Worm gear transmission pumping unit and method

A worm gear and pumping unit technology, which is used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of reduced transmission efficiency of the reducer, shortened service life of the pumping unit, and many transmission links of the reducer. , to achieve the effect of reducing transmission links, compact structure and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

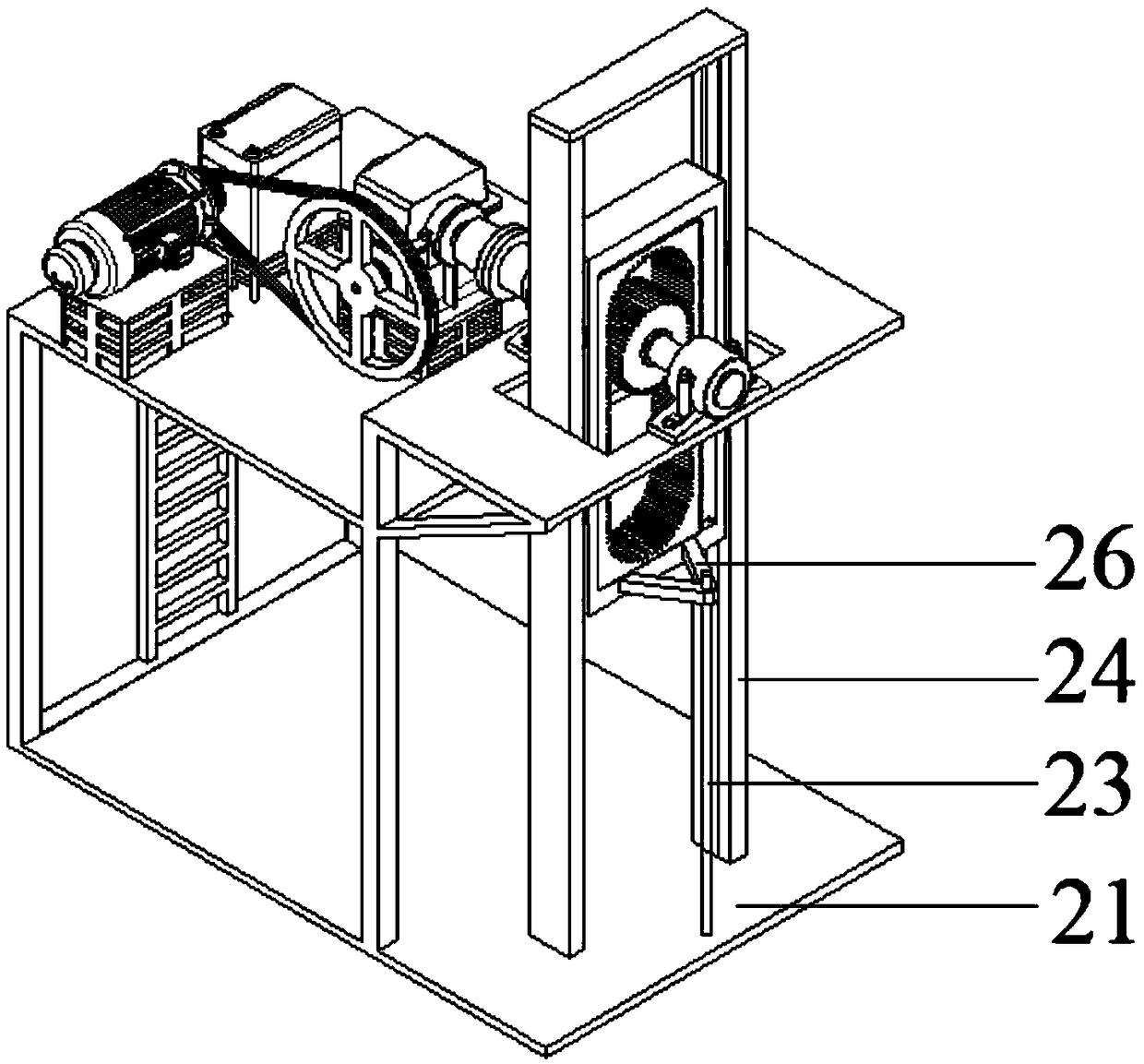

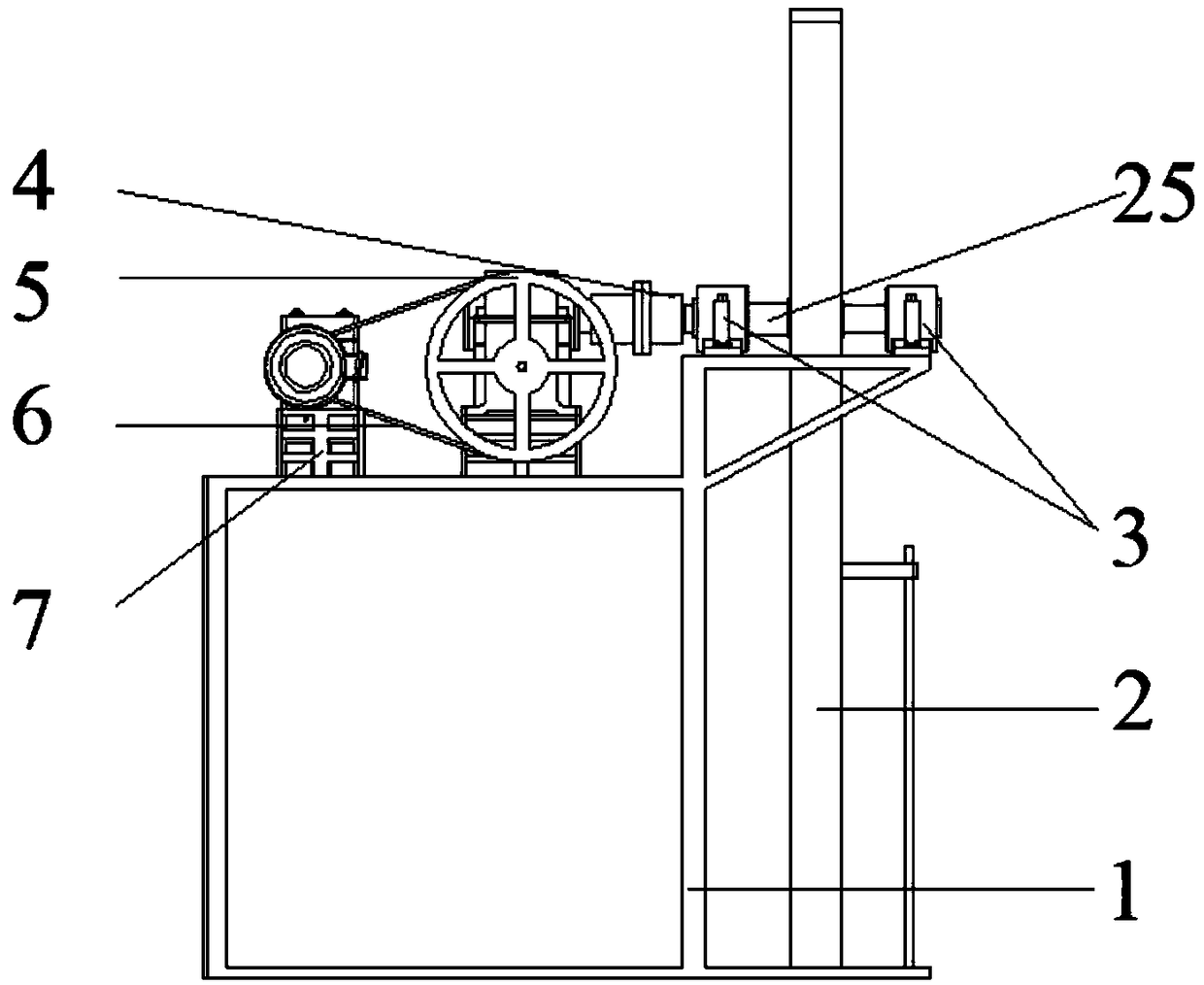

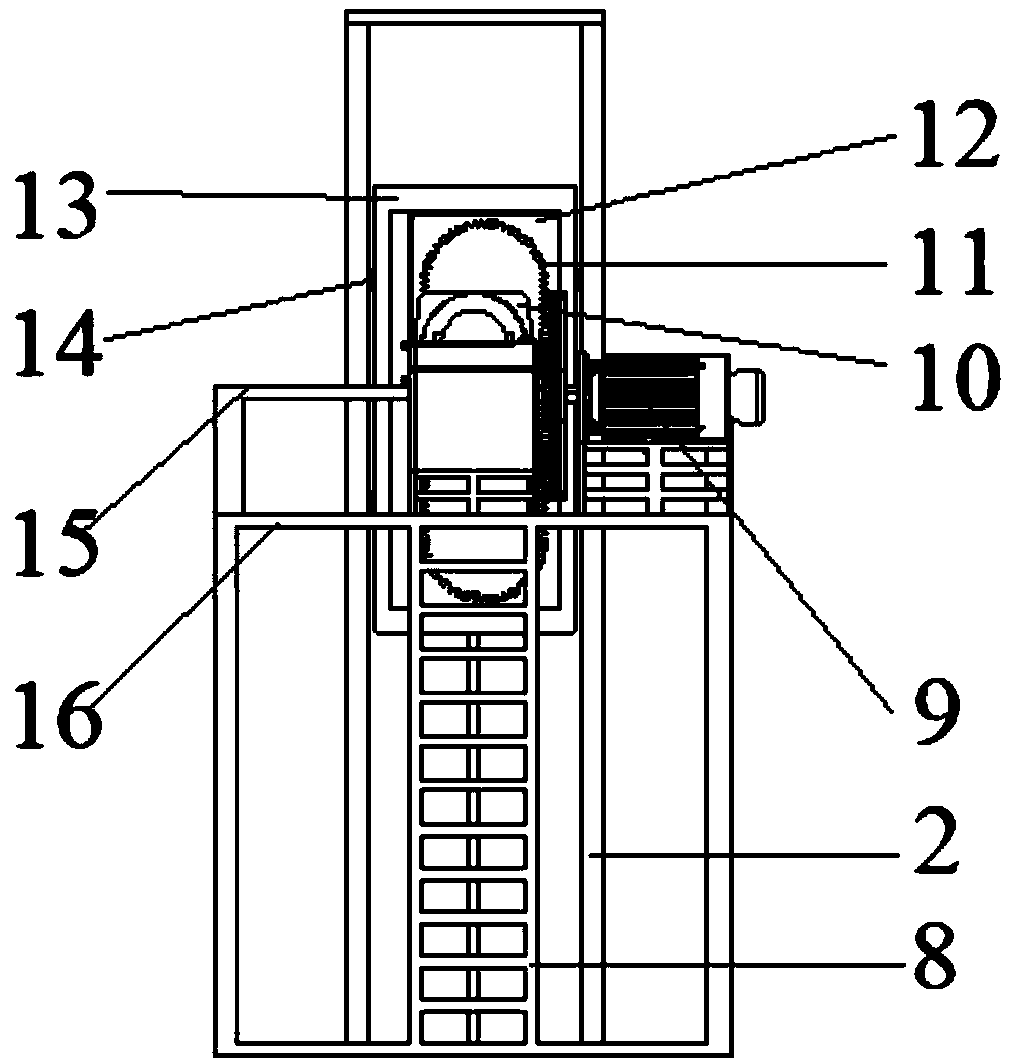

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] see Figure 1 to Figure 5 , a worm and gear drive pumping unit, comprising a frame, a transmission mechanism, an annular reversing mechanism and a balance mechanism, the frame comprising a base 21, an escalator 8, a platform support frame 1, a low platform 16 and a high platform 15, in There are three transmission support frames 7 on the low platform 16, which are respectively used to install the variable frequency speed regulating motor 9, the super capacitor 19 and the worm gear reducer 10, and a rectangular hole is arranged in the middle of the high platform 15, which is used to install the annular reversing mechanism; Said annular reversing mechanism comprises ring gear 11, ring gear fixed frame 12, polished rod connecting frame 13, slide block 14 and guide rail 2, and described ring gear 11 is made up of upper half ring gear, lower half ring gear, right li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com