Hot diaphragm type ultrahigh molecular weight polyethylene composite oil pumping pipe

A technology of ultra-high molecular weight and polyethylene, applied in the direction of drill pipe, casing, layered products, etc., to achieve the effect of increasing oil pumping efficiency and improving oil pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

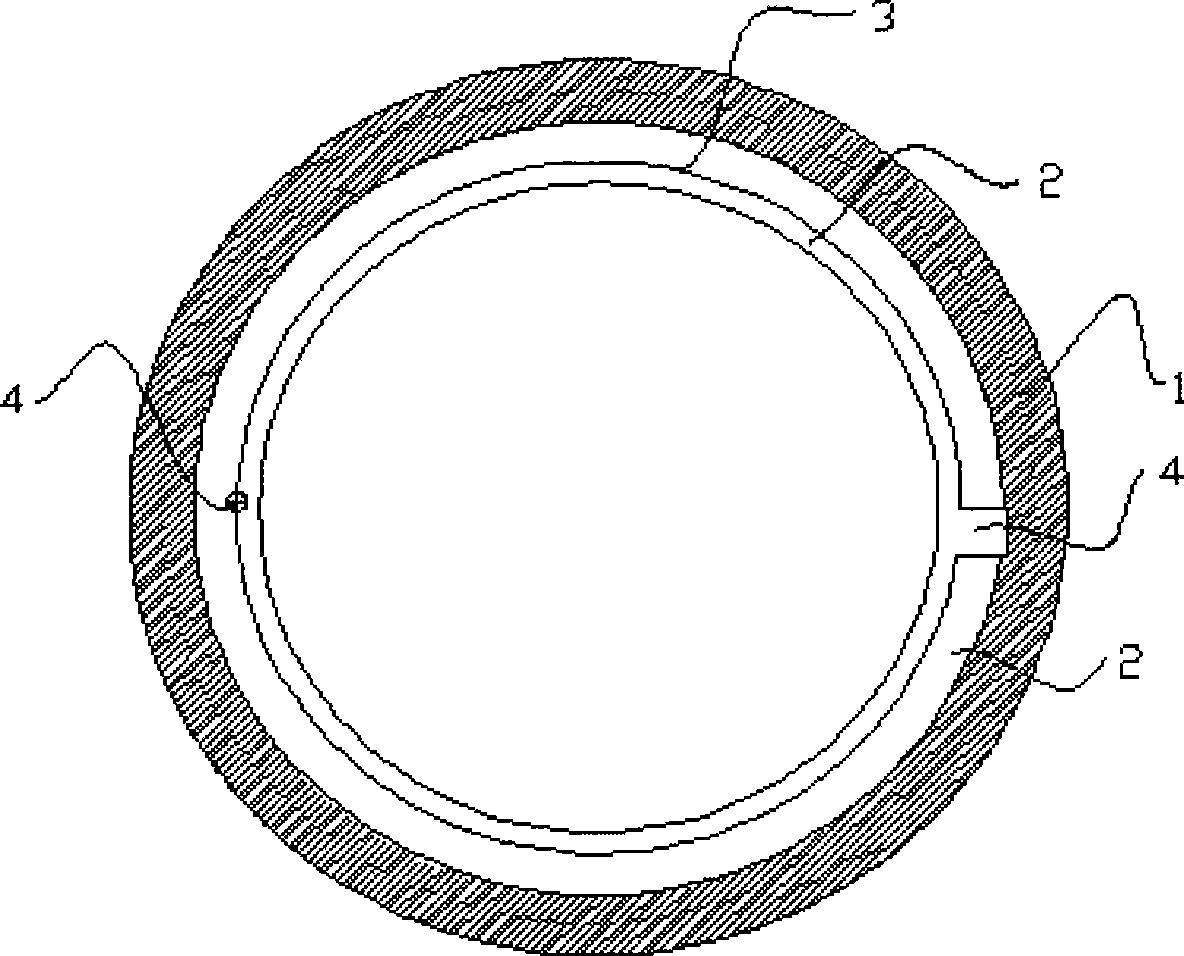

[0026] Such as figure 1 , hot-film ultra-high molecular weight polyethylene composite oil suction pipe, including: metal outer pipe 1, ultra-high molecular weight polyethylene inner pipe 2, the electric heating film 3 is preset in the inner pipe interlayer; because the electric heating film can be better combined with the polyethylene Vinyl is bonded and has a large area, which can heat the inner layer better. The preset electric heating film should be within 2cm from the inner diameter side of the tube to ensure that the oil in the inner tube can be better heated on the one hand, and on the other hand Thick inner tube outer diameter can get better insulation effect.

[0027] The above-mentioned preset electrothermal film ground wire electrode 4 is exposed between the inner tube and the outer tube, and is connected to the metal outer tube. The electrode ground wire is set between the inner tube and the outer tube, and the outer metal tube can be directly used as a ground wire....

Embodiment 2

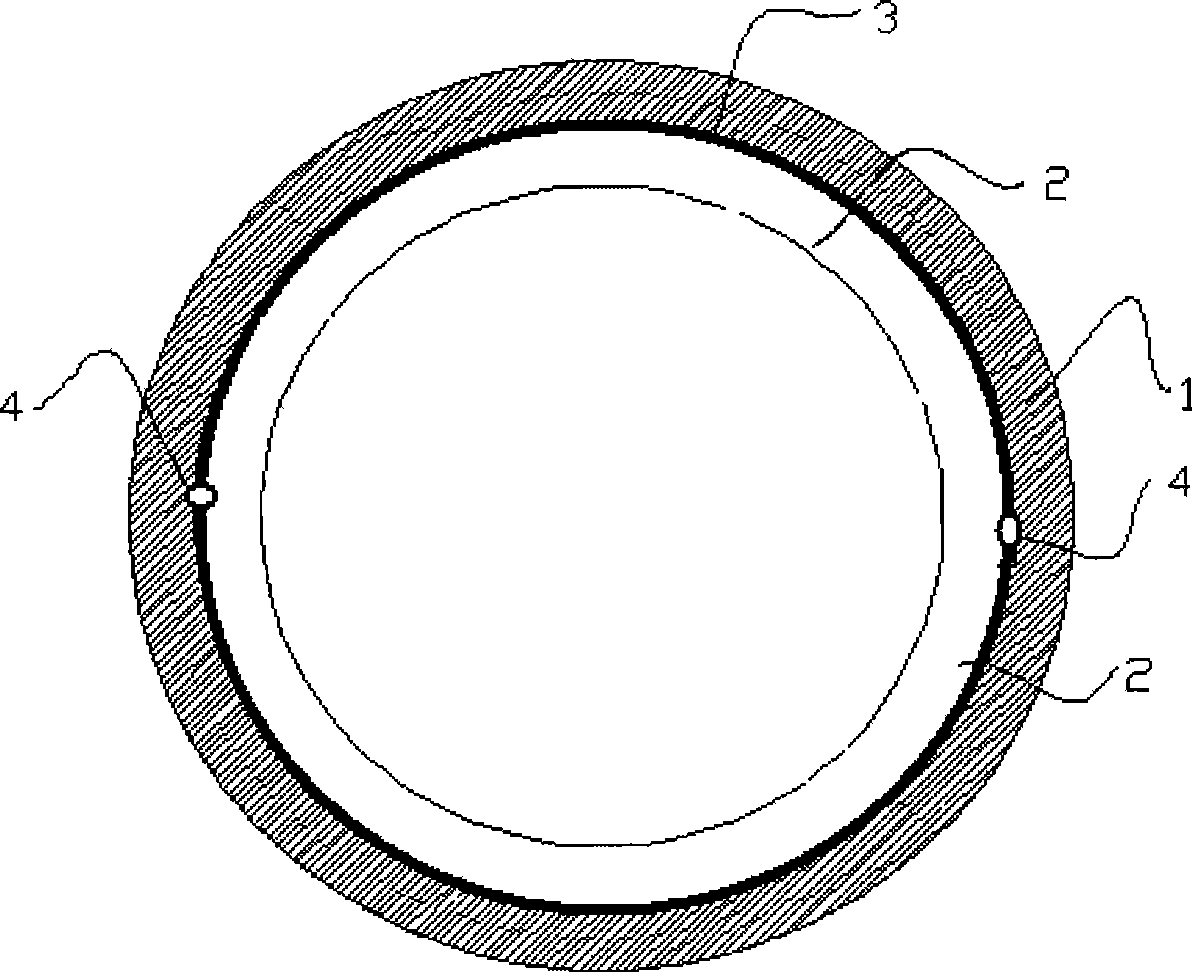

[0034] Such as figure 2 , hot-film ultra-high molecular weight polyethylene composite oil suction pipe, including: metal outer pipe 1, ultra-high molecular weight polyethylene inner pipe 2, the electric heating film 3 is preset between the above-mentioned outer pipe and inner pipe; the outer surface of the electric heating film 3 is coated There is an insulating heat-transfer layer, and a metal powder heat-conducting medium layer is glued between it and the inner tube 2, which can ensure that the oil in the inner tube can be better heated on the one hand, and on the other hand, the thicker inner tube outer diameter Can get better insulation effect. The advantage of this method is that it is easy to process, and there is no need to add the electrothermal film 3 into the inner tube 2 .

[0035] The above-mentioned preset electrothermal film ground wire electrode 4 is exposed between the inner tube and the outer tube, and is connected to the metal outer tube. The electrode grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com