Filling valve of vertical type injection molding machine

A technology for injection molding machines and filling valves, applied in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc. Liquid valve spool open state and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

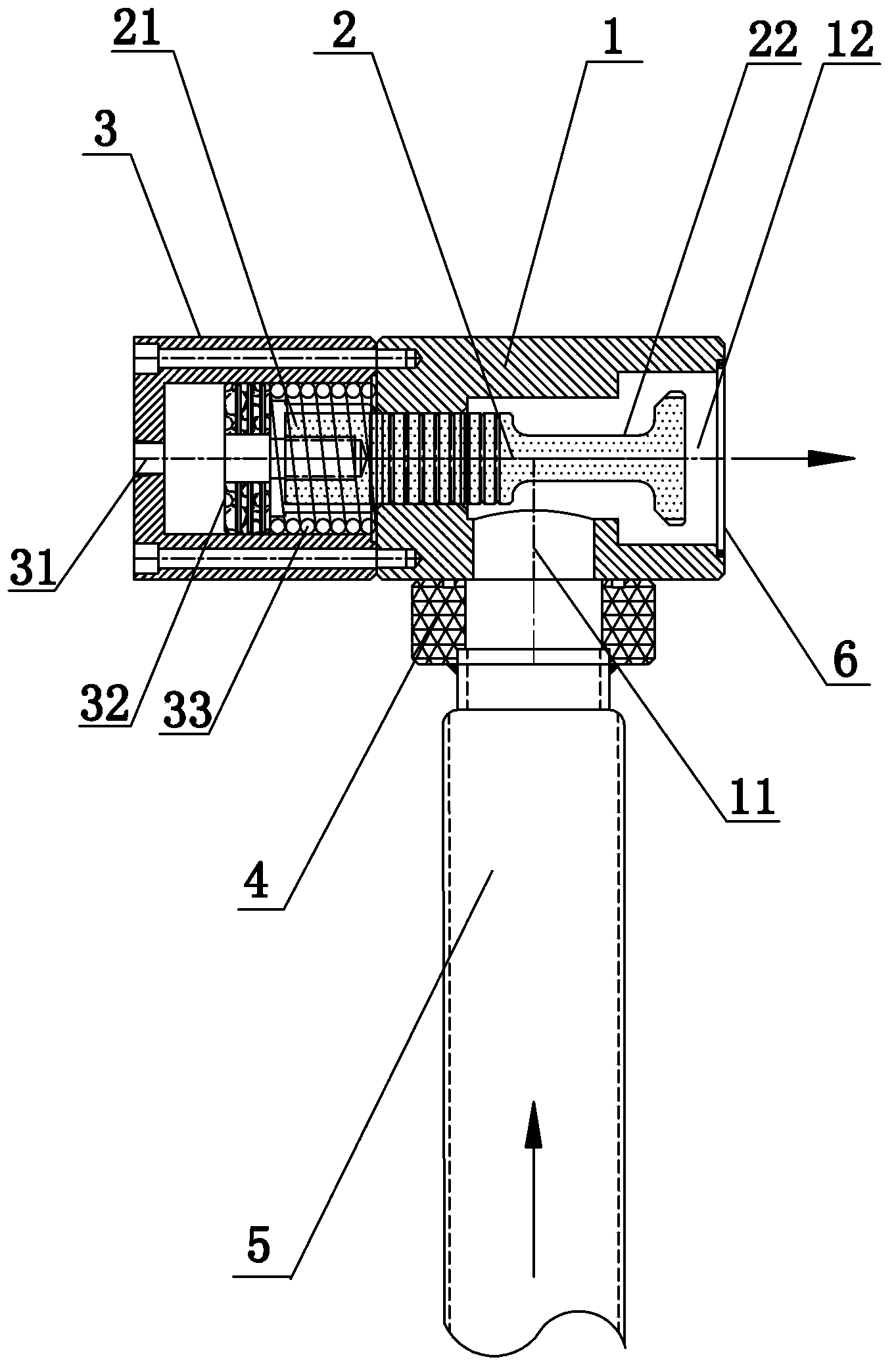

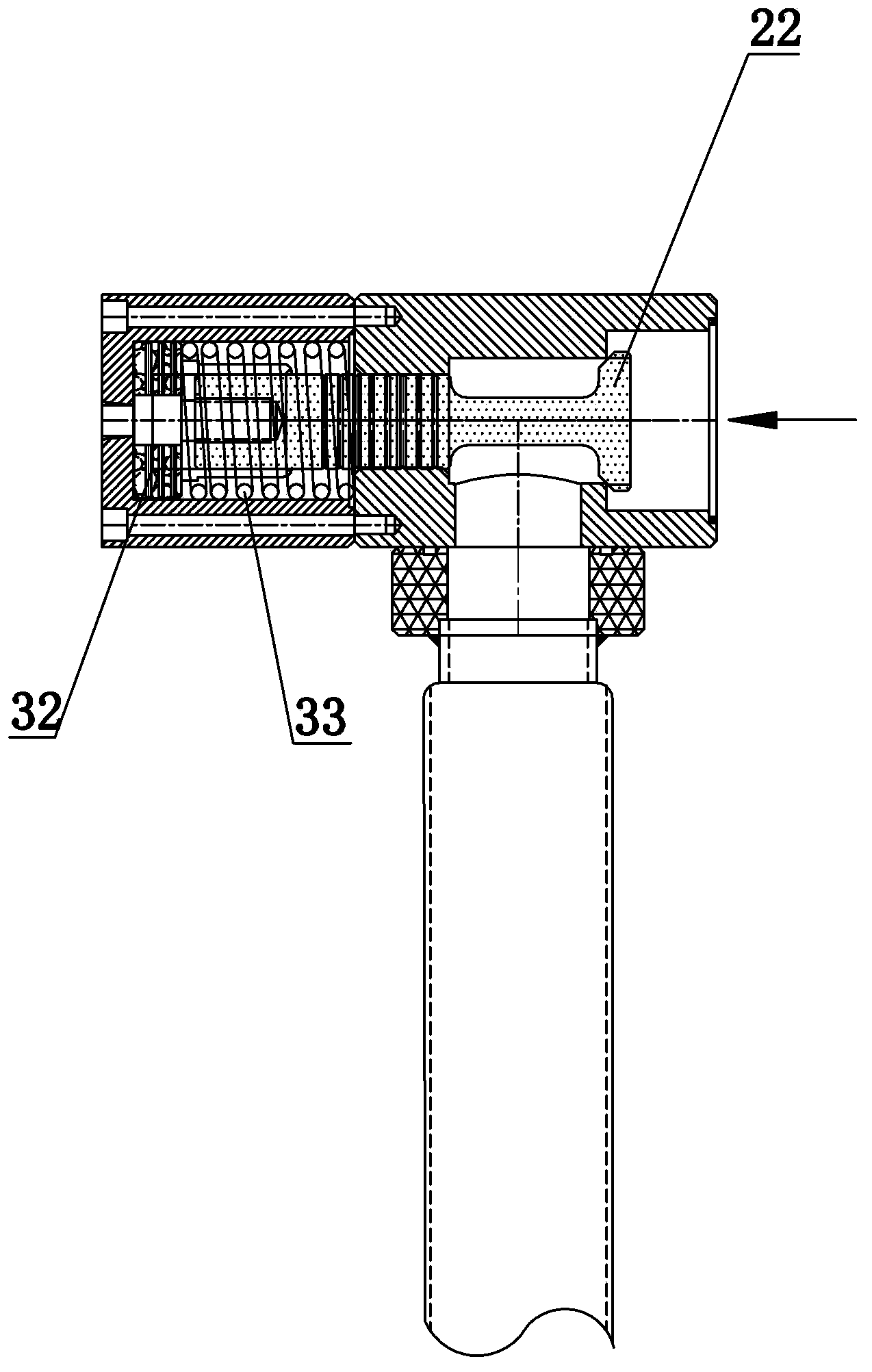

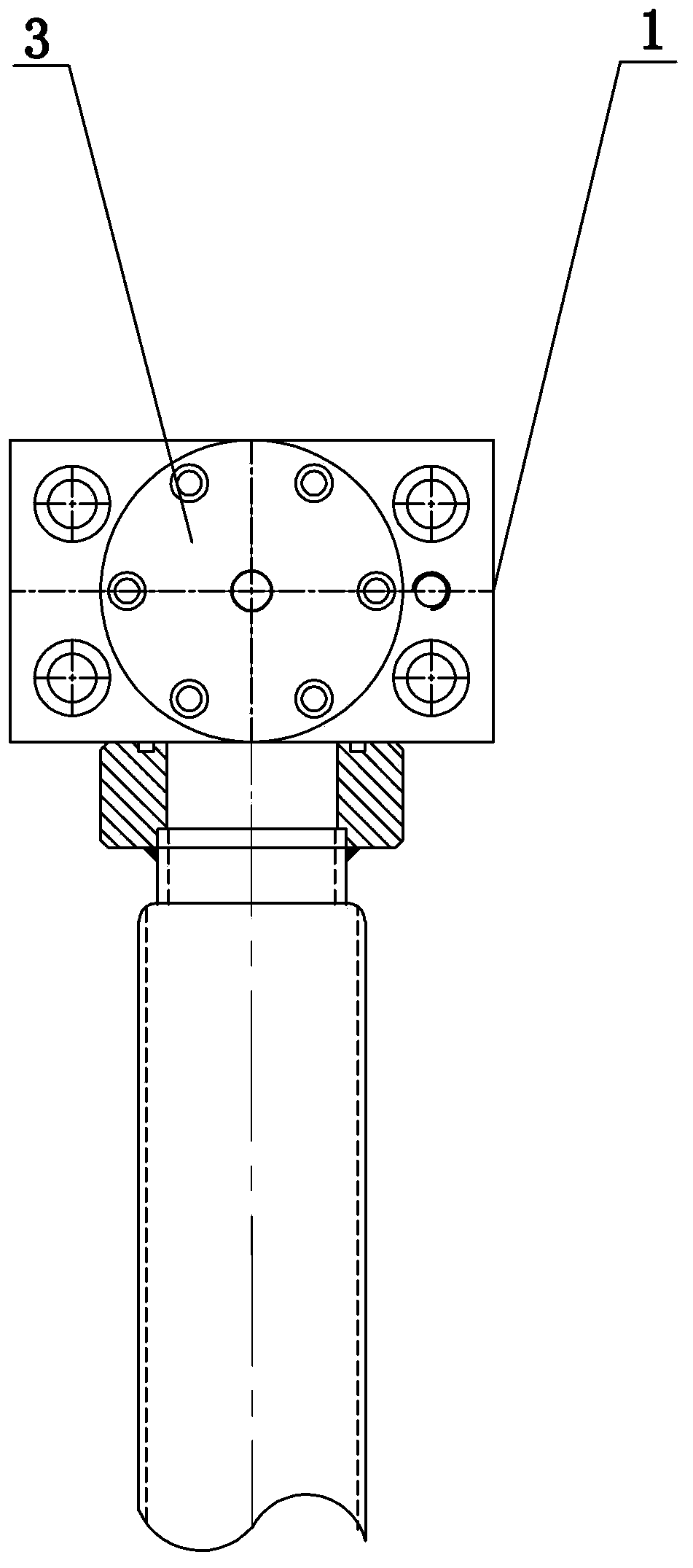

[0022] according to Figures 1 to 3 , the present invention provides a liquid filling valve for a vertical injection molding machine, comprising a valve body 1 with an oil inlet hole 11 at the bottom, an oil outlet hole 12 on the right side, and a valve core arranged in the cavity of the valve body 1 2. The left side of the valve body 1 is also fixedly connected with the valve core cylinder liner 3 provided with the pressure oil inlet hole 31 with screws, wherein the valve core 2 includes a leading end 21 and a sealing end 22, and the leading end 21 is fixed with a screw A spool piston 32 is fixedly connected, and the spool piston 32 is provided with a return spring 33 on the side close to the leading end 21, and the other end of the return spring 33 is connected with the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com