Carbon fiber hollow heating rod column

A technology of carbon fiber and hollow sucker rods, which is applied in the direction of drill pipes, isolation devices, drilling equipment, etc., can solve the problems that the oil production system cannot adapt, the corrosion of the downhole medium is intensified, and the proportion of deep wells and ultra-deep wells increases, so as to reduce replacement and maintenance costs, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

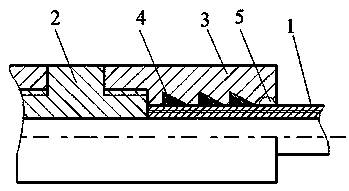

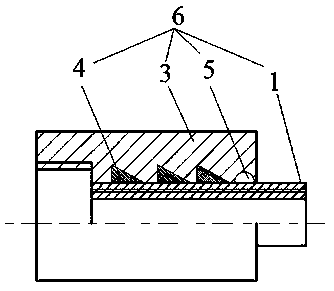

[0014] see Figure 1-2 , a carbon fiber hollow heating rod column according to an embodiment of the present invention, including a plurality of carbon fiber hollow sucker rods 6 and a metal hollow double-end joint 2, the carbon fiber hollow sucker rod 6 includes a metal joint 3, an adhesive 4, and a sealing ring 5 and a carbon fiber hollow pipe 1, one end of the metal joint 3 is bonded to the outside of one end of the carbon fiber hollow pipe 1 through an adhesive 4, the other end of the metal joint 3 is provided with an internal thread, and the two ends of the metal hollow double-ended joint 2 Both ends of the metal hollow double-ended joint 2 are threadedly connected to the metal joints 3 at one end of the two carbon fiber hollow tubes 1 .

[0015] Further, the end where the metal joint 3 is bonded to the carbon fiber hollow tube 1 is provided with a sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com