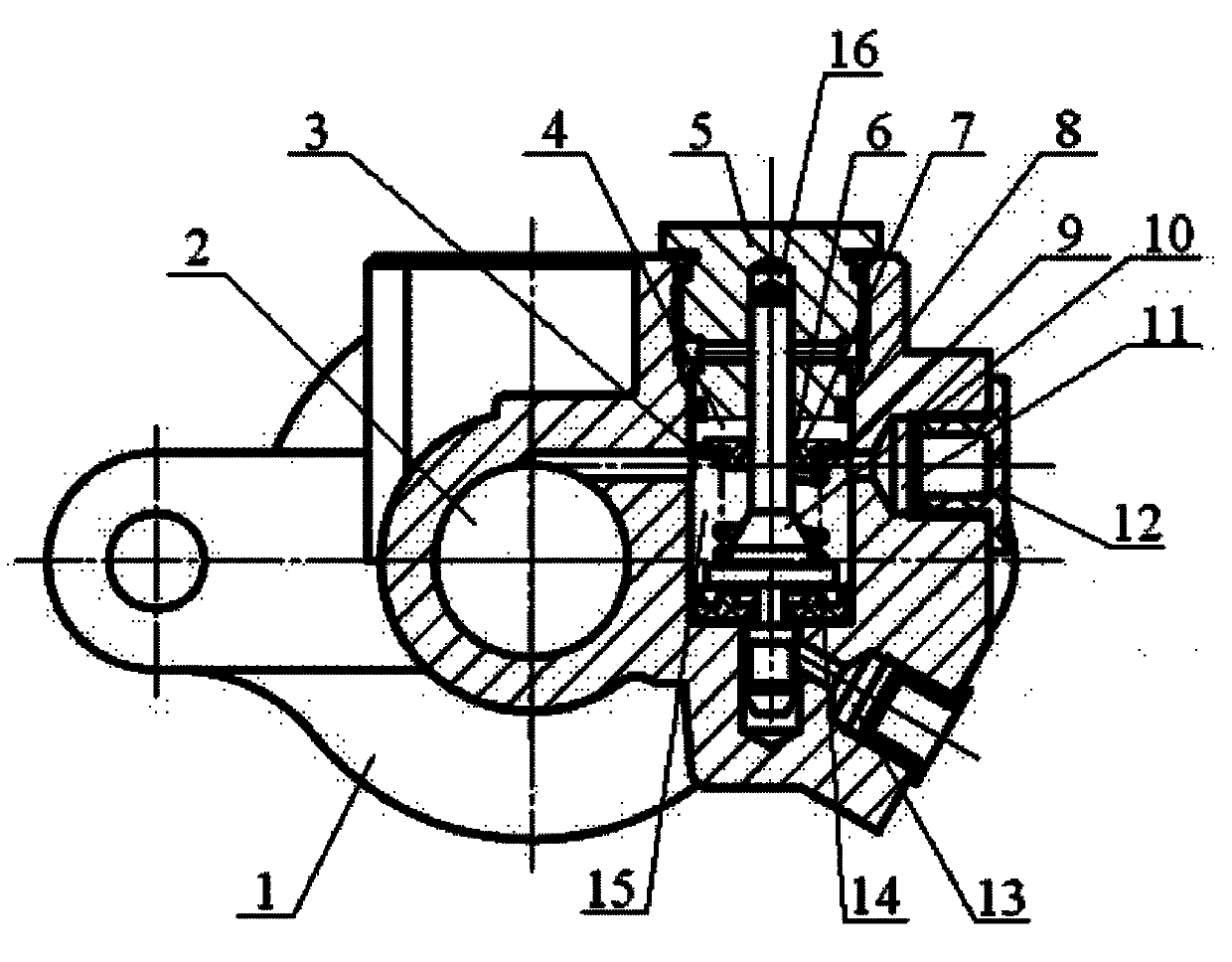

Dual-oil-feed mechanism of brake master cylinder

A technology of brake master cylinder and double oil inlet, applied in the direction of brake actuator, etc., can solve the problems of slow oil inlet speed and affect the working efficiency of the brake master cylinder, so as to improve the oil inlet speed, save the oil inlet time, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] see figure 1 , a dual oil inlet mechanism for a brake master cylinder, comprising a cylinder body 1, an oil chamber 2 is arranged in the cylinder body 1, a cavity is provided on the outer wall of the cylinder body 1, and a valve cover 5 is installed at the mouth of the cavity , A cavity is formed between the bonnet 5 and the groove walls around the cavity, the inner side of the bonnet 5 is provided with an axial blind hole 16, and a spool 6 is arranged in the cavity, and the upper end of the spool 6 is installed in the blind by sliding fit. In the hole 16, upper and lower valve seats 3, 14 are respectively arranged on both sides of the middle part and the bottom of the valve core 6, and upper and lower valve discs 7, 10 are respectively installed on the outer walls of the middle part and the bottom of the valve core 6, wherein the upper valve disc 7 is slidingly matched with the outer wall of the valve core 6, the lower valve disc 10 is fixedly installed on the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com