Pumping unit permanent magnet speed regulation and energy conservation device

A technology of permanent magnet speed regulation and energy-saving devices, which is applied in the direction of electromechanical devices, electromechanical transmission devices, control electromechanical transmission devices, etc., can solve the problems of harmonic pollution of power supply, speed out of control, high cost, etc. The effect of oil efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

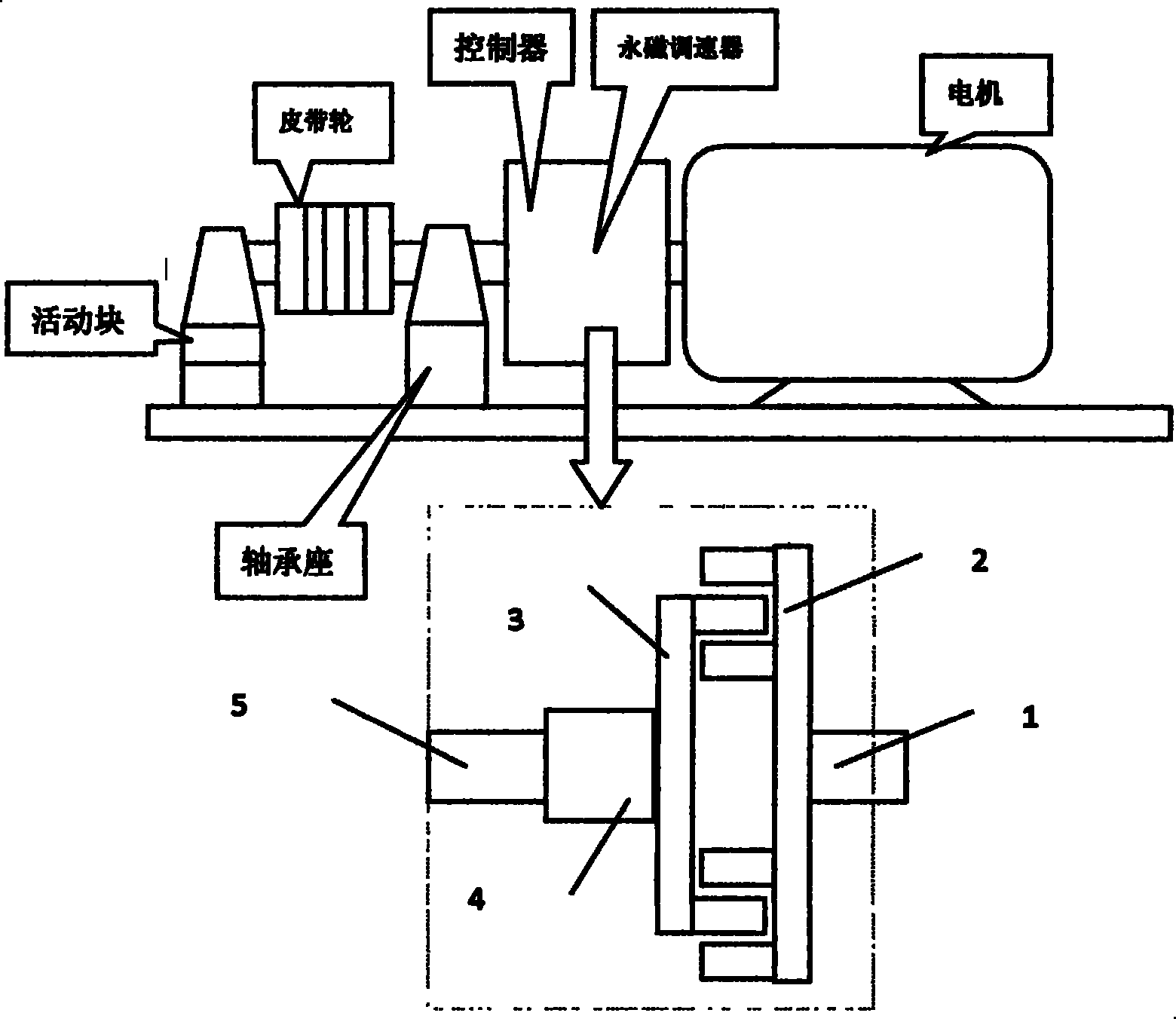

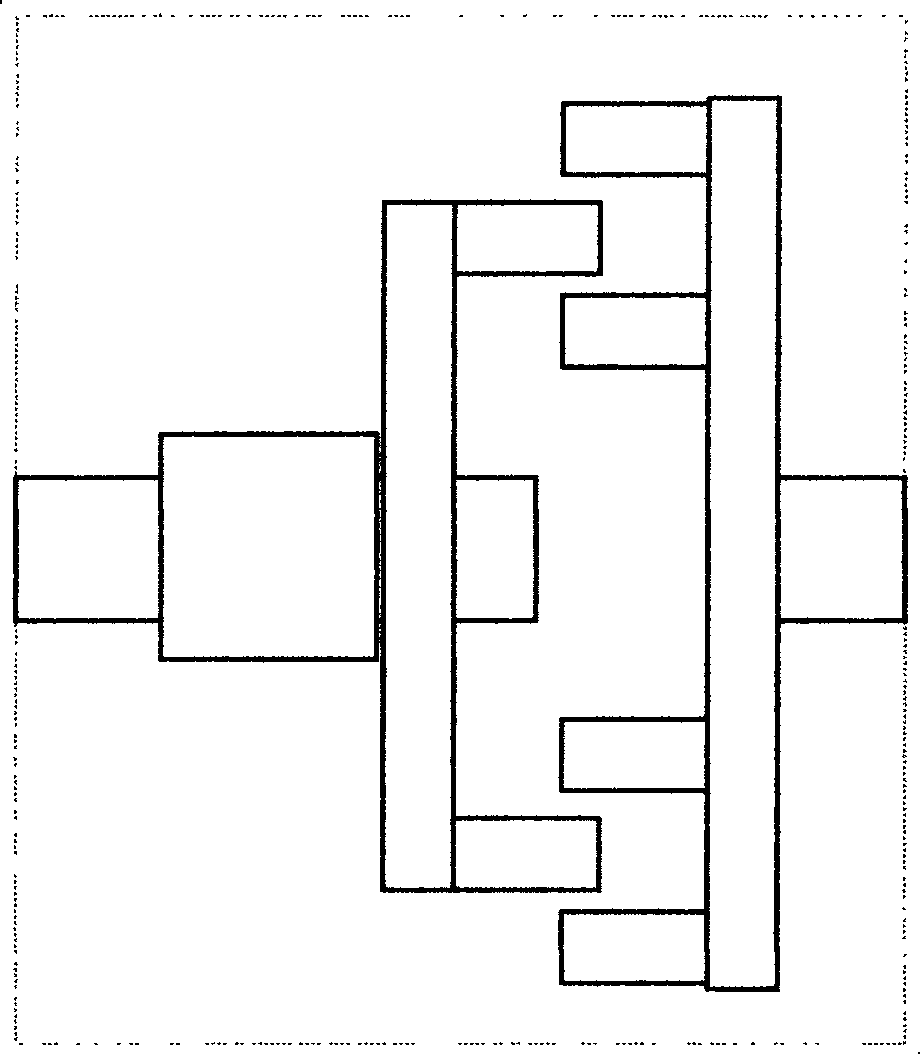

[0025] see figure 1 , 2 , 3, 4, the permanent magnet speed regulating mechanism in the pumping unit permanent magnet speed regulating energy-saving device in the present embodiment is made up of permanent magnet disk 3, conductor disk 2, brake 7, transmission shaft 5 and speed regulating mechanism 4 , The conductor disk 2 is installed on the motor shaft 1. The conductor disk 2 keeps synchronous speed with the motor, and the axial position is fixed; the speed regulating mechanism 4 makes the permanent magnet disk 3 move axially on the transmission shaft 5 under the control of the controller 6, thereby changing the permanent magnet disk 3 and The relative position of the conductor disk 2 changes the magnetic field intensity generated by the permanent magnet disk 3; when the conductor disk 2 cuts the magnetic field, the rotational speed and output torque of the permanent magnet disk 3 and the transmission shaft 5 change due to the change of the magnetic field intensity. Finally...

Embodiment 2

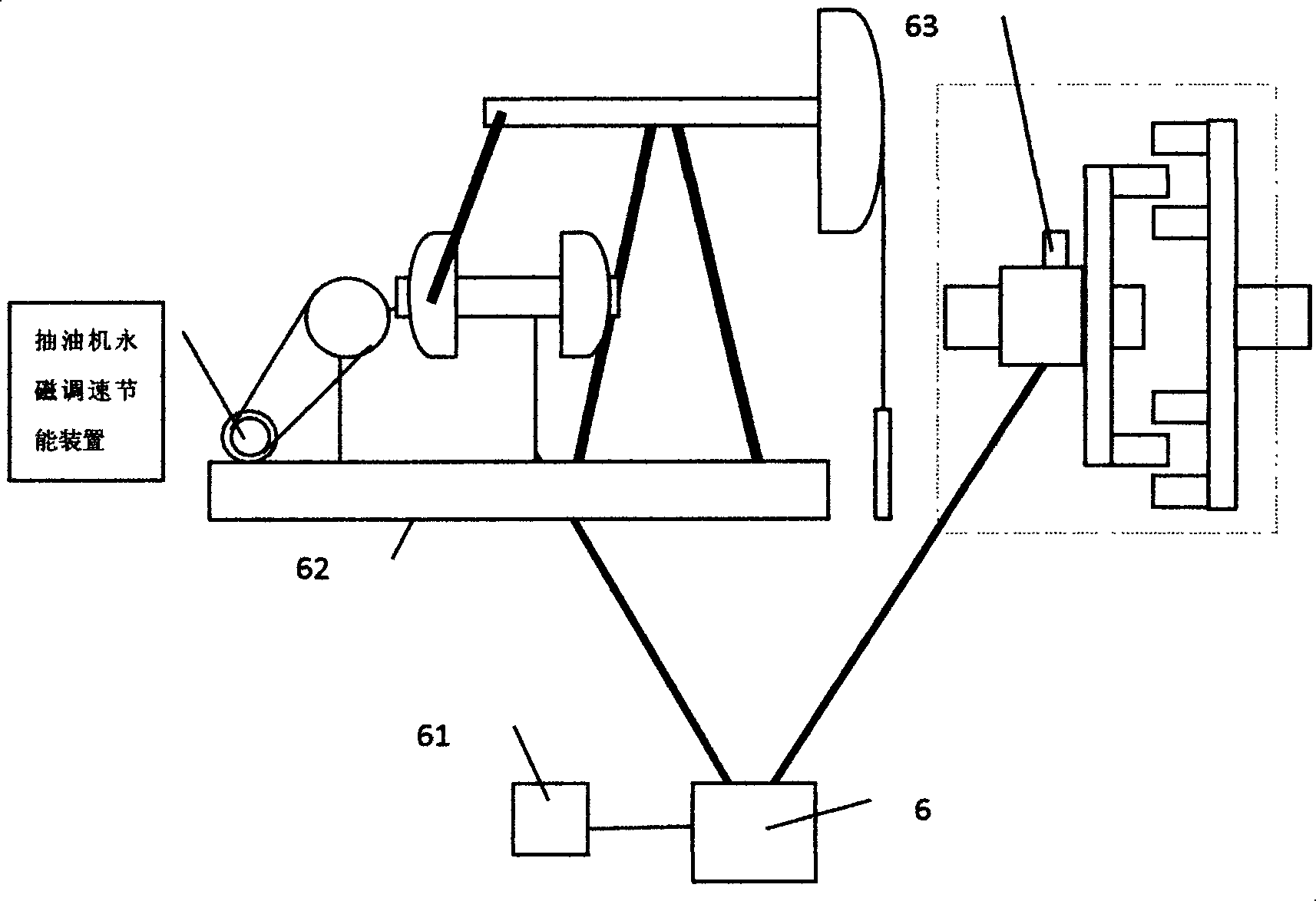

[0030] The difference between this embodiment and embodiment 1 is that, as attached Figure 6 As shown, the two bearing seats in the permanent magnet speed regulating energy-saving device of the pumping unit in this example are all installed on the right side of the pulley transmission mechanism 8, which makes the belt replacement more convenient. Simultaneously, movable block 81 also can be removed. In addition, when designing and installing two bearing housings, the ability of the pulley to withstand lateral forces should be fully considered.

[0031] In the permanent magnet speed regulating energy-saving device of the pumping unit of the present invention, if the mechanism that promotes the motion of the permanent magnet disk 3 adopts two kinds of actuators, the angle actuator and the electric push rod, the purpose of the present invention can be achieved equally; Magnet disc 3 is installed on the motor shaft 1, and conductor disc 2 is installed on the power transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com