Automatic adjusting device for locations of balance blocks of petroleum pumping unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

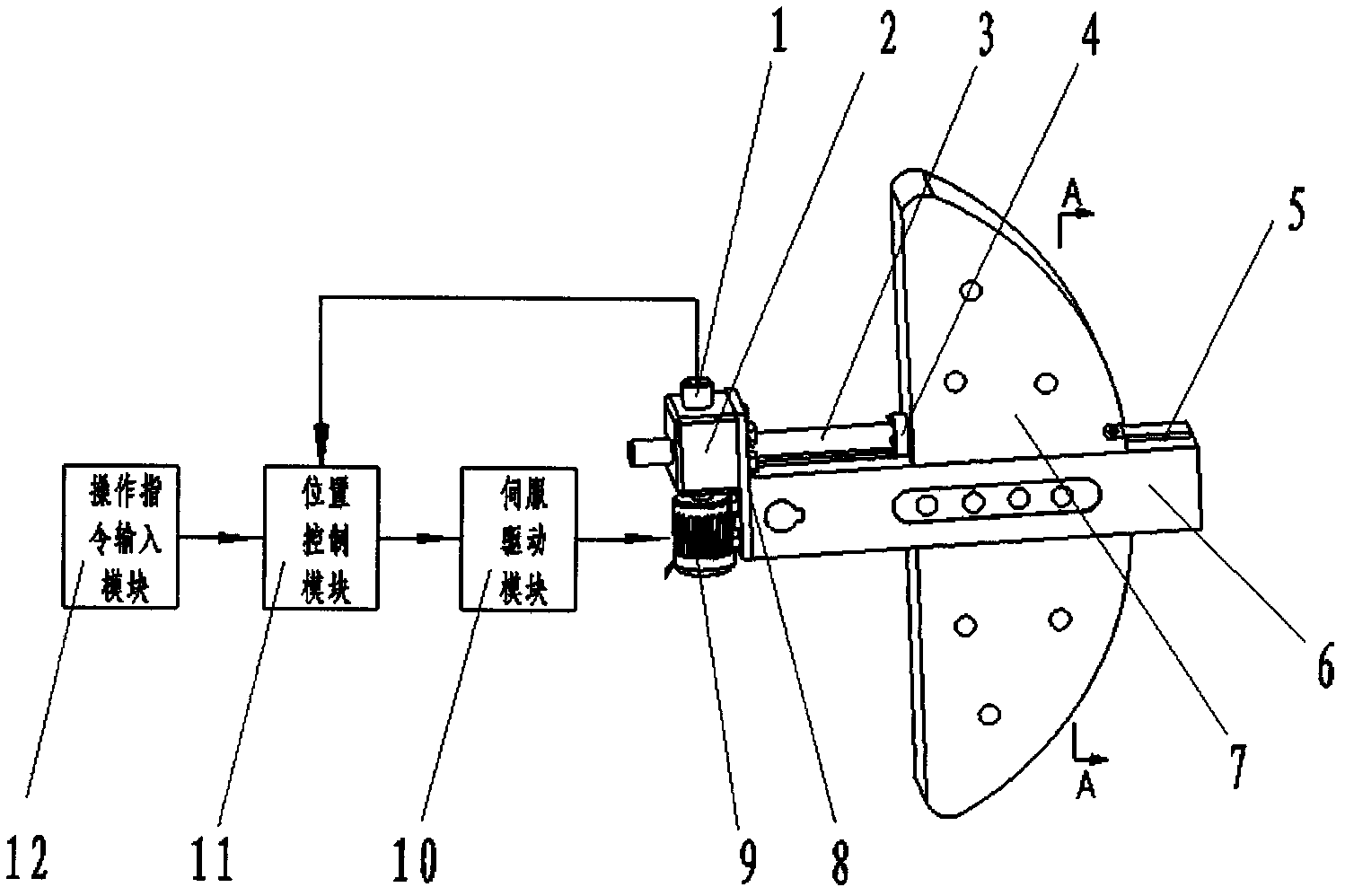

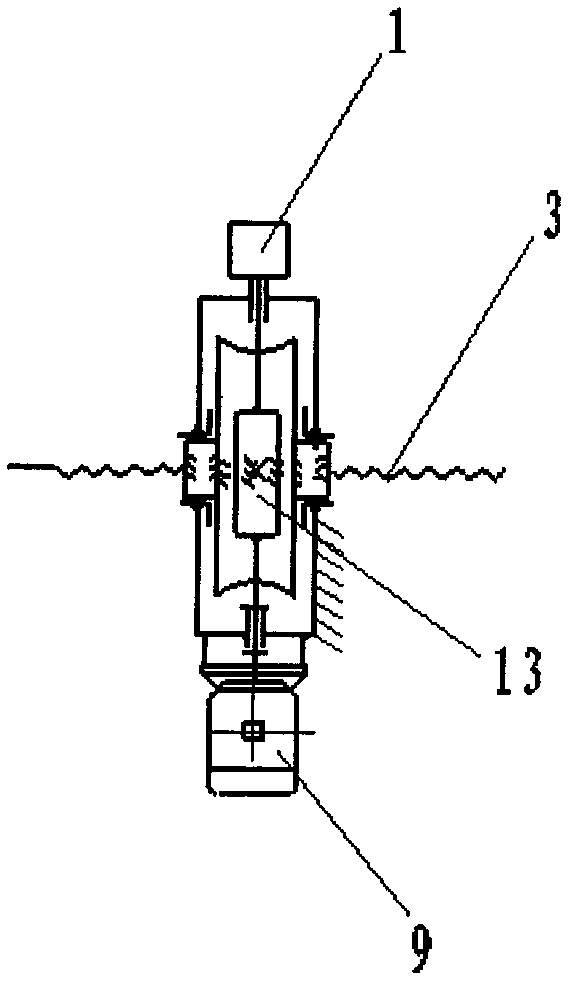

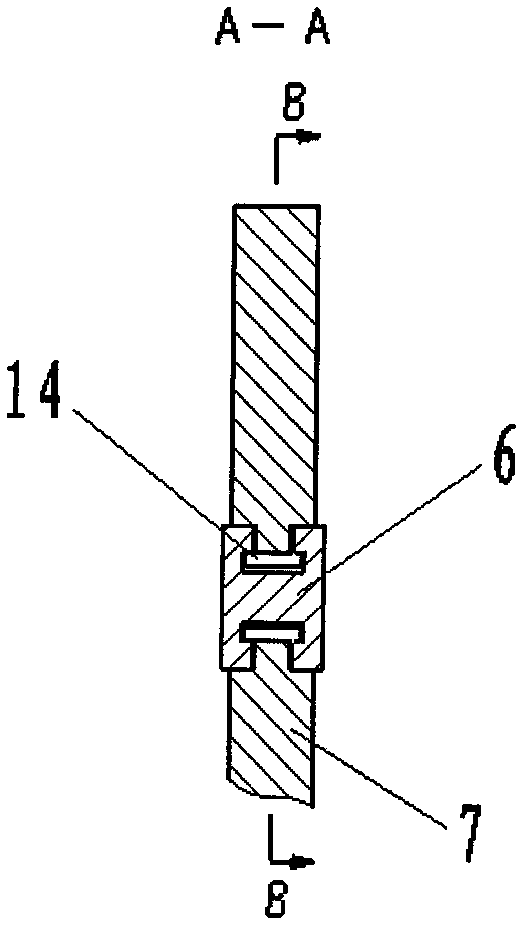

[0014] figure 1 It is an automatic adjustment device for the position of a balance weight of an oil pumping unit disclosed in the present invention, and the device includes an operation command input module 12, a position control module 11, a servo drive module 10, an encoder 1, a motor 9 and a flange 4. The operation command input module 12 is connected to the position control module 11, the output signal of the encoder 1 is connected to the position control module 11, the position control module 11 is connected to the servo drive module 10, the servo drive module 10 is connected to the motor 9, and the motor 9 The output shaft is connected with the input end of the worm 13 of the worm gear reducer 2 , the encoder 1 and the motor 10 are coaxially installed on the non-input end of the worm 13 , and the end of the lead screw 3 is fixedly connected with the balance weight 7 through the flange 4 . The worm gear reducer 2 is fixed on one end of the crank 6 by a connecting plate 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com