Overload protection valve and overload valve with overload protection valve

A technology of overload protection valve and valve sleeve, applied in the direction of fluid pressure actuating device, fluid pressure actuating system safety, mechanical equipment, etc., can solve the problem of overload safety valve not having, being damaged by controlled parts, increasing enterprise cost, etc. To achieve the effect of improving the opening and closing performance, prolonging the service life and speeding up the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

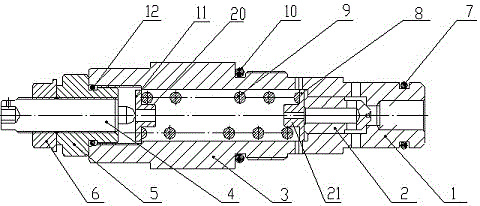

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

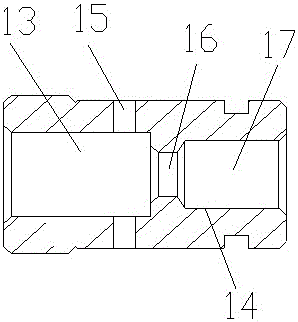

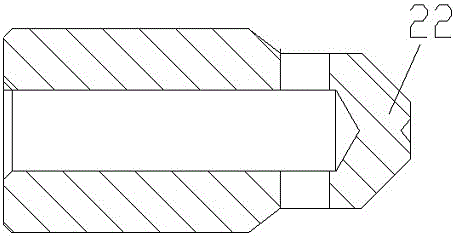

[0027] As shown in the figure, an overload protection valve includes a valve sleeve 1, a valve core 2, a valve sleeve seat 3, a pressure regulating screw 4, a pressure regulating valve seat 5, and a lock nut 6. In order to improve the sealing performance of the overload valve, A sealing ring 7 is provided outside the valve sleeve 1 , a sealing ring 10 is provided outside the valve sleeve seat 3 , and a sealing ring 12 is provided outside the pressure regulating valve seat 5 . The valve sleeve seat 3 is connected to the rear end of the valve sleeve 1. In order to improve the processing speed and processing accuracy of the two, the valve sleeve 1 and the valve sleeve seat 3 are processed separately, and the rear end of the valve sleeve 1 and the front end of the valve sleeve seat 3 are made of Snap connection. The front end of the pressure regulating valve seat 5 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com