, and the material distribution port 34 is provided with more than two distribution chambers, one of which corresponds to the cooling chamber 33 respectively, and the end of the cooling chamber 33 relative to the material distribution port 34 is connected to the receiving plate 31, The holding plate 32 is used to fix the cooling cavity 33, the surface of the cooling cavity 33 is wrapped with a cooling belt 35, the holding plate 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com