Heavy spherical pump with double oil filling

A double-inlet, heavy-ball technology is applied in pumps, pumps with flexible working elements, and liquid displacement machinery, etc. It can solve the problems of wasting energy, long working cycle, and polluting the environment, and achieve faster oil inlet speed. , Reduced labor intensity and short working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

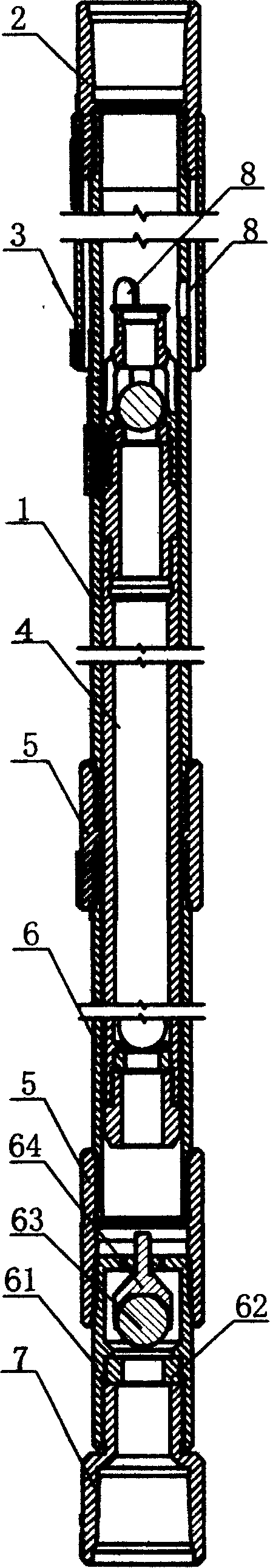

[0008] As shown in the accompanying drawings, the double-inlet heavy ball pump includes a pump barrel 1, an upper joint 2 set on the outer periphery of the upper end of the pump barrel 1, and a sleeve 3 set on the outer end of the upper joint 2, which is installed on the pump barrel 1 The internal plunger assembly 4, the pump cylinder collar 5 set with the lower end of the pump cylinder 1, the pilot valve 6 connected to the lower end of the pump cylinder 1 through the pump cylinder collar 5, and the pilot valve 6 The lower joint 7 fitted at the lower end is provided with three holes 8 on the cylinder wall of the pump barrel 1 within the reciprocating stroke of the plunger assembly 4, and the holes 8 are located at the end of the plunger assembly 4 when it goes up to the limit position. The lower end of the plunger assembly 4, and the hole 8 is located at the upper end of the plunger assembly 4 when the plunger assembly 4 falls below the reciprocating stroke of the pump cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com