A double-layer steel pipe expandable external packer

An expandable packer technology, applied in sealing/isolation, wellbore/well components, measurement, etc., can solve the problems of easy rock formation disconnection, easy generation of impurities in the oil body, and influence on the quality of the oil body, etc., to achieve Improve stability, enhance efficiency, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

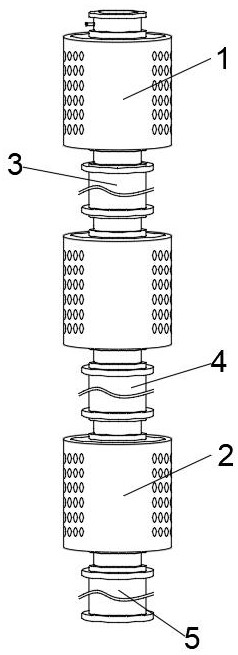

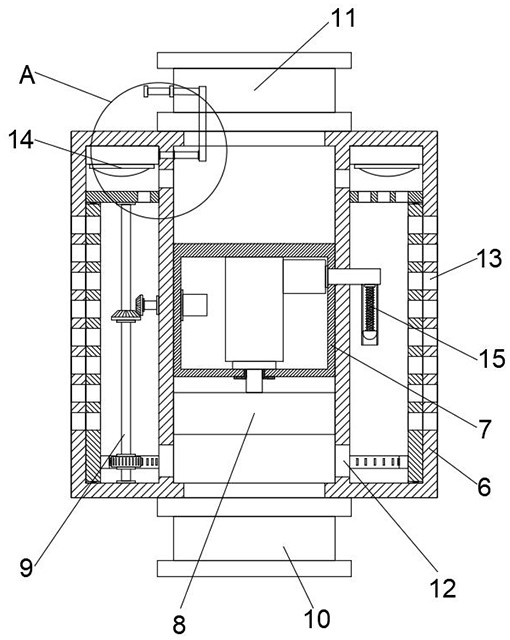

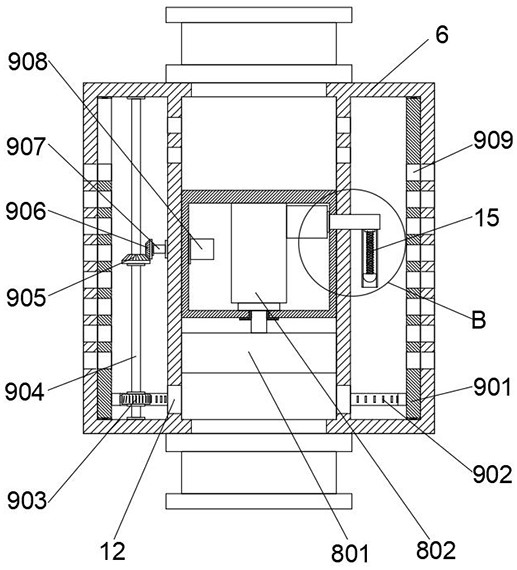

[0020] Embodiment 1: as figure 1 - Figure 5 As shown, a double-layer steel pipe expansion type external packer is connected to the central control room based on the regional network signal, including the main structure 1, the split structure 2, the main connecting pipe 3 and the split connecting pipe 4, and the split structure 2 is at least There is one, the top of the split structure 2 is connected to the split structure 2 through the main connecting pipe 3, the two split structures 2 are connected through the split connecting pipe 4, and the lowest end of the split structure 2 is installed with The extension pipe 5, the main structure 1 and the split structure 2 are all composed of a ring pipe body 6, a power box 7, a bottom seal assembly 8, a ring side seal assembly 9 and a pressure detection assembly 15, and the two ends of the ring pipe body 6 are respectively provided with The liquid inlet nozzle 10 and the liquid outlet nozzle 11, the power box 7 are fixed at the cent...

Embodiment 2

[0022] Embodiment 2: as Image 6As shown, this embodiment is based on the entire oil pumping area, that is, there are multiple packers, a double-layer steel pipe expansion type external packer, and the central control room includes: a positioning label module, which is used to position the separator Calibrate and generate positioning label information; where multiple dividers are marked as n, n is a positive integer, and the main structure 1 and multiple split structures 2 in the divider are marked as i, where the value range of i is 0, 1 , 2, 3, 4...p, and when the value of i is 0, it refers to the main structure 1, and when the value of i is a positive integer, it refers to the split structure 2; each position of multiple separators is {1, 2, 3, 4, ..., n}, so a single positioning label information is expressed as {n0, n1, n2, n3 ..., ni}, n0 refers to the main structure 1 of the nth separator, and n2 refers to the nth The second split structure 2 of the first divider; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com