Flexible connecting device of high-temperature and high-pressure pipeline and using method of flexible connecting device

A connection device and pipeline technology, which is applied to expansion compensation devices, adjustable connections, pipes/pipe joints/pipe fittings for pipelines, etc., can solve the problems of difficult sealing and sealing of non-welded connection pipes, and achieve significant economic benefits and savings. Construction cost, material and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

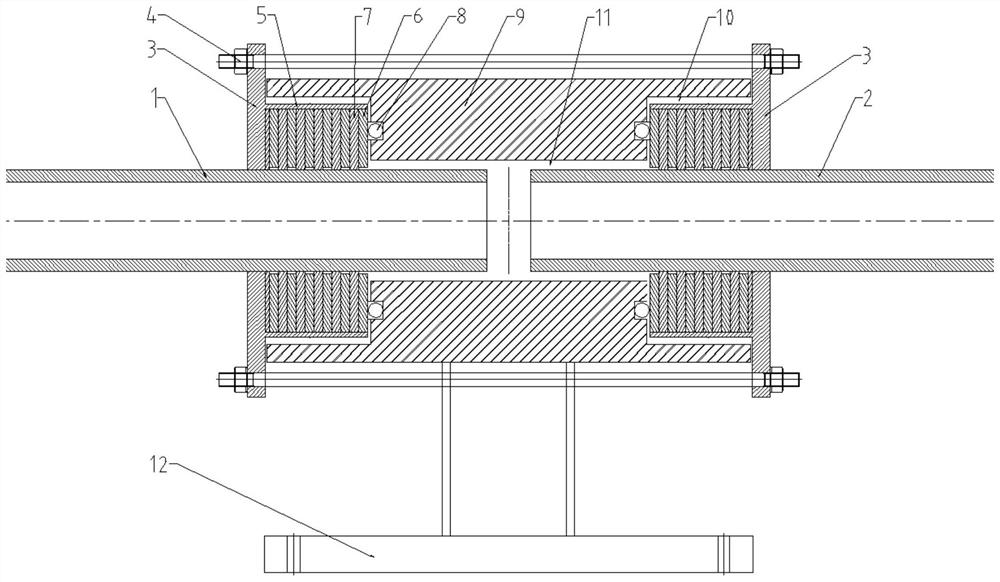

[0038] Such as figure 1As shown, this embodiment provides a pipe connection device, including a first pipe 1 and a second pipe 2, and the first pipe 1 and the second pipe 2 are respectively set on two mounting flanges on the left and right sides. 3, the two mounting flanges 3 are passed through by screw rods, and the screw rods are fastened by mounting bolts and nuts 4, and the mounting bolts and nuts 4 are located on the outside of the mounting flange 3, and the mounting flange 3 has a limiting groove 5 , there is a seal in the limiting groove 5, and there is a cage 9 between the limiting groove 5 and the limiting groove 5, and the cage 9 is in sealing connection with the sealing member, and the cage 9 is located on the mounting flange 3 On the inner side, the first pipe 1 and the second pipe 2 pass through the seal and are located in the holder holder 9 (the end surface contact or butt joint of the first pipe 1 and the second pipe 2 is located in the holder holder 9), so Th...

Embodiment 2

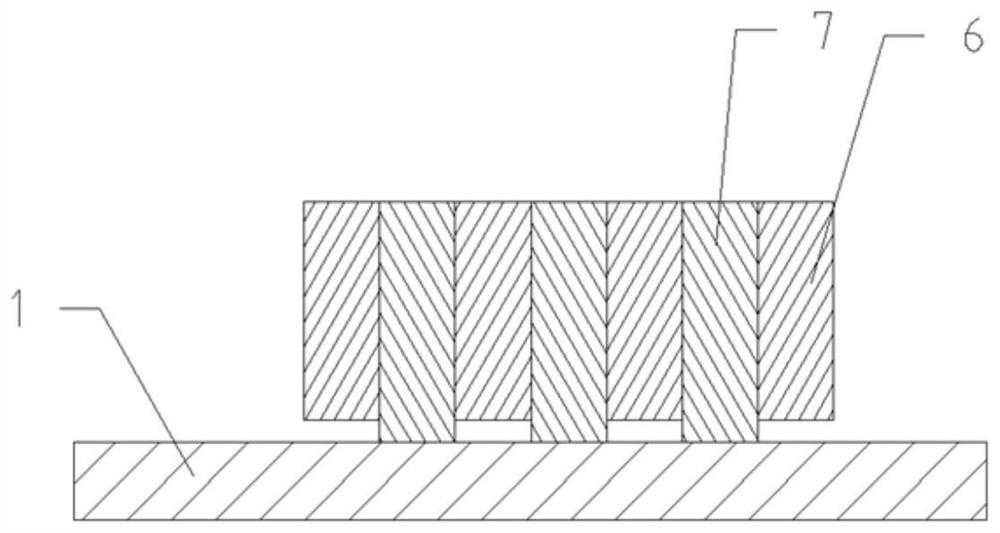

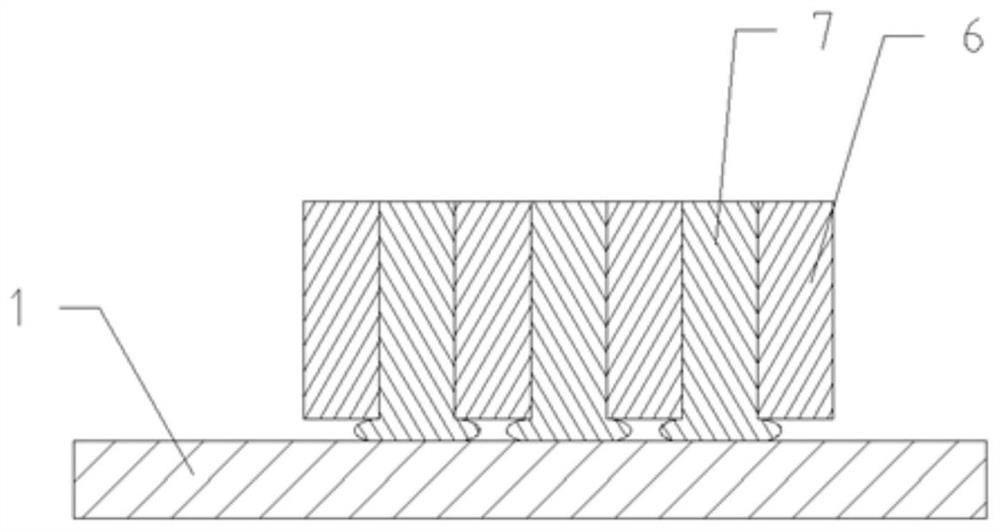

[0044] Such as figure 1 As shown, the quantity of metal sealing gasket 6 and composite molten salt gasket 7 varies with the pressure of the two pipelines. If the pressure is high, a few more layers can be placed, and if the pressure is low, a few layers can be placed. Even if some metal sealing gaskets 6 and composite molten salt gaskets The gasket 7 is located outside the limiting groove 5, and the metal gasket 6 is always in contact with the cage 9 through the metal hollow sealing ring 8 for end-face sealing. Metal hollow sealing ring 8 is made of high-temperature-resistant metal tube, filled with inert gas, and the inert gas expands after being heated, which can ensure the close contact between metal hollow sealing ring 8 and metal gasket 6 to play the role of end face sealing under high temperature. Alternate distribution of metal sealing pads 6 and composite molten salt gaskets 7, under the condition of pressure and constraints on the outer periphery of the two pipes, the...

Embodiment 3

[0047] Although the first pipe 1 and the second pipe 2 are in close contact with the metal sealing gasket 6 and the composite molten salt gasket 7, they can still expand and contract in the axial direction of the first pipe 1 and the second pipe 2, that is, the left, right and left sides can be guaranteed. degrees of freedom to move in the right direction. There is a second movement gap 11 between the first pipe 1, the second pipe 2 and the cage 9, and a first movement gap 10 between the mounting flange 3 and the cage 9, which can ensure the pipes to expand up, down, forward and backward. Time-lapse free movement. The cage 9 is connected to the fixed bracket 12 and remains stationary. The metal hollow sealing ring 8 and the metal gasket 6 are adjusted by adjusting the contact distance between the metal gasket 6 and the cage 9 by adjusting the mounting bolts and nuts 4. The relative displacement between the ring 8 and the metal gasket 6, but can still maintain close contact. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com